You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Huskee(Tractor Supply Co.) model #44-9717-8/MTD #14AJ839 P131 transaxle ID

#1

T

totallymopar

T

totallymopar

I have an early 90's(I believe) Huskee Lawn tractor,fairly rugged construction,20HP Twin cyl.engine(industrial/commercial) HUGE rear tires(on 13" rims!).It has a hydrostatic variable speed tranny,also rather large,1-1/2" axles 4-bolt rim mount, with cooling fins on it.Is there any way to identify who made the tranny,and where to find it? Also,I want to use it as a runner,when I'm not mowing with it.Top speed now is just under 10 MPH.I would like it to go 20,or a bit faster,but don't want to grenade the rear end.The rear axle pulley (3-1/4") is splined,and I plan to leave that alone.There is room to put a larger one on the front--I was thinking about 5"" up from the 3-1/2 on it now.With the stock pulleys,and the engine at 3600RPM max,the axle pulley is rotating at about 3877 max. RPM. If I change the engine pulley to 5",with engine at 3600RPM max,the tranny pulley will spin at around 5539 max rpm.Will the hydrostatic tranny in this be up to the speed increase? If not,what transmission would be recommended? The tractor is in very good condition,no leaks or wet spots on the transmission case,and runs well.

#3

T

totallymopar

T

totallymopar

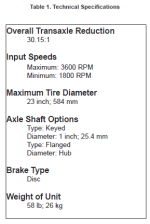

Thanks for the info.Yes,you are right-it is a Hydrogear unit,model 618 0249.I researched the specs,and with a max 3600 RPM on the input shaft,and a 30.15 reduction ratio,the best I'm going to get,with the 21" tires is 7 MPH,without damaging the tranny.. After all it IS a Lawnmower. These guys they show on YouTube,going 20-25 MPH are shredding their rear ends-I know what cavitation can do.What about a rear-end out of a ATV-might that work?

#4

Tiger Small Engine

Tiger Small Engine

A larger pulley will result in slower speed, a smaller pulley faster speed, you got it backwards. Riding mowers stock usually travel forwards at about 5-6 mph. You said now it will go just under 10 mph (I would like to see that). At 10 mph it must be like riding a car without shocks. At 20 mph it would be like riding a bucking Bronco on steroids.Without the hydro gear model number having to the reference the main housing PN. Which indicates it is one of the four 618 model units. These are not design to operate above 3600 rpm input speeds. Severly damage can occur above this speed from cavitation.

View attachment 66814

#5

StarTech

The OP was going to try to increase the engine pulley and leave the trans pulley alone. Say he makes the engine twice as large as the trans pulley that would be an 1 to 2 ratio; hence, if the engine pulley turns once the trans pulley turns twice. And if he made the engine half as large as the trans pulley the ratio would be 2 to 1. This 2 to 1 is something you see a lot when working on 4 cycle engines; Crankshaft to Camshaft.

A hydrostatic has it limits due its design. Now geared transaxle is a lot more forgiving but even they have their limits.

StarTech

Sorry but you got it backwards. Please re-read the OP initial post.A larger pulley will result in slower speed, a smaller pulley faster speed, you got it backwards. Riding mowers stock usually travel forwards at about 5-6 mph. You said now it will go just under 10 mph (I would like to see that). At 10 mph it must be like riding a car without shocks. At 20 mph it would be like riding a bucking Bronco on steroids.

The OP was going to try to increase the engine pulley and leave the trans pulley alone. Say he makes the engine twice as large as the trans pulley that would be an 1 to 2 ratio; hence, if the engine pulley turns once the trans pulley turns twice. And if he made the engine half as large as the trans pulley the ratio would be 2 to 1. This 2 to 1 is something you see a lot when working on 4 cycle engines; Crankshaft to Camshaft.

A hydrostatic has it limits due its design. Now geared transaxle is a lot more forgiving but even they have their limits.

#6

B

bertsmobile1

The standard trick s to invert the stack pulley as I first mentioned

This is phase 1 of conversion to racing mower so it goes just that bit faster , in fact usually about twice as fast

On a varidrive you need to fit a much larger front belt so best done to a Peerless/ Tecumseh or a Danna manual box

However your warning about the ride quality is quite correct

Racing mowers do not matter because they are usually running on a fairly flat trotting track

But in your yard it would be a totally different matter .

B

bertsmobile1

I did say the stack , ie engine pulley could be made largerA larger pulley will result in slower speed, a smaller pulley faster speed, you got it backwards. Riding mowers stock usually travel forwards at about 5-6 mph. You said now it will go just under 10 mph (I would like to see that). At 10 mph it must be like riding a car without shocks. At 20 mph it would be like riding a bucking Bronco on steroids.

The standard trick s to invert the stack pulley as I first mentioned

This is phase 1 of conversion to racing mower so it goes just that bit faster , in fact usually about twice as fast

On a varidrive you need to fit a much larger front belt so best done to a Peerless/ Tecumseh or a Danna manual box

However your warning about the ride quality is quite correct

Racing mowers do not matter because they are usually running on a fairly flat trotting track

But in your yard it would be a totally different matter .

#7

T

totallymopar

T

totallymopar

I think I need to clarify what I am doing.Because this is a large tractor,with 21-1/2" tires already on it,and the twin cylinder engine,I would be using this as dual-purpose machine.When using it as a mower,I leave the stock 3-1/2" drive/4-3/4 deck dual pulley on the engine,the 3-1/4" pulley on the rear, which gives me up to 7 mph.I did the math on it.Average engine speed at around 3300,giving me 3600 on the tranny pulley(the max rating)-- with the 30.15 reduction ratio of the tranny,,I am getting a rear axle speed of 119.4 RPM max.The 21-1/2 " tires go 5.66 feet for every rpm.5.66 x 119.4=675.82 feet per minute. That's 40549.25 feet in one hour.Which is 7.68 mph,in stock form-original pulleys,tires,everything. When i am not using it as a mower,I want to use it as a runner,like an ATV,but on a smooth surface.I live very close to town and can take it in on a back road, on a smooth surface.I was wanting to get it up to around 15-20 mph.But the ONLY way to make it go faster at all,is to swap out the hydro rear end with a gear drive with less reduction(I have a spare Spicer/Dana 4360 140ch 6-speed with a ratio of supposedly under 9:1,2000 rpm limit that's a bolt in),that would give me a top speed of 9.38 MPH,or a Peerless 820,8:1 ratio-also a bolt in,for a speed of 16 mph.Either that,or put larger tires on it.If I could go 7 ft/rpm,that would work out to 19 mph,or even 8 ft/rpm,which would be 22.3 mph-just what I need.This would require about a 30" dia. tire--all without overspinning the input shaft on the tranny.

#8

T

totallymopar

T

totallymopar

You can't invert the pulley-the shaft bore on the small pulley(3-1/2") end is 1" for the engine with the keyway,whereas the large pulley(4-3/4) end is too large for the engine shaft with no keyway.And there is a washer welded inside the pulley shaft where the bolt holds the pulley assembly on the end of the engine shaft.I had another pulley assembly,where I cut the large pulley off and welded it onto the smaller one at the top,then slide it onto the engine shaft,and bolt it on.I wouldn't be driving it around the yard that fast-- but driving it as a runner at the higher speed,on a smooth surface road,then when mowing in the yard,go back to the stock pulley setup,for the low speed. A multi-purpose tractor.I did say the stack , ie engine pulley could be made larger

The standard trick s to invert the stack pulley as I first mentioned

This is phase 1 of conversion to racing mower so it goes just that bit faster , in fact usually about twice as fast

On a varidrive you need to fit a much larger front belt so best done to a Peerless/ Tecumseh or a Danna manual box

However your warning about the ride quality is quite correct

Racing mowers do not matter because they are usually running on a fairly flat trotting track

But in your yard it would be a totally different matter .

#9

T

totallymopar

T

totallymopar

Mine goes at a little over 7-1/2 mph,due to the large (21.5") and very wide rear tires.This is a commercial-duty tractor,made for large yards/acreages,so it was probably made to go faster,to cut mowing time. It has a 3-1/2" on the engine,and a 3-1/4" on the rear,stock.Usually,most mowers have the smaller pulley on the engine,and larger at the tranny--but not this one.Nothing had been changed-that's the way it was made.Even in my yard,which is hardly level at all,it does not do that badly-there are huge springs under the seat,and the front end is a massive casting,with front wheels almost as large as the rears on most other mowers.Only a Fordson is larger.A larger pulley will result in slower speed, a smaller pulley faster speed, you got it backwards. Riding mowers stock usually travel forwards at about 5-6 mph. You said now it will go just under 10 mph (I would like to see that). At 10 mph it must be like riding a car without shocks. At 20 mph it would be like riding a bucking Bronco on steroids.

#10

T

totallymopar

T

totallymopar

The transaxle is limited to 3600 rpm until cavitation takes place,because it uses oil.A gear drive uses grease,but it is limited to 2000 RPM.Being gear drive means it is more durable,and grease is less subsceptible to cavitation than oil(but not immune).Hydros can spin faster at the input,but have a much higher ratio(30:1),while gears have less than half of the reduction(8-to-15:1),but can only spin less than 2/3rds the RPM of a hydro.So,whatever gains are made in RPM at the input shaft of a hydro(3600),are lost in the greater reduction(30:1),as compared to a gear.and whatever gains are made in the lower reduction ratio of a gear(8-15:1) are lost in the lower rpm of the input shaft(2000).Bottom line-transmissions used in lawn tractors are intended for low ground speeds for mowing,not for "transportation''.Nobody mows their lawn at 25 mph.But when you are financially strapped,and you have two lawn tractors sitting in your garage for free,and the price for a used ATV,or even a nonworking rusty go-Kart are through the roof--and your only vehicle is down with a shelled tranny at $2500 to replace it(even when you install it yourself)--and you HAVE to get groceries and items you NEED to function every day,and there are NO busses,taxis,Uber,GoGo Grandparent,family,friends,or ANYONE else to take you anywhere,then you get DESPERATELY creative to turn those lawn tractors into something that doesn't take an hour to get into town on.And they are a LOT cheaper on gas than my 6400-lb V8 Dodge Ram 250 Mark III conversion van.Sorry but you got it backwards. Please re-read the OP initial post.

The OP was going to try to increase the engine pulley and leave the trans pulley alone. Say he makes the engine twice as large as the trans pulley that would be an 1 to 2 ratio; hence, if the engine pulley turns once the trans pulley turns twice. And if he made the engine half as large as the trans pulley the ratio would be 2 to 1. This 2 to 1 is something you see a lot when working on 4 cycle engines; Crankshaft to Camshaft.

A hydrostatic has it limits due its design. Now geared transaxle is a lot more forgiving but even they have their limits.

#11

B

bertsmobile1

B

bertsmobile1

Mechanical gear boxes can go a lot faster than that

However you do need to change the bentonite grease for lighter lithium grease .

The racers use 00 or 000 lithium/ graphite grease in the boxes but you do have to add a vent or they leak like a sieve .

However that is not a consideration when speed is the only criteria .

Funny enough I get asked to make mowers go slower more than go faster

I have a lot of retirees in my run and converting ride ons to tow motors to move caravans & trailers around their yard is a lot cheaper than buying one of those electric jockey wheels

However you do need to change the bentonite grease for lighter lithium grease .

The racers use 00 or 000 lithium/ graphite grease in the boxes but you do have to add a vent or they leak like a sieve .

However that is not a consideration when speed is the only criteria .

Funny enough I get asked to make mowers go slower more than go faster

I have a lot of retirees in my run and converting ride ons to tow motors to move caravans & trailers around their yard is a lot cheaper than buying one of those electric jockey wheels

#12

T

totallymopar

T

totallymopar

When you say faster,you mean input shaft speed above 2000? how long will the gearbox hold up with the new grease? I'm certainly going to clean out all the grease anyway,its about 20 years old in the Spicer 4360.(date 2004).Where do you get the 00/000 lithium graphite grease-available locally? You mentioned a vent on the housing-where,and what kind? Then you said not a consideration if only for speed.If you mean I'm only using as a runner,not mowing or towing,then a vent is unnecessary? I want to do around 20-25 mph on it.Excuse the questions,but I'm new to transaxles on lawnmowers-a bit different than working on my cars.Mechanical gear boxes can go a lot faster than that

However you do need to change the bentonite grease for lighter lithium grease .

The racers use 00 or 000 lithium/ graphite grease in the boxes but you do have to add a vent or they leak like a sieve .

However that is not a consideration when speed is the only criteria .

Funny enough I get asked to make mowers go slower more than go faster

I have a lot of retirees in my run and converting ride ons to tow motors to move caravans & trailers around their yard is a lot cheaper than buying one of those electric jockey wheels

#13

Tiger Small Engine

Tiger Small Engine

I understand what you are saying when on a financial budget. Ain’t nothing cheap these days. Don’t forget about brakes. Stopping a mower going 20 mph is going to be important.When you say faster,you mean input shaft speed above 2000? how long will the gearbox hold up with the new grease? I'm certainly going to clean out all the grease anyway,its about 20 years old in the Spicer 4360.(date 2004).Where do you get the 00/000 lithium graphite grease-available locally? You mentioned a vent on the housing-where,and what kind? Then you said not a consideration if only for speed.If you mean I'm only using as a runner,not mowing or towing,then a vent is unnecessary? I want to do around 20-25 mph on it.Excuse the questions,but I'm new to transaxles on lawnmowers-a bit different than working on my cars.

#14

StarTech

StarTech

Now come trees and vehicles makes great brakes; although, it can be a little too aggressive of a stop.

#15

B

bertsmobile1

B

bertsmobile1

The gear boxes are good for around 4000 rpm to 5000 rpm

Simple check is to take the wheels off & use a corded drill or air drill to drive the input shaft

When you go too fast the gears will lock.

Now brakes are a totally different thing

We fit band brakes to the axel or some times disc brakes if it has a strait axel .

Using the gear box brake from high speed will remove the teeth on at least one gear

The brake locks the diff so the wheels turn in different directions which is why the stop is so abrupt

It is exactly the same thing as shoving an automatic car into Park while moving

Now mowers get away with it because they are smaller. lighter & go slower

But most of the gears are powder pressings so have a very finite shock load limit on the teeth

Simple check is to take the wheels off & use a corded drill or air drill to drive the input shaft

When you go too fast the gears will lock.

Now brakes are a totally different thing

We fit band brakes to the axel or some times disc brakes if it has a strait axel .

Using the gear box brake from high speed will remove the teeth on at least one gear

The brake locks the diff so the wheels turn in different directions which is why the stop is so abrupt

It is exactly the same thing as shoving an automatic car into Park while moving

Now mowers get away with it because they are smaller. lighter & go slower

But most of the gears are powder pressings so have a very finite shock load limit on the teeth

#16

T

totallymopar

T

totallymopar

well,I have a spare Spicer 4360 140CH,6 speed trans,that I put up on my bench,rear end only,(no wheels or anything on it).I spun it witha drill,marking the input shaft to count the revolutions,while watching the axle shafts. I counted approximately 6 revolutions of the input shaft, to get 1 on the axles-in the highest gear position.That would be about 6:1 reduction,right? so,if I spin the input at 2000,to be safe,I would get 333.33 rpm at the wheels,and with 21-1/2" tires,at 5.66 ft/rpm, X 333.33=1,886.66 ft/min. X 60 min.=113,200 ft/hr. Which is 113,200 divided by 5280=21.4 mph.WHOOPEE! all without exceeding the rated rpm of the manufacturer,and room (maybe,at 3,000 on the input) to go 32 mph! Am I correct on this? Not that I'm really going to go over 30MPH-but nice to know I CAN if I need to.This is a BIG lawn tractor,with fairly large wheels,and it handles well.The steering is tight on it,and it has good braking. As is,it does close to 8 mph,with no difficulty over rough ground.and although I know 8 is not 20 or 30,I still feel fairly safe on it.

#17

B

bertsmobile1

B

bertsmobile1

The question is what type of brake ?

if it is a disc on the gear box, stopping from 20 mph will strip the teeth of at least one gear .

They are only powder pressings which are good for low loads and provide excellent lubrication to the contact faces of the teeth

Burt their impact ( shock load ) strength is very low .

So if you have an external brake , all is well but if it is a standard internal diff lock than you are in trouble

The racers kill the engine to stop

if it is a disc on the gear box, stopping from 20 mph will strip the teeth of at least one gear .

They are only powder pressings which are good for low loads and provide excellent lubrication to the contact faces of the teeth

Burt their impact ( shock load ) strength is very low .

So if you have an external brake , all is well but if it is a standard internal diff lock than you are in trouble

The racers kill the engine to stop

#19

G

Gord Baker

G

Gord Baker

You have a great Machine. Leave it alone and buy an ATV.I have an early 90's(I believe) Huskee Lawn tractor,fairly rugged construction,20HP Twin cyl.engine(industrial/commercial) HUGE rear tires(on 13" rims!).It has a hydrostatic variable speed tranny,also rather large,1-1/2" axles 4-bolt rim mount, with cooling fins on it.Is there any way to identify who made the tranny,and where to find it? Also,I want to use it as a runner,when I'm not mowing with it.Top speed now is just under 10 MPH.I would like it to go 20,or a bit faster,but don't want to grenade the rear end.The rear axle pulley (3-1/4") is splined,and I plan to leave that alone.There is room to put a larger one on the front--I was thinking about 5"" up from the 3-1/2 on it now.With the stock pulleys,and the engine at 3600RPM max,the axle pulley is rotating at about 3877 max. RPM. If I change the engine pulley to 5",with engine at 3600RPM max,the tranny pulley will spin at around 5539 max rpm.Will the hydrostatic tranny in this be up to the speed increase? If not,what transmission would be recommended? The tractor is in very good condition,no leaks or wet spots on the transmission case,and runs well.