You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Help with oil plug B&S 31P777

#1

B

Bange

B

Bange

Hey guys!

As some already know, I am repairing a Murray 42" with B&S 31P777 and one of the problems is the oil plug that came with a water valve (don't laugh).

I need to know the measures of such a plug to make an appropriate one, because here it is either very expensive or it is very difficult to get original parts.

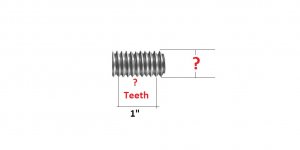

I need the following measures:

What is the external measure of the plug thread?

How many threads per inch? I believe it is 20 ... is that correct?

Wrong valve...?

As some already know, I am repairing a Murray 42" with B&S 31P777 and one of the problems is the oil plug that came with a water valve (don't laugh).

I need to know the measures of such a plug to make an appropriate one, because here it is either very expensive or it is very difficult to get original parts.

I need the following measures:

What is the external measure of the plug thread?

How many threads per inch? I believe it is 20 ... is that correct?

Wrong valve...?

#3

Scrubcadet10

Tractor supply sells 3/8 pipe, male thread on both ends, then a cap on one end.

Scrubcadet10

Ditto,More than likely a 3/8” pipe thread.

Tractor supply sells 3/8 pipe, male thread on both ends, then a cap on one end.

#5

B

bertsmobile1

B

bertsmobile1

No

Pipe threads are named by the size of the hole that the liquid flows through

So a 3/8 pipe thread is around 9/16 outside diameter

And to make things more confusing it will be a tapered thread so it locks into itself air tight

Pipe threads are named by the size of the hole that the liquid flows through

So a 3/8 pipe thread is around 9/16 outside diameter

And to make things more confusing it will be a tapered thread so it locks into itself air tight

#6

B

Bange

B

Bange

I understand ... but I waste time or money looking for a representative ... the best thing is to do it.

But do you say that the thread is tapered (not parallel)?

This complicates a little without knowing the angle.

Do you know the standard (BSP, NPT)?

But do you say that the thread is tapered (not parallel)?

This complicates a little without knowing the angle.

Do you know the standard (BSP, NPT)?

#9

B

Bange

B

Bange

Okay, being NPT, I already saw that the thread tooth angle is 60 ° and the taper can be 2 °.

But I also saw that every NPT / BSP female is parallel, so the male can be at standard NPT angle (1 ° 45 ' to 2 °) or parallel.

I believe that the fact that bertsmobile1 uses both NPT and BSP in "taps & dies", is due to aluminum fluff in the housing, as it will be compliant for both 55 ° (BSP) and 60 ° (NPT) teeth.

I also saw that all thread material in tubes, for the 3/8 tube, the thread has 18 wires per inch ... if confirmed, this information is enough for me to make the thread in an aluminum or bronze tube, I don't know yet .

But I also saw that every NPT / BSP female is parallel, so the male can be at standard NPT angle (1 ° 45 ' to 2 °) or parallel.

I believe that the fact that bertsmobile1 uses both NPT and BSP in "taps & dies", is due to aluminum fluff in the housing, as it will be compliant for both 55 ° (BSP) and 60 ° (NPT) teeth.

I also saw that all thread material in tubes, for the 3/8 tube, the thread has 18 wires per inch ... if confirmed, this information is enough for me to make the thread in an aluminum or bronze tube, I don't know yet .

#10

Scrubcadet10

Scrubcadet10

I don't mean to sound condescending but i think you're over thinking it some....go to your hardware store. Buy a 3/8 NPT tube, male thread on both ends and buy a cap or valve to fit on one end.

Teflonsealing tape on both ends. Install it. You're done.

Or you can call Briggs And Stratton and ask them what size thread the 31p777 engine sump drain plug is.

Teflonsealing tape on both ends. Install it. You're done.

Or you can call Briggs And Stratton and ask them what size thread the 31p777 engine sump drain plug is.

#11

Scrubcadet10

www.partstree.com

www.partstree.com

Or look at #15, in the parts list

Scrubcadet10

PartsTree - Home of OEM Parts for Outdoor Power Equipment

We are committed to providing you with the largest selection of OEM parts from the best brands, the best diagrams and part search tools anywhere.

www.partstree.com

www.partstree.com

Or look at #15, in the parts list

#12

StarTech

And the Briggs is 3/8-18 NPT. If you use a 9/16 drill bit you can confirm this.

StarTech

They are different thread pitch.No

I use BSPT taps & dies or NPT taps & dies

| 3/8 | BSPT | 19 | 0.5709" |

| 3/8 | NPT | 18 | 0.5625" |

And the Briggs is 3/8-18 NPT. If you use a 9/16 drill bit you can confirm this.

NPT (normal pipe tapered) and NPSM (normal pipe straight male) are two different animals. Also BSPP (British Standard Parallel Pipe) and BSPT (British Standard Pipe Taper) are two more different animals.Okay, being NPT, I already saw that the thread tooth angle is 60 ° and the taper can be 2 °.

But I also saw that every NPT / BSP female is parallel, so the male can be at standard NPT angle (1 ° 45 ' to 2 °) or parallel.

I believe that the fact that bertsmobile1 uses both NPT and BSP in "taps & dies", is due to aluminum fluff in the housing, as it will be compliant for both 55 ° (BSP) and 60 ° (NPT) teeth.

I also saw that all thread material in tubes, for the 3/8 tube, the thread has 18 wires per inch ... if confirmed, this information is enough for me to make the thread in an aluminum or bronze tube, I don't know yet .

#13

B

bertsmobile1

I thing you will find Bange is in a third world country so there is no Harbour Freight 10 minutes down the road.

This is why he is doing the work arounds.

One of the downsides of the new format is the location tags have been deleted .

B

bertsmobile1

Scrubby.I don't mean to sound condescending but i think you're over thinking it some....go to your hardware store. Buy a 3/8 NPT tube, male thread on both ends and buy a cap or valve to fit on one end.

Teflonsealing tape on both ends. Install it. You're done.

Or you can call Briggs And Stratton and ask them what size thread the 31p777 engine sump drain plug is.

I thing you will find Bange is in a third world country so there is no Harbour Freight 10 minutes down the road.

This is why he is doing the work arounds.

One of the downsides of the new format is the location tags have been deleted .

#14

Scrubcadet10

Scrubcadet10

didn't realize thatScrubby.

I thing you will find Bange is in a third world country so there is no Harbour Freight 10 minutes down the road.

This is why he is doing the work arounds.

One of the downsides of the new format is the location tags have been deleted .

#15

B

Bange

B

Bange

Scrubcadet10

The world here is another one of my friends ... 3/8 is not standard for ordinary people, just for industry and nobody sells a 10 or 15cm piece, only 3 or 6 meter sticks. In addition to conical threads here it is only for materials under pressure (gases or fluids), minus the public water service.

I saw the plug and it didn't look like a conical thread ... it's actually cheap there ... but what I'm thinking about is a piece of pipe so that the oil falls out of the chassis so it doesn't get dirty.

StarTech

Yes, in numbers there is a small difference that is significant when the materials are hard ... aluminum is compliant and ends up sealing, even with this small difference.

In the materials I have seen so far, the female thread allows for a tapered or parallel male ... the seal, in the case of straight, can be a little damaged and you should abuse teflon tape or put a soft metal washer (aluminum , copper), to compensate.

bertsmobile1

Bingo! This is one of my biggest problems with imported parts ... difficult to find, to have in stock, with a reasonable price ... which never happens.

The world here is another one of my friends ... 3/8 is not standard for ordinary people, just for industry and nobody sells a 10 or 15cm piece, only 3 or 6 meter sticks. In addition to conical threads here it is only for materials under pressure (gases or fluids), minus the public water service.

I saw the plug and it didn't look like a conical thread ... it's actually cheap there ... but what I'm thinking about is a piece of pipe so that the oil falls out of the chassis so it doesn't get dirty.

StarTech

Yes, in numbers there is a small difference that is significant when the materials are hard ... aluminum is compliant and ends up sealing, even with this small difference.

In the materials I have seen so far, the female thread allows for a tapered or parallel male ... the seal, in the case of straight, can be a little damaged and you should abuse teflon tape or put a soft metal washer (aluminum , copper), to compensate.

bertsmobile1

Bingo! This is one of my biggest problems with imported parts ... difficult to find, to have in stock, with a reasonable price ... which never happens.

#16

B

Bange

B

Bange

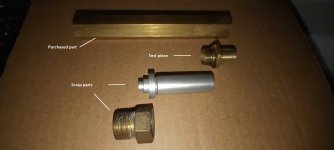

Continuation...

Yesterday I researched the market and found 3 stores and only 1 accepted to sell me, a piece as said by Scrubcadet10, if it were in iron it would be quite cheap, but I prefer in aluminum or brass, I found what is called here "long nipple" , in brass, whose value is BRL 55.00 (+ -USD 11.00) and the plug for BRL 22.00 (+ - USD 4.2) ... total BRL 77.00 (+ - USD 15) ... but I didn't buy it.

Today I bought a hexagonal piece in brass 7/8 with 10cm long for BRL 40.00 (+ - USD 7.5).

I also made a test piece with the water valve that came in place of the plug, but the piece only went halfway, signaling that either the thread was obstructed or the taper of the NPT is in the housing.

Since I don't have a 3/8 thread opener, I improvised one that solved the problem.

The plan now is to make an extended plug with the purchased hexagon and other pieces of my scrap.

Yesterday I researched the market and found 3 stores and only 1 accepted to sell me, a piece as said by Scrubcadet10, if it were in iron it would be quite cheap, but I prefer in aluminum or brass, I found what is called here "long nipple" , in brass, whose value is BRL 55.00 (+ -USD 11.00) and the plug for BRL 22.00 (+ - USD 4.2) ... total BRL 77.00 (+ - USD 15) ... but I didn't buy it.

Today I bought a hexagonal piece in brass 7/8 with 10cm long for BRL 40.00 (+ - USD 7.5).

I also made a test piece with the water valve that came in place of the plug, but the piece only went halfway, signaling that either the thread was obstructed or the taper of the NPT is in the housing.

Since I don't have a 3/8 thread opener, I improvised one that solved the problem.

The plan now is to make an extended plug with the purchased hexagon and other pieces of my scrap.

#17

M

muddy51

M

muddy51

Hey Bange,

The drain plug is probably National Pipe Thread (NPT)

I got these sizes on line

Nominal Pipe Size 3/8"

OD .675"

Threads per inch 18

Angle between threads 60degrees

Taper 3/4"/ft

Use teflon tape or pipe dope to seal

Need some way to attach tool to tighten and loosen

If what's there now works leave it as is.

The drain plug is probably National Pipe Thread (NPT)

I got these sizes on line

Nominal Pipe Size 3/8"

OD .675"

Threads per inch 18

Angle between threads 60degrees

Taper 3/4"/ft

Use teflon tape or pipe dope to seal

Need some way to attach tool to tighten and loosen

If what's there now works leave it as is.

#19

B

Bange

B

Bange

muddy 51

Yes, friends have already passed on this information ... but I imagined that the taper (angle) was on the male thread (plug) but after placing the test plug I saw that the angle is on the female thread (engine).

But when passing the improvised tool, the NPT thread was changed to a normal thread (without an angle) ... this will facilitate my project.

Slomo

Yes, in fact it is a bathroom or kitchen faucet (I didn't know the name "faucet" ... google previously translated it as a water valve).

The kitchen faucet improvised by the previous owner, served for me to make the test plug.?

Yes, friends have already passed on this information ... but I imagined that the taper (angle) was on the male thread (plug) but after placing the test plug I saw that the angle is on the female thread (engine).

But when passing the improvised tool, the NPT thread was changed to a normal thread (without an angle) ... this will facilitate my project.

Slomo

Yes, in fact it is a bathroom or kitchen faucet (I didn't know the name "faucet" ... google previously translated it as a water valve).

The kitchen faucet improvised by the previous owner, served for me to make the test plug.?

#20

B

Bange

B

Bange

Evolution ...

Turned and ready parts, lacking a nitrile rubber, a soft washer and a small chain to hold the lid.

Preparation of the exagonal part.

Internal turning with the same size as the connection pipe

Detail of the internal channels for better sealing.

Turning the sealing pin to the opposite side of the pipe

Preparation of the connection pipe

Parts to be pressed

Before pressing, the brass one goes to the oven, the aluminum one goes to the freezer.

Chemical lock

Chemical lock application

Using the lathe to press

Turned and ready parts, lacking a nitrile rubber, a soft washer and a small chain to hold the lid.

Preparation of the exagonal part.

Internal turning with the same size as the connection pipe

Detail of the internal channels for better sealing.

Turning the sealing pin to the opposite side of the pipe

Preparation of the connection pipe

Parts to be pressed

Before pressing, the brass one goes to the oven, the aluminum one goes to the freezer.

Chemical lock

Chemical lock application

Using the lathe to press

#22

VRR.DYNDNS>BIZ

VRR.DYNDNS>BIZ

Perfect answer. Believe it.I don't mean to sound condescending but i think you're over thinking it some....go to your hardware store. Buy a 3/8 NPT tube, male thread on both ends and buy a cap or valve to fit on one end.

Teflonsealing tape on both ends. Install it. You're done.

Or you can call Briggs And Stratton and ask them what size thread the 31p777 engine sump drain plug is.

#23

B

Bange

B

Bange

I totally agree ... but when the option is too far away or too expensive, there are other possible and fully acceptable options ... not for everything, of course!

#25

B

Bange

B

Bange

A small modification ...

Nitrile rubber is expensive and would still have to be adapted ... but there is an almost inexhaustible and free source on the floor of car workshops.

It is an O-ring of the fuel injector nozzles.

Then...

I tried to make an aluminum washer, it didn't look good ... so I made it out of brass too.

With a good grip I don't think it would leak, but I added teflon tape as a guarantee.

I am concerned with vibration ... as the lid will not need a tightening tool, only the hand, can it loosen and leak? It will be seen during the first hours of use ...

This is for those who open engines: is it worth making a magnetic trap to retain iron filings present in the oil?

Nitrile rubber is expensive and would still have to be adapted ... but there is an almost inexhaustible and free source on the floor of car workshops.

It is an O-ring of the fuel injector nozzles.

Then...

I tried to make an aluminum washer, it didn't look good ... so I made it out of brass too.

With a good grip I don't think it would leak, but I added teflon tape as a guarantee.

I am concerned with vibration ... as the lid will not need a tightening tool, only the hand, can it loosen and leak? It will be seen during the first hours of use ...

This is for those who open engines: is it worth making a magnetic trap to retain iron filings present in the oil?

#26

R

Rivets

R

Rivets

You’ve stuck more time than 99% of us here and you’re having fun. Go for it, what do you have to lose. Only thing I would question, do you think there are that many iron filings in an aluminum block engine? Aren’t most of the bearings/bushings aluminum?

#27

B

Bange

B

Bange

Really, spending my time on the things I like is fun ... boring is not having the materials on hand and taking a while to get them, doing is another fun.

Just as there was no magnetic plug in my car, after putting it on I was amazed at what was circulating and I imagine the harm it does ...

After analyzing the oil that came out of my B&S (I don't know how long it was there), I noticed shiny particles, in fact I don't know if iron, bronze or aluminum, hence the question) that come out with the friction of some parts and I find it interesting to apply the same reasoning as for my car.

You commented something interesting ... if they are not made of iron or steel, it will not do any good ... as I have not yet discarded the oil, I will pass a magnet on it and see the result.

Just as there was no magnetic plug in my car, after putting it on I was amazed at what was circulating and I imagine the harm it does ...

After analyzing the oil that came out of my B&S (I don't know how long it was there), I noticed shiny particles, in fact I don't know if iron, bronze or aluminum, hence the question) that come out with the friction of some parts and I find it interesting to apply the same reasoning as for my car.

You commented something interesting ... if they are not made of iron or steel, it will not do any good ... as I have not yet discarded the oil, I will pass a magnet on it and see the result.

#28

B

Born2Mow

B

Born2Mow

Exactly. AND the short pipe extension will mean that oil drains into the pan, and not all over the mower frame.....go to your hardware store. Buy a 3/8 NPT tube, male thread on both ends and buy a cap or valve to fit on one end. Teflon sealing tape on both ends. Install it. You're done.

#29

B

Bange

B

Bange

Analyzing the oil ...

Due to the lack of knowledge of a standard procedure (which can even be centrifuging and not magnetic), I adopted a very simple one that can be seen and understood by the photos and video below, remembering only that the oil was not at the working temperature and that the debris in greater volume and size must be retained in the oil filter.

This was the initial oil collection pot.

Attaching a magnet to the bottom of the pot

Iron filings ...

Wrapping the magnet in a PVC film and immersing it in the oil.

Iron particles captured by the magnet.

It was not in my plans to replace the oil filter now, however, after the presence of iron filings was confirmed, I decided to remove the oil from its interior ... and I found another problem ... the engine thread is 3/8 inch and the filter thread is 1.5mm, sacrificing the motor thread.

Well, the evaluation was preliminary and I do not consider it conclusive, but it only served to confirm the presence of iron filings, which certainly passed through the filter, if they are harmful in size or volume, I can say nothing, but logic tells me that it is.

I will think of a way to set a trap, but this will take a lot more time.

Due to the lack of knowledge of a standard procedure (which can even be centrifuging and not magnetic), I adopted a very simple one that can be seen and understood by the photos and video below, remembering only that the oil was not at the working temperature and that the debris in greater volume and size must be retained in the oil filter.

This was the initial oil collection pot.

Attaching a magnet to the bottom of the pot

Iron filings ...

Wrapping the magnet in a PVC film and immersing it in the oil.

Iron particles captured by the magnet.

It was not in my plans to replace the oil filter now, however, after the presence of iron filings was confirmed, I decided to remove the oil from its interior ... and I found another problem ... the engine thread is 3/8 inch and the filter thread is 1.5mm, sacrificing the motor thread.

Well, the evaluation was preliminary and I do not consider it conclusive, but it only served to confirm the presence of iron filings, which certainly passed through the filter, if they are harmful in size or volume, I can say nothing, but logic tells me that it is.

I will think of a way to set a trap, but this will take a lot more time.

#30

B

bertsmobile1

B

bertsmobile1

I really wish people with little understanding of the lubrication system would refrain from posting simplistic "experiments " on the web.

All mower oil filters have a bypass valve so when the filter is clogged the oil bypasses the filter so the engine does not seize .

If you can see it then it CAN NOT PASS THROUGH THE FILTER PAPER unless the paper is damaged.

Next there are a lot of things that are ferro magnetic, like gravel dust for one.

Oil filters on mowers get changed on an hours of operation or lapsed time basis, not on a full yet basis.

And yes the oil filter thread can be NPT or Metric

However the thread cout & profiles are close enough for it not to matter.

Remember these are no formula 1 engines running at 11 tenths of their design limits

Mower engines , now that Honda have exited the market are the cheapest easiest to make lowest output engines it is possible to manufacture & sell.

They are really not much more advanced technically that they were in 1920

All mower oil filters have a bypass valve so when the filter is clogged the oil bypasses the filter so the engine does not seize .

If you can see it then it CAN NOT PASS THROUGH THE FILTER PAPER unless the paper is damaged.

Next there are a lot of things that are ferro magnetic, like gravel dust for one.

Oil filters on mowers get changed on an hours of operation or lapsed time basis, not on a full yet basis.

And yes the oil filter thread can be NPT or Metric

However the thread cout & profiles are close enough for it not to matter.

Remember these are no formula 1 engines running at 11 tenths of their design limits

Mower engines , now that Honda have exited the market are the cheapest easiest to make lowest output engines it is possible to manufacture & sell.

They are really not much more advanced technically that they were in 1920

#31

B

Bange

B

Bange

My level of knowledge in this equipment is very low, so some questions may seem naive, but I believe they are valid since most users are in fact ignorant and I believe that this forum exists to clarify doubts about defects, operation, exchange experiences as you and many others do so gently.

Of course, these engines are very simple, but if treated with the care and importance of a Formula 1, they should give the owner a lot more satisfaction.

I do not know, internally or for information (now I do), an original B&S filter with a bypass valve, I know that in the automotive industry there is ... but I see no problem with having an extra guarantee with a magnetic trap, like in a car.

In the event that the owner changes the filter regularly, I think that the presence of such a trap can prove the quality of the filter, show that the change must be made in less time or even that a random or manufacturing problem has occurred.

To change the filter itself, it's like the drain without the extension ... the oil runs over the chassis ... I saw a JD model with an "easy change" filter, very smart ... there is something similar for the 31P777 ?

Of course, these engines are very simple, but if treated with the care and importance of a Formula 1, they should give the owner a lot more satisfaction.

I do not know, internally or for information (now I do), an original B&S filter with a bypass valve, I know that in the automotive industry there is ... but I see no problem with having an extra guarantee with a magnetic trap, like in a car.

In the event that the owner changes the filter regularly, I think that the presence of such a trap can prove the quality of the filter, show that the change must be made in less time or even that a random or manufacturing problem has occurred.

To change the filter itself, it's like the drain without the extension ... the oil runs over the chassis ... I saw a JD model with an "easy change" filter, very smart ... there is something similar for the 31P777 ?

#32

B

Bange

B

Bange

Well ... I bought another automotive filter with the same thread as the previous one (M20), only a little bigger.

This decision was not to further spoil what was started by the previous owner.

I also opened the old filter to analyze more filings and get to know it from the inside.

I washed it with gasoline to loosen the oil and filings, then I filtered the coffee (rs) and captured the filings with the magnet.

I certainly didn't capture everything and I don't know if it's too much or too little.

In the oil filter element, not everything that shone was made of iron.

I discovered the two internal valves ...

One thing that worries me is the bypass valve spring ... it is very strong and depending on the pressure of the pump, it will not open in the event of a clog and the internal irrigation of the engine can be impaired. In cars around here, the oil pressure ranges from 20 to 70 PSI, depending on the engine, I don't know what my B&S pressure is ... would anyone know?

This decision was not to further spoil what was started by the previous owner.

I also opened the old filter to analyze more filings and get to know it from the inside.

I washed it with gasoline to loosen the oil and filings, then I filtered the coffee (rs) and captured the filings with the magnet.

I certainly didn't capture everything and I don't know if it's too much or too little.

In the oil filter element, not everything that shone was made of iron.

I discovered the two internal valves ...

One thing that worries me is the bypass valve spring ... it is very strong and depending on the pressure of the pump, it will not open in the event of a clog and the internal irrigation of the engine can be impaired. In cars around here, the oil pressure ranges from 20 to 70 PSI, depending on the engine, I don't know what my B&S pressure is ... would anyone know?

#33

V

Virgil_c

www.ereplacementparts.com

www.ereplacementparts.com

V

Virgil_c

Not sure where you are but check This outHey guys!

As some already know, I am repairing a Murray 42" with B&S 31P777 and one of the problems is the oil plug that came with a water valve (don't laugh).

I need to know the measures of such a plug to make an appropriate one, because here it is either very expensive or it is very difficult to get original parts.

I need the following measures:

What is the external measure of the plug thread?

How many threads per inch? I believe it is 20 ... is that correct?

Wrong valve...?

View attachment 56204

View attachment 56205

Plug-Oil Drain 691680 - OEM Briggs and Stratton - eReplacementParts.com

Buy the official Briggs and Stratton Plug-Oil Drain 691680 replacement - Use our model diagrams, repair help, and video tutorials to help get the job done.

#34

B

Bange

B

Bange

Virgil_c

I live a little far from the big lawn mower market (USA), where everything that is imported is very expensive or difficult to find. Things that are simple and even cheap for Americans, are complicated and expensive for Brazilians, leaving us with the creativity for various solutions.

The problem (plug) has already been solved, leaving two questions:

1 - What is the pressure of the B&S 31P777 oil pump?

2 - How and where to place a magnetic trap to capture iron filings?

These are important questions for me, but they do not prevent the machine from working and can wait a longer time.

I saw an adapter on Amazon (Briggs & Stratton 492061 Remote Oil Filter Adapter), which can solve both issues and a third one, which is the clean filter change ... but the price to get my hands more than doubles and the solution is also to make one, and this is not difficult for me.

I live a little far from the big lawn mower market (USA), where everything that is imported is very expensive or difficult to find. Things that are simple and even cheap for Americans, are complicated and expensive for Brazilians, leaving us with the creativity for various solutions.

The problem (plug) has already been solved, leaving two questions:

1 - What is the pressure of the B&S 31P777 oil pump?

2 - How and where to place a magnetic trap to capture iron filings?

These are important questions for me, but they do not prevent the machine from working and can wait a longer time.

I saw an adapter on Amazon (Briggs & Stratton 492061 Remote Oil Filter Adapter), which can solve both issues and a third one, which is the clean filter change ... but the price to get my hands more than doubles and the solution is also to make one, and this is not difficult for me.

#35

S

sheenist

S

sheenist

Bange:A simple way to determine the size and threads per inch is to find or create a piece of round wood that is slightly tapered to start in the threaded hole. Screw into the threaded hole abaou a 1/2" then remove. The marks left on the wood will tell you the correct number of threads per inch. It will also tell you the minor dia. of the thread. I have seen this done with a small limb from a tree that had the bark removed with a pocket knife. It takes longer to read this than to do it. Good luck.

Sheenist

Sheenist

#36

VRR.DYNDNS>BIZ

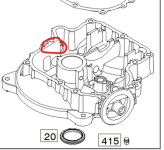

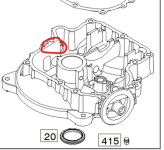

The red circle is the location of the drain plug. Also, synthetic oil is over kill and wasted money in my opinion. Low oil casuess damage but in 50 years i HAVE ONLY SEEN 1 engine damaged from poor oil changes and that was caused by oil port pluggage.

The red circle is the location of the drain plug. Also, synthetic oil is over kill and wasted money in my opinion. Low oil casuess damage but in 50 years i HAVE ONLY SEEN 1 engine damaged from poor oil changes and that was caused by oil port pluggage.

VRR.DYNDNS>BIZ

My level of knowledge in this equipment is very low, so some questions may seem naive, but I believe they are valid since most users are in fact ignorant and I believe that this forum exists to clarify doubts about defects, operation, exchange experiences as you and many others do so gently.

Of course, these engines are very simple, but if treated with the care and importance of a Formula 1, they should give the owner a lot more satisfaction.

I do not know, internally or for information (now I do), an original B&S filter with a bypass valve, I know that in the automotive industry there is ... but I see no problem with having an extra guarantee with a magnetic trap, like in a car.

In the event that the owner changes the filter regularly, I think that the presence of such a trap can prove the quality of the filter, show that the change must be made in less time or even that a random or manufacturing problem has occurred.

To change the filter itself, it's like the drain without the extension ... the oil runs over the chassis ... I saw a JD model with an "easy change" filter, very smart ... there is something similar for the 31P777 ?

The red circle is the location of the drain plug. Also, synthetic oil is over kill and wasted money in my opinion. Low oil casuess damage but in 50 years i HAVE ONLY SEEN 1 engine damaged from poor oil changes and that was caused by oil port pluggage.

The red circle is the location of the drain plug. Also, synthetic oil is over kill and wasted money in my opinion. Low oil casuess damage but in 50 years i HAVE ONLY SEEN 1 engine damaged from poor oil changes and that was caused by oil port pluggage.

#37

VRR.DYNDNS>BIZ

VRR.DYNDNS>BIZ

B&S has lawn mower engines today that do not recommend oil changes over the life of the engine. I agree, as long as the level is maintained.

#40

B

Bange

As for gearboxes, without contact with fuel and the outside environment, it is more than logical.

As for the level, regardless of the combustion engine or gearbox, it must always be inspected and topped up during its useful life...because if the volume is insufficient, lubrication is impaired and the engine's useful life is reduced.

B

Bange

Well, I find it strange that an internal combustion engine manufacturer does not recommend changing the oil, as it deteriorates, loses its lubricating characteristics, whether due to mileage, downtime or hours of use.B&S has lawn mower engines today that do not recommend oil changes over the life of the engine. I agree, as long as the level is maintained.

As for gearboxes, without contact with fuel and the outside environment, it is more than logical.

As for the level, regardless of the combustion engine or gearbox, it must always be inspected and topped up during its useful life...because if the volume is insufficient, lubrication is impaired and the engine's useful life is reduced.

#41

B

bertsmobile1

They did a Vox Pop and found out that most home owners hate doing oil changes, so they eliminated it

Back in the days when a mower could last 50 years if maintained properly, maintenance was important.

Now days when 2 years is considered a reasonable service life and by 5 years they are worn out or in Cal no longer EPA compliant why bother to change the oil.

People conflate car & truck engines with mower engines

They only similarity is the parts have the same names

IF your car needed an oil change every 50 to 100 hours you would be doing it almost weekly

Most mowers will happily fun for several years on the original oil without mush in the way of adverse effects

Unlike pressure fed lubrications systems, full splash does not allow contaminants that can cause excessive wear into the journals because there is not the space for them to get in.

This is why the old side valve engines would run with treacle in the sump.

And yes they would run better but mower engines are very low stress engines

My 125 cc 2 stroke premix motorcycle has 14 Hp and will push me along at 60 mph on the flat all day long running at 6000 rpm

My 250 cc 4 stroke full splash 1927 motorcycle will do the same running at it's top speed of 4,500 rpm

Yet my 500cc mower engine stuggles to cut the grass

B

bertsmobile1

SimpleWell, I find it strange that an internal combustion engine manufacturer does not recommend changing the oil, as it deteriorates, loses its lubricating characteristics, whether due to mileage, downtime or hours of use.

As for gearboxes, without contact with fuel and the outside environment, it is more than logical.

As for the level, regardless of the combustion engine or gearbox, it must always be inspected and topped up during its useful life...because if the volume is insufficient, lubrication is impaired and the engine's useful life is reduced.

They did a Vox Pop and found out that most home owners hate doing oil changes, so they eliminated it

Back in the days when a mower could last 50 years if maintained properly, maintenance was important.

Now days when 2 years is considered a reasonable service life and by 5 years they are worn out or in Cal no longer EPA compliant why bother to change the oil.

People conflate car & truck engines with mower engines

They only similarity is the parts have the same names

IF your car needed an oil change every 50 to 100 hours you would be doing it almost weekly

Most mowers will happily fun for several years on the original oil without mush in the way of adverse effects

Unlike pressure fed lubrications systems, full splash does not allow contaminants that can cause excessive wear into the journals because there is not the space for them to get in.

This is why the old side valve engines would run with treacle in the sump.

And yes they would run better but mower engines are very low stress engines

My 125 cc 2 stroke premix motorcycle has 14 Hp and will push me along at 60 mph on the flat all day long running at 6000 rpm

My 250 cc 4 stroke full splash 1927 motorcycle will do the same running at it's top speed of 4,500 rpm

Yet my 500cc mower engine stuggles to cut the grass

#42

F

Forest#2

F

Forest#2

Do as scrubcadet10 says.

Get a 3/8 NPT pipe nipple 4 inches long, galvanized or black iron, a 3/8 pipe CAP and a roll of teflon tape 1/2 or 3/4 inch wide. Put 3 layers of teflon tape on the pipe threads (wrapped opposite direction from the way the threads turn into the block) Take a pair of pliers or channel locks and gently snug the pipe nipple into the ALUMINUM BLOCK. If you tighten the pipe nipple too tight YOU WILL CRACK THE ALUMINUM BLOCK because it's a taper threaded pipe and block and wedges or expands the aluminum as it gets tighter. Then install 3 layers of teflon on the pipe nipple and install the cap. The 4 inch long nipple will allow you to drain/change the oil into a catch pan by removing the cap instead of letting the oil spill onto the mower frame.

As they say you are over thunking.

Get a 3/8 NPT pipe nipple 4 inches long, galvanized or black iron, a 3/8 pipe CAP and a roll of teflon tape 1/2 or 3/4 inch wide. Put 3 layers of teflon tape on the pipe threads (wrapped opposite direction from the way the threads turn into the block) Take a pair of pliers or channel locks and gently snug the pipe nipple into the ALUMINUM BLOCK. If you tighten the pipe nipple too tight YOU WILL CRACK THE ALUMINUM BLOCK because it's a taper threaded pipe and block and wedges or expands the aluminum as it gets tighter. Then install 3 layers of teflon on the pipe nipple and install the cap. The 4 inch long nipple will allow you to drain/change the oil into a catch pan by removing the cap instead of letting the oil spill onto the mower frame.

As they say you are over thunking.

#44

B

bertsmobile1

B

bertsmobile1

Reported

But perhaps we should allow all of the idiots who wan to kill themselves self medicating with methotrexate ( which is highly toxic ) fill themselves as the world would be better off without them

But perhaps we should allow all of the idiots who wan to kill themselves self medicating with methotrexate ( which is highly toxic ) fill themselves as the world would be better off without them

#45

S

sheenist

S

sheenist

From what I see in the pic, it looks like a special fine thread. Take the unit that screws into the threaded hole to your local friendly machinist and he will measure the male thread and tell you what it is. It is NOT water pipe threads, I can guarantee you.

Sheenist

Sheenist