You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Guidance for replacing spindle bearings on Tiger Cub

#1

A

aggiejet

A

aggiejet

My local Scag dealer will no longer rebuild (replace bearing and seals) in my Tiger Cub spindle so I thought I might attempt it myself as opposed to buying a new $250 spindle. However, my first attempt at removing the spindle nut proved futile. I am using a 1/2” impact gun on the nut, but I can’t keep the spindle from spinning while clamped in the jaws of a 4” vise.

So is there a technique for removing the spindle nut beyond the obvious ( bigger vise and impact)? Additionally, what is the torque for installation of the new bearings?

So is there a technique for removing the spindle nut beyond the obvious ( bigger vise and impact)? Additionally, what is the torque for installation of the new bearings?

#2

B

bertsmobile1

B

bertsmobile1

The usual method is to take the pulley bolt off first while holding the blade then pull the spindle out leaving the blade on the spindle

Unless they bearings are heat shrunk into the housing ( heat the housing & chill the bearings ) there are only so many times you can replace the bearings before there is too much wear and the bearing will not be held secure enough in the housing

As for the blade retainer, they self tighten in use particularly if you do not keep the blades sharp

I often have to cut the heads off after which they will undo with my fingers .

Round things need to be held in a pipe clamp or between a pair of V blocks

Unless they bearings are heat shrunk into the housing ( heat the housing & chill the bearings ) there are only so many times you can replace the bearings before there is too much wear and the bearing will not be held secure enough in the housing

As for the blade retainer, they self tighten in use particularly if you do not keep the blades sharp

I often have to cut the heads off after which they will undo with my fingers .

Round things need to be held in a pipe clamp or between a pair of V blocks

#3

StarTech

StarTech

You would need a thin wall impact socket. I believe I use a 12 point 1-1/2" deep well socket here but it has been a few year since my last rebuild of one these as I can get Oregon 82-325 spindles as low if not lower then the parts alone. You also need a long punch and heavy to drive out the bearing cups and Approiate OD sized socket to drive the cups back in. And of course wheel bearing grease. EP2.

For each spindle you would need:

481024 upper seal (35UC05)

481025 lower seal (Rotary 13523)

481022 taper bearing and cup set, 2 each (L44649/l44610)

And possibly the spindle shaft 43589 and the nut 481035, Reason being the threads on the lower side gets damaged from mowing.

From a shop view point it is less time consuming and more profitable to install the after market spindles.

For each spindle you would need:

481024 upper seal (35UC05)

481025 lower seal (Rotary 13523)

481022 taper bearing and cup set, 2 each (L44649/l44610)

And possibly the spindle shaft 43589 and the nut 481035, Reason being the threads on the lower side gets damaged from mowing.

From a shop view point it is less time consuming and more profitable to install the after market spindles.

#4

A

aggiejet

I have gotten about 1200 hours out of my original spindle bearings. What kind of life are you getting with the Oregon brand? Do you know what brand of bearings they use?

A

aggiejet

Thanks for the replies. Good idea about V block. I also didn’t give the race replacement much thought. That would be a challenge as well. Just seems a waste not to “just“ replace the bearings, but it appears to be a much larger task than I envisioned.You would need a thin wall impact socket. I believe I use a 12 point 1-1/2" deep well socket here but it has been a few year since my last rebuild of one these as I can get Oregon 82-325 spindles as low if not lower then the parts alone. You also need a long punch and heavy to drive out the bearing cups and Approiate OD sized socket to drive the cups back in. And of course wheel bearing grease. EP2.

For each spindle you would need:

481024 upper seal (35UC05)

481025 lower seal (Rotary 13523)

481022 taper bearing and cup set, 2 each (L44649/l44610)

And possibly the spindle shaft 43589 and the nut 481035, Reason being the threads on the lower side gets damaged from mowing.

From a shop view point it is less time consuming and more profitable to install the after market spindles.

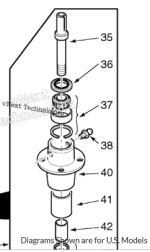

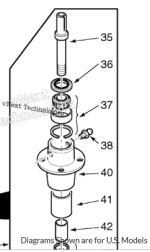

View attachment 65399

I have gotten about 1200 hours out of my original spindle bearings. What kind of life are you getting with the Oregon brand? Do you know what brand of bearings they use?

#5

B

bertsmobile1

B

bertsmobile1

Fortunately most tapered roller bearings are fairly good.

I have a lot of old 2000 & 3000 series Cubs that also use the correct bearing for blade spindles, tapered rollers .

When they get a little slack I take a few thou off the spacer.

To date the only actual bearings replaced were off a couple of mowers where the owners never greased them

Down side is of course the spacers will need to be replaced when new bearings are fitted but on these housing the bearings should last almost forever .

The shop up the road replaces the bearings when they get the slightest wear because he does not machine the spacer so he can not take up the wear .

Think about wheel bearings , you just keep repacking them and nipping up the bolts till you get significant grooves in the cups .

I have a lot of old 2000 & 3000 series Cubs that also use the correct bearing for blade spindles, tapered rollers .

When they get a little slack I take a few thou off the spacer.

To date the only actual bearings replaced were off a couple of mowers where the owners never greased them

Down side is of course the spacers will need to be replaced when new bearings are fitted but on these housing the bearings should last almost forever .

The shop up the road replaces the bearings when they get the slightest wear because he does not machine the spacer so he can not take up the wear .

Think about wheel bearings , you just keep repacking them and nipping up the bolts till you get significant grooves in the cups .

#6

A

aggiejet

A

aggiejet

I’m not sure what you mean by “pulley bolt”? The belt pulley is held in place by a tapered collar, which uses two 1/4”x1” bolts to attach it to the pulley.The usual method is to take the pulley bolt off first while holding the blade then pull the spindle out leaving the blade on the spindle

Unless they bearings are heat shrunk into the housing ( heat the housing & chill the bearings ) there are only so many times you can replace the bearings before there is too much wear and the bearing will not be held secure enough in the housing

As for the blade retainer, they self tighten in use particularly if you do not keep the blades sharp

I often have to cut the heads off after which they will undo with my fingers .

Round things need to be held in a pipe clamp or between a pair of V blocks

Attachments

#7

StarTech

Those same screws are used to remove the pulley pressing out the tapered collar. Personally I recommend those 1/4" cap screws be grade 8 rated. Even then those collars can be a little stubborn about coming out.

StarTech

It just Bert throwing something out without even looking up the mower. Assuming things will get you into trouble at times. This is why I normally need the equipment actual model number so I can look it before responding. Just too many designs to remember everything.I’m not sure what you mean by “pulley bolt”? The belt pulley is held in place by a tapered collar, which uses two 1/4”x1” bolts to attach it to the pulley.

Those same screws are used to remove the pulley pressing out the tapered collar. Personally I recommend those 1/4" cap screws be grade 8 rated. Even then those collars can be a little stubborn about coming out.

#8

A

aggiejet

A

aggiejet

Not only grade 8, but fresh new grade 8. I twisted both of mine off removing the right spindle last week. But mine are the originals and about 20 years/1200 hours old. I’m sure they’re a little fatigued. I’m working on making a YouTube of it in an effort to save somebody a little frustration.It just Bert throwing something out without even looking up the mower. Assuming things will get you into trouble at times. This is why I normally need the equipment actual model number so I can look it before responding. Just too many designs to remember everything.

Those same screws are used to remove the pulley pressing out the tapered collar. Personally I recommend those 1/4" cap screws be grade 8 rated. Even then those collars can be a little stubborn about coming out.

#9

B

bertsmobile1

Memory is not what it used to be .

However the tip about shortening the inner spacer still holds

The outer races are a problem because they are really difficult to knock out .

It is SOP for tapered rollers where the bearing cones do not have adjusters

Some gear ( not mowers ) use shims to set the bearing preload

B

bertsmobile1

Guilty as chargedIt just Bert throwing something out without even looking up the mower. Assuming things will get you into trouble at times. This is why I normally need the equipment actual model number so I can look it before responding. Just too many designs to remember everything.

Those same screws are used to remove the pulley pressing out the tapered collar. Personally I recommend those 1/4" cap screws be grade 8 rated. Even then those collars can be a little stubborn about coming out.

Memory is not what it used to be .

However the tip about shortening the inner spacer still holds

The outer races are a problem because they are really difficult to knock out .

It is SOP for tapered rollers where the bearing cones do not have adjusters

Some gear ( not mowers ) use shims to set the bearing preload

#10

A

aggiejet

A

aggiejet

update :

I was able to disassemble the hub today. I soaked the spindle nut in Kroil for a couple of days and then today heated the nut and spindle with a hand held Mapp gas torch. Used a pipe wrench on opposite end of nut and used a standard 1 1/2” socket on 1/2” impact and nut came right off. Threads on spindle are in good shape.

I was only able to remove the race for the top bearing. The bottom bearing race does not display enough of a lip to get a bite with any punch or chisel I have.

I understand why nobody rebuilds these hubs now. It seems to me that the above mentioned race is not removable, and therefore most shops rebuilding one probably just replaces the bearings only. That’s really not a proper repair.

I also base my assumptions on the dearth of information regarding spindle rebuild guidance. That said, I’m looking for a torque value for the spindle nut. I’ve messaged Scag for the info and of course they haven’t replied.

I’m on a mission now. Keep ya posted.

I was able to disassemble the hub today. I soaked the spindle nut in Kroil for a couple of days and then today heated the nut and spindle with a hand held Mapp gas torch. Used a pipe wrench on opposite end of nut and used a standard 1 1/2” socket on 1/2” impact and nut came right off. Threads on spindle are in good shape.

I was only able to remove the race for the top bearing. The bottom bearing race does not display enough of a lip to get a bite with any punch or chisel I have.

I understand why nobody rebuilds these hubs now. It seems to me that the above mentioned race is not removable, and therefore most shops rebuilding one probably just replaces the bearings only. That’s really not a proper repair.

I also base my assumptions on the dearth of information regarding spindle rebuild guidance. That said, I’m looking for a torque value for the spindle nut. I’ve messaged Scag for the info and of course they haven’t replied.

I’m on a mission now. Keep ya posted.

#11

B

bertsmobile1

B

bertsmobile1

No information is because these jobs are done by skilled fitters who know

To remove tapered races the easiest way is to run a bead of electric weld fully around the middle of the race

When it cools the race will contract & drop out.

Again std practice in engineering workshops because doing it this way does not damage the housing

Installing is done by chilling the race & heating the housing

Workshops who do a lot of them will have CO2 pellets for the chilling because it will come out shrunk and DRY

If you put it in your freezer it must be in a sealed plastic bag with as much air as possible removed

When I do steering races on my vintage motorcycles I make a steel drift to install them with and chill the race on the drift so it haas big thermal mass so heats up slower .

I use the same set up for a few mower spindles where the bearings are a light press interfearance fit or tighter

To remove tapered races the easiest way is to run a bead of electric weld fully around the middle of the race

When it cools the race will contract & drop out.

Again std practice in engineering workshops because doing it this way does not damage the housing

Installing is done by chilling the race & heating the housing

Workshops who do a lot of them will have CO2 pellets for the chilling because it will come out shrunk and DRY

If you put it in your freezer it must be in a sealed plastic bag with as much air as possible removed

When I do steering races on my vintage motorcycles I make a steel drift to install them with and chill the race on the drift so it haas big thermal mass so heats up slower .

I use the same set up for a few mower spindles where the bearings are a light press interfearance fit or tighter

#12

A

aggiejet

A

aggiejet

Well if you have to run a bead on these races to extract it there is NO WAY a mower shop is doing that to rebuild one. And in my opinion, thats a bad design/engineering to make a spindle that bearing replacement takes that level of skill and special tools.No information is because these jobs are done by skilled fitters who know

To remove tapered races the easiest way is to run a bead of electric weld fully around the middle of the race

When it cools the race will contract & drop out.

Again std practice in engineering workshops because doing it this way does not damage the housing

Installing is done by chilling the race & heating the housing

Workshops who do a lot of them will have CO2 pellets for the chilling because it will come out shrunk and DRY

If you put it in your freezer it must be in a sealed plastic bag with as much air as possible removed

When I do steering races on my vintage motorcycles I make a steel drift to install them with and chill the race on the drift so it haas big thermal mass so heats up slower .

I use the same set up for a few mower spindles where the bearings are a light press interfearance fit or tighter

#13

B

bertsmobile1

Great Dane for instance has spindle bearings being replaced annually or at 100 Hrs which ever came first

One of the reason why mower companies switched to the wrong style of bearings ( deep groove balls ) is because they are cheaper to buy & install

On top of that every time you knock them out you take a bit of the housing out with them so after X bearing replacements it is new housing time .

A proficient shop with knowledgable mechanics would have done exactly what I suggested originally & shortened the spacer to take up the wear in the bearings then slipped in a spacer under the blade if needed to make up the difference in blade clearance .

That is the difference between a real mechanic and a parts swapper with no formal education or trade certification who are allowed to be called "technicians" which you will find in 99% of the mower shops .

Not meaning to sound rude but you seem to have little idea about what is good sound engineering practice

Good is seldom easy

And I do this regularly and I am a mower repair technician who runs a mower repair workshop for a living

If the tapers have been fitted properly then the thick end is inwards and sitting on a shoulder or retaining ring

If you want to chomp your knuckles with a hammer & punch then you get a big diameter punch, grind a long tapper on one edge so it can sit flat against the side of the housing then grind a step into the tapered edge so it can locate on the small protruding lip of the race

You can also use a long nail punch with a notch cut on the end to locate onto the race

I have even see a long cold chisel cut in a similar way

However all of these run the risk of damaging the lip that the race sits on which is why the bead of weld has been used for about as long as electric welding has been around.

In a workshop situation where the gear is there ready to use it is a 30 sec job

It takes longer to go to the corner and wheel the welder to the mower than it does to lay the bead and before you wheel the welder back you will hear the tinkle of the race hitting the floor .

And it is a lot faster then mucking around with hammers & punches

B

bertsmobile1

This is the difference between throw away domestic mowers & long life commercial mowersWell if you have to run a bead on these races to extract it there is NO WAY a mower shop is doing that to rebuild one. And in my opinion, thats a bad design/engineering to make a spindle that bearing replacement takes that level of skill and special tools.

Great Dane for instance has spindle bearings being replaced annually or at 100 Hrs which ever came first

One of the reason why mower companies switched to the wrong style of bearings ( deep groove balls ) is because they are cheaper to buy & install

On top of that every time you knock them out you take a bit of the housing out with them so after X bearing replacements it is new housing time .

A proficient shop with knowledgable mechanics would have done exactly what I suggested originally & shortened the spacer to take up the wear in the bearings then slipped in a spacer under the blade if needed to make up the difference in blade clearance .

That is the difference between a real mechanic and a parts swapper with no formal education or trade certification who are allowed to be called "technicians" which you will find in 99% of the mower shops .

Not meaning to sound rude but you seem to have little idea about what is good sound engineering practice

Good is seldom easy

And I do this regularly and I am a mower repair technician who runs a mower repair workshop for a living

If the tapers have been fitted properly then the thick end is inwards and sitting on a shoulder or retaining ring

If you want to chomp your knuckles with a hammer & punch then you get a big diameter punch, grind a long tapper on one edge so it can sit flat against the side of the housing then grind a step into the tapered edge so it can locate on the small protruding lip of the race

You can also use a long nail punch with a notch cut on the end to locate onto the race

I have even see a long cold chisel cut in a similar way

However all of these run the risk of damaging the lip that the race sits on which is why the bead of weld has been used for about as long as electric welding has been around.

In a workshop situation where the gear is there ready to use it is a 30 sec job

It takes longer to go to the corner and wheel the welder to the mower than it does to lay the bead and before you wheel the welder back you will hear the tinkle of the race hitting the floor .

And it is a lot faster then mucking around with hammers & punches

#14

Tiger Small Engine

Tiger Small Engine

I am surprised your shop used to rebuild spindles (original poster). If OEM spindles cost $250 each, consider aftermarket ones. I realize you are rebuilding yours. I tried to rebuild expensive spindles on a Wright Stander I used to have and gave up, everything was seized up. Need a bearing press to get them out. Anyway, nothing wrong with swimming upstream sometimes for the challenge, experience, and cost savings.This is the difference between throw away domestic mowers & long life commercial mowers

Great Dane for instance has spindle bearings being replaced annually or at 100 Hrs which ever came first

One of the reason why mower companies switched to the wrong style of bearings ( deep groove balls ) is because they are cheaper to buy & install

On top of that every time you knock them out you take a bit of the housing out with them so after X bearing replacements it is new housing time .

A proficient shop with knowledgable mechanics would have done exactly what I suggested originally & shortened the spacer to take up the wear in the bearings then slipped in a spacer under the blade if needed to make up the difference in blade clearance .

That is the difference between a real mechanic and a parts swapper with no formal education or trade certification who are allowed to be called "technicians" which you will find in 99% of the mower shops .

Not meaning to sound rude but you seem to have little idea about what is good sound engineering practice

Good is seldom easy

And I do this regularly and I am a mower repair technician who runs a mower repair workshop for a living

If the tapers have been fitted properly then the thick end is inwards and sitting on a shoulder or retaining ring

If you want to chomp your knuckles with a hammer & punch then you get a big diameter punch, grind a long tapper on one edge so it can sit flat against the side of the housing then grind a step into the tapered edge so it can locate on the small protruding lip of the race

You can also use a long nail punch with a notch cut on the end to locate onto the race

I have even see a long cold chisel cut in a similar way

However all of these run the risk of damaging the lip that the race sits on which is why the bead of weld has been used for about as long as electric welding has been around.

In a workshop situation where the gear is there ready to use it is a 30 sec job

It takes longer to go to the corner and wheel the welder to the mower than it does to lay the bead and before you wheel the welder back you will hear the tinkle of the race hitting the floor .

And it is a lot faster then mucking around with hammers & punches

#15

StarTech

StarTech

I only seen one of these spindle that the cup was nearly impossible to drive out. It was so worn out there was nothing to work with beside the spindle shaft itself was also damaged. I when I said nothing it was so worn that even the cast iron housing was grooved. In that case it was better to just replace the spindle with a good after market spindle. Besides at the time the spindle was only $109 retail with my cost a lot less.

A few after market are Oregon 82-325, Rotary 9153, and Stens 285-597. The best price of the three is the Oregon version.

A few after market are Oregon 82-325, Rotary 9153, and Stens 285-597. The best price of the three is the Oregon version.

#16

A

aggiejet

Thanks for the input. You’re right, I really don’t know zip about engineering. But Ive spent a lifetime repairing stuff, albeit I’m not a real machinist, but primarily a parts replacer. However, I replaced a plenum gasket in Dodge Ram 1500 5.9, and in the process had to replace two manifold stud bolts. That was definitely more than parts replacement. IMO, That plenum was an example of bad engineering. (A thin steel plate bolted to an aluminum manifold with improperly sized attaching screws) But I digress……

Im curious if Scag designed these spindles with the assumption that their network of dealer shops would be capable of the rebuild you describe. What you are talking about is real machining knowledge and skill and I salute you sir for having and deploying that skill. It’s bugs the crap out of me that we have become such a throw away society because of cheap parts.

That said, I’m lucky enough to have time to waste on this endeavor. I love doing stuff like this because I learn something I didn’t know, or develop a skill I didn’t have. And I got a MIG welder. My guess is I’ll end up welding the race to the hub, but I’m gonna give it a try.

Additionally, do you know the torque value for the 1 1/16” spindle nut?

Update: talked to Scag today. 150 ft/lbs is torque for spindle nut

A

aggiejet

Bert,This is the difference between throw away domestic mowers & long life commercial mowers

Great Dane for instance has spindle bearings being replaced annually or at 100 Hrs which ever came first

One of the reason why mower companies switched to the wrong style of bearings ( deep groove balls ) is because they are cheaper to buy & install

On top of that every time you knock them out you take a bit of the housing out with them so after X bearing replacements it is new housing time .

A proficient shop with knowledgable mechanics would have done exactly what I suggested originally & shortened the spacer to take up the wear in the bearings then slipped in a spacer under the blade if needed to make up the difference in blade clearance .

That is the difference between a real mechanic and a parts swapper with no formal education or trade certification who are allowed to be called "technicians" which you will find in 99% of the mower shops .

Not meaning to sound rude but you seem to have little idea about what is good sound engineering practice

Good is seldom easy

And I do this regularly and I am a mower repair technician who runs a mower repair workshop for a living

If the tapers have been fitted properly then the thick end is inwards and sitting on a shoulder or retaining ring

If you want to chomp your knuckles with a hammer & punch then you get a big diameter punch, grind a long tapper on one edge so it can sit flat against the side of the housing then grind a step into the tapered edge so it can locate on the small protruding lip of the race

You can also use a long nail punch with a notch cut on the end to locate onto the race

I have even see a long cold chisel cut in a similar way

However all of these run the risk of damaging the lip that the race sits on which is why the bead of weld has been used for about as long as electric welding has been around.

In a workshop situation where the gear is there ready to use it is a 30 sec job

It takes longer to go to the corner and wheel the welder to the mower than it does to lay the bead and before you wheel the welder back you will hear the tinkle of the race hitting the floor .

And it is a lot faster then mucking around with hammers & punches

Thanks for the input. You’re right, I really don’t know zip about engineering. But Ive spent a lifetime repairing stuff, albeit I’m not a real machinist, but primarily a parts replacer. However, I replaced a plenum gasket in Dodge Ram 1500 5.9, and in the process had to replace two manifold stud bolts. That was definitely more than parts replacement. IMO, That plenum was an example of bad engineering. (A thin steel plate bolted to an aluminum manifold with improperly sized attaching screws) But I digress……

Im curious if Scag designed these spindles with the assumption that their network of dealer shops would be capable of the rebuild you describe. What you are talking about is real machining knowledge and skill and I salute you sir for having and deploying that skill. It’s bugs the crap out of me that we have become such a throw away society because of cheap parts.

That said, I’m lucky enough to have time to waste on this endeavor. I love doing stuff like this because I learn something I didn’t know, or develop a skill I didn’t have. And I got a MIG welder. My guess is I’ll end up welding the race to the hub, but I’m gonna give it a try.

Additionally, do you know the torque value for the 1 1/16” spindle nut?

Update: talked to Scag today. 150 ft/lbs is torque for spindle nut

#17

B

bertsmobile1

B

bertsmobile1

Coming from an engineering background & working for a long time in tertiary metallurgy ( recycling & foundry ) I gained an appreciation about how much pollution is generated when you make some thing .

So yes , throw away engineering pisses me off as well as dose under speced products because the same pollution is generated and almost the same resources are used to make a junk part that will barely outlast warranty as a part that will last forever.

But those sorts of decisions are made in board rooms and directors make money from increased sales and in particular from repetitive sales of the same item because the original can not be economically repaired so until we get governments with testicles that mandate minimum life expectencies & heavily tax throw aways nothing will change till we pollute ourselves out of existance, and that day is a lot closer than most think . The EU tried it "end of life - reprocessing" mandate & taxes but those got canned , however they did bring in mandated durability indexes so EU products will have ( hidden usually ) expected operation hours till failure . Thus a shopper can see the $ 50 trimmer has a 50 hour life & the $ 100 trimmer has a 150 hour life then make an informed decision.

Add to that people are stupid, lazy , greedy & selfish and if we were not as a species humans would have died out before we crawled out of the caves & into the forests

So do I buy the Rolls Royce that will run for 200 years & has a genuine warranty forever or that Ford that will be lucky to get out of the sales room before it breaks down ?

So yes , throw away engineering pisses me off as well as dose under speced products because the same pollution is generated and almost the same resources are used to make a junk part that will barely outlast warranty as a part that will last forever.

But those sorts of decisions are made in board rooms and directors make money from increased sales and in particular from repetitive sales of the same item because the original can not be economically repaired so until we get governments with testicles that mandate minimum life expectencies & heavily tax throw aways nothing will change till we pollute ourselves out of existance, and that day is a lot closer than most think . The EU tried it "end of life - reprocessing" mandate & taxes but those got canned , however they did bring in mandated durability indexes so EU products will have ( hidden usually ) expected operation hours till failure . Thus a shopper can see the $ 50 trimmer has a 50 hour life & the $ 100 trimmer has a 150 hour life then make an informed decision.

Add to that people are stupid, lazy , greedy & selfish and if we were not as a species humans would have died out before we crawled out of the caves & into the forests

So do I buy the Rolls Royce that will run for 200 years & has a genuine warranty forever or that Ford that will be lucky to get out of the sales room before it breaks down ?

#18

A

aggiejet

A

aggiejet

I have successfully rebuilt two spindle hubs and posted videos of the process on YouTube.

1) Removing spindle belt drive pulley and hub.

2) Tear down of spindle hub

3) Installation of races, bearings, and seals

If you have any questions or critiques, I’ll try to answer them. Thanks for the feedback.

1) Removing spindle belt drive pulley and hub.

2) Tear down of spindle hub

3) Installation of races, bearings, and seals

If you have any questions or critiques, I’ll try to answer them. Thanks for the feedback.

#19

B

bertsmobile1

B

bertsmobile1

Nice videos thanks for sharing

We are compiling videos with correct information in This thread please put a link to your there so we can direct others to them .

We are compiling videos with correct information in This thread please put a link to your there so we can direct others to them .