rancher_mac

Member

- Joined

- May 10, 2023

- Threads

- 4

- Messages

- 34

Sounds good. I’ll be out of town but when I’m back I’ll do those things you mentioned. It is actually a different muffler on it, but the youtube video in the video about the governor is an instructional one I found. It’s hard to come by the stock muffler that fits the MTD frame at a reasonable price so I was able to use a muffler from a zero turn instead. Saved myself $100 or so and my neighbor is welding the pipes for me. Also, I actually do have that repair manual. Been referring to it a lot as I’ve been trouble shooting. Might be getting some more needle valves as I’ve polished seats but still have leaks. I’m sure it will be solved here at some point…Your one picture is really dark and We cannot see what you are indicating that you see gas pooling in both cylinders????????????

Something to keep in mind on those engines is when they are not warmed up or hot and when you turn the key off the spark stops the governor goes wide open and the carb is dumping max gas into the intake manifold while the engine is coasting to as stop. If the engine is hot you will see gas vapor coming out of the carb throat. If the engine is cold you will see raw gas in the intake manifold below the carb because it's not hot enough to vaporize rapidly.

Some later model engines use a Anti Backfire Solenoid (ABS) on the bottom of the carb and it reduces the gas going into the manifold when the key is turned off.

Also you WILL FIND on some of the opposed twins that some engines ALWAYS require an immediate full choke for a quick start even when the engine is hot. Nothing is wrong, just the nature of the beast.

Do you have the Briggs service manual for that engine????

If you are going to keep that ENGINE you might want to eventually invest in a

Briggs Twin cylinder l-head service manual 02-271172 at about $30

Not to take anything away from this site, but here is a link to a site that has a really good small engine reference library for all kinds of small engine service manuals, but you have to be a member and post for awhile BEFORE YOU ARE ALLOWED TO VIEW AND DOWNLOAD SUCH.

Professional Power Equipment Technicians & Education Network (PPETEN) • Index page

With some searching few years ago I downloaded a freebie Service manual, BUT I also found a used manual on fleece bay at a reduced rate and just purchase such for the shop use.

Just a hint about static governor adjust. Ignore left/right/CW/CCW rotation of the shaft in the videos.

The governor shaft and lever is most generally turned/rotated in the same direction

that forces the throttle wide open when doing the static governor adjust.

Also on that engine the big screw that moves back and forth as you increase and decrease the throttle is the max RPM adjustment screw.

Sometimes this screw has to be adjusted to get the governor engine speed corrected at max throttle. (especially if the governor does not increase the engine speed enough when the engine is under a load mowing.

That bolt's nut that holds the governor arm clamp secured to the governor shaft coming out of the engine on those engines has to be tight. If you limp wrist the nut the lever will slip on the shaft and the governor will not work correctly AGAIN because the arm did not stay secured/locked to the shaft.

But be careful and not twist off the bolt or break the clamp. Use a 1/4 inch drive ratchet and a 6 point socket.

Leave the breather off the top of the carb push it outside and let it run at medium speed until it gets warmed up and do hot engine tests, killing and re-starting the engine checking for running rich, etc.

You are gaining ground for now, but sometimes Murphy will spring up again.

Them are good old engines when not worn out and only require little bit of TLC for long term use. You will find they are user friendly to work on when you get familiar with them.

That is a unusual exhaust on that one. They usually dump out and the muffler bolts in that square slot in front of the engine in the frame opening.

Just unbolt the muffler and it drops down out of the frame and leaves the two exhaust pipes bolted to the engine.

Also do not see a mower deck.

You will find that,

Patience is your friend.

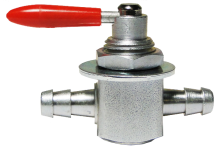

What’s your opinion on installing a fuel shutoff solenoid? I see a few available that fit this carb. I know they can be a pain to some people but it would at least cut off flow from the main jet when engine is shut off.

Last edited: