You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Craftsman Steering Problem

#1

J

jimbeau

J

jimbeau

I have a GT6000 with 'tight turn' steering. When turning all the way either right or left the inside wheel flops to 90º of travel. I have replaced all the steering parts and have good alignment. The mower steers fine until I make a hard turn. Ideas?

Attachments

#2

B

bertsmobile1

B

bertsmobile1

IF it is brand new send it back

A view of the underside with the mower standing vertical would be good

I have never seen one of this style of steering let alone worked on one

From the IPL I can not see anything obvious that would make the wheels turn too far yet still have them pointing strait ahead

I can see only 3 things that would cause this problem

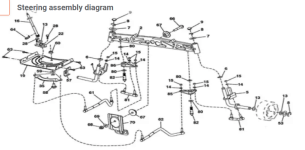

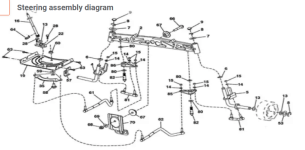

1) wrong Selector plate gear part # 35 in the Sears diagram Part #440770

2) wrong Lawn tractor steering plate # 19 in the Sears Diagram Part #194729

3) Lawn tractor sector gear cap shown as #122 in the Sears diagram Part #444962

The first if too big would allow the drag links to move too much

The plate has 2 slots that the caps run in which looks like what acts as a steering stop

If they fall out of the slots then there is no steering stop

To me it looks very much like they are drawn in upside down and the flange would go to the top to prevent them falling out of the hole

I also noticed that no nuts & washers are shown so unless the selector plate is threaded I can not see what holds the drag links to the gear plate

Again this is just an IDEA from what I see in the diagram

However I note that all of the steering parts are flagged as "best sellers" so it looks like you are not alone .

A horriidly complicated work around for not using adjustable drag links in the first place

There is an old engineering addage which which goes something like this

"There is no design so simple that works so well that it can not be made more unreliable by making it more complicated "

A long winded way of expressing the KISS principle .

A view of the underside with the mower standing vertical would be good

I have never seen one of this style of steering let alone worked on one

From the IPL I can not see anything obvious that would make the wheels turn too far yet still have them pointing strait ahead

I can see only 3 things that would cause this problem

1) wrong Selector plate gear part # 35 in the Sears diagram Part #440770

2) wrong Lawn tractor steering plate # 19 in the Sears Diagram Part #194729

3) Lawn tractor sector gear cap shown as #122 in the Sears diagram Part #444962

The first if too big would allow the drag links to move too much

The plate has 2 slots that the caps run in which looks like what acts as a steering stop

If they fall out of the slots then there is no steering stop

To me it looks very much like they are drawn in upside down and the flange would go to the top to prevent them falling out of the hole

I also noticed that no nuts & washers are shown so unless the selector plate is threaded I can not see what holds the drag links to the gear plate

Again this is just an IDEA from what I see in the diagram

However I note that all of the steering parts are flagged as "best sellers" so it looks like you are not alone .

A horriidly complicated work around for not using adjustable drag links in the first place

There is an old engineering addage which which goes something like this

"There is no design so simple that works so well that it can not be made more unreliable by making it more complicated "

A long winded way of expressing the KISS principle .

#3

J

jimbeau

J

jimbeau

Thanks. I have a YT3000 'freebie' that has the same setup and steers ok. I swapped the plate, drag links, etc. with my GT6000 and have the same symptoms. I tried caps on the drag links where they go in the steering plate. They don't quite reach the end of the steering slot. I agree that the lack of a steering stop is the likely culprit but am at a loss of how it works. The front wheels have a metal stop on the inside of the spindle but by the time it makes contact the opposite wheel has turned sideways. I can think of several 'fixes' that involve welding or modifying drag links but I think that installing new parts should restore the steering function.

FYI: The drag link goes up into the steering plate and has a washer and locknut. The cap sets on top of the locknut. This all has to be assembled while the steering plate is off, or loosely attached, in order to get a wrench on the locknut.

FYI: The drag link goes up into the steering plate and has a washer and locknut. The cap sets on top of the locknut. This all has to be assembled while the steering plate is off, or loosely attached, in order to get a wrench on the locknut.

#4

sgkent

sgkent

you write you used the parts from the other mower. You are unclear whether the problem changed mowers or the problem remained with the same mower. If the problem stayed with the same mower, I would put the mower up on stands in the garage on a swept clean floor. Using some chalk and a plumb line drop to the floor and mark some spots that are consistent between mowers - e.g., where the axles are, center of the tire, frame points etc., and distance above the floor, then measure diagonally side to side on the points, e;g, front left to right rear and front right to left rear. When you move the mower you can use a tape on the spots to see if the frame is square or bent. If the frame is square, try putting the other mower up and see it the spots align or if there is a noticeable difference. You may find that the frame is tweaked to where the geometry is way off. In order for the one wheel to swing further, the arc between sides they travel have to be measurably different somewhere as in an inch or so. A slight 1/8" difference here and there isn't going to matter.

Just a wild guess looking at the parts diagram I would make sure that the front piece that everything mounts to is not tweaked either front to back on one side, twisted, or camber. If any of those dimensions are way off, say from hitting something or a cracked member somewhere, the arc the arms and rods travel will change. The same may be true if the ride height on one side changes as in the frame being torqued. Also make sure the center plate is not tweaked or someone drilled new bolt holes moving it or where the steering bolts or clamps to it.

Just a wild guess looking at the parts diagram I would make sure that the front piece that everything mounts to is not tweaked either front to back on one side, twisted, or camber. If any of those dimensions are way off, say from hitting something or a cracked member somewhere, the arc the arms and rods travel will change. The same may be true if the ride height on one side changes as in the frame being torqued. Also make sure the center plate is not tweaked or someone drilled new bolt holes moving it or where the steering bolts or clamps to it.

#5

StarTech

StarTech

The NZTR steering is very sensitive to wear. And yes the inside turn wheel will go to nearly 90 degrees especially if wheels are toed out when going straight. Many of these mowers came out of the factory toed out which was many customers complaint as it cause both tire wear and steering problems.

The problem I have seen with the NZTR steering is the toe problems where a 1/8" bend adjustment can change the toe adjustment by as much as one inch. Usually when I repairing these system, every part get replaced with new parts. The short links usually has to be bent more to get the toe alignment right. Most times I only bend them where they are up to a 1/16" shorter each overall using a hydraulic press. Just putting on new parts will correct the toe problem without further bending of the new parts.

This NZTR steering is not DIYer friendly repair wise. I can spend several hours getting it right with the tools and experience I have with it.

On the following diagram items 80 thru 86 are the parts that wear the heaviest along with the ball joints in the items 61 and 62. Also items 67 can some alignment problems too.

.

.

The problem I have seen with the NZTR steering is the toe problems where a 1/8" bend adjustment can change the toe adjustment by as much as one inch. Usually when I repairing these system, every part get replaced with new parts. The short links usually has to be bent more to get the toe alignment right. Most times I only bend them where they are up to a 1/16" shorter each overall using a hydraulic press. Just putting on new parts will correct the toe problem without further bending of the new parts.

This NZTR steering is not DIYer friendly repair wise. I can spend several hours getting it right with the tools and experience I have with it.

On the following diagram items 80 thru 86 are the parts that wear the heaviest along with the ball joints in the items 61 and 62. Also items 67 can some alignment problems too.

.

.

#6

B

bertsmobile1

B

bertsmobile1

FWIW with all of these non adjustable steering set up's I put a threaded adjuster in some how

Some times the drag links are a suitable size to the threaded for a std tie rod end , some times I cut a strait section of a drag link then thread it and use a long sleeve nut ( called joiners for some strange reason ) and 1/2 width lock nuts

Whoever thought this system up was an idiot

While it will work perfectly backwards , front wards all that will happen is the wheels lock and the mower slide like what used to happen with solid rear axels

Probably the easiest thing to do would be to put a dolop of weld on the last 1 or 2 spaces between the teeth on the steering gear thus preventing it turning too far .

Some times the drag links are a suitable size to the threaded for a std tie rod end , some times I cut a strait section of a drag link then thread it and use a long sleeve nut ( called joiners for some strange reason ) and 1/2 width lock nuts

Whoever thought this system up was an idiot

While it will work perfectly backwards , front wards all that will happen is the wheels lock and the mower slide like what used to happen with solid rear axels

Probably the easiest thing to do would be to put a dolop of weld on the last 1 or 2 spaces between the teeth on the steering gear thus preventing it turning too far .

#7

StarTech

StarTech

I agree it is a very dumb design as its way over complicated. The designer was just trying to meet the demand for extra tight turning radius that only a true ZTR can do.

As the system develop wear which happens rather quickly depending on usage the mower can have correctly toed one direction and when going in the opposite direction have the toe change a lot. As I said before to correct the system when worn takes replacing every steering component. Even then you are very lucky if the alignment is right.

On this system adding adjustable ball joints or adjustable sleeves on items 61 and 62 don't really help that much as items 81 are the one that affects the adjustment the most. As if the 81s out whack by under a 16th of inch they can cause over an inch of alignment problem.

Now limiting the steering sector by welding up the last teeth on each side is something I haven't tried here to limit the overall turning radius but that should would work as an aftermarket design change. Just wish both spindles would turn the same amount at the max turning point but they don't due to play in the system. Luckily most customers don't need that tight of a turn when mowing.

As the system develop wear which happens rather quickly depending on usage the mower can have correctly toed one direction and when going in the opposite direction have the toe change a lot. As I said before to correct the system when worn takes replacing every steering component. Even then you are very lucky if the alignment is right.

On this system adding adjustable ball joints or adjustable sleeves on items 61 and 62 don't really help that much as items 81 are the one that affects the adjustment the most. As if the 81s out whack by under a 16th of inch they can cause over an inch of alignment problem.

Now limiting the steering sector by welding up the last teeth on each side is something I haven't tried here to limit the overall turning radius but that should would work as an aftermarket design change. Just wish both spindles would turn the same amount at the max turning point but they don't due to play in the system. Luckily most customers don't need that tight of a turn when mowing.

#8

B

bertsmobile1

B

bertsmobile1

Well whoever designed it had no idea how to split vectors a 1st year engineering subject

Anything over 45 deg and you are at the mercy of the diff to enact a turn

It would work well with rear wheel steering & front drive wheels but with that set up it would be a disaster

Obviously some shinny bum demanded that "they produce a tractor that steered as tight as a ZTR " because the results from the focus group stated the biggest problem with tractors was the turning radius

Then of course it would have been demonstrated in the car park on bitumen but not on grass where the friction is way way less.

I am amazed they have not been burried under a pile of law suits from people who did a very tight turn to avoid an object but the mower just kept on going strait & either hit it or went over the edge.

I did a recovery from a swimming pool last year because a McCulloh with the old tight turn failed to respond to a tight turn and just kept on going into the swimming pool

Anything over 45 deg and you are at the mercy of the diff to enact a turn

It would work well with rear wheel steering & front drive wheels but with that set up it would be a disaster

Obviously some shinny bum demanded that "they produce a tractor that steered as tight as a ZTR " because the results from the focus group stated the biggest problem with tractors was the turning radius

Then of course it would have been demonstrated in the car park on bitumen but not on grass where the friction is way way less.

I am amazed they have not been burried under a pile of law suits from people who did a very tight turn to avoid an object but the mower just kept on going strait & either hit it or went over the edge.

I did a recovery from a swimming pool last year because a McCulloh with the old tight turn failed to respond to a tight turn and just kept on going into the swimming pool

#9

J

jimbeau

J

jimbeau

Thanks. I think that will work.FWIW with all of these non adjustable steering set up's I put a threaded adjuster in some how

Some times the drag links are a suitable size to the threaded for a std tie rod end , some times I cut a strait section of a drag link then thread it and use a long sleeve nut ( called joiners for some strange reason ) and 1/2 width lock nuts

Whoever thought this system up was an idiot

While it will work perfectly backwards , front wards all that will happen is the wheels lock and the mower slide like what used to happen with solid rear axels

Probably the easiest thing to do would be to put a dolop of weld on the last 1 or 2 spaces between the teeth on the steering gear thus preventing it turning too far .

#10

Hammermechanicman

Hammermechanicman

When the ball hoints wear out this kit is better than OEM. This is what i put in.

Adjustable Drag Link Kit for 597069802 597069902 597069702 Husqvarna Craftsman | eBay

Find many great new & used options and get the best deals for Adjustable Drag Link Kit for 597069802 597069902 597069702 Husqvarna Craftsman at the best online prices at eBay! Free shipping for many products!

www.ebay.com

#11

J

jimbeau

J

jimbeau

Thanks to all. When I got the mower it had a sever toe-out. I replaced the drag links with adjustable ones (threaded ends). They were too long. I cut off 1/4" from each thread and that aligned the tires. I agree that most of us don't need sharp turns but I find that I can't judge the turns accurately enough to prevent the flop-outs. Stops on the steering plate should. work by stopping the drag links. I also think you might weld something on the spindles to stop the wheel. Any ideas about buying the parts to put the mower back to regular steering (only one drag link on each side?)

#12

J

jimbeau

J

jimbeau

Thanks. I installed this kit and it took care of the alignment but didn't help the flop-out. I had to cut off 1/4" of each thread in order to get alignment.When the ball hoints wear out this kit is better than OEM. This is what i put in.

Adjustable Drag Link Kit for 597069802 597069902 597069702 Husqvarna Craftsman | eBay

Find many great new & used options and get the best deals for Adjustable Drag Link Kit for 597069802 597069902 597069702 Husqvarna Craftsman at the best online prices at eBay! Free shipping for many products!www.ebay.com

#13

J

jimbeau

J

jimbeau

Thanks. I installed this kit and it took care of the alignment but didn't help the flop-out. I had to cut off 1/4" of each thread in order to get alignment.When the ball hoints wear out this kit is better than OEM. This is what i put in.

Adjustable Drag Link Kit for 597069802 597069902 597069702 Husqvarna Craftsman | eBay

Find many great new & used options and get the best deals for Adjustable Drag Link Kit for 597069802 597069902 597069702 Husqvarna Craftsman at the best online prices at eBay! Free shipping for many products!www.ebay.com

#14

J

jimbeau

J

jimbeau

Thanks. I installed this kit and it took care of the alignment but didn't help the flop-out. I had to cut off 1/4" of each thread in order to get alignment.

#15

sgkent

sgkent

have you tried (probably with two people) pushing the front of the tires together then the back when the wheels are straight ahead to see if there is a change in toe? I use a track rod or tape measure with a line drawn on the tire using a nail and piece of wood to make the line to measure toe. Lift tire, spin and use chalk to make a wide while line, use nail thru piece of plywood, bend tip, set on ground spin tire with nail rubbing on chalk to make a fine line, remove tool, set wheel down, do other, then rock or roll vehicle a foot or so, then use tape or track rod to measure toe. Set to manufacturer's specs, if none exist typically set between 1/16" and 1/8" toe in.

#16

B

bertsmobile1

B

bertsmobile1

When some one starts to market an uprated after market part it says something about the original design

#17

J

jimbeau

J

jimbeau

THANKS TO ALL! I am new to forums. I think while replying to one response I inadvertently erased it. The suggestion was to restrict the travel of the steering plate, thereby limiting the angle of turn. I tried that but the normal play in the linkage required quite a loss of steering plate angle to avoid the flop-out. I think if I can physically restrict the spindle turn in both directions I will get the maximum steering angle while avoiding flop-out. I report any finding. Again, thanks for your suggestions.

#18

J

jimbeau

J

jimbeau

Here is A fix that works for me. This scheme restricts the turn angle of the steering plate. If the linkage is tight you may need nothing or can use only one bolt. This restrictor can be moved when the linkage gets looser. I adjusted mine until just before the inside wheel flopped and I lost steering. The advantage of this over welding a restrictor on the steering plate or wheel yoke.is adjustability. Mount a restrictor on each side of the steering plate. If a wheel flops on either side move the corresponding restrictor in a little bit. Hope this helps someone.

Attachments

#19

J

johnorlandi

J

johnorlandi

Jimbeau is this something you made or purchased if you made would you please send some dimensions and how to install

My son bought a craftsman T3200 model 13BGA22W093 from Lowes and he has the same problem. Lowes won't help they told him to go to Craftsman and they won't help (after several emails) they told him to go to MTD so he is going to write them and see what they can do. The lawn tractor is still under warrantee, and he also purchased the extended warrantee, and the closest service center is over 100 miles. Any help would be appreciated

Happy Thanksgiving

My son bought a craftsman T3200 model 13BGA22W093 from Lowes and he has the same problem. Lowes won't help they told him to go to Craftsman and they won't help (after several emails) they told him to go to MTD so he is going to write them and see what they can do. The lawn tractor is still under warrantee, and he also purchased the extended warrantee, and the closest service center is over 100 miles. Any help would be appreciated

Happy Thanksgiving

#20

J

jimbeau

J

jimbeau

I made this out of scrap metal. The goal is to limit how far the steering plate turns in either direction. Technically, you need two washers and a bolt/nut for the stop. I used two bolts and spacer washers to keep the stop from slipping. This whole steering setup is poorly designed. It MIGHT work when new but as soon as the linkage ball joints wear a little, problems begin. If I had a newer machine I would try one bolt (the largest that will fit in the slot) with a heavy washer on top and one on the bottom. You can move this stop as needed.

I was given this mower and all of its components are well worn. I considered the steering a Safety issue that needed a fix. If you enlarge the 3rd picture you can see slot. It's easy to reach up and drop the bolt thru. Hope this helps.

I was given this mower and all of its components are well worn. I considered the steering a Safety issue that needed a fix. If you enlarge the 3rd picture you can see slot. It's easy to reach up and drop the bolt thru. Hope this helps.

#21

B

bertsmobile1

Looks like it will work fine

There is a weird idea that the only reason people buy ZTR's over tractors is the tighter turning so the answer to a problem that did not actually exist was to make tractors turn as tight as as a ZTR .

B

bertsmobile1

Nice jobHere is A fix that works for me. This scheme restricts the turn angle of the steering plate. If the linkage is tight you may need nothing or can use only one bolt. This restrictor can be moved when the linkage gets looser. I adjusted mine until just before the inside wheel flopped and I lost steering. The advantage of this over welding a restrictor on the steering plate or wheel yoke.is adjustability. Mount a restrictor on each side of the steering plate. If a wheel flops on either side move the corresponding restrictor in a little bit. Hope this helps someone.

Looks like it will work fine

There is a weird idea that the only reason people buy ZTR's over tractors is the tighter turning so the answer to a problem that did not actually exist was to make tractors turn as tight as as a ZTR .

#22

J

johnorlandi

J

johnorlandi

Jimbeau

thank you my son and I talked about maybe using a bolt as a stop. First, he is going to try to get MTD to fix it. This tractor is brand new only has 15/20 hours if that.

thank you my son and I talked about maybe using a bolt as a stop. First, he is going to try to get MTD to fix it. This tractor is brand new only has 15/20 hours if that.