You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Cub Cadet service and belts

#1

P

Pumpguy

P

Pumpguy

I have a 2 year old Cub Cadet XT2LX42 riding mower Model 13AJA1CSO10 with just 37 hours on it and broke the upper drive belt.

I will start by commenting that I really like the features of this mower. It drives like it has power steering, has a very tight turning circle for mowing around trees, and I don't have to clutch and shift like my old 1992 42" Craftsman 5 speed. In all the 18 years I had this Craftsman, I only had to change the mower deck belt once, and never the upper main drive belt.

The Cub Cadet's owners manual has instructions for changing the mower deck belt, but for the upper main drive belt, it says to have a dealer do it, which I did. Including pick up and delivery, material and labor, the bill came to $461.74. I will give them that they gave me a 4 day turnaround which I appreciate very much.

In looking at the belts, both the old broken upper drive belt, its new replacement, and the mower deck drive belt, they all appear to be the common black industrial V belts, and not the better Kevlar types which the ones I have seen are brown or blue-green in color and much stiffer.

I contacted Cub Cadet customer service, 1-877 428 2349, and asked how I can get a factory service manual so I can see how to change the upper drive belt myself. I was told this is not available to end users, and is only available to authorized dealers through their dealer portal.

IMO, This is not good customer service. Dealers don't buy lawn mowers, they only sell them. Its the end users that buy lawn mowers and they should get the best possible factory support. In fact, this policy may now be illegal considering recent Right To Repair legislation.

QUESTIONS:

1) Can anyone comment on my suspicion that the OEM belts are just common polyester cord black industrial V belts? If yes, what better belts should I be using, and where's the best place to get them?

2) Does anyone know where or how I can get a factory service manual for this mower? Even a Haynes type aftermarket manual would be better than what I have now.

I will start by commenting that I really like the features of this mower. It drives like it has power steering, has a very tight turning circle for mowing around trees, and I don't have to clutch and shift like my old 1992 42" Craftsman 5 speed. In all the 18 years I had this Craftsman, I only had to change the mower deck belt once, and never the upper main drive belt.

The Cub Cadet's owners manual has instructions for changing the mower deck belt, but for the upper main drive belt, it says to have a dealer do it, which I did. Including pick up and delivery, material and labor, the bill came to $461.74. I will give them that they gave me a 4 day turnaround which I appreciate very much.

In looking at the belts, both the old broken upper drive belt, its new replacement, and the mower deck drive belt, they all appear to be the common black industrial V belts, and not the better Kevlar types which the ones I have seen are brown or blue-green in color and much stiffer.

I contacted Cub Cadet customer service, 1-877 428 2349, and asked how I can get a factory service manual so I can see how to change the upper drive belt myself. I was told this is not available to end users, and is only available to authorized dealers through their dealer portal.

IMO, This is not good customer service. Dealers don't buy lawn mowers, they only sell them. Its the end users that buy lawn mowers and they should get the best possible factory support. In fact, this policy may now be illegal considering recent Right To Repair legislation.

QUESTIONS:

1) Can anyone comment on my suspicion that the OEM belts are just common polyester cord black industrial V belts? If yes, what better belts should I be using, and where's the best place to get them?

2) Does anyone know where or how I can get a factory service manual for this mower? Even a Haynes type aftermarket manual would be better than what I have now.

#2

ILENGINE

Also keep in mind that some manufacturer manuals are designed for trained techs, and do not give a step by step repair. Meaning if you are going to replace the drive belts, the first step in the service manual may be remove drive belt. How to do that may not be spelled out, or what has to happen before you can remove the belt.

ILENGINE

Question one. MTD belts are a unique length, width and cut angle, and is the reason that the good techs on here push for OEM belts because generic off the shelf belts either don't work or work for a short period of time. and for question 2, I am sure that there are manuals out there, but as a dealer I have to sift through 5 pages and 2 dealer login screens just to get to them.I have a 2 year old Cub Cadet XT2LX42 riding mower Model 13AJA1CSO10 with just 37 hours on it and broke the upper drive belt.

I will start by commenting that I really like the features of this mower. It drives like it has power steering, has a very tight turning circle for mowing around trees, and I don't have to clutch and shift like my old 1992 42" Craftsman 5 speed. In all the 18 years I had this Craftsman, I only had to change the mower deck belt once, and never the upper main drive belt.

The Cub Cadet's owners manual has instructions for changing the mower deck belt, but for the upper main drive belt, it says to have a dealer do it, which I did. Including pick up and delivery, material and labor, the bill came to $461.74. I will give them that they gave me a 4 day turnaround which I appreciate very much.

In looking at the belts, both the old broken upper drive belt, its new replacement, and the mower deck drive belt, they all appear to be the common black industrial V belts, and not the better Kevlar types which the ones I have seen are brown or blue-green in color and much stiffer.

I contacted Cub Cadet customer service, 1-877 428 2349, and asked how I can get a factory service manual so I can see how to change the upper drive belt myself. I was told this is not available to end users, and is only available to authorized dealers through their dealer portal.

IMO, This is not good customer service. Dealers don't buy lawn mowers, they only sell them. Its the end users that buy lawn mowers and they should get the best possible factory support. In fact, this policy may now be illegal considering recent Right To Repair legislation.

QUESTIONS:

1) Can anyone comment on my suspicion that the OEM belts are just common polyester cord black industrial V belts? If yes, what better belts should I be using, and where's the best place to get them?

2) Does anyone know where or how I can get a factory service manual for this mower? Even a Haynes type aftermarket manual would be better than what I have now.

Also keep in mind that some manufacturer manuals are designed for trained techs, and do not give a step by step repair. Meaning if you are going to replace the drive belts, the first step in the service manual may be remove drive belt. How to do that may not be spelled out, or what has to happen before you can remove the belt.

#3

P

Pumpguy

I am a professional mechanic and experienced machinist. My thing is industrial pumps, and also as a hobby off road and dual sport motorcycles, but not riding mowers. I have all sorts of service manuals for these, and once I see the recommended way to deal with a problem, I can usually get'er done.

I have had several others recommended Kevlar belts and have one of each on order, so we'll see how they wok out. My goal right now is to get or see a proper factory service manual for this mower to see the proper way a certain task is done, and other info like wiring diagrams, etc. Only getting 37 hours on an upper drive belt is just not acceptable.

I've tried doing youtube searches, but many I have seen are too amateurish and/or incompetent to be useful.

P

Pumpguy

Thanks for your reply.Question one. MTD belts are a unique length, width and cut angle, and is the reason that the good techs on here push for OEM belts because generic off the shelf belts either don't work or work for a short period of time. and for question 2, I am sure that there are manuals out there, but as a dealer I have to sift through 5 pages and 2 dealer login screens just to get to them.

Also keep in mind that some manufacturer manuals are designed for trained techs, and do not give a step by step repair. Meaning if you are going to replace the drive belts, the first step in the service manual may be remove drive belt. How to do that may not be spelled out, or what has to happen before you can remove the belt.

I am a professional mechanic and experienced machinist. My thing is industrial pumps, and also as a hobby off road and dual sport motorcycles, but not riding mowers. I have all sorts of service manuals for these, and once I see the recommended way to deal with a problem, I can usually get'er done.

I have had several others recommended Kevlar belts and have one of each on order, so we'll see how they wok out. My goal right now is to get or see a proper factory service manual for this mower to see the proper way a certain task is done, and other info like wiring diagrams, etc. Only getting 37 hours on an upper drive belt is just not acceptable.

I've tried doing youtube searches, but many I have seen are too amateurish and/or incompetent to be useful.

#4

B

bertsmobile1

B

bertsmobile1

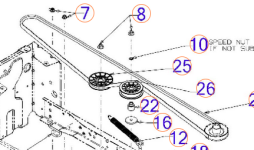

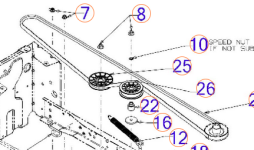

Nothing particularly difficult about the upper rear belt replacement

Start by removing the battery & battery carrier if it is under the seat

get a spring hook & remove the spring after taking a photo of where it mounts

Now the tricky bit

Most times the large pulley will run too close to the frame rails for the belt to be replaced, this is a design feature ( cheapness ) as the frame rails become the belt keepers so the large pulley has to come off, or the whole transmission has to be dropped ( or body raised ) to get the clearance needed.

Most times there is no clean access to get a rattle gun onto the pulley nut so it is often quicker to drop the transmission 2" as that is only 6 bolts . 4 are easy to get to while the torque braces are difficult to get to

Again depending upon the exact model & I have not checked yours the double variable pulley will also need to be loosened so it can be tilted to allow the belt to be replaced.

Leave the variable pulley in it's mount & loosen the mounting bolts on either the frame or transmission ( model dependent ) .

The only mowers that use plain polyester cord belts that I know of are the Australian Cox & Greenfields all others use kevlar reinforced belts some are wrapped & some ( ZTR Hydros ) are raw edge .

However the covers come in a variety of colours from black open weave through to blue ( Pix) green ( Gates ) light brown ( Dunlop ) and a pile of others I have no idea of the actual makers because they are mostly retail name branded .

Clutching belts as found on manual PTO's must be wrapped because they are required to slip

Drive belts do not need to be wrapped but usually are to resist then getting sticky when hot & picking up debris

Start by removing the battery & battery carrier if it is under the seat

get a spring hook & remove the spring after taking a photo of where it mounts

Now the tricky bit

Most times the large pulley will run too close to the frame rails for the belt to be replaced, this is a design feature ( cheapness ) as the frame rails become the belt keepers so the large pulley has to come off, or the whole transmission has to be dropped ( or body raised ) to get the clearance needed.

Most times there is no clean access to get a rattle gun onto the pulley nut so it is often quicker to drop the transmission 2" as that is only 6 bolts . 4 are easy to get to while the torque braces are difficult to get to

Again depending upon the exact model & I have not checked yours the double variable pulley will also need to be loosened so it can be tilted to allow the belt to be replaced.

Leave the variable pulley in it's mount & loosen the mounting bolts on either the frame or transmission ( model dependent ) .

The only mowers that use plain polyester cord belts that I know of are the Australian Cox & Greenfields all others use kevlar reinforced belts some are wrapped & some ( ZTR Hydros ) are raw edge .

However the covers come in a variety of colours from black open weave through to blue ( Pix) green ( Gates ) light brown ( Dunlop ) and a pile of others I have no idea of the actual makers because they are mostly retail name branded .

Clutching belts as found on manual PTO's must be wrapped because they are required to slip

Drive belts do not need to be wrapped but usually are to resist then getting sticky when hot & picking up debris

#5

StarTech

StarTech

Bert you are thinking the CVT system and this one is a hydrostatic version which a lot easier to do.

Looks like the dealer seen an easy mark.

My lord this is a simple job. Would need the deck off and may have to drop the double stack engine pulley.

As for the yes it is probably a poly cord belt as hydro belts don't need to be Kevlar corded. As the belt size it is spec'd as an A sec (1/2") x 91.10 inches so a 91" Kevlar will fit. The only I change otherwise and that depends on the wear is the v-idler.

Looks like the dealer seen an easy mark.

My lord this is a simple job. Would need the deck off and may have to drop the double stack engine pulley.

As for the yes it is probably a poly cord belt as hydro belts don't need to be Kevlar corded. As the belt size it is spec'd as an A sec (1/2") x 91.10 inches so a 91" Kevlar will fit. The only I change otherwise and that depends on the wear is the v-idler.

#6

B

bertsmobile1

B

bertsmobile1

Sorry about that .

Yes without checking it sounded like he had a CVT type of tranny

Yes without checking it sounded like he had a CVT type of tranny

#7

P

Pumpguy

P

Pumpguy

Thank you both so much for your replies. I really appreciate your expertise. This is much more info than I had before. Right now the only thing that's putting me off is getting the deck off, but thats only because I've never had to do that before.

Wait..... by deck do you mean the mower blade deck, or the yellow sheet metal pan that the seat and battery mounts to?

If mower deck, I don't see that as a problem.

To repeat a comment from my first post, I'm really bummed that the drive belt on this mower only lasted 37 hours. My old '92 Craftsman still had the original drive belt on it when I scrapped it 2 years ago. I used it for 18 years, and the PO maybe 3 or 4 years before that. The rest of the time it sat idle. I would think thats about 500 hours at the very least.

Wait..... by deck do you mean the mower blade deck, or the yellow sheet metal pan that the seat and battery mounts to?

If mower deck, I don't see that as a problem.

To repeat a comment from my first post, I'm really bummed that the drive belt on this mower only lasted 37 hours. My old '92 Craftsman still had the original drive belt on it when I scrapped it 2 years ago. I used it for 18 years, and the PO maybe 3 or 4 years before that. The rest of the time it sat idle. I would think thats about 500 hours at the very least.

#8

StarTech

StarTech

Yes it is the mower blade deck.

Beside to remove the fender pan would a major undertaking even for an experienced tech.

As for the belt failure make sure the idler pulley bearings are good. But could have been just a stick or something like a sweet gum ball getting into the belt path.

Beside to remove the fender pan would a major undertaking even for an experienced tech.

As for the belt failure make sure the idler pulley bearings are good. But could have been just a stick or something like a sweet gum ball getting into the belt path.

#10

L

Lawnmowerpartsusa

L

Lawnmowerpartsusa

This belt might help you.

lawnmowerpartsglobal.com

lawnmowerpartsglobal.com

1/2" X100" Deck Belt Made with Kevlar for Cub Cadet/MTD 754-05021 954-05021 XT1-LT42 XT2-LX42 CYT4220 CYT4220S XT2-LX42KH XT2-LX42KW Enduro Lawn Tractors with 42" Mower Decks - Your source for all your lawn mower and Lawn tractor parts replacement pa

1/2" X100" Deck Belt Made with Kevlar for Cub Cadet/MTD 754-05021 954-05021 XT1-LT42 XT2-LX42 CYT4220 CYT4220S XT2-LX42KH XT2-LX42KW Enduro Lawn Tractors with 42" Mower Decks

lawnmowerpartsglobal.com

lawnmowerpartsglobal.com

#12

B

bertsmobile1

B

bertsmobile1

All mower deck belts apart from walk behinds and Australian made ride ons use kevlar belts

Polly fibre belts will fail after a couple of mows

some drive belts can be plain covered polly belts

ZTRs dives do not clutch so they can be plain belts but again they get hot & sticky so pick up debris which also causes belt failure

Polly fibre belts will fail after a couple of mows

some drive belts can be plain covered polly belts

ZTRs dives do not clutch so they can be plain belts but again they get hot & sticky so pick up debris which also causes belt failure

#13

P

Pumpguy

P

Pumpguy

Thank you for your reply. You say "some drive belts can be plain covered poly belts" and I have to believe that's what I originally got and have now.

I can say with absolute certainty that the OEM belts on this tractor, the ones that came new on it and the upper drive belt the dealer installed, are not the same as the replacement Kevlar belts I have now as on hand spares.

The OEM belts have the appearance of common poly cord V belts like my drill press uses. Also, they have the stiffness of a limp wet noodle compared to the replacement Kevlar belts I have as spares when these break.

I can say with absolute certainty that the OEM belts on this tractor, the ones that came new on it and the upper drive belt the dealer installed, are not the same as the replacement Kevlar belts I have now as on hand spares.

The OEM belts have the appearance of common poly cord V belts like my drill press uses. Also, they have the stiffness of a limp wet noodle compared to the replacement Kevlar belts I have as spares when these break.

#14

B

bertsmobile1

B

bertsmobile1

Belt threads are about as much fun as oil threads and very similar as every one who has no understanding of what goes into their production & design considers them self an expert

OEM branded belts are always the best

There are litterally thousands of different rubber compounds used for making belts

Then there is the size of the reinforcing cords,

The position of the reinforcing cords .

The actual fibre size & lay of the cords

Plus of course the chemistry of the cords

And then the outer cover, single wrap, double wrap, polly wrap, cotton wrap kevlar wrap or no wrap

While paying a lot does not mean the belt will be good, paying very little will always mean the belt is junk .

OEM branded belts are always the best

There are litterally thousands of different rubber compounds used for making belts

Then there is the size of the reinforcing cords,

The position of the reinforcing cords .

The actual fibre size & lay of the cords

Plus of course the chemistry of the cords

And then the outer cover, single wrap, double wrap, polly wrap, cotton wrap kevlar wrap or no wrap

While paying a lot does not mean the belt will be good, paying very little will always mean the belt is junk .

#15

P

Pumpguy

P

Pumpguy

Agree completely. Experience is the best teacher, so I'll just have to wait and see what happens.