You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Inconsistent 330000 exhaust valve clearance specs in manuals

#1

I

ianviney

I

ianviney

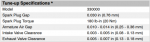

I have a John Deere JD110 ride-on mower with a Briggs and Stratton 330000 series engine. I have previously used the valve clearances in the B&S Operators Manual (here, p9), which says 0.005" - 0.007" for the exhaust valve:

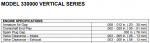

However, I am now replacing the camshaft so I have consulted the B&S Repair Manual (here, p177) and I noticed it says 0.003" - 0.005" for the exhaust valve:

Which one is correct, or doesn't it matter?

Thanks.

However, I am now replacing the camshaft so I have consulted the B&S Repair Manual (here, p177) and I noticed it says 0.003" - 0.005" for the exhaust valve:

Which one is correct, or doesn't it matter?

Thanks.

#2

B

bertsmobile1

B

bertsmobile1

Does not matter

Get 100 experienced mechanics to set a 0.005" gap and you will get 101 different gaps.

This experiment has been done thousands of times where a gap is set with feelers then checked with a dial gauge

Get 100 experienced mechanics to set a 0.005" gap and you will get 101 different gaps.

This experiment has been done thousands of times where a gap is set with feelers then checked with a dial gauge

#4

StarTech

StarTech

The .005 - .007 is the correct spec. and it does matter as the exhaust valve expands more. But as said everyone has a different feel for the correct spacing. Here is I use the .005 will go in and the .006 won't method knowing these valve tends to open up over time so its somewhere between .005 and .006.

And yes there is at a couple errors in the service manual. The main bearing spec in the 310000 series is wrong also which I have corrected in my version of the service manual along the missing rocker arm stud torque specs.

Tnx for finding this error and I have update the service manual with the correct info for my forum's group download directory files.

And yes there is at a couple errors in the service manual. The main bearing spec in the 310000 series is wrong also which I have corrected in my version of the service manual along the missing rocker arm stud torque specs.

Tnx for finding this error and I have update the service manual with the correct info for my forum's group download directory files.

#5

B

bertsmobile1

YES

The actual spec is 0.006" +/- 0.001"

But Joe public is considered to be too stupid so they get written as a range.

To squeeze that extra season or two from some engine I have done inlets down to 0.0015"

The gap is only there so that when the valve expands fully the rockers do not prevent it from closing .

B

bertsmobile1

Are you saying that anything from 0.003" to 0.007" is acceptable?

YES

The actual spec is 0.006" +/- 0.001"

But Joe public is considered to be too stupid so they get written as a range.

To squeeze that extra season or two from some engine I have done inlets down to 0.0015"

The gap is only there so that when the valve expands fully the rockers do not prevent it from closing .

#6

StarTech

StarTech

Not all are so stupid but many can't even find their way out of a wet paper bag with both ends open. I got quite a few customers here in that class but at least they will admit it and ask for help. It all depends of their knowledge and abilities.

And yes I understand the expansion factor but I don't go below the suggested spec numbers as here customers do abuse their equipment and extreme heating is just one of the problems here.

And I have actually seen valve gap specs down at .001 in. on some engines that I have work on, just don't remember which ones as I refer to the specs each time as I do adjustments. Saying the The actual spec is 0.006" +/- 0.001" and saying spec is .005" - .007" is in my opinion that is the same thing. It allows a little leeway either for differences in measuring and even the our feeler gauges are not prefect. Here a .001" can make a world of difference just depends on what you are working on. It like the spindles shafts I getting knurled so they have journals a .001 larger for tight bearing fit instead of a loose fit. Can't see the difference but it is there; that why they make calipers and feeler gauges.

Also changing either the intake or exhaust specs changes the duration of the valve opening affecting engine torque and hp levels too. Too much duration at idle can cause a rough idle especially on larger engines. I ran variable duration lifters in my car so I would have a smooth idle but had the benefits of the longer duration camshaft at higher rpms.

And yes I understand the expansion factor but I don't go below the suggested spec numbers as here customers do abuse their equipment and extreme heating is just one of the problems here.

And I have actually seen valve gap specs down at .001 in. on some engines that I have work on, just don't remember which ones as I refer to the specs each time as I do adjustments. Saying the The actual spec is 0.006" +/- 0.001" and saying spec is .005" - .007" is in my opinion that is the same thing. It allows a little leeway either for differences in measuring and even the our feeler gauges are not prefect. Here a .001" can make a world of difference just depends on what you are working on. It like the spindles shafts I getting knurled so they have journals a .001 larger for tight bearing fit instead of a loose fit. Can't see the difference but it is there; that why they make calipers and feeler gauges.

Also changing either the intake or exhaust specs changes the duration of the valve opening affecting engine torque and hp levels too. Too much duration at idle can cause a rough idle especially on larger engines. I ran variable duration lifters in my car so I would have a smooth idle but had the benefits of the longer duration camshaft at higher rpms.

#7

B

bertsmobile1

B

bertsmobile1

Actually because the numbers are in .001" .005-.007 is actually .0045 to ,0075 because .0005 would be considered rounding error ( +/- 1/2 the measurement )

It is like saying .01" is the same as .010", something they tried to drum into the heads of the students in engineering drawing and one of the things the calculator generation fails to understand that there is always an inferred precision in any number so you don't go putting an answer down to 4 decimal places just because that is what is on the display.

I would regularly give students an F for doing this regardless of weather the answer was right or wrong .

A particular problem when converting from metric to imperial & visa versa

Same as 1/8" and .125" are not the same thing either.

It is like saying .01" is the same as .010", something they tried to drum into the heads of the students in engineering drawing and one of the things the calculator generation fails to understand that there is always an inferred precision in any number so you don't go putting an answer down to 4 decimal places just because that is what is on the display.

I would regularly give students an F for doing this regardless of weather the answer was right or wrong .

A particular problem when converting from metric to imperial & visa versa

Same as 1/8" and .125" are not the same thing either.

#8

StarTech

StarTech

Yes everything is subjective to interpreter way of thinking. That is like the tax table the state here wants me to use for under $2. It has taxes figured one way and the computer figures it differently depending the precision the programmer decided to use. Or like precision my machinist uses when threading things vs the over the counter threading dies and taps I have vs screw vendors threading. Everything is subjective.

Not all measurements systems are the same either as I have to convert between US imperial liquid measurements and English (UK) liquid measurements. AN example is the US pint is 16 oz and the UK is 20 oz. Personally I prefer the metric system as it is more universally used standard.

But either way it is, it is like discussing which oil is better. Everyone has a opinion and there is no totally right or totally wrong answer when you get down to the nitty gritty of it.

Not all measurements systems are the same either as I have to convert between US imperial liquid measurements and English (UK) liquid measurements. AN example is the US pint is 16 oz and the UK is 20 oz. Personally I prefer the metric system as it is more universally used standard.

But either way it is, it is like discussing which oil is better. Everyone has a opinion and there is no totally right or totally wrong answer when you get down to the nitty gritty of it.

#9

B

Born2Mow

>> IMHO, while it is important to achieve adequate "valve lift at fully open", for the average working engine (NOT racing engine) the clearance is there to allow some lubricating oil to get between the cam and lifter surfaces so that there is an oil film between the 2 parts when the lifter rides up the cam lobe. Otherwise cam lobe wear would be extremely excessive.

Therefore: 1) Some clearance is always better than NO clearance, and 2) quibbling over 0.001 or 0.002" clearance is like withholding water from a thirsty man to decide if flavored water is better/worse than Perrier. Sure, Indy car engine mechanics need to get it right, lawn tractor engine mechanics "close is good enough".

I can see where the 0.007" (the looser setting) might be the setting when the engine leaves the factory. Because the factory knows the valves will be seating themselves during the first 20 hours, and the clearance will be reduced. Not wanting the camshaft to fail would be the primary concern, and far more important than a little added noise. The exhaust valves can always be adjusted to the tighter measurement at the first tune up.

Just my 2 cents.

B

Born2Mow

>> In my experience, exhaust valves are generally looser by at least 0.002" on air cooled engines. This allows the hotter valve to grow more. So that in use, when fully warm, both clearances become nearly the same.Are you saying that anything from 0.003" to 0.007" is acceptable?

>> IMHO, while it is important to achieve adequate "valve lift at fully open", for the average working engine (NOT racing engine) the clearance is there to allow some lubricating oil to get between the cam and lifter surfaces so that there is an oil film between the 2 parts when the lifter rides up the cam lobe. Otherwise cam lobe wear would be extremely excessive.

Therefore: 1) Some clearance is always better than NO clearance, and 2) quibbling over 0.001 or 0.002" clearance is like withholding water from a thirsty man to decide if flavored water is better/worse than Perrier. Sure, Indy car engine mechanics need to get it right, lawn tractor engine mechanics "close is good enough".

I can see where the 0.007" (the looser setting) might be the setting when the engine leaves the factory. Because the factory knows the valves will be seating themselves during the first 20 hours, and the clearance will be reduced. Not wanting the camshaft to fail would be the primary concern, and far more important than a little added noise. The exhaust valves can always be adjusted to the tighter measurement at the first tune up.

Just my 2 cents.

#10

I

ianviney

I

ianviney

That's interesting. A measurement of 0.125" has an implied precision of +/- 0.0005", but what is the implied precision of 1/8"? I don't think you can say that the number 8 has an implied precision because it's not a measurement. In fact, I would say that, devoid of context, 1/8" and 0.125" are exactly the same. It's only when we have the context of a spec or a measurement that they might be different.Same as 1/8" and .125" are not the same thing either.

#12

StarTech

So far every new engine I have check are within the range given in the manuals and this only if I am having to check things on a new install. Generally here the first time an engine checked is when there is other problems. But of course I am not dealer so I see equipment after the warranties have expired.

StarTech

In general that is true but there are a few engine that are spec'd differently.>> In my experience, exhaust valves are generally looser by at least 0.002" on air cooled engines. This allows the hotter valve to grow more. So that in use, when fully warm, both clearances become nearly the same.

Correct these engines are not super critical adjustment wise. I have seen engine to come in where the spec is .005-.007 to be as much as .015 or more out causing only starting problems.>> IMHO, while it is important to achieve adequate "valve lift at fully open", for the average working engine (NOT racing engine) the clearance is there to allow some lubricating oil to get between the cam and lifter surfaces so that there is an oil film between the 2 parts when the lifter rides up the cam lobe. Otherwise cam lobe wear would be extremely excessive.

Therefore: 1) Some clearance is always better than NO clearance, and 2) quibbling over 0.001 or 0.002" clearance is like withholding water from a thirsty man to decide if flavored water is better/worse than Perrier. Sure, Indy car engine mechanics need to get it right, lawn tractor engine mechanics "close is good enough".

I can see where the 0.007" (the looser setting) might be the setting when the engine leaves the factory. Because the factory knows the valves will be seating themselves during the first 20 hours, and the clearance will be reduced. Not wanting the camshaft to fail would be the primary concern, and far more important than a little added noise. The exhaust valves can always be adjusted to the tighter measurement at the first tune up.

Just my 2 cents.

So far every new engine I have check are within the range given in the manuals and this only if I am having to check things on a new install. Generally here the first time an engine checked is when there is other problems. But of course I am not dealer so I see equipment after the warranties have expired.