You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Husqvarna YTH 2348 - Bringing it back to life

#1

benaford

benaford

New poster here. I've enjoyed reading this forum over the years, but never made any posts, but I'm in need of some advice.

Background: A few years ago, I bought a Husqvarna YTH2348 with a Briggs engine for $500 from a guy who was moving away and needed to offload it. Right up front, he told me that it would not start without a shot of starter fluid, and that was true. It never started easily. I used the mower for grass cutting and leaf mulching for two seasons and then it just stopped starting all together. I attempted to rebuild the carb, but I could never get it to start and run again. I ran out of time an mental bandwidth to keep messing with such a fussy mower. Fast forward three years, the mower has been sitting idle, gathering dirt and rust under my deck because I just never got the energy tackle the repair.

Now, to the present day. I've decided to either get this thing running again or sell it as salvage. I pulled the hood, seat, and removed the deck and pressure washed the dirt and debris from the chassis. Then I parked it in my garage where I can spend time cleaning and digging into the motor. Yesterday, I pulled the carburetor, spark plugs (2), fuel pump, coils (2), valve covers (2), battery and starter. My plan is to work through a troubleshooting flowchart beginning with battery and working my way through the ignition system.

Engine Start Troubleshooting Flow:

1. Battery voltage: yes/no

2. Spark plugs: firing yes/no

3. Coils multimeter check: within range yes/no

4. Fuel pump pushing gas: yes/no

5. Carburetor (after getting a rebuild) sending fuel: yes/no

What else should be in my troubleshooting process? Should I remove the flywheel and sand it down? It's very rusty - see images.

Images

Thanks in advance for any wisdom you can offer. I've seen quite a few posts on here about this particular mower, but none about bringing one back from the dead. I thought it might be an interesting thread for someone else down the line.

Background: A few years ago, I bought a Husqvarna YTH2348 with a Briggs engine for $500 from a guy who was moving away and needed to offload it. Right up front, he told me that it would not start without a shot of starter fluid, and that was true. It never started easily. I used the mower for grass cutting and leaf mulching for two seasons and then it just stopped starting all together. I attempted to rebuild the carb, but I could never get it to start and run again. I ran out of time an mental bandwidth to keep messing with such a fussy mower. Fast forward three years, the mower has been sitting idle, gathering dirt and rust under my deck because I just never got the energy tackle the repair.

Now, to the present day. I've decided to either get this thing running again or sell it as salvage. I pulled the hood, seat, and removed the deck and pressure washed the dirt and debris from the chassis. Then I parked it in my garage where I can spend time cleaning and digging into the motor. Yesterday, I pulled the carburetor, spark plugs (2), fuel pump, coils (2), valve covers (2), battery and starter. My plan is to work through a troubleshooting flowchart beginning with battery and working my way through the ignition system.

Engine Start Troubleshooting Flow:

1. Battery voltage: yes/no

2. Spark plugs: firing yes/no

3. Coils multimeter check: within range yes/no

4. Fuel pump pushing gas: yes/no

5. Carburetor (after getting a rebuild) sending fuel: yes/no

What else should be in my troubleshooting process? Should I remove the flywheel and sand it down? It's very rusty - see images.

Images

Thanks in advance for any wisdom you can offer. I've seen quite a few posts on here about this particular mower, but none about bringing one back from the dead. I thought it might be an interesting thread for someone else down the line.

#2

R

Rivets

R

Rivets

Checking coil with multi meter NO. Today’s coils cannot be tested with a multi meter. After you reassemble everything, make sure that you throttle control cable is completely closing the choke butterfly. Can’t count the hard starting problem is caused by a cable which is not completely closing the choke on startup. Let us knew what you find.

#3

benaford

benaford

Wow, I didn't realize that you can't test these with a meter. What about videos like this one ? I've used multimeter to test coils on my pushmower - they aren't new but definitely not ancient.

#4

R

Rivets

R

Rivets

Any ignition system which does not have points has a Hall Effect trigger embedded in the coil. You need a very, very $$$$ piece of equipment to test them. I know that everything you see on U-tube videos is the absolute truth, but this is the one time those idiots got it wrong.

#5

ILENGINE

ILENGINE

Honda is the only one that I know of that list testing the coils with the meter and gives resistance readings.

#6

benaford

benaford

Any ignition system which does not have points has a Hall Effect trigger embedded in the coil. You need a very, very $$$$ piece of equipment to test them. I know that everything you see on U-tube videos is the absolute truth, but this is the one time those idiots got it wrong.

This part got me laughing out loud - Thanks for the info. I'm learning something every day."I know that everything you see on U-tube videos is the absolute truth..."

#8

R

Rivets

R

Rivets

Post all engine numbers, model, type and code and we should be able to find you an exact replacement.

#9

StarTech

StarTech

First a lot times just the throttle cable needs readjusting as it might not be fully closing the carburetor choke.

And here is some info the new Briggs Magnetron Coils.

The configuration of new Magnetron coil may look like they removed the triggering device but in fact

it is just a redesign. Now to answer your question what is inside the coil.

1 ea 13mm x 34.5mm single sided circuit board.

5 ea SMD transistors.

8 ea SMD resistors, inductors, and/or capacitors.

(SMDs were destroyed upon board removal so actually identification wasn’t possible.)

1 ea D13003 transistor.

Primary Winding reading is 1.5 - 1.7 Ω.

Secondary Winding reading is about 6 KΩ +- several hundred ohms.

The kill terminal is directly connected to the non-ground side of the primary; hence, explains why you

or anyone else can NOT test the primary trigger circuit. Otherwords this means you can not test to find

out if a Magnetron coil is good or not without installing it in most cases unless you have a specialized

coil tester.

The D13003 emitter is connected to non-grounded side of the coil’s primary via two SMD resistors in

parallel with total resistance value of 1.0 Ω. (One these SMD resistors marked with the 1R0 code for a

1.0 Ω resistor was ½ watt size.) The collector is connected the coil’s primary winding that is grounded.

The base is connected to the rest of the trigger circuitry.

The coil’s transformer turns ratio is approximately 1 to 18 with secondary closest to the core.

In theory if the output D13003 transistor should short the collector-emitter junction and the coil’s

primary winding is still good the ohms reading will drop to 0.5 Ω - 0.7 Ω. If the coil’s primary winding

should short then the ohms reading should be near zero. If the coil’s primary winding should open then

the reading will be well above 1.7 Ω. Applying any voltage to the kill terminal would result in either

coil’s primary winding shorting or opening due to high current experienced. And this don't cover other electrical failures.

Applying voltage also can short out the electronics thus making the coil useless. It is also expected that a cold solder joint

connecting the external kill terminal to circuit board would lead to a non kill operation.

Also the high tension lead can be replaced if you wish to fight the glue considering the price of

aftermarket versions of this coil.

This info was acquired through the destruction of the new OEM version of this coil. It also explains the

configuration differences as they have gone to SMD trigger version.

Now for those that wondering why we put diodes in the kill circuit of the dual coil models it because of

the feedback loop created causing one coil to kill the other. This explains why they are destroyed when

12V is applied as these is no built-in reverse bias protection. Now with this in mind you might think

Kohler coils would be the same wiring. Not so as these diodes are incorporated into coil itself thus

preventing many of the problems that the Briggs have because they don’t incorporate these diodes.

And here is some info the new Briggs Magnetron Coils.

The configuration of new Magnetron coil may look like they removed the triggering device but in fact

it is just a redesign. Now to answer your question what is inside the coil.

1 ea 13mm x 34.5mm single sided circuit board.

5 ea SMD transistors.

8 ea SMD resistors, inductors, and/or capacitors.

(SMDs were destroyed upon board removal so actually identification wasn’t possible.)

1 ea D13003 transistor.

Primary Winding reading is 1.5 - 1.7 Ω.

Secondary Winding reading is about 6 KΩ +- several hundred ohms.

The kill terminal is directly connected to the non-ground side of the primary; hence, explains why you

or anyone else can NOT test the primary trigger circuit. Otherwords this means you can not test to find

out if a Magnetron coil is good or not without installing it in most cases unless you have a specialized

coil tester.

The D13003 emitter is connected to non-grounded side of the coil’s primary via two SMD resistors in

parallel with total resistance value of 1.0 Ω. (One these SMD resistors marked with the 1R0 code for a

1.0 Ω resistor was ½ watt size.) The collector is connected the coil’s primary winding that is grounded.

The base is connected to the rest of the trigger circuitry.

The coil’s transformer turns ratio is approximately 1 to 18 with secondary closest to the core.

In theory if the output D13003 transistor should short the collector-emitter junction and the coil’s

primary winding is still good the ohms reading will drop to 0.5 Ω - 0.7 Ω. If the coil’s primary winding

should short then the ohms reading should be near zero. If the coil’s primary winding should open then

the reading will be well above 1.7 Ω. Applying any voltage to the kill terminal would result in either

coil’s primary winding shorting or opening due to high current experienced. And this don't cover other electrical failures.

Applying voltage also can short out the electronics thus making the coil useless. It is also expected that a cold solder joint

connecting the external kill terminal to circuit board would lead to a non kill operation.

Also the high tension lead can be replaced if you wish to fight the glue considering the price of

aftermarket versions of this coil.

This info was acquired through the destruction of the new OEM version of this coil. It also explains the

configuration differences as they have gone to SMD trigger version.

Now for those that wondering why we put diodes in the kill circuit of the dual coil models it because of

the feedback loop created causing one coil to kill the other. This explains why they are destroyed when

12V is applied as these is no built-in reverse bias protection. Now with this in mind you might think

Kohler coils would be the same wiring. Not so as these diodes are incorporated into coil itself thus

preventing many of the problems that the Briggs have because they don’t incorporate these diodes.

#10

benaford

Product: 289571 Model: YTH2348 Serial: 042210A001055 (bottom right hand of tag is another number: 199684)

benaford

I apologize for my ignorance if I'm saying something dumb here, but I looked at the tag under the seat and this is what I have:Post all engine numbers, model, type and code and we should be able to find you an exact replacement.

Product: 289571 Model: YTH2348 Serial: 042210A001055 (bottom right hand of tag is another number: 199684)

#11

StarTech

StarTech

917.289571 (YTH 2348) - Craftsman Yard Tractor (2010-04) And according to the serial it is a 2010 model. According the Craftsman owners manual it came with a B&S Model . 445577-1187-B1 engine.

#12

benaford

benaford

Ok, another dumb question - "Craftsman Yard Tractor"? Is this a situation where the manufacturer just label slaps different brands on the same tractor?917.289571 (YTH 2348) - Craftsman Yard Tractor (2010-04) And according to the serial it is a 2010 model. According the Craftsman owners manual it came with a B&S Model . 445577-1187-B1 engine.

#13

ILENGINE

ILENGINE

Briggs model numbers should be stamp3d into the metal OHV valve cover. On V twin the one without fuel pump

#14

benaford

benaford

Got it:

- Model: 445577

- Type: 1187 B1

- Code: 091114YG

#15

benaford

benaford

Last night, I pulled off the rest of the guards and housings around the engine block for cleaning. I also pulled the fuel tank (no easy task!) and flushed it out. There was quite a bit of gunk - even an entire leaf - not sure how that got in the fuel tank. I pressure washed and scrubbed down the engine and frame an then wiped down to get rid of excess water.

Here's a picture of the before and after.

I'm getting ready to start putting everything back together, but I was wondering if there's something I can spray or pour into the intakes or spark plug holes to clean out internal corrosion and buildup left by water getting into there. Maybe just put a shop vac on there and try to pull out loose debris?

Thanks -

Here's a picture of the before and after.

I'm getting ready to start putting everything back together, but I was wondering if there's something I can spray or pour into the intakes or spark plug holes to clean out internal corrosion and buildup left by water getting into there. Maybe just put a shop vac on there and try to pull out loose debris?

Thanks -

#16

D

Davisrf

D

Davisrf

So lets go back to your # 1 - # 5 steps. You don'tg need to test the coil if the spark plugs are sparking blue (indicating enough high voltgage from the coil) , If no spark or not blue, replace the coil. So, # 1 - 4 is easy to check, and make sure they are all ok. # 5, seeing how you have taken the carb apart, put it back together, doesn't work then buy a new carg. But yes, be sure that the butterfly is shutting on the original carb, so you get full choke, before you buy a new carb. Also make sure that the accelerator linkage is not causing the idle to be too high. Let us know what the solution is. good luckNew poster here. I've enjoyed reading this forum over the years, but never made any posts, but I'm in need of some advice.

Background: A few years ago, I bought a Husqvarna YTH2348 with a Briggs engine for $500 from a guy who was moving away and needed to offload it. Right up front, he told me that it would not start without a shot of starter fluid, and that was true. It never started easily. I used the mower for grass cutting and leaf mulching for two seasons and then it just stopped starting all together. I attempted to rebuild the carb, but I could never get it to start and run again. I ran out of time an mental bandwidth to keep messing with such a fussy mower. Fast forward three years, the mower has been sitting idle, gathering dirt and rust under my deck because I just never got the energy tackle the repair.

Now, to the present day. I've decided to either get this thing running again or sell it as salvage. I pulled the hood, seat, and removed the deck and pressure washed the dirt and debris from the chassis. Then I parked it in my garage where I can spend time cleaning and digging into the motor. Yesterday, I pulled the carburetor, spark plugs (2), fuel pump, coils (2), valve covers (2), battery and starter. My plan is to work through a troubleshooting flowchart beginning with battery and working my way through the ignition system.

Engine Start Troubleshooting Flow:

1. Battery voltage: yes/no

2. Spark plugs: firing yes/no

3. Coils multimeter check: within range yes/no

4. Fuel pump pushing gas: yes/no

5. Carburetor (after getting a rebuild) sending fuel: yes/no

What else should be in my troubleshooting process? Should I remove the flywheel and sand it down? It's very rusty - see images.

Images

Thanks in advance for any wisdom you can offer. I've seen quite a few posts on here about this particular mower, but none about bringing one back from the dead. I thought it might be an interesting thread for someone else down the line.

#17

StarTech

StarTech

Just the color of the spark can vary depending on the chemical make of the surrounding air. For example in Hawaii the spark are usually bright orange due the salt (sodium) content of the air.

And just because you get a good spark outside the compression zone doesn't mean everything is fine. I have good sparks due still have no fire in the cylinder. Usually good spark outside is good but are rare occasions that it is not.

And just because you get a good spark outside the compression zone doesn't mean everything is fine. I have good sparks due still have no fire in the cylinder. Usually good spark outside is good but are rare occasions that it is not.

#18

S

Shoesole

S

Shoesole

Or you could simply pull a spark plug, hook up the plug wire to it and ground the plug body, spin the engine over and see if the plug sparks. Very simple way to check for spark. Also, I notice that nobody (unless I missed it) has suggested that a compression test be done.....If it won't fire off with starting fluid, then you either most likely have no spark or no compression.... And, of course you could also have a sheared flywheel key, happens all the time....Which results in no spark or spark at the wrong time.

#19

F

Freddie21

F

Freddie21

Good list, but keep it basic. Start by checking, and maybe, changing the oil. Clean the gas tank and replace fuel filter and lines, if necessary. See if pump will pump gas at the carb. Check for spark then prime with cleaner to see if it sputters. Clean the side of the flywheel and coil with sandpaper or brush. Set the coil gap. Replace the plug. If it sputters with cleaner thru carb, then remove carb, clean all internal and external parts with carb cleaner and air. Run small wires thru all jets nd openings. Clean again and blow with air. Replace carb with new gaskets. See what happens.

#20

A

Air4Dave

A

Air4Dave

Boy, you've got a lot to deal with now but...with cost of new mowers these days, the old ones are worth putting SOME money into, but be careful to take stock of the entire mower's condition: is the deck itself in good working order (pulleys free, deck wheels, blade spindles spin smoothly, and belt usable), how is the steering linkages as to alignment and not too worn, front wheel bearings good?, and the seat, starter engages, and tires. Carbs are comparably cheap nowadays but make sure you get the number off the carb! Replace the plugs and air cleaner. The battery needs to be replaced after that long - do yourself a favor here! By all means, clean up that flywheel and adjust the gap. Change the fuel and filter. After replacing the above mentioned, see if it will start and run...it should if you've done the above AND, like a previous poster said...make sure the throttle cable fully closes the choke! If it runs, then go ahead and change the oil and filter. Hopefully, for less than $200 you can get it running and working again!

#21

S

SamB

There are some wonderful people here and will help all they can. Bad attitude will get that door shut. Hard.

btw, Good luck with your mower!

S

SamB

"I apologize for my ignorance if I'm saying something dumb" Posting something in good faith and with a good attitude is never 'dumb'.I apologize for my ignorance if I'm saying something dumb here, but I looked at the tag under the seat and this is what I have:

Product: 289571 Model: YTH2348 Serial: 042210A001055 (bottom right hand of tag is another number: 199684)

There are some wonderful people here and will help all they can. Bad attitude will get that door shut. Hard.

btw, Good luck with your mower!

#22

benaford

benaford

Thanks for that - I really do appreciate all the comments and suggestions. As time permits this week, I'll begin re-assembly and hopefully this will be a successful job. As a former aircraft mechanic (military) turned desk jockey, this has been a fun way to re-engage the hands-on, mechanical side of my brain. It's also been a bonding experience with my sons as we have gotten to walk through the troubleshooting process together. They live in a digital, disposable world where if something breaks you just throw it away and get a new one. The mower project has allowed me to demonstrate the value of being 'handy' and talk them through the basics of combustion engines and how to select and properly use hand tools. Lots of good things have come from this little summer project regardless of whether or not the mower ever runs again. My grandfather was a tremendous mechanic - he could fix anything. He'd spend hours underneath an old sycamore tree in his yard tearing down, cleaning, painting and re-assembling mowers, weedeaters, tillers and tractors. I always looked up to him for his ability to take any old hunk of junk and make it new again. I'm just trying to honor him by passing a little of that down to my boys. Y'all are a big help with keeping this project going."I apologize for my ignorance if I'm saying something dumb" Posting something in good faith and with a good attitude is never 'dumb'.

There are some wonderful people here and will help all they can. Bad attitude will get that door shut. Hard.

btw, Good luck with your mower!

#23

benaford

benaford

Last night I started putting things back together, but I'm stuck. I was putting the starter motor back on and realized that one of the threaded inserts (heli coil) is stripped out where the starter bolt threads into the engine. I can find the bolt part number, but I'm having a hard time figuring out what size heli coil to buy to repair it with. Does anyone know of a way to make sure I'm ordering the correct replacement size?

Thanks -

Thanks -

#24

R

Rivets

R

Rivets

It goes according to bolt size. If you have a 5/16”-18, you will use a 5/16” HeliCoils. 1/4“-20 use 1/4” and 3/8”-16 use 3/8.

#25

J

Joed756

J

Joed756

I recently got an old Scotts mower in with a similar back story. The oil looked good, it was out of gas. Gave it a squirt of brake clean and it popped and sputtered. This told me that everything but fuel delivery was likely OK. I removed the carb and poured rusty water from it. Cleaned the carb real well in about 10 minutes, reinstalled, shot of brake clean and she is running like a top. It cost nothing.

#26

benaford

benaford

Since I didn't have any other way of measuring the bolt size, I went to the 'nuts and bolts' section of my Lowe's and tried sizes until I determined that it's a 5/16". Ordered that size thread repair kit from Amazon and I'll get to work repairing the heli coil insert when it arrives this week.It goes according to bolt size. If you have a 5/16”-18, you will use a 5/16” HeliCoils. 1/4“-20 use 1/4” and 3/8”-16 use 3/8.

#27

benaford

benaford

Update. Still waiting on the heli coil repair kit, so I started getting the other components installed. Yesterday I was able to install the cleaned out fuel tank, new fuel lines, new fuel filter, and new carb. I was putting the valve covers back on and realized that the vacuum tube on the left side valve cover that connects to the fuel pump was severely cracked and split. The IPL lists this part number as 793147, but when I searched for that part number it has a completely different shape/angle the the existing vacuum tube. I don't think it would even work on my tractor. After some digging, I found another option that looks just like the one currently on my tractor, Part # 596163. Ordered it and a new fuel pump (why not?) last night and now I'll have an entirely new fuel system.

Here's the two different parts - see the very different shape:

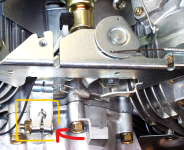

I also cleaned off and re-installed the coils, heat shields and cleaned/painted the top part of the flywheel to get rid of the rust. Here's a picture of my progress so far:

Front

Left

Right

Carb

Here's the two different parts - see the very different shape:

I also cleaned off and re-installed the coils, heat shields and cleaned/painted the top part of the flywheel to get rid of the rust. Here's a picture of my progress so far:

Front

Left

Right

Carb

#28

C

ccheatha

C

ccheatha

In reading your initial post, my first thought was that I’d start small; instead of putting all the work into tearing it all down, I’d first see if I could pinpoint the startup issue. If I could do that, then I might go into a mode of total clean-up. At any rate, yeah, when you first took ownership and it would only start with a shot of starter, does sound like a fuel flow issue (whether thru the fuel line or carb). Since you stated that there was so much gunk in the gas tank, I’d probably just replace the carb and go from there. Hope it works out for you. I’m kind of like your grandfather; always fixing old mowers, weed eaters, etc. Good luck.

#29

E

Eggbert

E

Eggbert

Remove the flywheel bolt and look to see if the keyway is out of position (sheared or partly sheared).

#30

B

Brucewayne

B

Brucewayne

First I am not a repair person. I had trouble with my mower shutting off. Just as a wild guess I removed the fuel filter and went to my local advanced auto and purchased the same size fuel filter to fit the hose ends. It does not shut off now. The only point is sometimes it is something very simple.New poster here. I've enjoyed reading this forum over the years, but never made any posts, but I'm in need of some advice.

Background: A few years ago, I bought a Husqvarna YTH2348 with a Briggs engine for $500 from a guy who was moving away and needed to offload it. Right up front, he told me that it would not start without a shot of starter fluid, and that was true. It never started easily. I used the mower for grass cutting and leaf mulching for two seasons and then it just stopped starting all together. I attempted to rebuild the carb, but I could never get it to start and run again. I ran out of time an mental bandwidth to keep messing with such a fussy mower. Fast forward three years, the mower has been sitting idle, gathering dirt and rust under my deck because I just never got the energy tackle the repair.

Now, to the present day. I've decided to either get this thing running again or sell it as salvage. I pulled the hood, seat, and removed the deck and pressure washed the dirt and debris from the chassis. Then I parked it in my garage where I can spend time cleaning and digging into the motor. Yesterday, I pulled the carburetor, spark plugs (2), fuel pump, coils (2), valve covers (2), battery and starter. My plan is to work through a troubleshooting flowchart beginning with battery and working my way through the ignition system.

Engine Start Troubleshooting Flow:

1. Battery voltage: yes/no

2. Spark plugs: firing yes/no

3. Coils multimeter check: within range yes/no

4. Fuel pump pushing gas: yes/no

5. Carburetor (after getting a rebuild) sending fuel: yes/no

What else should be in my troubleshooting process? Should I remove the flywheel and sand it down? It's very rusty - see images.

Images

Thanks in advance for any wisdom you can offer. I've seen quite a few posts on here about this particular mower, but none about bringing one back from the dead. I thought it might be an interesting thread for someone else down the line.

#31

G

g-man57

G

g-man57

I read thru the posts and didn't see one thing to check - maybe I missed it... But I always like to check the simple things first. You said it used to start but then stopped starting at all. Did you check he safety switch on the seat? Never know... Timing is another thing.

If you have gas and spark, it should fire - especially with a shot of fluid. With a little gas in the hole you are bypassing he carb - at least to see that it trys to fire. Sputter or whatever. You have to get that far before you need to buy a new carb.

This is a fun thread - when you get the problem solved, it would be fun to read what you did.

If you have gas and spark, it should fire - especially with a shot of fluid. With a little gas in the hole you are bypassing he carb - at least to see that it trys to fire. Sputter or whatever. You have to get that far before you need to buy a new carb.

This is a fun thread - when you get the problem solved, it would be fun to read what you did.

#32

poncho144

Bite the bullet dude, save yourself a lotta time and anguish. Simply upgrade to a NEW mower, 'cause I've been there, done that....

poncho144

I thought I was a tight wad when it comes to fix'n stuff that's beyond any reasonable hope, but you have just topped me.New poster here. I've enjoyed reading this forum over the years, but never made any posts, but I'm in need of some advice.

Background: A few years ago, I bought a Husqvarna YTH2348 with a Briggs engine for $500 from a guy who was moving away and needed to offload it. Right up front, he told me that it would not start without a shot of starter fluid, and that was true. It never started easily. I used the mower for grass cutting and leaf mulching for two seasons and then it just stopped starting all together. I attempted to rebuild the carb, but I could never get it to start and run again. I ran out of time an mental bandwidth to keep messing with such a fussy mower. Fast forward three years, the mower has been sitting idle, gathering dirt and rust under my deck because I just never got the energy tackle the repair.

Now, to the present day. I've decided to either get this thing running again or sell it as salvage. I pulled the hood, seat, and removed the deck and pressure washed the dirt and debris from the chassis. Then I parked it in my garage where I can spend time cleaning and digging into the motor. Yesterday, I pulled the carburetor, spark plugs (2), fuel pump, coils (2), valve covers (2), battery and starter. My plan is to work through a troubleshooting flowchart beginning with battery and working my way through the ignition system.

Engine Start Troubleshooting Flow:

1. Battery voltage: yes/no

2. Spark plugs: firing yes/no

3. Coils multimeter check: within range yes/no

4. Fuel pump pushing gas: yes/no

5. Carburetor (after getting a rebuild) sending fuel: yes/no

What else should be in my troubleshooting process? Should I remove the flywheel and sand it down? It's very rusty - see images.

Images

Thanks in advance for any wisdom you can offer. I've seen quite a few posts on here about this particular mower, but none about bringing one back from the dead. I thought it might be an interesting thread for someone else down the line.

Bite the bullet dude, save yourself a lotta time and anguish. Simply upgrade to a NEW mower, 'cause I've been there, done that....

#33

Mfb

Mfb

Absolutely FANTASTIC info! All my mowers presently work, but I'd love to be able to find something this nice for all the broken stuff I DO have....My compliments to @StarTech... way to go!First a lot times just the throttle cable needs readjusting as it might not be fully closing the carburetor choke.

And here is some info the new Briggs Magnetron Coils.

The configuration of new Magnetron coil may look like they removed the triggering device but in fact

it is just a redesign. Now to answer your question what is inside the coil.

1 ea 13mm x 34.5mm single sided circuit board.

5 ea SMD transistors.

8 ea SMD resistors, inductors, and/or capacitors.

(SMDs were destroyed upon board removal so actually identification wasn’t possible.)

1 ea D13003 transistor.

Primary Winding reading is 1.5 - 1.7 Ω.

Secondary Winding reading is about 6 KΩ +- several hundred ohms.

The kill terminal is directly connected to the non-ground side of the primary; hence, explains why you

or anyone else can NOT test the primary trigger circuit. Otherwords this means you can not test to find

out if a Magnetron coil is good or not without installing it in most cases unless you have a specialized

coil tester.

The D13003 emitter is connected to non-grounded side of the coil’s primary via two SMD resistors in

parallel with total resistance value of 1.0 Ω. (One these SMD resistors marked with the 1R0 code for a

1.0 Ω resistor was ½ watt size.) The collector is connected the coil’s primary winding that is grounded.

The base is connected to the rest of the trigger circuitry.

The coil’s transformer turns ratio is approximately 1 to 18 with secondary closest to the core.

In theory if the output D13003 transistor should short the collector-emitter junction and the coil’s

primary winding is still good the ohms reading will drop to 0.5 Ω - 0.7 Ω. If the coil’s primary winding

should short then the ohms reading should be near zero. If the coil’s primary winding should open then

the reading will be well above 1.7 Ω. Applying any voltage to the kill terminal would result in either

coil’s primary winding shorting or opening due to high current experienced. And this don't cover other electrical failures.

Applying voltage also can short out the electronics thus making the coil useless. It is also expected that a cold solder joint

connecting the external kill terminal to circuit board would lead to a non kill operation.

Also the high tension lead can be replaced if you wish to fight the glue considering the price of

aftermarket versions of this coil.

This info was acquired through the destruction of the new OEM version of this coil. It also explains the

configuration differences as they have gone to SMD trigger version.

Now for those that wondering why we put diodes in the kill circuit of the dual coil models it because of

the feedback loop created causing one coil to kill the other. This explains why they are destroyed when

12V is applied as these is no built-in reverse bias protection. Now with this in mind you might think

Kohler coils would be the same wiring. Not so as these diodes are incorporated into coil itself thus

preventing many of the problems that the Briggs have because they don’t incorporate these diodes.

#34

C

ccheatha

C

ccheatha

You have to understand… some of us just love the challenge! I get the biggest kick out of getting something to run that had stopped running for some reason. It’s like solving a puzzle.I thought I was a tight wad when it comes to fix'n stuff that's beyond any reasonable hope, but you have just topped me.

Bite the bullet dude, save yourself a lotta time and anguish. Simply upgrade to a NEW mower, 'cause I've been there, done that....

#35

D

DABS

D

DABS

Anti backfire valve screwed into the Nikki carb? Lots of times they get gummed up and need help with solventYou have to understand… some of us just love the challenge! I get the biggest kick out of getting something to run that had stopped running for some reason. It’s like solving a puzzle.

#36

poncho144

poncho144

Yeh...feel that way 'bout real old Harleys, Indians and Triumphs...You have to understand… some of us just love the challenge! I get the biggest kick out of getting something to run that had stopped running for some reason. It’s like solving a puzzle.

#37

S

Shoesole

S

Shoesole

First thing is to check for spark and if you have spark, then do a compression test (do these before you put any money into it).....I've owned a zero turn Husky for seven years, with the Koehler engine....Great machine!New poster here. I've enjoyed reading this forum over the years, but never made any posts, but I'm in need of some advice.

Background: A few years ago, I bought a Husqvarna YTH2348 with a Briggs engine for $500 from a guy who was moving away and needed to offload it. Right up front, he told me that it would not start without a shot of starter fluid, and that was true. It never started easily. I used the mower for grass cutting and leaf mulching for two seasons and then it just stopped starting all together. I attempted to rebuild the carb, but I could never get it to start and run again. I ran out of time an mental bandwidth to keep messing with such a fussy mower. Fast forward three years, the mower has been sitting idle, gathering dirt and rust under my deck because I just never got the energy tackle the repair.

Now, to the present day. I've decided to either get this thing running again or sell it as salvage. I pulled the hood, seat, and removed the deck and pressure washed the dirt and debris from the chassis. Then I parked it in my garage where I can spend time cleaning and digging into the motor. Yesterday, I pulled the carburetor, spark plugs (2), fuel pump, coils (2), valve covers (2), battery and starter. My plan is to work through a troubleshooting flowchart beginning with battery and working my way through the ignition system.

Engine Start Troubleshooting Flow:

1. Battery voltage: yes/no

2. Spark plugs: firing yes/no

3. Coils multimeter check: within range yes/no

4. Fuel pump pushing gas: yes/no

5. Carburetor (after getting a rebuild) sending fuel: yes/no

What else should be in my troubleshooting process? Should I remove the flywheel and sand it down? It's very rusty - see images.

Images

Thanks in advance for any wisdom you can offer. I've seen quite a few posts on here about this particular mower, but none about bringing one back from the dead. I thought it might be an interesting thread for someone else down the line.

#38

benaford

benaford

Ha! Yeah, I wish that was an option for me, but it's just not in the cards right now. I'm on a budget that doesn't include the price for a new mower. Someday, though!I thought I was a tight wad when it comes to fix'n stuff that's beyond any reasonable hope, but you have just topped me.

Bite the bullet dude, save yourself a lotta time and anguish. Simply upgrade to a NEW mower, 'cause I've been there, done that....

#39

benaford

benaford

Definitely. There's some kind of kick I get out of fixing something that everyone else would have thrown away. It's just part of my nature, I guess. Glad to know I'm not the only one.You have to understand… some of us just love the challenge! I get the biggest kick out of getting something to run that had stopped running for some reason. It’s like solving a puzzle.

#40

benaford

benaford

Will do!I read thru the posts and didn't see one thing to check - maybe I missed it... But I always like to check the simple things first. You said it used to start but then stopped starting at all. Did you check he safety switch on the seat? Never know... Timing is another thing.

If you have gas and spark, it should fire - especially with a shot of fluid. With a little gas in the hole you are bypassing he carb - at least to see that it trys to fire. Sputter or whatever. You have to get that far before you need to buy a new carb.

This is a fun thread - when you get the problem solved, it would be fun to read what you did.

#41

benaford

benaford

I hadn't thought about the compression test. What does that involve?First thing is to check for spark and if you have spark, then do a compression test (do these before you put any money into it).....I've owned a zero turn Husky for seven years, with the Koehler engine....Great machine!

#42

benaford

benaford

If the safety switch is bad, will the starter engage at all? I'm not sure where it breaks the circuit.I read thru the posts and didn't see one thing to check - maybe I missed it... But I always like to check the simple things first. You said it used to start but then stopped starting at all. Did you check he safety switch on the seat? Never know... Timing is another thing.

If you have gas and spark, it should fire - especially with a shot of fluid. With a little gas in the hole you are bypassing he carb - at least to see that it trys to fire. Sputter or whatever. You have to get that far before you need to buy a new carb.

This is a fun thread - when you get the problem solved, it would be fun to read what you did.

#43

benaford

benaford

Weekend update - using the repair kit I ordered, I was able to drill out the bad starter bolt threads, put in new inserts and mount up the starter. I'm still waiting on the new fuel pump an vacuum tube, but I dropped in my old battery and put some fuel in the tank for a test fire. The starter spun the engine, but would hang up before completing one full revolution. I remembered reading somewhere about someone else who had a battery that was showing good voltage but was not strong enough to crank. I added a jump starter and the starter turned the engine over. Guess the battery is bad after all. At least now I know that the starter does work. Also, I pulled the spark plugs and laid them on the engine - I could definitely see the spark. I sprayed starter fluid into the intake to see if it would fire up, but had no luck with that. Ran out of time to do any more work this weekend, but I'll install the new fuel pump, vacuum tube and buy a new battery this week and keep working my way through the process.

Thanks to everyone who has replied to this thread - here's hoping I get somewhere with this soon.

Thanks to everyone who has replied to this thread - here's hoping I get somewhere with this soon.

#44

D

davis2

D

davis2

Ummm... You do understand that this thread is about REPAIRING lawn equipment???I thought I was a tight wad when it comes to fix'n stuff that's beyond any reasonable hope, but you have just topped me.

Bite the bullet dude, save yourself a lotta time and anguish. Simply upgrade to a NEW mower, 'cause I've been there, done that....

#45

T

Timtoo

T

Timtoo

I have been following the thread and agree that timing could be your problem with the no-start. Unless I missed it, you never said that you removed the flywheel and checked the key to be sure it wasn't sheered. Have you done this?Weekend update - using the repair kit I ordered, I was able to drill out the bad starter bolt threads, put in new inserts and mount up the starter. I'm still waiting on the new fuel pump an vacuum tube, but I dropped in my old battery and put some fuel in the tank for a test fire. The starter spun the engine, but would hang up before completing one full revolution. I remembered reading somewhere about someone else who had a battery that was showing good voltage but was not strong enough to crank. I added a jump starter and the starter turned the engine over. Guess the battery is bad after all. At least now I know that the starter does work. Also, I pulled the spark plugs and laid them on the engine - I could definitely see the spark. I sprayed starter fluid into the intake to see if it would fire up, but had no luck with that. Ran out of time to do any more work this weekend, but I'll install the new fuel pump, vacuum tube and buy a new battery this week and keep working my way through the process.

Thanks to everyone who has replied to this thread - here's hoping I get somewhere with this soon.

#46

woodstover

woodstover

Compression test and since you had the valve covers off, should be checking the clearances and adjusting if necessary.

#47

benaford

benaford

No, I did not remove the flywheel.I have been following the thread and agree that timing could be your problem with the no-start. Unless I missed it, you never said that you removed the flywheel and checked the key to be sure it wasn't sheered. Have you done this?

#48

smoothmower

smoothmower

I have the same mower and find it does a fantastic cut without accumulating clippings inside the mower deck, easy clean with a leaf blower. Got it without engine and installed a Vanguard 16 hp twin, then gave her a makeup paint. My pictures were too big for the server to process, sorry. If your engine is kaput (do a compression test), the mower is well worth to repower. The 16 hp vanguard twin, inexpensive and ubiquitous, did just fine for me. Use a thin hose to siphon the tranny oil, refill with tractor oil (walmart) and the tranny will reward you with a smooth ride that does not steal power from the mowing deck. Aliexpress has new carburetors for your 23 hp under 35 bucks, coils at 15 bucks and other needs for cheap.Weekend update - using the repair kit I ordered, I was able to drill out the bad starter bolt threads, put in new inserts and mount up the starter. I'm still waiting on the new fuel pump an vacuum tube, but I dropped in my old battery and put some fuel in the tank for a test fire. The starter spun the engine, but would hang up before completing one full revolution. I remembered reading somewhere about someone else who had a battery that was showing good voltage but was not strong enough to crank. I added a jump starter and the starter turned the engine over. Guess the battery is bad after all. At least now I know that the starter does work. Also, I pulled the spark plugs and laid them on the engine - I could definitely see the spark. I sprayed starter fluid into the intake to see if it would fire up, but had no luck with that. Ran out of time to do any more work this weekend, but I'll install the new fuel pump, vacuum tube and buy a new battery this week and keep working my way through the process.

Thanks to everyone who has replied to this thread - here's hoping I get somewhere with this soon.

#49

smoothmower

smoothmower

I have the same mower and find it does a fantastic cut without accumulating clippings inside the mower deck, easy clean with a leaf blower. Got it without engine and installed a Vanguard 16 hp twin, then gave her a makeup paint. The hood came from a craftsman mower. If your engine is kaput (do a compression test, Temu has the tester kit for under 20 bucks), the mower is well worth to repower. The 16 hp vanguard twin, inexpensive and ubiquitous, did just fine for me, larger engines are triple the price. Use a thin hose to siphon the tranny oil, refill with tractor oil (walmart) and the tranny will reward you with a smooth ride that does not steal power from the mowing deck. Aliexpress has new carburetors for your 23 hp under 35 bucks, coils at 15 bucks and other needs for cheap.

#50

benaford

benaford

That's a great job on reclaiming your mower and I appreciate the input. I was googling that motor and I see it around $1,600. I don't think I would be willing to go that far to salvage this mower, but maybe if I found one second hand.

#51

S

SamB

A good friend wanted it. I sold it and bought a brand new Honda CB750 Four. Took a while to getting used to going that fast that quickly. It never needed a wrench on it, except points and plugs. I did miss just standing around with my HD friends admiring their bikes at most any gas station.

p.s. I also had a Triumph 650 Bonneville. Pushed it home more than once.

S

SamB

I understand, I had a Harley Panhead, 1951 FLH. Chrome springer front end, low riser ape hanger bars. fishtail pipes. Linkert carb. Beautiful bike, lots of chrome, Easy Rider style. Worked on it all the time.Yeh...feel that way 'bout real old Harleys, Indians and Triumphs...

A good friend wanted it. I sold it and bought a brand new Honda CB750 Four. Took a while to getting used to going that fast that quickly. It never needed a wrench on it, except points and plugs. I did miss just standing around with my HD friends admiring their bikes at most any gas station.

p.s. I also had a Triumph 650 Bonneville. Pushed it home more than once.

#53

benaford

Here's a short clip I took of the engine running

Next steps are to figure out the correct throttle cable settings to control engine RPM, attempt to get the tractor to drive and then I'll start putting the deck back together and assessing it's ability to cut grass. Still quite a ways to go, but it feels great to at least know the engine runs and seems decently healthy.

benaford

Yeah, here's my latest update. Once I replaced the fuel pump, vacuum tube and battery, I attempted to start with no luck. I pulled the plugs and checked them again and I could definitely see them firing. On a whim, I adjusted the coils down closer to the flywheel and re-installed the plugs. Boom. Started right up burping out gunk and smoke - all that old oil and water that had collected in the cylinders. After a few minutes, the smoke died down and it was running decently. I tried to throttle down, but there was no response. When I looked, the linkage had come loose where it connects to the carb. I reconnected the linkage, but still no response to moving the throttle back and forth. I realized there was a lot of slack in the throttle cable, so I attempted a few different settings and then tightened the cable back down, but I just can't figure it out. I don't know where the throttle cable SHOULD be at Choke or Min Throttle. I need some kind of a reference in order to get it set up right. Any help in this area would be super.Beneford did you get the Husqvarna going?

Here's a short clip I took of the engine running

Next steps are to figure out the correct throttle cable settings to control engine RPM, attempt to get the tractor to drive and then I'll start putting the deck back together and assessing it's ability to cut grass. Still quite a ways to go, but it feels great to at least know the engine runs and seems decently healthy.

#54

S

SamB

S

SamB

What I do is put the lever on the full choke position, then loosen the cable clamp at the carb and move the housing and center wire toward the carb until the carb choke butterfly is closed , then tighten the housing clamp. Moving the throttle lever should now go from full choke to full throttle.Yeah, here's my latest update. Once I replaced the fuel pump, vacuum tube and battery, I attempted to start with no luck. I pulled the plugs and checked them again and I could definitely see them firing. On a whim, I adjusted the coils down closer to the flywheel and re-installed the plugs. Boom. Started right up burping out gunk and smoke - all that old oil and water that had collected in the cylinders. After a few minutes, the smoke died down and it was running decently. I tried to throttle down, but there was no response. When I looked, the linkage had come loose where it connects to the carb. I reconnected the linkage, but still no response to moving the throttle back and forth. I realized there was a lot of slack in the throttle cable, so I attempted a few different settings and then tightened the cable back down, but I just can't figure it out. I don't know where the throttle cable SHOULD be at Choke or Min Throttle. I need some kind of a reference in order to get it set up right. Any help in this area would be super.

Here's a short clip I took of the engine running

Next steps are to figure out the correct throttle cable settings to control engine RPM, attempt to get the tractor to drive and then I'll start putting the deck back together and assessing it's ability to cut grass. Still quite a ways to go, but it feels great to at least know the engine runs and seems decently healthy.

#55

benaford

benaford

Ok, newest issue. I got the throttle to semi-work. Engine would start, throttle up and down. Good enough. I put the mower deck back on, fired it up and to my surprise, everything was functioning as intended. After about five minutes of mowing, the engine seemed to rev a little bit and then it died. Would not start again. The starter engages for a couple of seconds and then shuts down. Really weird.

Edit: I went back after 30 minutes and it fired right up again. However, now the engine is surging, not running smoothly like before. What could be the culprit?

Edit: I went back after 30 minutes and it fired right up again. However, now the engine is surging, not running smoothly like before. What could be the culprit?

#56

benaford

benaford

After some more research, I'm starting to suspect the governor could be the culprit. When I was cleaning up the engine, I removed the gov. linkage and didn't take note of how it was indexed in relation to the gov shaft that runs into the engine. I'm thinking that when I re-installed everything, I didn't have the correct gov setting. I'm not sure how the governor system works, but I have noticed that the mower seems to run 'hot' and even at the lowest throttle setting, it feels like the engine rpms are too high. Explains why I'm not getting much throttle response. Question is, how can I know where the gov shaft needs to be rotated to when I put the linkage connector back on the gov shaft?

#57

benaford

benaford

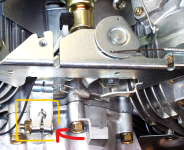

Don't know if anyone is still following this thread, but I've come this far so I might as well see it through. I found a couple of videos on Youtube detailing the ins and outs of adjusting the governor. After some tweaking, I got the engine to respond to movement in the throttle. That issue seems to be good to go now. Went ahead and mowed the yard that day and got about 30 min into the job when the mower lost power and died again. Opened the hood and immediately noticed oil/grime covering the left side of the engine, mostly around the valve cover.

I suspected the valve cover seal might be leaking so I removed both covers and ordered new gaskets. Should arrive this week. I also decided to drain the oil and do a complete oil change while it's down. (Have never actually changed the oil in this tractor.) I also plan on adjusting the valves while I have everything pulled off. Never done that either. I did notice that the breather tube (brand new) has a split in the gasket where it mounts inside the valve cover. The more I consider all the possible scenarios, I think it's likely that I cut the breather tube when I was putting it in and that compromised the seal allowing oil/fuel to spray out while the engine was under load.

More to come...

I suspected the valve cover seal might be leaking so I removed both covers and ordered new gaskets. Should arrive this week. I also decided to drain the oil and do a complete oil change while it's down. (Have never actually changed the oil in this tractor.) I also plan on adjusting the valves while I have everything pulled off. Never done that either. I did notice that the breather tube (brand new) has a split in the gasket where it mounts inside the valve cover. The more I consider all the possible scenarios, I think it's likely that I cut the breather tube when I was putting it in and that compromised the seal allowing oil/fuel to spray out while the engine was under load.

More to come...

#58

D

davis2

D

davis2

I'm watching. Keep working at it!Don't know if anyone is still following this thread, but I've come this far so I might as well see it through. I found a couple of videos on Youtube detailing the ins and outs of adjusting the governor. After some tweaking, I got the engine to respond to movement in the throttle. That issue seems to be good to go now. Went ahead and mowed the yard that day and got about 30 min into the job when the mower lost power and died again. Opened the hood and immediately noticed oil/grime covering the left side of the engine, mostly around the valve cover.

View attachment 69197View attachment 69198

I suspected the valve cover seal might be leaking so I removed both covers and ordered new gaskets. Should arrive this week. I also decided to drain the oil and do a complete oil change while it's down. (Have never actually changed the oil in this tractor.) I also plan on adjusting the valves while I have everything pulled off. Never done that either. I did notice that the breather tube (brand new) has a split in the gasket where it mounts inside the valve cover. The more I consider all the possible scenarios, I think it's likely that I cut the breather tube when I was putting it in and that compromised the seal allowing oil/fuel to spray out while the engine was under load.

View attachment 69199

More to come...

#59

B

bertsmobile1

B

bertsmobile1

When you put the new rocker cover gaskets on smear the engine side with bentonite grease ( the smelly tan/ brown wheel bearing grease ) so they will strip off clean next time.

One step better is to coat the other side with a sealant , I like to use Hylomar

One step better is to coat the other side with a sealant , I like to use Hylomar

#60

benaford

benaford

While I was waiting for the gasket covers to come in this week, I bought a feeler gauge and adjusted the valve clearance. I changed the oil and filter and installed a new breather tube. Today, I put in the new gasket covers, buttoned everything back up and attempted to start the engine. However, now I'm not getting any ignition. Spark seems fine (engine fires with starter fluid but immediately dies). I pulled the fuel line from the carb and it's really not getting any fuel to the engine. I just don't understand - I just replaced the fuel pump, filter and all the lines. How could it already be clogged? Is there any way the fuel pump could have gotten fouled up by the oil spraying out of the leaking gasket cover? I can pick up a new fuel filter locally, but if it needs another pump, I'll have to order that and wait. I'm wondering if there's anything else that could be causing a no fuel situation other than a fuel pump going bad.

#61

B

bertsmobile1

B

bertsmobile1

Are you sure you hooked the pump up the right way ?

Both the inlet & outlets have one way valves so try blowing through them

Next did you put the impulse line on the top spiggot ?

Both the inlet & outlets have one way valves so try blowing through them

Next did you put the impulse line on the top spiggot ?

#62

benaford

benaford

Ok, double check my connections here, but I THINK I have the hoses hooked up correctly. It has been working with this configuration, so I don't think the hoses are hooked up the wrong way. I did try blowing on the in/out lines and they seem to be free of obstruction. Is there any way that the valves being out of adjustment could cause the fuel pump to not operate correctly. I did adjust the valves, but it's possible my adjustments weren't correct. It was my first time to do that, so I'm definitely not great at it.Are you sure you hooked the pump up the right way ?

Both the inlet & outlets have one way valves so try blowing through them

Next did you put the impulse line on the top spiggot ?

#63

benaford

benaford

I'm having a double portion of humble pie tonight. In my frustration with the fuel system, I started scouring youtube for information about pulse fuel pumps - trying to understand how they work and determine if that could be my issue. I found a vid of a guy pulsing air in the breather tube with his mouth, and (out of options) I decided to try for myself. Still no fuel through the system. Pulled off the fuel pump and blew on both sides to validate the check-valves and diaphragm. All good. At this point, I start to think there's a blockage in the fuel pickup inside of the tank. Looked under the seat and I saw streaks of grime on the chassis that seemed to be coming from the fuel tank fitting. Suspecting a leak, I pulled out the pickup and found that the seal that keeps it in the tank had corroded and split into two pieces. This was also allowing some fuel to leak at the fitting. And then... then it dawns on me. The mower was OUT OF GAS.  I dropped the fuel feed line into a gas tank and the mower fired right up and purred like a kitten. It all started coming together in my mind. Since the mower has been inoperable for so long, when it died while my son was mowing, my first thought went to all of the things that could have broken and I skipped right over the most obvious thing of all. On the bright side, I was able to discover a couple more leaks on the mower while I was troubleshooting. I also was able to change the oil, adjust the valves, replace the old valve seals and also learn a lot about how pulse fuel pumps work. So, now I'm waiting on the fuel tank fitting and grommet to come in the mail and really hoping that I'll be back in action.

I dropped the fuel feed line into a gas tank and the mower fired right up and purred like a kitten. It all started coming together in my mind. Since the mower has been inoperable for so long, when it died while my son was mowing, my first thought went to all of the things that could have broken and I skipped right over the most obvious thing of all. On the bright side, I was able to discover a couple more leaks on the mower while I was troubleshooting. I also was able to change the oil, adjust the valves, replace the old valve seals and also learn a lot about how pulse fuel pumps work. So, now I'm waiting on the fuel tank fitting and grommet to come in the mail and really hoping that I'll be back in action.

#64

N

Nitescan

N

Nitescan

I know this is a couple weeks old- but couldn't stop reading your progress. Excellent.... Excellent work!! Super stoked for you to be back in business.I'm having a double portion of humble pie tonight. In my frustration with the fuel system, I started scouring youtube for information about pulse fuel pumps - trying to understand how they work and determine if that could be my issue. I found a vid of a guy pulsing air in the breather tube with his mouth, and (out of options) I decided to try for myself. Still no fuel through the system. Pulled off the fuel pump and blew on both sides to validate the check-valves and diaphragm. All good. At this point, I start to think there's a blockage in the fuel pickup inside of the tank. Looked under the seat and I saw streaks of grime on the chassis that seemed to be coming from the fuel tank fitting. Suspecting a leak, I pulled out the pickup and found that the seal that keeps it in the tank had corroded and split into two pieces. This was also allowing some fuel to leak at the fitting. And then... then it dawns on me. The mower was OUT OF GAS.I dropped the fuel feed line into a gas tank and the mower fired right up and purred like a kitten. It all started coming together in my mind. Since the mower has been inoperable for so long, when it died while my son was mowing, my first thought went to all of the things that could have broken and I skipped right over the most obvious thing of all. On the bright side, I was able to discover a couple more leaks on the mower while I was troubleshooting. I also was able to change the oil, adjust the valves, replace the old valve seals and also learn a lot about how pulse fuel pumps work. So, now I'm waiting on the fuel tank fitting and grommet to come in the mail and really hoping that I'll be back in action.

#65

benaford

Yep... that'll do it. New spindle and belt on order.

benaford

Thank you! Glad you enjoyed reading. Tractor is up and running fairly smoothly now. Especially considering it's age and how long it sat out in the elements with no maintenance. Two weeks ago, I was mowing with it and noticed a grinding noise coming from the deck. I assume there was a stick or some other debris hung under the deck and kept mowing. The noise became louder and I began losing power when I hit longer grass. Shutting off the PTO made the noise go away and restored power so I knew it had to be something going on with the deck. Upon inspecting, I noticed the drive belt was begging to fray and smoke. I released the belt tension and attempted to spin the three spindles by hand. Two spun easily, but the third was completely locked in place - thus the smoking/fraying belt and loud noise. The spindle housing had locked up during mowing and completely failed. I removed the spindle from the deck and this is what I found:I know this is a couple weeks old- but couldn't stop reading your progress. Excellent.... Excellent work!! Super stoked for you to be back in business.

Yep... that'll do it. New spindle and belt on order.

#66

S

slomo

S

slomo

LOVE the desire to get the kids involved in post 22.

Get a junk pushed to the curb mower. Push it at the boys. Tell them to take it ALL APART. Reassemble and test it. Have them do all the work. You are there to instruct. Great project for winter.

Get a junk pushed to the curb mower. Push it at the boys. Tell them to take it ALL APART. Reassemble and test it. Have them do all the work. You are there to instruct. Great project for winter.

#67

benaford

benaford

Man, such a great idea. Mechanical things engage a part of our brains that seems to be falling asleep due to the solid state, electrical nature of so many products now. Something about the satisfying click of a ratchet driver in your hands or the smooth spinning of a freshly cleaned and oiled set of bearings is therapeutic in a way that some of us don't know that we need. Sometimes I like to give my kids an old tv or other appliance and just let them disassemble it down to all of it's pieces to see what's inside. Thankful my dad and grandfather did that for me, and I want to pass it along.LOVE the desire to get the kids involved in post 22.

Get a junk pushed to the curb mower. Push it at the boys. Tell them to take it ALL APART. Reassemble and test it. Have them do all the work. You are there to instruct. Great project for winter.