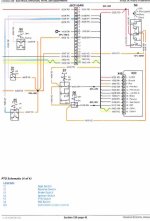

John Deeree X590 SN:161099 (not sure of the year model......2023+-?)

I would like to replace the blank switch cover (the one intended to serve for the optional mulch system, I think), on the dash, with a Carling Techno, Contura X switch, V6D1S001.

This switch has 3 terminals: 1 power in (center post), and 2 leads out (switch can toggle between the two leads, with center being off.

I would like to use one of the leads out to control a 12v sprayer, source from battery if possible, and the other lead out to temporarily by pass the brake when starting the mower (bad knee and back, difficult to push down brake to start)..........just not sure if this can be accomplished and if so, need some help with the wiring of it.

Thoughts and suggestions would be greatly appreciated.

I would like to replace the blank switch cover (the one intended to serve for the optional mulch system, I think), on the dash, with a Carling Techno, Contura X switch, V6D1S001.

This switch has 3 terminals: 1 power in (center post), and 2 leads out (switch can toggle between the two leads, with center being off.

I would like to use one of the leads out to control a 12v sprayer, source from battery if possible, and the other lead out to temporarily by pass the brake when starting the mower (bad knee and back, difficult to push down brake to start)..........just not sure if this can be accomplished and if so, need some help with the wiring of it.

Thoughts and suggestions would be greatly appreciated.