burningstew

Forum Newbie

- Joined

- Oct 14, 2022

- Threads

- 1

- Messages

- 3

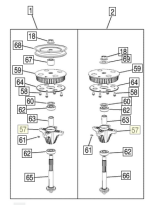

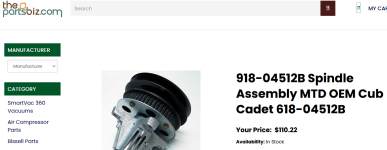

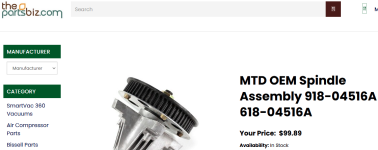

Hi first post and newish to the forum, wasnt sure if i should post here or in the general repairs section. Anyways, I ended up with a cub cadet i1042 (model 17AE9BKR010) a while ago and im just now getting around to fixing its issue with uneven mowing, one side is off by 3/4". Replaced a damaged blade with little/no change. Took the deck off and the spindle appears fine however the spindle housing has an ear thats completely broken off putting the blade at an angle. Unfortunately a new OEM spindle assembly is nearly 200$ and a fleabay one is ~140$.

Is there a way to safely rig/shim this so the blade is even again? Bearings seem fine and spin quietly and there is very little play in the pulley/blade itself. If not id also be open to getting a new housing as its only 40$ and reusing the guts from the current one, though ive never had one apart and dont know how involved/feasible such a task is, any advice?

Is there a way to safely rig/shim this so the blade is even again? Bearings seem fine and spin quietly and there is very little play in the pulley/blade itself. If not id also be open to getting a new housing as its only 40$ and reusing the guts from the current one, though ive never had one apart and dont know how involved/feasible such a task is, any advice?