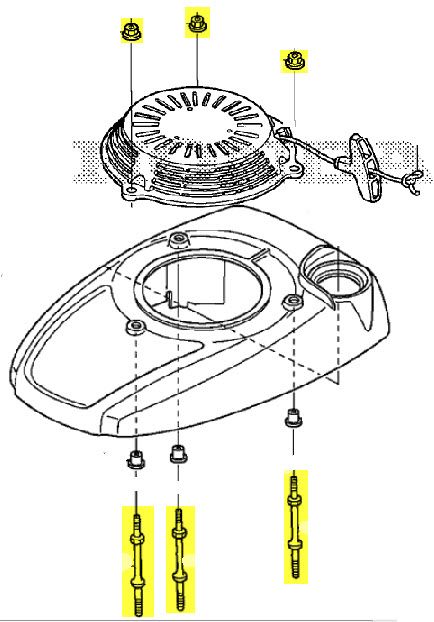

Attempted to remove the recoil on a GSV 190 engine to replace the cord. The engine sits on a 2009 Toro commercial mower model 22156. When attempting to remove the three 10mm nuts holding the recoil, the studs came out of the top of the motor as the 10mm nuts were frozen to the studs. When trying to remove the nut/stud assembly from the upper engine/recoil shroud, I found that a deep set 10mm socket would not clear the stud flange under the housing. This made the nut removal very tedious.

Is this a common problem with these engines?

How does one avoid this, locktite on the stud threads to the engine and antiseize on the hold down nuts for the recoil?

Thanks,

Toro1

Is this a common problem with these engines?

How does one avoid this, locktite on the stud threads to the engine and antiseize on the hold down nuts for the recoil?

Thanks,

Toro1