You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Intec 12.5 Vertical

#1

K

Knots

K

Knots

I have a Briggs 12.5 hp vertical engine model number 219802, type 0117E1.

It is dripping oil out of breather on fuel pump when running. Also, if you loosen the dipstick cap while running it dances around wildly.

Engine has low hour’s and runs ok. No fuel in oil.

I suspect a blown head gasket but would like advice from an expert.

If it is likely a head gasket issue, is the Briggs

796189 the set I need?

Thank you,

Knots

It is dripping oil out of breather on fuel pump when running. Also, if you loosen the dipstick cap while running it dances around wildly.

Engine has low hour’s and runs ok. No fuel in oil.

I suspect a blown head gasket but would like advice from an expert.

If it is likely a head gasket issue, is the Briggs

796189 the set I need?

Thank you,

Knots

#2

R

Rivets

R

Rivets

Sounds to me like a blown head gasket. Yes, you have the correct number for the head kit.

#3

K

Knots

K

Knots

When replacing head gasket on Briggs single cylinder engines, should the gasket go on dry or with some kind of sealant like Copperkote ?

#4

A

artemjemmy

A

artemjemmy

Nope. I have never used that before and I don't think briggs recommends any sealants. Before we do call it on the head gasket though, did you make sure it isn't just overfilled with oil or something simple? Typically blown head gaskets will cause engine smoking and there will be fumes coming out of the dipstick if you take it out after the engine has been running for a while.When replacing head gasket on Briggs single cylinder engines, should the gasket go on dry or with some kind of sealant like Copperkote ?

#5

R

Rivets

R

Rivets

Always install head gaskets dry. After torquing head bolts to specs, run engine for 5 minutes and then recheck the torque. In the OP’s first post he said the oil had no fuel in it.

#6

A

artemjemmy

A

artemjemmy

does briggs recommend retorquing? I have never done that before, although I do typically overtorque their specs because I feel they are too small, I will usually do something like 25 ft lbs when they call for 220 in lbsAlways install head gaskets dry. After torquing head bolts to specs, run engine for 5 minutes and then recheck the torque. In the OP’s first post he said the oil had no fuel in it.

#7

B

bertsmobile1

B

bertsmobile1

It is a hang over from the solid copper gasket days that settle a bit particularly if they were not full soft before use .

And if it is not the gasket it can only really be the breather being blocked or stuck closed

However compared to leaking head gaskets , failed breathers are quite rare .

And if it is not the gasket it can only really be the breather being blocked or stuck closed

However compared to leaking head gaskets , failed breathers are quite rare .

#8

A

artemjemmy

A

artemjemmy

What about a bad or a broken ring? Or scored cylinder walls? I've seen a few weird cases where the engine has compression to run but has terrible blow-byIt is a hang over from the solid copper gasket days that settle a bit particularly if they were not full soft before use .

And if it is not the gasket it can only really be the breather being blocked or stuck closed

However compared to leaking head gaskets , failed breathers are quite rare .

#9

StarTech

Any engine using this particular gasket design that comes into my shop for the first time get a leak down test done to check the head gasket condition.

This particular head gasket design to prone to blowing between the cylinder and the push rod galley. While replacing head gasket make sure the head is not warped.

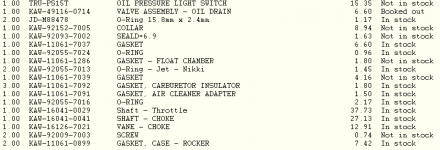

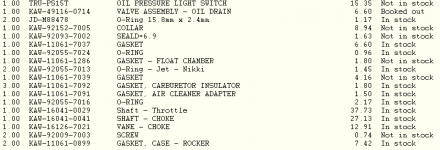

Also torque the head screws [bolts] to 20.8 fl/lbs [250 in/lbs] using three step torque method [1/3, 2/3, and Full] and in the proper torquing pattern [see below image]. This is the current torque specs for these gaskets and not what the chart says that is being passed around that specs 18.3 ft/lbs [220 in/lbs]. By going to 25 ft/lbs you risk aluminum thread pull out when the engine reaches full operating temperature. Also going to full torque all at once risks warping the head. Heads are not cheap. This head was $212 the last time I checked.

Valve clearance is .004-.006" for both intake and exhaust rockers. Rocker Jam Nut or set screw torqued 45 lb-in. Rocker cover screws [bolts] are torque to 65 in/lbs. Note some of these covers are mounted with RTV instead of a paper gasket. Both ways are acceptable. It just that RTV is less likely to leak when applied properly.

Personally I use the RTV method but I have the surface prep / accelerator chemical and know not to allow oil contact for at least 12 hrs. Also when the RTV is applied, screws are only tighten finger tight for at least 12 hrs, then the rocker cover is torque to final torque. I know it time consuming but it is what works here for leak proof application. The 30 minutes cure time on the product tube just don't work in a near airless application. Even at 12 hrs some uncured liquid squeeze out happens.

StarTech

Here this particular gasket design doesn't present itself as smoker most times here in my shop. I had one engine that burned one quart per 1/2 gallon of fuel and the only thing that was apparent while mowing was a smell of oil burning. Many modern oils don't smoke near as much as older oils did either. Most times the only indication of a blown head gasket is loss of oil volume and oil present in the air cleaner side of the carburetor. Now the fuel pump vent does sometimes have oil leaking out of it too.Typically blown head gaskets will cause engine smoking and there will be fumes coming out of the dipstick if you take it out after the engine has been running for a while.

Any engine using this particular gasket design that comes into my shop for the first time get a leak down test done to check the head gasket condition.

This particular head gasket design to prone to blowing between the cylinder and the push rod galley. While replacing head gasket make sure the head is not warped.

Also torque the head screws [bolts] to 20.8 fl/lbs [250 in/lbs] using three step torque method [1/3, 2/3, and Full] and in the proper torquing pattern [see below image]. This is the current torque specs for these gaskets and not what the chart says that is being passed around that specs 18.3 ft/lbs [220 in/lbs]. By going to 25 ft/lbs you risk aluminum thread pull out when the engine reaches full operating temperature. Also going to full torque all at once risks warping the head. Heads are not cheap. This head was $212 the last time I checked.

Valve clearance is .004-.006" for both intake and exhaust rockers. Rocker Jam Nut or set screw torqued 45 lb-in. Rocker cover screws [bolts] are torque to 65 in/lbs. Note some of these covers are mounted with RTV instead of a paper gasket. Both ways are acceptable. It just that RTV is less likely to leak when applied properly.

Personally I use the RTV method but I have the surface prep / accelerator chemical and know not to allow oil contact for at least 12 hrs. Also when the RTV is applied, screws are only tighten finger tight for at least 12 hrs, then the rocker cover is torque to final torque. I know it time consuming but it is what works here for leak proof application. The 30 minutes cure time on the product tube just don't work in a near airless application. Even at 12 hrs some uncured liquid squeeze out happens.

#10

K

Knots

K

Knots

Here this particular gasket design doesn't present itself as smoker most times here in my shop. I had one engine that burned one quart per 1/2 gallon of fuel and the only thing that was apparent while mowing was a smell of oil burning. Many modern oils don't smoke near as much as older oils did either. Most times the only indication of a blown head gasket is loss of oil volume and oil present in the air cleaner side of the carburetor. Now the fuel pump vent does sometimes have oil leaking out of it too.

Any engine using this particular gasket design that comes into my shop for the first time get a leak down test done to check the head gasket condition.

This particular head gasket design to prone to blowing between the cylinder and the push rod galley. While replacing head gasket make sure the head is not warped.

Also torque the head screws [bolts] to 20.8 fl/lbs [250 in/lbs] using three step torque method [1/3, 2/3, and Full] and in the proper torquing pattern [see below image]. This is the current torque specs for these gaskets and not what the chart says that is being passed around that specs 18.3 ft/lbs [220 in/lbs]. By going to 25 ft/lbs you risk aluminum thread pull out when the engine reaches full operating temperature. Also going to full torque all at once risks warping the head. Heads are not cheap. This head was $212 the last time I checked.

View attachment 59190

Valve clearance is .004-.006" for both intake and exhaust rockers. Rocker Jam Nut or set screw torqued 45 lb-in. Rocker cover screws [bolts] are torque to 65 in/lbs. Note some of these covers are mounted with RTV instead of a paper gasket. Both ways are acceptable. It just that RTV is less likely to leak when applied properly.

Personally I use the RTV method but I have the surface prep / accelerator chemical and know not to allow oil contact for at least 12 hrs. Also when the RTV is applied, screws are only tighten finger tight for at least 12 hrs, then the rocker cover is torque to final torque. I know it time consuming but it is what works here for leak proof application. The 30 minutes cure time on the product tube just don't work in a near airless application. Even at 12 hrs some uncured liquid squeeze out happens.

#11

K

Knots

K

Knots

Intec 219802 type 0117E1

I checked one other thing on this engine. The air filter and breather box are both dry and clean. About the crankcase breather in this engine, can anyone tell me where it is located? Might as well check it before I pull head and spend $50.00 on gaskets.

Many thanks to all who have responded.

Much appreciated!

Knots

I checked one other thing on this engine. The air filter and breather box are both dry and clean. About the crankcase breather in this engine, can anyone tell me where it is located? Might as well check it before I pull head and spend $50.00 on gaskets.

Many thanks to all who have responded.

Much appreciated!

Knots

#13

B

bertsmobile1

"weird"

Yes there are other causes but about 90% of the times it will be a head gasket .

Then around 9 % of the time it will be a breather

the final 1% is "other causes"

So we start with the obvious and then move to the obscure

When the head is off you can inspect the bore for cross hatching / scoring etc

It is an intek engine which is renown for blowing head gaskets

I keep about 30 in stock because I am forever changing them and the warehouse regularly runs out of them in the middle of the season

And for repeat performers I have some solid copper ones because despite lapping they just keep on blowing .

It is fundamentially bad design , copied from Vanguard but cheapened .

There is not enough clamping force on the bridge region between the bore & the push rod tunnel

So either then bolts need to be moved in, another bolt added or the bridge needs to be wider .

B & S's answer was to rough cut the surfaces with a fly cutter so the clamping faces are rough & hold the gasket tighter

Some times it works and some times it does not work .

B

bertsmobile1

And you put it right.What about a bad or a broken ring? Or scored cylinder walls? I've seen a few weird cases where the engine has compression to run but has terrible blow-by

"weird"

Yes there are other causes but about 90% of the times it will be a head gasket .

Then around 9 % of the time it will be a breather

the final 1% is "other causes"

So we start with the obvious and then move to the obscure

When the head is off you can inspect the bore for cross hatching / scoring etc

It is an intek engine which is renown for blowing head gaskets

I keep about 30 in stock because I am forever changing them and the warehouse regularly runs out of them in the middle of the season

And for repeat performers I have some solid copper ones because despite lapping they just keep on blowing .

It is fundamentially bad design , copied from Vanguard but cheapened .

There is not enough clamping force on the bridge region between the bore & the push rod tunnel

So either then bolts need to be moved in, another bolt added or the bridge needs to be wider .

B & S's answer was to rough cut the surfaces with a fly cutter so the clamping faces are rough & hold the gasket tighter

Some times it works and some times it does not work .

#14

VRR.DYNDNS>BIZ

VRR.DYNDNS>BIZ

Even a dirty air filter, and a few more like bad breather. Head gasket need to be proven in my thinking.Nope. I have never used that before and I don't think briggs recommends any sealants. Before we do call it on the head gasket though, did you make sure it isn't just overfilled with oil or something simple? Typically blown head gaskets will cause engine smoking and there will be fumes coming out of the dipstick if you take it out after the engine has been running for a while.

#15

VRR.DYNDNS>BIZ

VRR.DYNDNS>BIZ

I believe since your bulk order of gaskets a gasket change has been made.And you put it right.

"weird"

Yes there are other causes but about 90% of the times it will be a head gasket .

Then around 9 % of the time it will be a breather

the final 1% is "other causes"

So we start with the obvious and then move to the obscure

When the head is off you can inspect the bore for cross hatching / scoring etc

It is an intek engine which is renown for blowing head gaskets

I keep about 30 in stock because I am forever changing them and the warehouse regularly runs out of them in the middle of the season

And for repeat performers I have some solid copper ones because despite lapping they just keep on blowing .

It is fundamentially bad design , copied from Vanguard but cheapened .

There is not enough clamping force on the bridge region between the bore & the push rod tunnel

So either then bolts need to be moved in, another bolt added or the bridge needs to be wider .

B & S's answer was to rough cut the surfaces with a fly cutter so the clamping faces are rough & hold the gasket tighter

Some times it works and some times it does not work .

#16

A

artemjemmy

A

artemjemmy

I test for head gasket leaks using a cylinder leakdown tester with the valve cover off, then try to feel a air current from the cylinder to the pushrod cavity. I bet if you had a smoke machine or something it would work even better.Even a dirty air filter, and a few more like bad breather. Head gasket need to be proven in my thinking.

#17

A

artemjemmy

A

artemjemmy

Yup, there really needs to be a bolt in the bridge between the cylinder and pushrod cavity. For those engines that keep blowing head gaskets, do you check if the head is warped? You can use a machinists straight edge or a piece of plate glass and place the head on it and try to fit feeler gauges to check for warpage.And you put it right.

"weird"

Yes there are other causes but about 90% of the times it will be a head gasket .

Then around 9 % of the time it will be a breather

the final 1% is "other causes"

So we start with the obvious and then move to the obscure

When the head is off you can inspect the bore for cross hatching / scoring etc

It is an intek engine which is renown for blowing head gaskets

I keep about 30 in stock because I am forever changing them and the warehouse regularly runs out of them in the middle of the season

And for repeat performers I have some solid copper ones because despite lapping they just keep on blowing .

It is fundamentially bad design , copied from Vanguard but cheapened .

There is not enough clamping force on the bridge region between the bore & the push rod tunnel

So either then bolts need to be moved in, another bolt added or the bridge needs to be wider .

B & S's answer was to rough cut the surfaces with a fly cutter so the clamping faces are rough & hold the gasket tighter

Some times it works and some times it does not work .

#18

B

bertsmobile1

B

bertsmobile1

At a rough guess I would do 20 or so intek gaskets a season.

If you are suggesting I swap gaskets just because I can then you have no idea of the way I work.

Nothing gets replaced unless it needs to be replaced thus I use about 50 spark plugs a year and about 30 fuel filters a year .

That is against around a 300 job average year .

The only real proof is to pull the head & check and in doing this you destroy the gasket so it is a moot point.

Excessive crankcase pressure is either charge leaking in or the breather blocked.

A blocked breather, can easily be checked with a damp finger over the end of the tube, takes about 2 minutes

Leaking inlet valve seals & bad rings can be checked by working the throttle with your finger & watching / listening.

You also pick up blown gaskets this way as well because the engine will faulter on initial acceleration as it will be sucking in crankcase fume rather than fuel then steady out when the speed has been maintained .

If the gasket was not at fault then the customer gets it done for free.

I believe it stems from a casting fault as some will run 1000 hours without problems while others will do a gasket a season from new .

Usually I can diagnose a blown gasket by the sound the engine makes when it starts then the way it sounds when the blades are engaged .

Now I could spend an full hour doing a dozen thests to confirm the gasket leak or 1/2 hour to replace the the gasket if all goes well .

Crankcases are cast on a multi head machine so one bad mould can affect as few as 1 in 100 castings depending upon the size of the machine.

Or it could be because they are not scrapping the first couple of rotations which are needed to get the machine & channels up to working temperature .

Tossing ingots into the melt pot in too large a batch can also cause temperature problems that will cause flow problems.

Had a "materials fault" at one time that was actually a lack of forklifts problem .

The driver would put 10 pallets ( stacks actually ) of ingots in front of the machine which was around a full shifts worth

Th ingots from the first 2 stacks , sat on the side for the regulation 3 minutes to pre warm & drive off water then got shoved in

As the stacks got further away the furnace man started to get behind so a lot of them were dropped directly into the furnace which drops the temperature which slows down the flow so you end up with porus castings because the parts of the casting solidifies & blocks off the feeder sprews before the entire casting has solidified leaving internal voids .

If you are suggesting I swap gaskets just because I can then you have no idea of the way I work.

Nothing gets replaced unless it needs to be replaced thus I use about 50 spark plugs a year and about 30 fuel filters a year .

That is against around a 300 job average year .

The only real proof is to pull the head & check and in doing this you destroy the gasket so it is a moot point.

Excessive crankcase pressure is either charge leaking in or the breather blocked.

A blocked breather, can easily be checked with a damp finger over the end of the tube, takes about 2 minutes

Leaking inlet valve seals & bad rings can be checked by working the throttle with your finger & watching / listening.

You also pick up blown gaskets this way as well because the engine will faulter on initial acceleration as it will be sucking in crankcase fume rather than fuel then steady out when the speed has been maintained .

If the gasket was not at fault then the customer gets it done for free.

I believe it stems from a casting fault as some will run 1000 hours without problems while others will do a gasket a season from new .

Usually I can diagnose a blown gasket by the sound the engine makes when it starts then the way it sounds when the blades are engaged .

Now I could spend an full hour doing a dozen thests to confirm the gasket leak or 1/2 hour to replace the the gasket if all goes well .

Crankcases are cast on a multi head machine so one bad mould can affect as few as 1 in 100 castings depending upon the size of the machine.

Or it could be because they are not scrapping the first couple of rotations which are needed to get the machine & channels up to working temperature .

Tossing ingots into the melt pot in too large a batch can also cause temperature problems that will cause flow problems.

Had a "materials fault" at one time that was actually a lack of forklifts problem .

The driver would put 10 pallets ( stacks actually ) of ingots in front of the machine which was around a full shifts worth

Th ingots from the first 2 stacks , sat on the side for the regulation 3 minutes to pre warm & drive off water then got shoved in

As the stacks got further away the furnace man started to get behind so a lot of them were dropped directly into the furnace which drops the temperature which slows down the flow so you end up with porus castings because the parts of the casting solidifies & blocks off the feeder sprews before the entire casting has solidified leaving internal voids .

#19

B

bertsmobile1

B

bertsmobile1

Standard Operating proceedure as a in a lot of cases they have been leaking for a very long time and the bridge is errodedYup, there really needs to be a bolt in the bridge between the cylinder and pushrod cavity. For those engines that keep blowing head gaskets, do you check if the head is warped? You can use a machinists straight edge or a piece of plate glass and place the head on it and try to fit feeler gauges to check for warpage.

#20

A

artemjemmy

A

artemjemmy

Yes, I don't find these engines to smoke too bad when they do blow head gaskets, but they do usually smoke more than normal, especially once they are hot. The customer complaint is usually that the engine is smoking when they do blow a gasket.Here this particular gasket design doesn't present itself as smoker most times here in my shop. I had one engine that burned one quart per 1/2 gallon of fuel and the only thing that was apparent while mowing was a smell of oil burning. Many modern oils don't smoke near as much as older oils did either. Most times the only indication of a blown head gasket is loss of oil volume and oil present in the air cleaner side of the carburetor. Now the fuel pump vent does sometimes have oil leaking out of it too.

Any engine using this particular gasket design that comes into my shop for the first time get a leak down test done to check the head gasket condition.

This particular head gasket design to prone to blowing between the cylinder and the push rod galley. While replacing head gasket make sure the head is not warped.

Also torque the head screws [bolts] to 20.8 fl/lbs [250 in/lbs] using three step torque method [1/3, 2/3, and Full] and in the proper torquing pattern [see below image]. This is the current torque specs for these gaskets and not what the chart says that is being passed around that specs 18.3 ft/lbs [220 in/lbs]. By going to 25 ft/lbs you risk aluminum thread pull out when the engine reaches full operating temperature. Also going to full torque all at once risks warping the head. Heads are not cheap. This head was $212 the last time I checked.

View attachment 59190

Valve clearance is .004-.006" for both intake and exhaust rockers. Rocker Jam Nut or set screw torqued 45 lb-in. Rocker cover screws [bolts] are torque to 65 in/lbs. Note some of these covers are mounted with RTV instead of a paper gasket. Both ways are acceptable. It just that RTV is less likely to leak when applied properly.

Personally I use the RTV method but I have the surface prep / accelerator chemical and know not to allow oil contact for at least 12 hrs. Also when the RTV is applied, screws are only tighten finger tight for at least 12 hrs, then the rocker cover is torque to final torque. I know it time consuming but it is what works here for leak proof application. The 30 minutes cure time on the product tube just don't work in a near airless application. Even at 12 hrs some uncured liquid squeeze out happens.

#21

A

artemjemmy

A

artemjemmy

30 fuel filters a year? what? What do you even do as a basic service then? Just an oil change? On riders and zero turns with a paper fuel filter, it gets changed with every basic service.At a rough guess I would do 20 or so intek gaskets a season.

If you are suggesting I swap gaskets just because I can then you have no idea of the way I work.

Nothing gets replaced unless it needs to be replaced thus I use about 50 spark plugs a year and about 30 fuel filters a year .

That is against around a 300 job average year .

The only real proof is to pull the head & check and in doing this you destroy the gasket so it is a moot point.

Excessive crankcase pressure is either charge leaking in or the breather blocked.

A blocked breather, can easily be checked with a damp finger over the end of the tube, takes about 2 minutes

Leaking inlet valve seals & bad rings can be checked by working the throttle with your finger & watching / listening.

You also pick up blown gaskets this way as well because the engine will faulter on initial acceleration as it will be sucking in crankcase fume rather than fuel then steady out when the speed has been maintained .

If the gasket was not at fault then the customer gets it done for free.

I believe it stems from a casting fault as some will run 1000 hours without problems while others will do a gasket a season from new .

Usually I can diagnose a blown gasket by the sound the engine makes when it starts then the way it sounds when the blades are engaged .

Now I could spend an full hour doing a dozen thests to confirm the gasket leak or 1/2 hour to replace the the gasket if all goes well .

Crankcases are cast on a multi head machine so one bad mould can affect as few as 1 in 100 castings depending upon the size of the machine.

Or it could be because they are not scrapping the first couple of rotations which are needed to get the machine & channels up to working temperature .

Tossing ingots into the melt pot in too large a batch can also cause temperature problems that will cause flow problems.

Had a "materials fault" at one time that was actually a lack of forklifts problem .

The driver would put 10 pallets ( stacks actually ) of ingots in front of the machine which was around a full shifts worth

Th ingots from the first 2 stacks , sat on the side for the regulation 3 minutes to pre warm & drive off water then got shoved in

As the stacks got further away the furnace man started to get behind so a lot of them were dropped directly into the furnace which drops the temperature which slows down the flow so you end up with porus castings because the parts of the casting solidifies & blocks off the feeder sprews before the entire casting has solidified leaving internal voids .

#22

B

bertsmobile1

B

bertsmobile1

For WIW a mower that comes in for a repair get the repair done then field tested for 1/2 hour and returned with a list of what needs to be done .

A mower that comes in for service gets a 1/2 hour run to evaluate it and heat the oil

The oil is changed then every problem I noticed when mowing gets attended to\

Every nut & bolt gets checked as does all of the bushes & bearings

Rear wheels & PTO come off for a derust , and coat of never sieze.

Flywheel comes off to check the stator & clean around the magnets & of course the fins

Under cowl wiring is checked for condition , starter gets a dusting of graphite on the bendix

Alternator output is checked as is battery capacity and battery cables get a visual and some times a terminal clean then over paint with liquid electrical tape .

All tyres are immersion checked for leaks at 40 psi then returned to correct value.

Steering bush is checked & lubed where required , some plastic ones get replaced as required

Steering & brakes adjusted

Belts checked & replaced as required.

Hydros get treated according to their type

Hydros with internal brakes get an oil change at around 200 to 300 hour intervals so it is not uncommon for my customers to get 2000+ hours out of the "non-Servicable " K46's and the like

Drive pedals get adjusted as necessary as does the neutral

Everything that can be lubed get a generous amount of dry lithium grease .

Front cross members with no provision for grease like all MTD's & most Husqvarnas get the pivot bolt removed , check grease & replaced where necessary

Particularly important on MTDs with pressed front cross member .

Air filters are always replaced regardless of their condition , but Donaldson type only get an outer change

Decks are leveled & attack angle adjusted.

Gauge / anti scalp wheels have axels checked and usually lowered to counter the effect of wear on their bore .

Governors are checked and the speeds verified with a tiny tach .

Magnetos on twins checked for diode failure

Cables removed flushed then relubed with Tri-Flow .

Float bowls come off for cleaning & checking the fuel solenoid.

Plugs come out and get either gapped& refitted or just replaced after checking the gap if they looked bad

Valve lash gets looked at if there is an indication that it is bad ( excessive noise or hesitation when cranking )

Generally takes about 1/2 day if I work dillgently to a whole day if I am being slack or have a lot of gate calls .

Customer pays fixed 4 hour service fee + parts.

There are way too many "cook book" mechanics out there who thinks a service is just replacing bits at prescribed hours

A mower that comes in for service gets a 1/2 hour run to evaluate it and heat the oil

The oil is changed then every problem I noticed when mowing gets attended to\

Every nut & bolt gets checked as does all of the bushes & bearings

Rear wheels & PTO come off for a derust , and coat of never sieze.

Flywheel comes off to check the stator & clean around the magnets & of course the fins

Under cowl wiring is checked for condition , starter gets a dusting of graphite on the bendix

Alternator output is checked as is battery capacity and battery cables get a visual and some times a terminal clean then over paint with liquid electrical tape .

All tyres are immersion checked for leaks at 40 psi then returned to correct value.

Steering bush is checked & lubed where required , some plastic ones get replaced as required

Steering & brakes adjusted

Belts checked & replaced as required.

Hydros get treated according to their type

Hydros with internal brakes get an oil change at around 200 to 300 hour intervals so it is not uncommon for my customers to get 2000+ hours out of the "non-Servicable " K46's and the like

Drive pedals get adjusted as necessary as does the neutral

Everything that can be lubed get a generous amount of dry lithium grease .

Front cross members with no provision for grease like all MTD's & most Husqvarnas get the pivot bolt removed , check grease & replaced where necessary

Particularly important on MTDs with pressed front cross member .

Air filters are always replaced regardless of their condition , but Donaldson type only get an outer change

Decks are leveled & attack angle adjusted.

Gauge / anti scalp wheels have axels checked and usually lowered to counter the effect of wear on their bore .

Governors are checked and the speeds verified with a tiny tach .

Magnetos on twins checked for diode failure

Cables removed flushed then relubed with Tri-Flow .

Float bowls come off for cleaning & checking the fuel solenoid.

Plugs come out and get either gapped& refitted or just replaced after checking the gap if they looked bad

Valve lash gets looked at if there is an indication that it is bad ( excessive noise or hesitation when cranking )

Generally takes about 1/2 day if I work dillgently to a whole day if I am being slack or have a lot of gate calls .

Customer pays fixed 4 hour service fee + parts.

There are way too many "cook book" mechanics out there who thinks a service is just replacing bits at prescribed hours

#23

K

Knots

K

Knots

Many thanks to Star Tech, Bertsmobile1, Rivets

And others for all the help.

I have one more question. Head gasket blown in center between piston and pushrod galley as you predicted.

How important is retorqueing head bolts after a 5 minute run? Looks like that is going to be difficult as the two head bolts on intake side are studs that support the gas tank bracket. Please advise. Maybe there is an easier way. Thanks again.

Knots

And others for all the help.

I have one more question. Head gasket blown in center between piston and pushrod galley as you predicted.

How important is retorqueing head bolts after a 5 minute run? Looks like that is going to be difficult as the two head bolts on intake side are studs that support the gas tank bracket. Please advise. Maybe there is an easier way. Thanks again.

Knots

#24

A

artemjemmy

A

artemjemmy

What do you charge for all this, bert?For WIW a mower that comes in for a repair get the repair done then field tested for 1/2 hour and returned with a list of what needs to be done .

A mower that comes in for service gets a 1/2 hour run to evaluate it and heat the oil

The oil is changed then every problem I noticed when mowing gets attended to\

Every nut & bolt gets checked as does all of the bushes & bearings

Rear wheels & PTO come off for a derust , and coat of never sieze.

Flywheel comes off to check the stator & clean around the magnets & of course the fins

Under cowl wiring is checked for condition , starter gets a dusting of graphite on the bendix

Alternator output is checked as is battery capacity and battery cables get a visual and some times a terminal clean then over paint with liquid electrical tape .

All tyres are immersion checked for leaks at 40 psi then returned to correct value.

Steering bush is checked & lubed where required , some plastic ones get replaced as required

Steering & brakes adjusted

Belts checked & replaced as required.

Hydros get treated according to their type

Hydros with internal brakes get an oil change at around 200 to 300 hour intervals so it is not uncommon for my customers to get 2000+ hours out of the "non-Servicable " K46's and the like

Drive pedals get adjusted as necessary as does the neutral

Everything that can be lubed get a generous amount of dry lithium grease .

Front cross members with no provision for grease like all MTD's & most Husqvarnas get the pivot bolt removed , check grease & replaced where necessary

Particularly important on MTDs with pressed front cross member .

Air filters are always replaced regardless of their condition , but Donaldson type only get an outer change

Decks are leveled & attack angle adjusted.

Gauge / anti scalp wheels have axels checked and usually lowered to counter the effect of wear on their bore .

Governors are checked and the speeds verified with a tiny tach .

Magnetos on twins checked for diode failure

Cables removed flushed then relubed with Tri-Flow .

Float bowls come off for cleaning & checking the fuel solenoid.

Plugs come out and get either gapped& refitted or just replaced after checking the gap if they looked bad

Valve lash gets looked at if there is an indication that it is bad ( excessive noise or hesitation when cranking )

Generally takes about 1/2 day if I work dillgently to a whole day if I am being slack or have a lot of gate calls .

Customer pays fixed 4 hour service fee + parts.

There are way too many "cook book" mechanics out there who thinks a service is just replacing bits at prescribed hour

#25

A

artemjemmy

A

artemjemmy

I never do it, but I do generally overtorque the bolts slightly from the briggs specification. I'm sure the OCD mechanics in here will say it is absolutely vital. So, you choose your pick. Are you afraid it will blow again? Take the long route.Many thanks to Star Tech, Bertsmobile1, Rivets

And others for all the help.

I have one more question. Head gasket blown in center between piston and pushrod galley as you predicted.

How important is retorqueing head bolts after a 5 minute run? Looks like that is going to be difficult as the two head bolts on intake side are studs that support the gas tank bracket. Please advise. Maybe there is an easier way. Thanks again.

Knots

#26

B

bertsmobile1

I am in OZ , my current rate is $ 72/ hr and parts usually run to about $ 250 depending upon the belts s lot of them are more than that down here .

As a comparrison the local JD dealers do pre-season safety checks for $ 275 and all you get for that is a list of what is not to brand new factory specification .

Then they come to me to see what of the $ 2500 quote actually needs to be done .

B

bertsmobile1

4 hours + partsWhat do you charge for all this, bert?

I am in OZ , my current rate is $ 72/ hr and parts usually run to about $ 250 depending upon the belts s lot of them are more than that down here .

As a comparrison the local JD dealers do pre-season safety checks for $ 275 and all you get for that is a list of what is not to brand new factory specification .

Then they come to me to see what of the $ 2500 quote actually needs to be done .

#27

A

artemjemmy

A

artemjemmy

So you said you get about 2 machines done a day right? How do you even get to all of the different machines during the spring mower rush? Maybe I am misunderstanding how you work as a mechanic.4 hours + parts

I am in OZ , my current rate is $ 72/ hr and parts usually run to about $ 250 depending upon the belts s lot of them are more than that down here .

As a comparrison the local JD dealers do pre-season safety checks for $ 275 and all you get for that is a list of what is not to brand new factory specification .

Then they come to me to see what of the $ 2500 quote actually needs to be done .

#28

StarTech

StarTech

He can only get about 15 units per 60 hr week out max at that rate. I am not that busy but during the Spring/Summer go through about 5-10 units per week during my 60 hr week and that pushing it. There is a lot of non billable time involved too as I am the chief cook and bottle washer. Even at this rate I got back up two weeks this last Spring but larger shops were running 4-6 weeks behind.

And I only do what is necessary as customers complain if the bill goes much over $300 on a $1500 machine. It doesn't long to get there a few $40-$75 belts. Four hours of labor here is $241 including taxes. Lately those bills have been in the $450 range as parts costs are going through the roof. Boy some of the spindles are over $100 each now. No wonder I rebuild so many during the peak season.

And I only do what is necessary as customers complain if the bill goes much over $300 on a $1500 machine. It doesn't long to get there a few $40-$75 belts. Four hours of labor here is $241 including taxes. Lately those bills have been in the $450 range as parts costs are going through the roof. Boy some of the spindles are over $100 each now. No wonder I rebuild so many during the peak season.

#29

R

Rivets

R

Rivets

When I retorque the head bolts I skip the two under the tank unless I find that one f the other bolts has loosened. If so I take the time to remove the tank and recheck all. Yes, this does take extra time, but as I taught my students, “Never time to do it right, but always time to do it over”.

#30

B

bertsmobile1

Some just buy parts, some just get repairs done & some get a full services done.

The more regular the service the faster they can get done & if I push hard I can squeeze in 4 a day

Nothing odd to have all 4 sump pumps running at the same time in busy periods

I recommend a full service every 2 to 4 years and annual oil changes in between depending upon the customer & their mowers.

Oil changes are done at the customers house & I have done 20 in a single day at one time as it only takes about 10 minutes to change oil only.

And while the pump is sucking the oil out I can change the blades on their push mower if they are an annual change over customer .

We use swing back blades down here so most need changing every season or two.

Blades on a push mower take about 5 minutes if I have a mounting plate ready to exchange , a saw chain takes about the same time

Spindle bearings & blades takes about 6 minutes a spindle if I don't have to cut the bolt or cup washer off

Very few customers have trailers so I can organize the work load to suit my available time

So I can drop off a finished job, do a couple of strait oil changes , pick up another service + a couple of flat tyres in a single run during the busy periods

I try to get customers to have the full services done during the off season

Commercial customers get overnight servicing / repairs so when I pull an all nighter I just leave the gate locked and sleep in .

The journal has around 300 entries a year, one entry per job .

The arbourist all have yard keys so they just drop a pile of blades on their peg & I text them when they are ready.

Commercial customers also have gate keys so they can drop a mower off at 4 to 5 pm on their way home & pick it up at 4 or 5 am on their way out .

That was the gold mine idea and is my biggest money spinner as some of them will drop a mower off every week, two in the busy season.

Down side is I need to have a lot of parts on hand .

Up side is you get to monitor things like deck idlers so you know this one will need to be done in the next X weeks.

Took a while to get them all on board but most never loose a minute during the day for breakdowns unless it is something out of the blue like management module failures .

When they happen I can usually advise them how to bypass the module so they can finish the days work then make a proper repair that night or at least a safe workaround till I can get the modules.

Those Scagg units are a real problem with a very high failure rate , followed by the brake modules on Time Cutters then the ECM module on Z masters .

Nothing kills a contractors day faster than having a break down so they end up with the team picking their noses for 1/2 the day because the mower has packed it in.

So for them the extra costs of extra servicing is a no brainer & I have just started doing blade sharpening for them so some will drop up to 30 sets of blades off on their way home & pick them up in the morning.

Most will have at least 2 spare useable belts in their trucks for emergencies but to be honest few have used them in the past 5 years

When things get right out of hand I have a 1/2 dozen loaner ride ons and about the same number of walk behinds.

They are also a big money spinner as it is nothing odd for the big shops to have 6 week lead times in high summer.

Part & parcel of my site rent is to maintain about 6 acres of street frontage so I get to kill 2 birds with one stone by using the customers mowers to do my own mowing & I am testing their mowers while doing my mowing .

What takes all of the time is broken stuff that I have never seen before , totally trashed mowers or parts that I can not get.

Which is the prime reason I stay on here because I get to find out the weaknesses of machines that are yet to be imported here so I know what to look for with a new to me mower .

having done he run for 9 years now I am familiar with most of the customers mowers so for instance Knots failed head gasket would have been diagnosed by the time it was on my trailer .

Unloading it I use the ramp to test the hydros and then it would sit for an hour to cool down before having the gasket replaced which is a 30 minute to 1 hour job depending upon how easy things come apart.

You lear things like to leave mufflers in place & pull the carb off at the head where possible and you learn where to us a T socket , where to use a wratchet , where to use an impact , where to use an air wrench & where to use modified tools .

The tool chest is full of ground down or welded up tools designed to make jobs faster or easier

I have a 4 ton yard crane that will lift a ride on up high enough to sit underneath comfortably in less than a minute and if that has a mower on it then there are a stack of motorcycle paddock stands that will lift a mower about 10" off the ground in under 15 seconds so fixing a flat takes no time at all as does pulling the rear wheels off to grease the axels & check the tyres for leaks .

B

bertsmobile1

I have about 500 customers on my booksSo you said you get about 2 machines done a day right? How do you even get to all of the different machines during the spring mower rush? Maybe I am misunderstanding how you work as a mechanic.

Some just buy parts, some just get repairs done & some get a full services done.

The more regular the service the faster they can get done & if I push hard I can squeeze in 4 a day

Nothing odd to have all 4 sump pumps running at the same time in busy periods

I recommend a full service every 2 to 4 years and annual oil changes in between depending upon the customer & their mowers.

Oil changes are done at the customers house & I have done 20 in a single day at one time as it only takes about 10 minutes to change oil only.

And while the pump is sucking the oil out I can change the blades on their push mower if they are an annual change over customer .

We use swing back blades down here so most need changing every season or two.

Blades on a push mower take about 5 minutes if I have a mounting plate ready to exchange , a saw chain takes about the same time

Spindle bearings & blades takes about 6 minutes a spindle if I don't have to cut the bolt or cup washer off

Very few customers have trailers so I can organize the work load to suit my available time

So I can drop off a finished job, do a couple of strait oil changes , pick up another service + a couple of flat tyres in a single run during the busy periods

I try to get customers to have the full services done during the off season

Commercial customers get overnight servicing / repairs so when I pull an all nighter I just leave the gate locked and sleep in .

The journal has around 300 entries a year, one entry per job .

The arbourist all have yard keys so they just drop a pile of blades on their peg & I text them when they are ready.

Commercial customers also have gate keys so they can drop a mower off at 4 to 5 pm on their way home & pick it up at 4 or 5 am on their way out .

That was the gold mine idea and is my biggest money spinner as some of them will drop a mower off every week, two in the busy season.

Down side is I need to have a lot of parts on hand .

Up side is you get to monitor things like deck idlers so you know this one will need to be done in the next X weeks.

Took a while to get them all on board but most never loose a minute during the day for breakdowns unless it is something out of the blue like management module failures .

When they happen I can usually advise them how to bypass the module so they can finish the days work then make a proper repair that night or at least a safe workaround till I can get the modules.

Those Scagg units are a real problem with a very high failure rate , followed by the brake modules on Time Cutters then the ECM module on Z masters .

Nothing kills a contractors day faster than having a break down so they end up with the team picking their noses for 1/2 the day because the mower has packed it in.

So for them the extra costs of extra servicing is a no brainer & I have just started doing blade sharpening for them so some will drop up to 30 sets of blades off on their way home & pick them up in the morning.

Most will have at least 2 spare useable belts in their trucks for emergencies but to be honest few have used them in the past 5 years

When things get right out of hand I have a 1/2 dozen loaner ride ons and about the same number of walk behinds.

They are also a big money spinner as it is nothing odd for the big shops to have 6 week lead times in high summer.

Part & parcel of my site rent is to maintain about 6 acres of street frontage so I get to kill 2 birds with one stone by using the customers mowers to do my own mowing & I am testing their mowers while doing my mowing .

What takes all of the time is broken stuff that I have never seen before , totally trashed mowers or parts that I can not get.

Which is the prime reason I stay on here because I get to find out the weaknesses of machines that are yet to be imported here so I know what to look for with a new to me mower .

having done he run for 9 years now I am familiar with most of the customers mowers so for instance Knots failed head gasket would have been diagnosed by the time it was on my trailer .

Unloading it I use the ramp to test the hydros and then it would sit for an hour to cool down before having the gasket replaced which is a 30 minute to 1 hour job depending upon how easy things come apart.

You lear things like to leave mufflers in place & pull the carb off at the head where possible and you learn where to us a T socket , where to use a wratchet , where to use an impact , where to use an air wrench & where to use modified tools .

The tool chest is full of ground down or welded up tools designed to make jobs faster or easier

I have a 4 ton yard crane that will lift a ride on up high enough to sit underneath comfortably in less than a minute and if that has a mower on it then there are a stack of motorcycle paddock stands that will lift a mower about 10" off the ground in under 15 seconds so fixing a flat takes no time at all as does pulling the rear wheels off to grease the axels & check the tyres for leaks .

#31

A

artemjemmy

A

artemjemmy

What state are you in bert? I noticed that you never mentioned anything about snow blowers or snow removal equipment, which would simply things somewhat for you.I have about 500 customers on my books

Some just buy parts, some just get repairs done & some get a full services done.

The more regular the service the faster they can get done & if I push hard I can squeeze in 4 a day

Nothing odd to have all 4 sump pumps running at the same time in busy periods

I recommend a full service every 2 to 4 years and annual oil changes in between depending upon the customer & their mowers.

Oil changes are done at the customers house & I have done 20 in a single day at one time as it only takes about 10 minutes to change oil only.

And while the pump is sucking the oil out I can change the blades on their push mower if they are an annual change over customer .

We use swing back blades down here so most need changing every season or two.

Blades on a push mower take about 5 minutes if I have a mounting plate ready to exchange , a saw chain takes about the same time

Spindle bearings & blades takes about 6 minutes a spindle if I don't have to cut the bolt or cup washer off

Very few customers have trailers so I can organize the work load to suit my available time

So I can drop off a finished job, do a couple of strait oil changes , pick up another service + a couple of flat tyres in a single run during the busy periods

I try to get customers to have the full services done during the off season

Commercial customers get overnight servicing / repairs so when I pull an all nighter I just leave the gate locked and sleep in .

The journal has around 300 entries a year, one entry per job .

The arbourist all have yard keys so they just drop a pile of blades on their peg & I text them when they are ready.

Commercial customers also have gate keys so they can drop a mower off at 4 to 5 pm on their way home & pick it up at 4 or 5 am on their way out .

That was the gold mine idea and is my biggest money spinner as some of them will drop a mower off every week, two in the busy season.

Down side is I need to have a lot of parts on hand .

Up side is you get to monitor things like deck idlers so you know this one will need to be done in the next X weeks.

Took a while to get them all on board but most never loose a minute during the day for breakdowns unless it is something out of the blue like management module failures .

When they happen I can usually advise them how to bypass the module so they can finish the days work then make a proper repair that night or at least a safe workaround till I can get the modules.

Those Scagg units are a real problem with a very high failure rate , followed by the brake modules on Time Cutters then the ECM module on Z masters .

Nothing kills a contractors day faster than having a break down so they end up with the team picking their noses for 1/2 the day because the mower has packed it in.

So for them the extra costs of extra servicing is a no brainer & I have just started doing blade sharpening for them so some will drop up to 30 sets of blades off on their way home & pick them up in the morning.

Most will have at least 2 spare useable belts in their trucks for emergencies but to be honest few have used them in the past 5 years

When things get right out of hand I have a 1/2 dozen loaner ride ons and about the same number of walk behinds.

They are also a big money spinner as it is nothing odd for the big shops to have 6 week lead times in high summer.

Part & parcel of my site rent is to maintain about 6 acres of street frontage so I get to kill 2 birds with one stone by using the customers mowers to do my own mowing & I am testing their mowers while doing my mowing .

What takes all of the time is broken stuff that I have never seen before , totally trashed mowers or parts that I can not get.

Which is the prime reason I stay on here because I get to find out the weaknesses of machines that are yet to be imported here so I know what to look for with a new to me mower .

having done he run for 9 years now I am familiar with most of the customers mowers so for instance Knots failed head gasket would have been diagnosed by the time it was on my trailer .

Unloading it I use the ramp to test the hydros and then it would sit for an hour to cool down before having the gasket replaced which is a 30 minute to 1 hour job depending upon how easy things come apart.

You lear things like to leave mufflers in place & pull the carb off at the head where possible and you learn where to us a T socket , where to use a wratchet , where to use an impact , where to use an air wrench & where to use modified tools .

The tool chest is full of ground down or welded up tools designed to make jobs faster or easier

I have a 4 ton yard crane that will lift a ride on up high enough to sit underneath comfortably in less than a minute and if that has a mower on it then there are a stack of motorcycle paddock stands that will lift a mower about 10" off the ground in under 15 seconds so fixing a flat takes no time at all as does pulling the rear wheels off to grease the axels & check the tyres for leaks .

#32

B

bertsmobile1

B

bertsmobile1

It don't snow in NSW

Big problems with a lot of Americans is they forget there are more places on the planet than America

So I am in Gods own country way down south with 300 dry days a year so naturally we all drive black cars ( except me ) when a motorcycle would be the perfect mode of transport .

It is a bit on the flat side down here so the snow season is somewhat short and usually confined to altitudes of 2000' which there is not much of so Aussies go to NZ to ski.

This is why we invented the best snow making machine ever.

Several years ago the inventor layed 6' of snow in Death Valley to try & get some financial backing for his invention .

I think he went bust although we do have about 20 of his machines in what we call the snow fields.

Sydney is fairly close to LA temperature wise so here we mow weekly for about 9 months a year if there is some water .

Big problems with a lot of Americans is they forget there are more places on the planet than America

So I am in Gods own country way down south with 300 dry days a year so naturally we all drive black cars ( except me ) when a motorcycle would be the perfect mode of transport .

It is a bit on the flat side down here so the snow season is somewhat short and usually confined to altitudes of 2000' which there is not much of so Aussies go to NZ to ski.

This is why we invented the best snow making machine ever.

Several years ago the inventor layed 6' of snow in Death Valley to try & get some financial backing for his invention .

I think he went bust although we do have about 20 of his machines in what we call the snow fields.

Sydney is fairly close to LA temperature wise so here we mow weekly for about 9 months a year if there is some water .

#33

StarTech

StarTech

I'll see if I can export some of the 20 inches of rain and storms your way Bert that I got in December. Got to have some bad weather I reckon just to make you enjoy the good weather. Right now we should be in the 40 F for highs here but it been so warm that things that normally hibernating are coming out. Even my fruit trees are blooming out season. My chickens thinks they are part duck as they wade water up to their bellies. I relocated a 15 lb Snapper turtle Monday. I even heard a bullfrog croaking last night.

The weather is up messed up lately. One day it is 75F and the next it is 35F for highs. Yesterday it was 73F with drizzle and Monday they are forecasting snow. They even forecasting possible tornadoes tonight. Dang it makes it hard to work outdoors.

Everytime I pull out the generator to work on it, it started raining. I manage to cleaned a couple ZTR's engine compartments. Of course that can be done in the rain. I think I change uniforms about six times yesterday. I got to build a office and storage area so I can reclaim my shop area and my home. They charge two arms and a leg for delivery in my area for concrete.

The weather is up messed up lately. One day it is 75F and the next it is 35F for highs. Yesterday it was 73F with drizzle and Monday they are forecasting snow. They even forecasting possible tornadoes tonight. Dang it makes it hard to work outdoors.

Everytime I pull out the generator to work on it, it started raining. I manage to cleaned a couple ZTR's engine compartments. Of course that can be done in the rain. I think I change uniforms about six times yesterday. I got to build a office and storage area so I can reclaim my shop area and my home. They charge two arms and a leg for delivery in my area for concrete.

#34

B

bertsmobile1

And even back then there was a theory about the possibility that we were making a big mess of the planet , which is sort of ironic because it was the university dedicated to science & engineering

One of the predictions was an increase in the intensity & ferosity of weather changes

Down here we spent millions on an energy white paper , but the politicans ignored it

Then just as they did with smoking the vested interests turned it into a left vs right debate so we just argued about it for 4 decades and did nothing.

And now that some of the predictions are actually happening we are still running around blaming every one else.

Good thing is like you my tenure on this planet is rapidly coming to an end .

I worry for the fate of the children born today and wonder is they will actually live as long as I have.

Humans never ever learn and as the planet is going to hell in a hand basket we are still talking about doing the same thing that has achieved absolutely nothing for the past 5,000 years and preparing to kill each other once again.

Well if we kill enough of each other then the planet may have a chance to recover but I really doubt it .

Back in 1974 we profiled furnaces for 21% Oxygen , now days we are profiling down to 18% oxygen and even then some days there is not enough oxygen in the air to produce a neutral flame .

Chemical companies are still brainwashing us that every insect is a pest to be killed and the only way to save ourselves is to but more stuff to kill other stuff.

What I find quite ironic is scientists have had more of their predictions come true than those in any book of religion yet more people believe in religions than science

On the up side my strawberries are in their 3rd year of continual fruiting and I do like a real stawberry, one that tastes like a strawberry without the use of artifical flavours .

TheChinese Gooseberies are also fruiting again and the heat wave we had a month ago caused the fruit flys to hatch too early so I might get some apricots & peaches .

B

bertsmobile1

It has been 40 years since I left collegeI'll see if I can export some of the 20 inches of rain and storms your way Bert that I got in December. Got to have some bad weather I reckon just to make you enjoy the good weather. Right now we should be in the 40 F for highs here but it been so warm that things that normally hibernating are coming out. Even my fruit trees are blooming out season. My chickens thinks they are part duck as they wade water up to their bellies. I relocated a 15 lb Snapper turtle Monday. I even heard a bullfrog croaking last night.

The weather is up messed up lately. One day it is 75F and the next it is 35F for highs. Yesterday it was 73F with drizzle and Monday they are forecasting snow. They even forecasting possible tornadoes tonight. Dang it makes it hard to work outdoors.

Everytime I pull out the generator to work on it, it started raining. I manage to cleaned a couple ZTR's engine compartments. Of course that can be done in the rain. I think I change uniforms about six times yesterday. I got to build a office and storage area so I can reclaim my shop area and my home. They charge two arms and a leg for delivery in my area for concrete.

And even back then there was a theory about the possibility that we were making a big mess of the planet , which is sort of ironic because it was the university dedicated to science & engineering

One of the predictions was an increase in the intensity & ferosity of weather changes

Down here we spent millions on an energy white paper , but the politicans ignored it

Then just as they did with smoking the vested interests turned it into a left vs right debate so we just argued about it for 4 decades and did nothing.

And now that some of the predictions are actually happening we are still running around blaming every one else.

Good thing is like you my tenure on this planet is rapidly coming to an end .

I worry for the fate of the children born today and wonder is they will actually live as long as I have.

Humans never ever learn and as the planet is going to hell in a hand basket we are still talking about doing the same thing that has achieved absolutely nothing for the past 5,000 years and preparing to kill each other once again.

Well if we kill enough of each other then the planet may have a chance to recover but I really doubt it .

Back in 1974 we profiled furnaces for 21% Oxygen , now days we are profiling down to 18% oxygen and even then some days there is not enough oxygen in the air to produce a neutral flame .

Chemical companies are still brainwashing us that every insect is a pest to be killed and the only way to save ourselves is to but more stuff to kill other stuff.

What I find quite ironic is scientists have had more of their predictions come true than those in any book of religion yet more people believe in religions than science

On the up side my strawberries are in their 3rd year of continual fruiting and I do like a real stawberry, one that tastes like a strawberry without the use of artifical flavours .

TheChinese Gooseberies are also fruiting again and the heat wave we had a month ago caused the fruit flys to hatch too early so I might get some apricots & peaches .

#35

StarTech

StarTech

I admit Humans are their own worst enemy. We have simply destroyed this world in the name progress. IF we actually put as much energy into saving our world as we do in destroying it. It might survive us in despite of our destroying ways but we won't if we don't change our ways. Maybe Covid-19 is a way nature is hitting back us back now.

I have seen huge changes over the years as storms have much more destructive each passing year in my area alone. I have learn that when storms are approaching and the temps are around 70F that I am in for a really bad weather day. And today is one of them since it is at 69F right now with storms on the horizon.

When peaches here I use permethrin which seems to do a better job keeping the worms out of the fruit after blossom petal fall that way the honey bees have a better chance of surviving the spraying of trees. Everything else seems to be useless. Then of course there are tree borers which I finally found a way to stop them. It like the potato beetles which are no longer affected by Sevin here but the biological I use works very well and is only targeted at the those beetles.

The problem here with peaches is also weather related as I have move 6 miles north of where I once live and every spring they fruit but then a cold snap hits freezing off the fruit so I am having which to a fruit tree crop that can survive the weather. At least apples and pears currently survive the Spring weather sudden changes but for how long I have no idea.

I have seen huge changes over the years as storms have much more destructive each passing year in my area alone. I have learn that when storms are approaching and the temps are around 70F that I am in for a really bad weather day. And today is one of them since it is at 69F right now with storms on the horizon.

When peaches here I use permethrin which seems to do a better job keeping the worms out of the fruit after blossom petal fall that way the honey bees have a better chance of surviving the spraying of trees. Everything else seems to be useless. Then of course there are tree borers which I finally found a way to stop them. It like the potato beetles which are no longer affected by Sevin here but the biological I use works very well and is only targeted at the those beetles.

The problem here with peaches is also weather related as I have move 6 miles north of where I once live and every spring they fruit but then a cold snap hits freezing off the fruit so I am having which to a fruit tree crop that can survive the weather. At least apples and pears currently survive the Spring weather sudden changes but for how long I have no idea.

#36

K

Knots

K

Knots

When I look at the Briggs parts manual and look at the picture it shows only one (1) valve seal which is number 690968. Is there only one valve that gets a seal? If so,

Which one? The gasket set I ordered is

796189.

Thanks,

Knots

Which one? The gasket set I ordered is

796189.

Thanks,

Knots

#37

Scrubcadet10

Scrubcadet10

In my experience the intake valve always gets the valve seal, if there is only one.

#38

B

bertsmobile1

Exhaust blows

So only the intake equires a valve stem seal

B

bertsmobile1

Intake sucksIn my experience the intake valve always gets the valve seal, if there is only one.

Exhaust blows

So only the intake equires a valve stem seal

#39

B

bertsmobile1

This is a true fact , what was overlooked is fruit fly is attracted by the smells of the ripening fruit so you don't spray for fruit fly when bees are foraging in those trees.

So in a decision mirroring the use of the cane toad to control the sugar cane beetle ( they never see each other ) we banned the residential use of the sprays and strictly regulated the commercial use.

The end result is most home gardeners can not grow any fruit apart from very early varieties or very late varieties to avoid the flys peak season and all commercial fruit & above ground veggies have to ne picked green and then chemically ripened.

This of course is a direct benefit to the large retail chains and big commercial growers who funded the research .

Currently Australia is veroa mite free so is supplying around 90% of the worlds bees, without which humans in western countries would starve .

This is a time bomb because all of the worlds bees will be too closely related thus very susceptible to a single disease wiping them all out forever .

So the "answer" to this is companies like Monsanto working to develop self fertile f hybrid crops so farmers will have to buy seed form Monsanto every season like Round Up resistant canola wheat & rice.

B

bertsmobile1

A research institution ( funded by agriculture interest & the major fresh fruit retailers ) found that the only 2 sprays that work with fruit fly were a big problem for bees.I admit Humans are their own worst enemy. We have simply destroyed this world in the name progress. IF we actually put as much energy into saving our world as we do in destroying it. It might survive us in despite of our destroying ways but we won't if we don't change our ways. Maybe Covid-19 is a way nature is hitting back us back now.

I have seen huge changes over the years as storms have much more destructive each passing year in my area alone. I have learn that when storms are approaching and the temps are around 70F that I am in for a really bad weather day. And today is one of them since it is at 69F right now with storms on the horizon.

When peaches here I use permethrin which seems to do a better job keeping the worms out of the fruit after blossom petal fall that way the honey bees have a better chance of surviving the spraying of trees. Everything else seems to be useless. Then of course there are tree borers which I finally found a way to stop them. It like the potato beetles which are no longer affected by Sevin here but the biological I use works very well and is only targeted at the those beetles.

The problem here with peaches is also weather related as I have move 6 miles north of where I once live and every spring they fruit but then a cold snap hits freezing off the fruit so I am having which to a fruit tree crop that can survive the weather. At least apples and pears currently survive the Spring weather sudden changes but for how long I have no idea.

This is a true fact , what was overlooked is fruit fly is attracted by the smells of the ripening fruit so you don't spray for fruit fly when bees are foraging in those trees.

So in a decision mirroring the use of the cane toad to control the sugar cane beetle ( they never see each other ) we banned the residential use of the sprays and strictly regulated the commercial use.

The end result is most home gardeners can not grow any fruit apart from very early varieties or very late varieties to avoid the flys peak season and all commercial fruit & above ground veggies have to ne picked green and then chemically ripened.

This of course is a direct benefit to the large retail chains and big commercial growers who funded the research .

Currently Australia is veroa mite free so is supplying around 90% of the worlds bees, without which humans in western countries would starve .

This is a time bomb because all of the worlds bees will be too closely related thus very susceptible to a single disease wiping them all out forever .

So the "answer" to this is companies like Monsanto working to develop self fertile f hybrid crops so farmers will have to buy seed form Monsanto every season like Round Up resistant canola wheat & rice.

#40

StarTech

StarTech

Must be the same folks that imported the Japanese beetle here to control the holy thistles. Which in ran rampant destroying a lot of our trees. They had buying bags to trap them which did none attracted even more of them. Our birds finally learned to eat both the adult and grubs but they are still a pest to be reckon with. They imported the Asian beetle (ladybug look alike) which fill our homes in the fall and winter months. On top that I am plagued with boxelder bugs too. There are times in the fall that I have wear a full body suit just to work outdoors because of these pests.

Just morning I was at the neighbor's house the south wall was just covered in the boxelder bugs.

Just morning I was at the neighbor's house the south wall was just covered in the boxelder bugs.

#41

Hammermechanicman

Hammermechanicman

Wow. You make me look bad. Most folks with $1500 box store mowers won't spend more than $150-$175 for an annual service. I don't do all that you do. I need to spend 2 hours or less on an annual maint service. JD mowers are different. Those folks will pay more. The local JD dealers are $350-$400 for annual maint. I am around $250 for those. And i do change all filters and spark plugs on every annual maint. I throw away probably 100 good plugs a year.For WIW a mower that comes in for a repair get the repair done then field tested for 1/2 hour and returned with a list of what needs to be done .

A mower that comes in for service gets a 1/2 hour run to evaluate it and heat the oil

The oil is changed then every problem I noticed when mowing gets attended to\

Every nut & bolt gets checked as does all of the bushes & bearings

Rear wheels & PTO come off for a derust , and coat of never sieze.

Flywheel comes off to check the stator & clean around the magnets & of course the fins

Under cowl wiring is checked for condition , starter gets a dusting of graphite on the bendix

Alternator output is checked as is battery capacity and battery cables get a visual and some times a terminal clean then over paint with liquid electrical tape .

All tyres are immersion checked for leaks at 40 psi then returned to correct value.

Steering bush is checked & lubed where required , some plastic ones get replaced as required

Steering & brakes adjusted

Belts checked & replaced as required.

Hydros get treated according to their type

Hydros with internal brakes get an oil change at around 200 to 300 hour intervals so it is not uncommon for my customers to get 2000+ hours out of the "non-Servicable " K46's and the like

Drive pedals get adjusted as necessary as does the neutral

Everything that can be lubed get a generous amount of dry lithium grease .

Front cross members with no provision for grease like all MTD's & most Husqvarnas get the pivot bolt removed , check grease & replaced where necessary

Particularly important on MTDs with pressed front cross member .

Air filters are always replaced regardless of their condition , but Donaldson type only get an outer change

Decks are leveled & attack angle adjusted.

Gauge / anti scalp wheels have axels checked and usually lowered to counter the effect of wear on their bore .

Governors are checked and the speeds verified with a tiny tach .

Magnetos on twins checked for diode failure

Cables removed flushed then relubed with Tri-Flow .

Float bowls come off for cleaning & checking the fuel solenoid.

Plugs come out and get either gapped& refitted or just replaced after checking the gap if they looked bad

Valve lash gets looked at if there is an indication that it is bad ( excessive noise or hesitation when cranking )

Generally takes about 1/2 day if I work dillgently to a whole day if I am being slack or have a lot of gate calls .

Customer pays fixed 4 hour service fee + parts.

There are way too many "cook book" mechanics out there who thinks a service is just replacing bits at prescribed hours

#42

StarTech

StarTech

Sure they are will more for JD maintenance as I got a Z950R in the shop that parts alone are already at $200+ just for engine work and that using Kawasaki parts from my distributor and not ones from JD dealer.

At least it look like he would had needed a complete new carburetor for that FX850. JD is asking $556.70 [my cost] for the replacement carburetor. But it is only $396.82 from Kawasaki. Hopefully Home Depot have what I need for part of the repair. If not then I order the item from McMaster. I knew going into this project that choke shaft was complete worn in two which damage the carburetor main body and that there was a major oil leak.

Prices are each.