You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Help to identify this strimmer make and model

#1

M

Mickrick

M

Mickrick

Hi, I was given this strimmer and would like to get it up and running again for a local community interest group to use. Trouble is there are absolutely no identifying marks on it whatsoever apart from Walbro and Stihl on the carburretor. I am planning to replace the damaged wiring and probably get a new aftermarket carburettor. Can anybody help me find out what make and model this is and what type of new carburettor it needs? Thanks in advance.

Edit: Carburettor is a WA163 it seems but may only be able to buy a refurb kit. Make and model of strimmer still unknown.

Edit: Carburettor is a WA163 it seems but may only be able to buy a refurb kit. Make and model of strimmer still unknown.

Attachments

#3

Fish

www.ereplacementparts.com

www.ereplacementparts.com

Fish

Echo SRM-250E Straight Shaft Trimmer / Brushcutter OEM Replacement Parts From eReplacementParts.com

Shop OEM replacement parts by symptoms or model diagrams for your Echo SRM-250E Straight Shaft Trimmer / Brushcutter!

#6

Fish

Let me see if I can run down the model.

Fish

ECHO air filter, #13031006530, new old stock | eBay

Find many great new & used options and get the best deals for ECHO air filter, #13031006530, new old stock at the best online prices at eBay! Free shipping for many products!

www.ebay.com

Let me see if I can run down the model.

#7

Fish

www.ereplacementparts.com

www.ereplacementparts.com

Fish

Echo SRM-250E Straight Shaft Trimmer / Brushcutter OEM Replacement Parts From eReplacementParts.com

Shop OEM replacement parts by symptoms or model diagrams for your Echo SRM-250E Straight Shaft Trimmer / Brushcutter!

#9

M

Mickrick

M

Mickrick

I am - Liverpool in the UK. Definitely looks like the Echo SRM-250E U-handle version from those diagrams. Unfortunately, the ignition coil appears to be discontinued so I'm going to have to bodge this where the lead has almost completely detached. I think a scrap lead and a heavy duty crimp connector are my best bet. Thanks for your help.

Attachments

#10

M

Mickrick

M

Mickrick

One further question if I may - how on earth do you prime these WA163 carburettors if there's no bulb? Tried blowing into the tank filler to pressurize the fuel line but that only filled the line a few inches. Have fed fuel in through the air filter port and started it but the strimmer dies before the fuel is drawn all the way up to the carb. Quite puzzling particularly as it's a new fuel line and filter.

#11

Fish

Fish

Your carb is likely gummed up with old gas. Only some trimmers used bulbs, they pull fuel into the carb to purge out the air, not primer the engine. The choke is used to pull the fuel into the engine.

#12

M

Mickrick

M

Mickrick

Thanks once again. I have replaced all the diaphragms and gaskets in the carb along with the needle assembly. Sprayed carb cleaner everywhere down every visible hole while doing this and so am fairly sure it's as clean as it's going to be. So to draw the fuel up the feed pipe I need to run the engine (for 5 seconds at a time dropping in fuel via the air intake port) with the choke fully on? Also, am awaiting new gasket material so I can remake the last gasket from the carb to the engine body as the existing one is a bit manky. If the impulse port is being blocked as I reassemble the engine (due to lack of positive location of the gasket) then I guess there'll be no pumping action at the diaphragm.Your carb is likely gummed up with old gas. Only some trimmers used bulbs, they pull fuel into the carb to purge out the air, not primer the engine. The choke is used to pull the fuel into the engine.

#13

B

bertsmobile1

For quite some time the check valves fitted to cube carbs have a rubber that is badly affected by carb cleaner

Slide the carb off the mounting bolts but leave the fuel lines attached.

Blow through the carb air hole holding the throttle wide open

You should get a strong flow of atomised fuel blowing out the engine side if the carb is working as it should

And this will happen even if the fuel lines were originally empty as the high speed air will suck fuel right out of the fuel tank .

B

bertsmobile1

I wish I had not seen this replyThanks once again. I have replaced all the diaphragms and gaskets in the carb along with the needle assembly. Sprayed carb cleaner everywhere down every visible hole while doing this and so am fairly sure it's as clean as it's going to be. So to draw the fuel up the feed pipe I need to run the engine (for 5 seconds at a time dropping in fuel via the air intake port) with the choke fully on? Also, am awaiting new gasket material so I can remake the last gasket from the carb to the engine body as the existing one is a bit manky. If the impulse port is being blocked as I reassemble the engine (due to lack of positive location of the gasket) then I guess there'll be no pumping action at the diaphragm.

For quite some time the check valves fitted to cube carbs have a rubber that is badly affected by carb cleaner

Slide the carb off the mounting bolts but leave the fuel lines attached.

Blow through the carb air hole holding the throttle wide open

You should get a strong flow of atomised fuel blowing out the engine side if the carb is working as it should

And this will happen even if the fuel lines were originally empty as the high speed air will suck fuel right out of the fuel tank .

#14

M

Mickrick

M

Mickrick

Thanks once again. Tried this this morning but it had absolutely no effect on the fuel level in the feed pipe - didn't budge a jot. I closed the choke, pulled the starter cord repeatedly and could see the level in feed pipe rising slowly so can tell that there is some connection between the carb and the fuel tank (i.e.the new needle isn't stuck down). However, when I loosened the carb away from the piston side, pushed the outlet of a paddling pool inflator style air pump into the air filter side and opened the throttle, the level didn't budge suggesting there isn't enough vacuum being generated to open the needle. All very frustrating. I dismantled the carb again to look for the check valves that some Youtube videos suggest can become blocked but couldn't see any. Is this a feature of the WA163 would you say or do all cube carbs have internal check valves somewhere? I don't have one but would ultrasonic cleaning help at all?I wish I had not seen this reply

For quite some time the check valves fitted to cube carbs have a rubber that is badly affected by carb cleaner

Slide the carb off the mounting bolts but leave the fuel lines attached.

Blow through the carb air hole holding the throttle wide open

You should get a strong flow of atomised fuel blowing out the engine side if the carb is working as it should

And this will happen even if the fuel lines were originally empty as the high speed air will suck fuel right out of the fuel tank .

#15

M

Mickrick

As you can see from the first set of photos, I have this sort of trimming head; yellow with six drive lugs on the spool.

Can anyone tell me how you are supposed to advance the line feed on these heads as it's certainly not a bump head? Maybe loosen the nut, pull apart the spool and head and twist 60 degrees perhaps?

Thanks

M

Mickrick

Got the machine running now (a little intermittently at time) - thanks for all your help.Hi, I was given this strimmer and would like to get it up and running again for a local community interest group to use. Trouble is there are absolutely no identifying marks on it whatsoever apart from Walbro and Stihl on the carburretor. I am planning to replace the damaged wiring and probably get a new aftermarket carburettor. Can anybody help me find out what make and model this is and what type of new carburettor it needs? Thanks in advance.

Edit: Carburettor is a WA163 it seems but may only be able to buy a refurb kit. Make and model of strimmer still unknown.

As you can see from the first set of photos, I have this sort of trimming head; yellow with six drive lugs on the spool.

Can anyone tell me how you are supposed to advance the line feed on these heads as it's certainly not a bump head? Maybe loosen the nut, pull apart the spool and head and twist 60 degrees perhaps?

Thanks

Attachments

#16

M

Mickrick

M

Mickrick

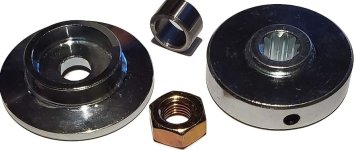

A further question if I may. What is the thread designation of the head end of the strimmer? I tried a M8 LH thread but the pitch was incorrect it seems as it bound up within a turn. Any help gratefully received.I am - Liverpool in the UK. Definitely looks like the Echo SRM-250E U-handle version from those diagrams. Unfortunately, the ignition coil appears to be discontinued so I'm going to have to bodge this where the lead has almost completely detached. I think a scrap lead and a heavy duty crimp connector are my best bet. Thanks for your help.

Attachments

#18

Fish

Fish

It looks like it should come off easily, and putting a replacement head, or even a blade is fairly easy.

This outfit here looks to be over on you side of the world.

www.diyspareparts.com

www.diyspareparts.com

This outfit here looks to be over on you side of the world.

Echo SRM-250 (SRM-250) Parts Diagram, Page 9

View Echo SRM-250 (SRM-250) Parts Diagram , Page 9 to easily locate and buy the spares that fit this machine.

#19

B

bertsmobile1

M8 LH could be 0.75mm ( super fine ) 1.0mm ( fine ) 1.25mm ( std ) or 1.5mm ( coarse ) pitches

It could also be a 7mm thread as used on some Japanese made trimmers

B

bertsmobile1

Unfortunately they do not usually indicate the threads used in parts books lest you buy them from a hard wear shopA further question if I may. What is the thread designation of the head end of the strimmer? I tried a M8 LH thread but the pitch was incorrect it seems as it bound up within a turn. Any help gratefully received.

M8 LH could be 0.75mm ( super fine ) 1.0mm ( fine ) 1.25mm ( std ) or 1.5mm ( coarse ) pitches

It could also be a 7mm thread as used on some Japanese made trimmers

#20

upupandaway

It looks like the Stihl FS81/86 which were made by Zenoah aka: Redmax so he could look at these for parts.

Mickrick,

If I were you, I would try a carb for a Stihl FS74 FS76 HT70 HT75 FS80R FS85R FS55 FS45 etc. It is the same size cube. That's what I did with my 80's Zenoah trimmer.

BTW, that will also fix your primer issue.

upupandaway

*BUT*It is not a Stihl.

Maybe Echo.

It looks like the Stihl FS81/86 which were made by Zenoah aka: Redmax so he could look at these for parts.

Mickrick,

If I were you, I would try a carb for a Stihl FS74 FS76 HT70 HT75 FS80R FS85R FS55 FS45 etc. It is the same size cube. That's what I did with my 80's Zenoah trimmer.

BTW, that will also fix your primer issue.

#21

M

Mickrick

M

Mickrick

Thanks for the tip*BUT*

It looks like the Stihl FS81/86 which were made by Zenoah aka: Redmax so he could look at these for parts.

Mickrick,

If I were you, I would try a carb for a Stihl FS74 FS76 HT70 HT75 FS80R FS85R FS55 FS45 etc. It is the same size cube. That's what I did with my 80's Zenoah trimmer.

#22

upupandaway

If so, you pull it out then turn it to give it more string then the pins fall back into the holes.

With the pic of the threads, maybe you should look at the Stihl(again) FS36 head if u find doing this annoying. It looks familiar.

upupandaway

Is the head orange plastic with the bottom like a big upside down cup that has like 8 holes that pins fall in???Got the machine running now (a little intermittently at time) - thanks for all your help.

As you can see from the first set of photos, I have this sort of trimming head; yellow with six drive lugs on the spool.

Can anyone tell me how you are supposed to advance the line feed on these heads as it's certainly not a bump head? Maybe loosen the nut, pull apart the spool and head and twist 60 degrees perhaps?

Thanks

If so, you pull it out then turn it to give it more string then the pins fall back into the holes.

With the pic of the threads, maybe you should look at the Stihl(again) FS36 head if u find doing this annoying. It looks familiar.

#23

M

Mickrick

If I lock the circular part above the arbor with a drill bit through it into the hole below, do I just then put a spanner on the square section and turn? If so, is it CW or CCW to loosen? If I do manage to get it off, I take it I can look for a replacement arbor (e.g. a Stihl compatible one) so that I can fit an 8" twisted wire brush weeding disc (which is what prompted the question about the thread designation in the first place)?

Thanks again

M

Mickrick

Thanks for your reply.See if you can remove the arbor, it goes with the old trimmer head. See what is underneath. Just put a drill bit in the hole to lock things, but don't use too much force.View attachment 66604

If I lock the circular part above the arbor with a drill bit through it into the hole below, do I just then put a spanner on the square section and turn? If so, is it CW or CCW to loosen? If I do manage to get it off, I take it I can look for a replacement arbor (e.g. a Stihl compatible one) so that I can fit an 8" twisted wire brush weeding disc (which is what prompted the question about the thread designation in the first place)?

Thanks again

#24

M

Mickrick

I've taken to loosening the bottom tri-lobe nut sufficiently to pull the spool far enough down to disengage the six lugs. I then turn it 60 degrees anti clockwise and pull on each of the two line ends to lengthen each by an inch or so. Repeat this far too often unfortunately as I'm strimming agains concrete so the working length shortens very quickly

Thanks for the tip about the FS36 - will probably need to change the arbor I guess?

M

Mickrick

It's as per this photo.Is the head orange plastic with the bottom like a big upside down cup that has like 8 holes that pins fall in???

If so, you pull it out then turn it to give it more string then the pins fall back into the holes.

With the pic of the threads, maybe you should look at the Stihl(again) FS36 head if u find doing this annoying. It looks familiar.

I've taken to loosening the bottom tri-lobe nut sufficiently to pull the spool far enough down to disengage the six lugs. I then turn it 60 degrees anti clockwise and pull on each of the two line ends to lengthen each by an inch or so. Repeat this far too often unfortunately as I'm strimming agains concrete so the working length shortens very quickly

Thanks for the tip about the FS36 - will probably need to change the arbor I guess?

Attachments

#25

upupandaway

(sorry I just noticed now, the yellow head with 6 pins- same as mine just not orange and not 8 pins. I was thinking 8 off top of my head.)

When u remove the adapter, if u get a female thread, maybe the FS80 tap head bolt adapter to fit current tap heads fits yours...

Some one is selling them: https://www.ebay.com/itm/1443233688...nRiDF89flkgR5Uibahi3OYcvU=|tkp:Bk9SR_LgicDNYg

BTW, don't get a trimmer head with 2 dangling chainsaw chains. It was sold by echo and stihl back in the 80's until it was recalled. My fs80 actually had that head. I read the recall only after one of the chains came off. Lucky I still have both ankles.

upupandaway

That would just remove the adapter bolt Fish posted. That would leave u a bolt for a cutter head or the like which you would need to buy a LH\RH nut.I just then put a spanner on the square section and turn?

(sorry I just noticed now, the yellow head with 6 pins- same as mine just not orange and not 8 pins. I was thinking 8 off top of my head.)

When u remove the adapter, if u get a female thread, maybe the FS80 tap head bolt adapter to fit current tap heads fits yours...

Some one is selling them: https://www.ebay.com/itm/1443233688...nRiDF89flkgR5Uibahi3OYcvU=|tkp:Bk9SR_LgicDNYg

BTW, don't get a trimmer head with 2 dangling chainsaw chains. It was sold by echo and stihl back in the 80's until it was recalled. My fs80 actually had that head. I read the recall only after one of the chains came off. Lucky I still have both ankles.

#26

M

Mickrick

M

Mickrick

Ouch!That would just remove the adapter bolt Fish posted. That would leave u a bolt for a cutter head or the like which you would need to buy a LH\RH nut.

(sorry I just noticed now, the yellow head with 6 pins- same as mine just not orange and not 8 pins)

BTW, don't get a trimmer head with 2 dangling chainsaw chains. It was sold by echo and stihl back in the 80's until it was recalled. My fs80 actually had that head. I read the recall only after one of the chains came off. Lucky I still have both ankles.

#28

M

Mickrick

Edit: just re-read - CCW to loosen. Thanks.

M

Mickrick

Great - thanks again. And for the benefit of my 36" Stilsons, CW or CCW to loosen?Yes, the arbor comes off like a bolt/nut, reverse thread, and you can attach a blade, or another universal type head. They will come in a form like this.

View attachment 66618

Edit: just re-read - CCW to loosen. Thanks.

#30

Fish

Fish

Clockwise/reverse thread.Great - thanks again. And for the benefit of my 36" Stilsons, CW or CCW to loosen?

#32

upupandaway

Don't know if your old tap head isn't common now, don't know if it is still reasonable $$ wise. It could be cheaper to get a used current gearbox and head if it fits the drive shaft.

upupandaway

last hacker tidbit, but if finding the original OEM compatible tap head is too much trouble, Look up the gearbox for a current echo trimmer. I say this because I had an even older Echo DA200(70's-80's almost identical to original Stihl fs80) and the motor fit the current echo shaft.Thanks again to everyone for their input on this - I really appreciate it.

Don't know if your old tap head isn't common now, don't know if it is still reasonable $$ wise. It could be cheaper to get a used current gearbox and head if it fits the drive shaft.