You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Greasing trimmer head gearboxes

#1

G

GearHead36

G

GearHead36

Not sure where to put this. I hope this is ok.

I have an Echo PAS with several attachments. Most of these have heads that need periodic greasing. Yet none of them have grease fittings. And yet, you're supposed to grease them every (I think) 25 hrs. How do you guys grease them? The videos I've found show people using Echo's Red Armor grease, which is stupid expensive. $38 for 8 oz. I can't believe shops are using something like this. I have to believe you guys have found a better way.

I have an Echo PAS with several attachments. Most of these have heads that need periodic greasing. Yet none of them have grease fittings. And yet, you're supposed to grease them every (I think) 25 hrs. How do you guys grease them? The videos I've found show people using Echo's Red Armor grease, which is stupid expensive. $38 for 8 oz. I can't believe shops are using something like this. I have to believe you guys have found a better way.

#2

StarTech

StarTech

Actually the new gearboxes without grease fittings are non greaseable except during repairs of the gearbox. Now the driveshaft still needs greasing which you must remove the gear head to access the driveshaft

#3

G

GearHead36

G

GearHead36

Most of my attachments do not have the new gearboxes. Mine has the grease plug, but it's like an oil plug, and doesn't fit any of my grease guns.Actually the new gearboxes without grease are non greaseable except during repairs of the gearbox. Now the driveshaft still needs greasing which you must remove the gear head to access the driveshaft

#4

7394

7394

Just remove the plug, butt yer grease gun end up to the hole & give it a pump.

Mine is grease able, & I give it a shot 1 x a year. Residential use. Even my Dealer said to be sure & grease the head, that was over 10 years ago tho.. But still running like new,..

Any grade 2 grease should be fine.

Mine is grease able, & I give it a shot 1 x a year. Residential use. Even my Dealer said to be sure & grease the head, that was over 10 years ago tho.. But still running like new,..

Any grade 2 grease should be fine.

#5

M

MParr

M

MParr

That’s how I do my edger and string trimmer.Just remove the plug, butt yer grease gun end up to the hole & give it a pump.

Mine is grease able, & I give it a shot 1 x a year. Residential use. Even my Dealer said to be sure & grease the head, that was over 10 years ago tho.. But still running like new,..

Any grade 2 grease should be fine.

#6

7394

7394

Works fine, a friend took his edger head plug & matched up a grease fitting to install & leave..

#7

Tiger Small Engine

Tiger Small Engine

That how I do it with customer trimmers. Mystic red and tacky grease until it is full. Stihl sells a tube of grease that is threaded into trimmer head. Great if you are only doing one trimmer. Many trimmers rarely get greased so are low on grease when I do a tune up.Just remove the plug, butt yer grease gun end up to the hole & give it a pump.

Mine is grease able, & I give it a shot 1 x a year. Residential use. Even my Dealer said to be sure & grease the head, that was over 10 years ago tho.. But still running like new,..

Any grade 2 grease should be fine.

#8

StarTech

StarTech

Come on folks the newer gearboxes are not greaseable. No grease path available.

They just pack with grease at the factory or whenever they are disassembled.

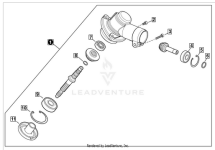

Newer Gearbox IPL

Item #2 is just a locator screw

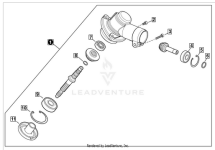

Older Gearbox

On the older item #2 was the grease fitting screw location with

item #3 being the locator screw.

And they even removed one of the bearings and several of the internal parts are

no longer available for repairs. IE you replace the complete gearbox if one those

are bad.

Basically they cheapen the design. And lighten the gearbox a few ounces.

They just pack with grease at the factory or whenever they are disassembled.

Newer Gearbox IPL

Item #2 is just a locator screw

Older Gearbox

On the older item #2 was the grease fitting screw location with

item #3 being the locator screw.

And they even removed one of the bearings and several of the internal parts are

no longer available for repairs. IE you replace the complete gearbox if one those

are bad.

Basically they cheapen the design. And lighten the gearbox a few ounces.

#9

M

MParr

M

MParr

Manufacturers would rather sell a new gear box. I imagine that many residential customers would care one way or the other.

I believe that @GearHead36 is referring to #2 in the second photo of @StarTech parts drawings.

I believe that @GearHead36 is referring to #2 in the second photo of @StarTech parts drawings.

#10

StarTech

StarTech

And this is what they are counting on. Residential use. Commercial use is consider too which is why they drop the five year warranty down to just two years. And I have seen these SRM-225 worn out in two years by commercial users.

I had to point out that they only had a Two year warranty when they tried to get them to repair them under warranty because all they saw the five warranty part and didn't read the fine print.

I got a customer that just purchase a SRM-225 and the lack grease port was one his complaints. The second was the HD store that he purchase the unit from wanted to charge him to warranty the brush cutter. Basically they would not register the trimmer for the customer to activate his warranty. Being a customer of mine otherwise I went online and registered it for him so he now has the five year warranty although most likely he still will have me to do repair work and bill him because of HD being such a pain to repairs done thru them.

I had to point out that they only had a Two year warranty when they tried to get them to repair them under warranty because all they saw the five warranty part and didn't read the fine print.

I got a customer that just purchase a SRM-225 and the lack grease port was one his complaints. The second was the HD store that he purchase the unit from wanted to charge him to warranty the brush cutter. Basically they would not register the trimmer for the customer to activate his warranty. Being a customer of mine otherwise I went online and registered it for him so he now has the five year warranty although most likely he still will have me to do repair work and bill him because of HD being such a pain to repairs done thru them.

#11

J

Joed756

J

Joed756

It seems to me you can drill and install a zerk fitting where 3, 4, and 5 are on the drawing. If a new gear head is needed for a two-piece unit you might save money by buying the lower half without the power unit.Come on folks the newer gearboxes are not greaseable. No grease path available.

They just pack with grease at the factory or whenever they are disassembled.

Newer Gearbox IPL

View attachment 68878

Item #2 is just a locator screw

Older Gearbox

View attachment 68879

On the older item #2 was the grease fitting screw location with

item #3 being the locator screw.

And they even removed one of the bearings and several of the internal parts are

no longer available for repairs. IE you replace the complete gearbox if one those

are bad.

Basically they cheapen the design. And lighten the gearbox a few ounces.

#12

G

GearHead36

Just had a thought... I bet a chainsaw bar greaser would work. That would only take one hand to apply the grease. Is that grease compatible with trimmer gearboxes. I haven't really looked mine over that hard. Can you refill them with grease?

G

GearHead36

The problem is, that takes 3 hands. One to hold the grease gun to the grease port, one to work the gun, and one to rotate the trimmer head.Just remove the plug, butt yer grease gun end up to the hole & give it a pump.

Mine is grease able, & I give it a shot 1 x a year. Residential use. Even my Dealer said to be sure & grease the head, that was over 10 years ago tho.. But still running like new,..

Any grade 2 grease should be fine.

Just had a thought... I bet a chainsaw bar greaser would work. That would only take one hand to apply the grease. Is that grease compatible with trimmer gearboxes. I haven't really looked mine over that hard. Can you refill them with grease?

#13

M

MParr

Also, you can take the plug down to NAPA and match the threads to a grease fitting.

On the string trimmer head, you may have to remove the debris shield to fit the tube.

M

MParr

With Echo, their Red Armor grease tubes will screw into the fill port of your machine.The problem is, that takes 3 hands. One to hold the grease gun to the grease port, one to work the gun, and one to rotate the trimmer head.

Just had a thought... I bet a chainsaw bar greaser would work. That would only take one hand to apply the grease. Is that grease compatible with trimmer gearboxes. I haven't really looked mine over that hard. Can you refill them with grease?

Also, you can take the plug down to NAPA and match the threads to a grease fitting.

On the string trimmer head, you may have to remove the debris shield to fit the tube.

#14

StarTech

StarTech

I give up...It no getting it thru your heads that the newer gearbox does not have an access hole to even try to grease the gears..

And MParr you really need to go look at one of the newer gearboxes

Now it might possible to drill, tap and install a zerk at the bevel gear joint. But you are risking having a piece metal being left in the gearbox; unless, you disassemble the unit, clean out the grease, drill and tap, and then reassemble. Now of course this voids the 5 years warranty.

And MParr you really need to go look at one of the newer gearboxes

Now it might possible to drill, tap and install a zerk at the bevel gear joint. But you are risking having a piece metal being left in the gearbox; unless, you disassemble the unit, clean out the grease, drill and tap, and then reassemble. Now of course this voids the 5 years warranty.

#15

M

MParr

Look at @GearHead36 reply above mine. It reads as though he has the older model PAS.

M

MParr

I was referring to the older models.I give up...It no getting it thru your heads that the newer gearbox does not have an access hole to even try to grease the gears..

And MParr you really need to go look at one of the newer gearboxes

Now it might possible to drill, tap and install a zerk at the bevel gear joint. But you are risking having a piece metal being left in the gearbox; unless, you disassemble the unit, clean out the grease, drill and tap, and then reassemble. Now of course this voids the 5 years warranty.

Look at @GearHead36 reply above mine. It reads as though he has the older model PAS.

#16

StarTech

StarTech

The OP didn't if which serial number or if he has one of new attachments.

It is the same with the PAS as newer one could be using the 99944200501 trimmer/brush cutter attachment.

It is the same with the PAS as newer one could be using the 99944200501 trimmer/brush cutter attachment.

#17

7394

Hold the hose end to the head hole, & other hand to give gun a pump.

7394

On the workbench, you lay the trimmer head up against something, so it can't slide away. Lay grease gun next to it.The problem is, that takes 3 hands. One to hold the grease gun to the grease port, one to work the gun, and one to rotate the trimmer head.

Hold the hose end to the head hole, & other hand to give gun a pump.

#18

M

mcspeed

M

mcspeed

My Stihl line trimmer head gets quite hot. Is this normal? Yes I grease it. Should I install a zirk so grease penetrates better?

#20

StarTech

Now I can tell that we need 285F to disassemble these FS gearboxes.

StarTech

This is relative. Your hot is probably not same as my feel hot. This is why I use a non contact thermometer. The FS do get fairly hot is use. As long the bearing feel like they are rotating fine I would not worry too much about.My Stihl line trimmer head gets quite hot. Is this normal? Yes I grease it. Should I install a zirk so grease penetrates better?

Now I can tell that we need 285F to disassemble these FS gearboxes.

#21

M

mcspeed

M

mcspeed

Thanks for the response. I will get a temp measurement next time. It spins freely and smooth so prolly fine.This is relative. Your hot is probably not same as my feel hot. This is why I use a non contact thermometer. The FS do get fairly hot is use. As long the bearing feel like they are rotating fine I would not worry too much about.

Now I can tell that we need 285F to disassemble these FS gearboxes.

#22

G

GearHead36

I started this thread because I'm having the same problem as mcspeed. My gear boxes are getting hot. Too hot to hold.

G

GearHead36

I didn't know that you could get grease fittings with the right thread. Thanks. A 10 pack is only $8, and should take care of all my attachments.Now those with grease port the screw is a M8 so a M8 grease zerk should fit.

I started this thread because I'm having the same problem as mcspeed. My gear boxes are getting hot. Too hot to hold.

#23

7394

Just a pump or two. Depending how much you use it. ,

Mine I do lots of vertical edging, & regular edging /whacking as well.

7394

One thing is not to feel a need to Totally fill the gear head. One can cause more heat by overfull.My Stihl line trimmer head gets quite hot. Is this normal? Yes I grease it. Should I install a zirk so grease penetrates better?

Just a pump or two. Depending how much you use it. ,

Mine I do lots of vertical edging, & regular edging /whacking as well.

#24

M

mcspeed

M

mcspeed

Took a temperature reading on my Stihl after working today, 165° F. I’m thinking this isn’t too hot?

#26

R

rutbuster1

R

rutbuster1

Come on folks the newer gearboxes are not greaseable. No grease path available.Actually the new gearboxes without grease fittings are non greaseable except during repairs of the gearbox. Now the driveshaft still needs greasing which you must remove the gear head to access the driveshaft

They just pack with grease at the factory or whenever they are disassembled.

Newer Gearbox IPL

View attachment 68878

Item #2 is just a locator screw

Older Gearbox

View attachment 68879

On the older item #2 was the grease fitting screw location with

item #3 being the locator screw.

And they even removed one of the bearings and several of the internal parts are

no longer available for repairs. IE you replace the complete gearbox if one those

are bad.

Basically they cheapen the design. And lighten the gearbox a few ounces.

Not sure where to put this. I hope this is ok.Not sure where to put this. I hope this is ok.

I have an Echo PAS with several attachments. Most of these have heads that need periodic greasing. Yet none of them have grease fittings. And yet, you're supposed to grease them every (I think) 25 hrs. How do you guys grease them? The videos I've found show people using Echo's Red Armor grease, which is stupid expensive. $38 for 8 oz. I can't believe shops are using something like this. I have to believe you guys have foun

I have an Echo PAS with several attachments. Most of these have heads that need periodic greasing. Yet none of them have grease fittings. And yet, you're supposed to grease them every (I think) 25 hrs. How do you guys grease them? The videos I've found show people using Echo's Red Armor grease, which is stupid expensive. $38 for 8 oz. I can't believe shops are using something like this. I have to believe you guys have found a better way.

You can drill a hole in the spot where the grease screw normally was at and thread it for either a grease fitting or screw. I've done many and put grease fittings on them. Takes about 15 minutes.Not sure where to put this. I hope this is ok.

I have an Echo PAS with several attachments. Most of these have heads that need periodic greasing. Yet none of them have grease fittings. And yet, you're supposed to grease them every (I think) 25 hrs. How do you guys grease them? The videos I've found show people using Echo's Red Armor grease, which is stupid expensive. $38 for 8 oz. I can't believe shops are using something like this. I have to believe you guys have found a better way.

#27

R

rutbuster1

R

rutbuster1

It's greaseable. You can either take the gearbox apart and grease it, or, you can drill and thread a hole for either a grease fitting or screw. I've done many of them without any problem. It's not hard and takes about 15 minutes to do it.Come on folks the newer gearboxes are not greaseable. No grease path available.

They just pack with grease at the factory or whenever they are disassembled.

Newer Gearbox IPL

View attachment 68878

Item #2 is just a locator screw

Older Gearbox

View attachment 68879

On the older item #2 was the grease fitting screw location with

item #3 being the locator screw.

And they even removed one of the bearings and several of the internal parts are

no longer available for repairs. IE you replace the complete gearbox if one those

are bad.

Basically they cheapen the design. And lighten the gearbox a few ounces.

#28

P

PGB1

P

PGB1

Press-In or Drive-In Zerk type grease fittings are what I use when there is a blank hole with a plug. McMaster-Carr has a wide assortment, as do many hardware and auto parts stores.

The next time I'm inside the gear box, I'll tap the hole and screw in a Zerk type fitting, like what RutBuster1 said. (I wait until the box is open for service to tap the hole, fearing chips will go in the gearbox. They probably won't.)

Paul

The next time I'm inside the gear box, I'll tap the hole and screw in a Zerk type fitting, like what RutBuster1 said. (I wait until the box is open for service to tap the hole, fearing chips will go in the gearbox. They probably won't.)

Paul

#29

L

Lord_Cavendish

L

Lord_Cavendish

Wow, that's messed-up. Glad that all my tools are old and user serviceable, even if it means hunting NOS parts on fleabay.Come on folks the newer gearboxes are not greaseable. No grease path available.

They just pack with grease at the factory or whenever they are disassembled.

Newer Gearbox IPL

View attachment 68878

Item #2 is just a locator screw

Older Gearbox

View attachment 68879

On the older item #2 was the grease fitting screw location with

item #3 being the locator screw.

And they even removed one of the bearings and several of the internal parts are

no longer available for repairs. IE you replace the complete gearbox if one those

are bad.

Basically they cheapen the design. And lighten the gearbox a few ounces.

#30

L

Lord_Cavendish

L

Lord_Cavendish

Old shop manual for one of my trimmers states to fill the gearbox 1/3rd full of grease after a rebuild. One of my first rebuilds I overfilled, and every time it warmed up it extruded grease.One thing is not to feel a need to Totally fill the gear head. One can cause more heat by overfull.

Just a pump or two. Depending how much you use it. ,

Mine I do lots of vertical edging, & regular edging /whacking as well.

#31

P

PGB1

I'm with Lord Cavendish- Glad most of my equipment is old-school. My tiller is about 45 years old. The steel gears are like brand new with no backlash at all.

P

PGB1

Unfortunately, I often find die cast white metal gears inside newer equipment. No wonder stuff ends up in landfills so quickly.Wow, that's messed-up. Glad that all my tools are old and user serviceable, even if it means hunting NOS parts on fleabay.

I'm with Lord Cavendish- Glad most of my equipment is old-school. My tiller is about 45 years old. The steel gears are like brand new with no backlash at all.

#32

B

bertsmobile1

These give a very long service life if the owners do 2 simple things

1) Never ever exceed the maximum line thickness

2) always cut at full speed

I replace a lot of bevel boxes on Honda trimmers because idiots like to run 3mm line in place of the 2.7mm max size

Most of the pros actually use the 2.5mm line because line is cheap & bevel boxes are expensive .

B

bertsmobile1

They are metal powder pressings on most line trimmersUnfortunately, I often find die cast white metal gears inside newer equipment. No wonder stuff ends up in landfills so quickly.

I'm with Lord Cavendish- Glad most of my equipment is old-school. My tiller is about 45 years old. The steel gears are like brand new with no backlash at all.

These give a very long service life if the owners do 2 simple things

1) Never ever exceed the maximum line thickness

2) always cut at full speed

I replace a lot of bevel boxes on Honda trimmers because idiots like to run 3mm line in place of the 2.7mm max size

Most of the pros actually use the 2.5mm line because line is cheap & bevel boxes are expensive .