You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Compression issue after rebuild

#1

E

Emsguy

E

Emsguy

Help everyone…. Ok, this is going to be lengthy. I have completely rebuilt my Briggs and Stratton model 31C707-0026-G. It all started with a broken piston Rod arm. I figured while I was rebuilding and the engine was old I replaced multiple parts. (Cam shaft, cam shaft timing gear, tappet valves, all gaskets) I just put everything back together, started it up with out the spark plug, turned the ignition key and the flywheel spins freely. Put the spark plug in, tried to turn it over and the fly wheel doesn’t want to turn. There is a lot of resistance. The flywheel just doesn’t want to turn. I did a little research and found that it could be a valve issue. I have a Briggs and Stratton service manual and adjusted the rocker valves to the required specs. Put the valve cover back on, cranked it over and had the same results. I now have back firing out of the carb and exhaust. It’s also very hard to turn over to the point where my starter was smoking, no issues with the battery and the starter is fine. After adjusting the valves, the flywheel will spin much better when I have the throttle cable to the lowest setting. When it’s at max, flywheel barely turns. I am suspecting that something is messed up with the timing in the cam shaft even though I lined the marks up. Does anyone have any suggestions?

#2

B

bertsmobile1

B

bertsmobile1

Check your valve lash

When you accidentially set them at TDC exhaust stroke rather then compression stroke that is exactly what happens .

When you accidentially set them at TDC exhaust stroke rather then compression stroke that is exactly what happens .

#3

E

Emsguy

E

Emsguy

Can you elaborate more or do you know of any YouTube videos that can explain it?Check your valve lash

When you accidentially set them at TDC exhaust stroke rather then compression stroke that is exactly what happens .

#4

StarTech

StarTech

To verify if compression remove the spark plug.

But I am thinking either an assembly error, wrong rod, or aluminum build up on the crankshaft journal.

But I am thinking either an assembly error, wrong rod, or aluminum build up on the crankshaft journal.

#5

J

Jegutierrez1

J

Jegutierrez1

I followed this lady on how to fix my riding mower but now i feel like im having the same problem as @Emsguy

#6

E

Emsguy

E

Emsguy

Ok so oddly enough I tightened the valves a little more than the specs and now it’s turning over with no problem… but now I have no start…

#7

E

Emsguy

E

Emsguy

I have compression now. I tightened the exhaust valve up a little more than specs… either my feeler gauge is wrong or some other reason. Now i have no startTo verify if compression remove the spark plug.

But I am thinking either an assembly error, wrong rod, or aluminum build up on the crankshaft journal.

#8

E

Emsguy

E

Emsguy

Also, I confirmed that I do have spark. I also sprayed a little carb cleaner into the intake to see if it would start and no luck

#9

E

Emsguy

E

Emsguy

Ok update on this… I took the whole thing apart and found that I had the cam shaft timing not lined up correctly….. smh…. Got everything back together, tried to adjust the valves again and now I have back firing out of the exhaust when I have the throttle cable at low speed. At this point I’m stumped…. Still won’t start

#11

T

Tbone0106

T

Tbone0106

Looking all the way back at the original post, it sure sounds like the wrong spark plug. As in too long. As in the piston is smacking the plug electrode.

Barring that, I'd check VERY carefully that the keyways on the top of the crankshaft and the flywheel align perfectly. There is a key in there to achieve that alignment, but only the proper torque on the flywheel nut will secure it sufficiently to the crankshaft. If the torque is too low, the flywheel will shift the very first time the spark plug fires, and that key will shear. Then your timing is gone, and that engine will never start.

Barring that, I'd check VERY carefully that the keyways on the top of the crankshaft and the flywheel align perfectly. There is a key in there to achieve that alignment, but only the proper torque on the flywheel nut will secure it sufficiently to the crankshaft. If the torque is too low, the flywheel will shift the very first time the spark plug fires, and that key will shear. Then your timing is gone, and that engine will never start.

#12

E

Emsguy

E

Emsguy

Thanks. I will check the flywheel key tonight and see if that fixes the issueLooking all the way back at the original post, it sure sounds like the wrong spark plug. As in too long. As in the piston is smacking the plug electrode.

Barring that, I'd check VERY carefully that the keyways on the top of the crankshaft and the flywheel align perfectly. There is a key in there to achieve that alignment, but only the proper torque on the flywheel nut will secure it sufficiently to the crankshaft. If the torque is too low, the flywheel will shift the very first time the spark plug fires, and that key will shear. Then your timing is gone, and that engine will never start.

#13

H

hlw49

H

hlw49

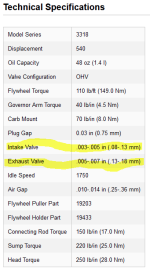

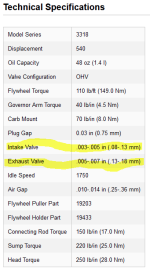

I watched her video and she was off on several key things. First off on the 33 cubic inch engine the valve setting is .003 to .005 on both valves. Next you always torque the pan and head gaskets in steps. I always do it in 1/3rds. She did not torque the rocker arm adjusting nut set screws. They torque to 45 inch lbs. Once you torque the set screws you should always recheck the valve clearance as it can change. Other than that she was pretty much on track. Those pan gaskets can be a pain in the arse to get off. I use gasket remover and that helps a lot.

#14

StarTech

And yes the clearances tend to change as you torque the set screws that why you have to slightly tighten them wile setting the clearance to take thread slack.

StarTech

Where you come up with both valve are the same? Here is the specs on my personal engine.I watched her video and she was off on several key things. First off on the 33 cubic inch engine the valve setting is .003 to .005 on both valves. Next you always torque the pan and head gaskets in steps. I always do it in 1/3rds. She did not torque the rocker arm adjusting nut set screws. They torque to 45 inch lbs. Once you torque the set screws you should always recheck the valve clearance as it can change. Other than that she was pretty much on track. Those pan gaskets can be a pain in the arse to get off. I use gasket remover and that helps a lot.

And yes the clearances tend to change as you torque the set screws that why you have to slightly tighten them wile setting the clearance to take thread slack.

#16

thesilentone

thesilentone

So many issues here, it's difficult to know where to start. The engine cranked without the spark plug, then no good once the plug is fitted ?

Is the spark plug the correct length and spec ? Is the battery good ?

Backfiring into the exhaust and carb sounds like timing all day long, however it's usually one or the other. (carb or exhaust), however it maybe dirt in the carb, this shows up as a similar problem.

What not just set the valve clearances to spec, that is what the specs are for !

This is a pretty basic big-pot motor, what broke the con rod ?

Is the spark plug the correct length and spec ? Is the battery good ?

Backfiring into the exhaust and carb sounds like timing all day long, however it's usually one or the other. (carb or exhaust), however it maybe dirt in the carb, this shows up as a similar problem.

What not just set the valve clearances to spec, that is what the specs are for !

This is a pretty basic big-pot motor, what broke the con rod ?

#17

E

Emsguy

Still no luck on it starting. Just put a new spark plug in and still no start. I am running out of ideas here. The last thing I can think of is taking a look at the carb but I literally just purchased a brand new one (Briggs and Stratton) so I highly doubt that’s it. When you start the engine, are you suppose to feel air come out of the air intake as well as air being pulled in? Oh and as in rebuilding component parts, I mean rebuilding everything on the frame of the tractor. Maybe I am having a hard time understanding the top dead center thing. The YouTube video I follow showed setting the valve clearances while one valve is completely opened.

Still no luck on it starting. Just put a new spark plug in and still no start. I am running out of ideas here. The last thing I can think of is taking a look at the carb but I literally just purchased a brand new one (Briggs and Stratton) so I highly doubt that’s it. When you start the engine, are you suppose to feel air come out of the air intake as well as air being pulled in? Oh and as in rebuilding component parts, I mean rebuilding everything on the frame of the tractor. Maybe I am having a hard time understanding the top dead center thing. The YouTube video I follow showed setting the valve clearances while one valve is completely opened.

E

Emsguy

Had the engine on its side after rebuilding all component parts. Didn’t realize all the oil leaked out and didn’t check the oil.So many issues here, it's difficult to know where to start. The engine cranked without the spark plug, then no good once the plug is fitted ?

Is the spark plug the correct length and spec ? Is the battery good ?

Backfiring into the exhaust and carb sounds like timing all day long, however it's usually one or the other. (carb or exhaust), however it maybe dirt in the carb, this shows up as a similar problem.

What not just set the valve clearances to spec, that is what the specs are for !

This is a pretty basic big-pot motor, what broke the con rod ?

#18

E

Emsguy

E

Emsguy

Valves are set to spec per the service manual.So many issues here, it's difficult to know where to start. The engine cranked without the spark plug, then no good once the plug is fitted ?

Is the spark plug the correct length and spec ? Is the battery good ?

Backfiring into the exhaust and carb sounds like timing all day long, however it's usually one or the other. (carb or exhaust), however it maybe dirt in the carb, this shows up as a similar problem.

What not just set the valve clearances to spec, that is what the specs are for !

This is a pretty basic big-pot motor, what broke the con rod ?

#19

thesilentone

There maybe a little 'blow back' into the carb when cranking, as there maybe a little lag, lead and overlap on the valves, to be honest, I don't really know.

thesilentone

If everything is assembled correctly, as they are keyed, it's simply a case of lining up the timing marks on the crank and cam shaft gears/teeth.Had the engine on its side after rebuilding all component parts. Didn’t realize all the oil leaked out and didn’t check the oil.Still no luck on it starting. Just put a new spark plug in and still no start. I am running out of ideas here. The last thing I can think of is taking a look at the carb but I literally just purchased a brand new one (Briggs and Stratton) so I highly doubt that’s it. When you start the engine, are you suppose to feel air come out of the air intake as well as air being pulled in? Oh and as in rebuilding component parts, I mean rebuilding everything on the frame of the tractor. Maybe I am having a hard time understanding the top dead center thing. The YouTube video I follow showed setting the valve clearances while one valve is completely opened.

There maybe a little 'blow back' into the carb when cranking, as there maybe a little lag, lead and overlap on the valves, to be honest, I don't really know.

#20

E

Emsguy

Do you know if the cam shaft style would make a difference? My old one is rounded at the end while the new one is slotted. From what I understand, the slotted one is also used for an engine with an oil pump.

Old one

E

Emsguy

If everything is assembled correctly, as they are keyed, it's simply a case of lining up the timing marks on the crank and cam shaft gears/teeth.

There maybe a little 'blow back' into the carb when cranking, as there maybe a little lag, lead and overlap on the valves, to be honest, I don't really know.

Do you know if the cam shaft style would make a difference? My old one is rounded at the end while the new one is slotted. From what I understand, the slotted one is also used for an engine with an oil pump.

Old one

#21

E

Emsguy

E

Emsguy

Do you know if the cam shaft style would make a difference? My old one is rounded at the end while the new one is slotted. From what I understand, the slotted one is also used for an engine with an oil pump.

New one

View attachment 63040

New oneDo you know if the cam shaft style would make a difference? My old one is rounded at the end while the new one is slotted. From what I understand, the slotted one is also used for an engine with an oil pump.

Old one

View attachment 63040

#23

StarTech

StarTech

As long as it is the 793880 superseded to 84005207 no it doesn't. Briggs went the oil pump only version to reduce inventory stocking.

#24

B

Bertrrr

B

Bertrrr

Pull the flywheel and see if the key is sheared or even partially sheared , this will throw off the ignition timing ,backfiring will contribute to this

#25

E

Emsguy

E

Emsguy

Checked it already, it’s finePull the flywheel and see if the key is sheared or even partially sheared , this will throw off the ignition timing ,backfiring will contribute to this

#26

Hammermechanicman

Hammermechanicman

I will throw the old $0.02 worth in.

Make 100% sure the cam to crank gear timing is correct

Make 100% sure the valves are being set properly. One valve open and adjust the other.

After valves are adjusted with spark plugs out slowly rotate engine and see that all valves open the same amount.

Double check valve lash.

Make 100% sure the flywheel key is intact and set coil gap to .010".

Install new spark plugs.

Get a can of starting fluid and with choke off and throttle at max spray about a 1 second shot into the intake and try to start engine. If everything is good engine will fire up for a few seconds. If it doesn't tell what it does.

If it doesn't start the next step would be a leakdown test but most DIY guys don't have one.

Make 100% sure the cam to crank gear timing is correct

Make 100% sure the valves are being set properly. One valve open and adjust the other.

After valves are adjusted with spark plugs out slowly rotate engine and see that all valves open the same amount.

Double check valve lash.

Make 100% sure the flywheel key is intact and set coil gap to .010".

Install new spark plugs.

Get a can of starting fluid and with choke off and throttle at max spray about a 1 second shot into the intake and try to start engine. If everything is good engine will fire up for a few seconds. If it doesn't tell what it does.

If it doesn't start the next step would be a leakdown test but most DIY guys don't have one.

#27

E

Emsguy

E

Emsguy

I will throw the old $0.02 worth in.

welp, I guess I have some positive news. I now have a large back fire from the exhaust with a ton of white smoke when I have the throttle lever on the “choke” position. Other than that still won’t start. Spark gap in the service manual says .30 which is what I have it at. I’ve adjusted the valves now about 7 times. I’m running out of ideas. I’ve checked the cam gear twice for timing and I corrected it the 2nd time I opened it.Make 100% sure the cam to crank gear timing is correct

Make 100% sure the valves are being set properly. One valve open and adjust the other.

After valves are adjusted with spark plugs out slowly rotate engine and see that all valves open the same amount.

Double check valve lash.

Make 100% sure the flywheel key is intact and set coil gap to .010".

Install new spark plugs.

Get a can of starting fluid and with choke off and throttle at max spray about a 1 second shot into the intake and try to start engine. If everything is good engine will fire up for a few seconds. If it doesn't tell what it does.

If it doesn't start the next step would be a leakdown test but most DIY guys don't have one.

#28

B

bertsmobile1

B

bertsmobile1

In cases like this I resort to a timing tape

In this case it is a piece of masking tape wrapped around the flywheel

Then with the piston at TDC ( or full front if you like ) I run a fine point pen down the side of the magneto laminations

I keep rotating and mark inlet opening & closing + the same for the exhaust + BDC

Then I peel it off & lay it on the bench

The distance between open & closed for each valve should be roughly the same and there must be about 1" of overlap at BDC .

Check that the coils are mounted the right way round ( usually kill wire is underneath )

If you don't know what you are doing then it is best to go by the book

The book says to turn the engine till it is on TDC compression stroke then go 1/4" back down which would be the firing stroke

TDC is when the piston is closest to the spark plug end of the cylinder

There are 2 on them on a 4 stroke

After the inlet has closed = firing stroke

When the exhaust is open = exhaust stroke

So forget what some smart arse says on boob tube.

Do it BY THE BOOK till you know what yo are doing & why .

In this case it is a piece of masking tape wrapped around the flywheel

Then with the piston at TDC ( or full front if you like ) I run a fine point pen down the side of the magneto laminations

I keep rotating and mark inlet opening & closing + the same for the exhaust + BDC

Then I peel it off & lay it on the bench

The distance between open & closed for each valve should be roughly the same and there must be about 1" of overlap at BDC .

Check that the coils are mounted the right way round ( usually kill wire is underneath )

If you don't know what you are doing then it is best to go by the book

The book says to turn the engine till it is on TDC compression stroke then go 1/4" back down which would be the firing stroke

TDC is when the piston is closest to the spark plug end of the cylinder

There are 2 on them on a 4 stroke

After the inlet has closed = firing stroke

When the exhaust is open = exhaust stroke

So forget what some smart arse says on boob tube.

Do it BY THE BOOK till you know what yo are doing & why .

#29

E

Emsguy

E

Emsguy

Thanks for the tip. Does this sound like valve issue to you? With the back firing and white smoke?In cases like this I resort to a timing tape

In this case it is a piece of masking tape wrapped around the flywheel

Then with the piston at TDC ( or full front if you like ) I run a fine point pen down the side of the magneto laminations

I keep rotating and mark inlet opening & closing + the same for the exhaust + BDC

Then I peel it off & lay it on the bench

The distance between open & closed for each valve should be roughly the same and there must be about 1" of overlap at BDC .

Check that the coils are mounted the right way round ( usually kill wire is underneath )

If you don't know what you are doing then it is best to go by the book

The book says to turn the engine till it is on TDC compression stroke then go 1/4" back down which would be the firing stroke

TDC is when the piston is closest to the spark plug end of the cylinder

There are 2 on them on a 4 stroke

After the inlet has closed = firing stroke

When the exhaust is open = exhaust stroke

So forget what some smart arse says on boob tube.

Do it BY THE BOOK till you know what yo are doing & why .

#30

thesilentone

If everything ' mechanical ' is OK, as has been discussed, timing, valve clearance etc, then time to look elsewhere.

You have a spark, so the only thing left is fuel.

How clean in the fuel you are using ?

Pour a little petrol into the inlet (not to much), then start the engine, it should run OK until that fuel has gone.

If it's still back-firing and spluttering, try another new spark plug.

If the problems still exist, you are doing/have done something wrong.

Just a final reminder, the valve your adjusting must be fully CLOSED.

thesilentone

This must be getting pretty frustrating.Thanks for the tip. Does this sound like valve issue to you? With the back firing and white smoke?

If everything ' mechanical ' is OK, as has been discussed, timing, valve clearance etc, then time to look elsewhere.

You have a spark, so the only thing left is fuel.

How clean in the fuel you are using ?

Pour a little petrol into the inlet (not to much), then start the engine, it should run OK until that fuel has gone.

If it's still back-firing and spluttering, try another new spark plug.

If the problems still exist, you are doing/have done something wrong.

Just a final reminder, the valve your adjusting must be fully CLOSED.

#31

Hammermechanicman

Hammermechanicman

I guess we are assuming the valves are seating and sealing properly. ????

Try rotating the engine till a valve is completely open and then check the lash on the other valve then rotate engine till the other valve is completely open and check the lash on the first valve.

It still sounds like a valve issue.

Try rotating the engine till a valve is completely open and then check the lash on the other valve then rotate engine till the other valve is completely open and check the lash on the first valve.

It still sounds like a valve issue.

#32

E

Emsguy

E

Emsguy

Fuel is almost brand new, Just got it a few weeks ago. I am beginning to wonder if something else got damaged when I ran this thing without oil (should've checked before starting.) When the dry engine stopped running, it completely snapped the arm rod in pieces, took a huge part out of the sump pan, and cracked the engine casing. Parts replaced were the sump pan (used), crank case (used), crank shaft (used) cam shaft, piston with the control rod, cam shaft timing gear, governor, and tappets. Also, during the midst of all of this the spark plug hole managed to strip out which I re-threaded with the "Sav-A-Thread 14m x 1.25 kit The push rods look straight to me. Do you think there could've been some kind of damage done to the valves during the dry run of the engine? The flywheel key was indeed partially after the engine abruptly stopped which has been replaced. At this point I am trying to rule out all options. I have not taken the carb apart yet because the thing was just replaced with an OEM Briggs last season and did not see much use. The engine ran just fine before all of this happened.This must be getting pretty frustrating.

If everything ' mechanical ' is OK, as has been discussed, timing, valve clearance etc, then time to look elsewhere.

You have a spark, so the only thing left is fuel.

How clean in the fuel you are using ?

Pour a little petrol into the inlet (not to much), then start the engine, it should run OK until that fuel has gone.

If it's still back-firing and spluttering, try another new spark plug.

If the problems still exist, you are doing/have done something wrong.

Just a final reminder, the valve your adjusting must be fully CLOSED.

#33

thesilentone

It ran for years defying all good practice advice.

You are to far in to abandon this project, however something key (and maybe simple) is missing here.

If in doubt, go back to the start and check it all again.

thesilentone

Years ago, I stuck a s/h piston and rod in a similar engine, cranked was marked, I just rubbed it with some emery tape. Welded to hole up in the engine, and ran it on the basis it would run until it died forever.Fuel is almost brand new, Just got it a few weeks ago. I am beginning to wonder if something else got damaged when I ran this thing without oil (should've checked before starting.) When the dry engine stopped running, it completely snapped the arm rod in pieces, took a huge part out of the sump pan, and cracked the engine casing. Parts replaced were the sump pan (used), crank case (used), crank shaft (used) cam shaft, piston with the control rod, cam shaft timing gear, governor, and tappets. Also, during the midst of all of this the spark plug hole managed to strip out which I re-threaded with the "Sav-A-Thread 14m x 1.25 kit The push rods look straight to me. Do you think there could've been some kind of damage done to the valves during the dry run of the engine? The flywheel key was indeed partially after the engine abruptly stopped which has been replaced. At this point I am trying to rule out all options. I have not taken the carb apart yet because the thing was just replaced with an OEM Briggs last season and did not see much use. The engine ran just fine before all of this happened.

It ran for years defying all good practice advice.

You are to far in to abandon this project, however something key (and maybe simple) is missing here.

If in doubt, go back to the start and check it all again.

#34

B

bertsmobile1

My original thoughts was the flywheel is not locked to the crankshaft so is slipping & sliding back & forth .

Some times you need to lap the flywheel in with fine grinding paste to get it to lock onto the taper.

Backfiring out the exhaust :-

Spark too late

Inconsistant sparking so unburned fuel fills muffler

Too rich a fuel mixture

Exhaust valve not fully closing ,

Backfiring through carb

Overheating ( not likely here )

Mixture too lean

Spark too early

inlet valve not fully closing .

So my initial thoughts were

1) loose flywheel

2) timed on the wrong stroke

3) valve lash set wrong ( bottom of the stroke not top of the stroke )

Note, top is nearest the spark plug , a bit confusing on vertical shaft engines .

BEcause you are new t all of this the easiest way to check the valves are closed when they should be is the see if you can turn the pushrods between your fingers

As you used the IOEC method of setting valve lash I would bet you have the lash set wrong so the valves are out of time which is why I suggested the tape

What I forgot to mention was to use 3 different coloured pens so you can clearly identify what is happening

When you tape the tape off you colour in the sections between each valve opening & closing .

Because it is a 4 stroke, you need to either divide the tape into upper & lower sections or do it twice with 2 pieces of tape .

I am fairly sure you have set the valve lash wrong & will find the valves open when they should be closed

B

bertsmobile1

IT really sounds like a timing issue to meThanks for the tip. Does this sound like valve issue to you? With the back firing and white smoke?

My original thoughts was the flywheel is not locked to the crankshaft so is slipping & sliding back & forth .

Some times you need to lap the flywheel in with fine grinding paste to get it to lock onto the taper.

Backfiring out the exhaust :-

Spark too late

Inconsistant sparking so unburned fuel fills muffler

Too rich a fuel mixture

Exhaust valve not fully closing ,

Backfiring through carb

Overheating ( not likely here )

Mixture too lean

Spark too early

inlet valve not fully closing .

So my initial thoughts were

1) loose flywheel

2) timed on the wrong stroke

3) valve lash set wrong ( bottom of the stroke not top of the stroke )

Note, top is nearest the spark plug , a bit confusing on vertical shaft engines .

BEcause you are new t all of this the easiest way to check the valves are closed when they should be is the see if you can turn the pushrods between your fingers

As you used the IOEC method of setting valve lash I would bet you have the lash set wrong so the valves are out of time which is why I suggested the tape

What I forgot to mention was to use 3 different coloured pens so you can clearly identify what is happening

When you tape the tape off you colour in the sections between each valve opening & closing .

Because it is a 4 stroke, you need to either divide the tape into upper & lower sections or do it twice with 2 pieces of tape .

I am fairly sure you have set the valve lash wrong & will find the valves open when they should be closed

#35

E

Emsguy

E

Emsguy

Know of any youtube videos showing this process?IT really sounds like a timing issue to me

My original thoughts was the flywheel is not locked to the crankshaft so is slipping & sliding back & forth .

Some times you need to lap the flywheel in with fine grinding paste to get it to lock onto the taper.

Backfiring out the exhaust :-

Spark too late

Inconsistant sparking so unburned fuel fills muffler

Too rich a fuel mixture

Exhaust valve not fully closing ,

Backfiring through carb

Overheating ( not likely here )

Mixture too lean

Spark too early

inlet valve not fully closing .

So my initial thoughts were

1) loose flywheel

2) timed on the wrong stroke

3) valve lash set wrong ( bottom of the stroke not top of the stroke )

Note, top is nearest the spark plug , a bit confusing on vertical shaft engines .

BEcause you are new t all of this the easiest way to check the valves are closed when they should be is the see if you can turn the pushrods between your fingers

As you used the IOEC method of setting valve lash I would bet you have the lash set wrong so the valves are out of time which is why I suggested the tape

What I forgot to mention was to use 3 different coloured pens so you can clearly identify what is happening

When you tape the tape off you colour in the sections between each valve opening & closing .

Because it is a 4 stroke, you need to either divide the tape into upper & lower sections or do it twice with 2 pieces of tape .

I am fairly sure you have set the valve lash wrong & will find the valves open when they should be closed

#36

B

bertsmobile1

B

bertsmobile1

Well as I know how to do it I don't go searching Boob Tube to find videos of other people doing it wrong .

You can pretty much trust Taryl Fixes All & Donny Boy 87 .

But you are missing the important point.

1) FIND OUT WHAT IS WRONG FIRST

then work out how to fix it .Fixing a problem that you don't have will not make your mower work

You can pretty much trust Taryl Fixes All & Donny Boy 87 .

But you are missing the important point.

1) FIND OUT WHAT IS WRONG FIRST

then work out how to fix it .Fixing a problem that you don't have will not make your mower work

#37

E

Emsguy

E

Emsguy

So to clarify, am I finding TDC on both the exhaust valve and intake valve and as I find the tdc, I adjust each correct?

#39

B

bertsmobile1

B

bertsmobile1

Ok lets get this right

Standing in front of the tractor looking down on the engine and turning the engine clockwise

TDC firing stroke , both valves closed

BDC power stroke inlet remains closed, exhaust just starts to open

TDC exhaust stroke exhaust starts to close inlet starts to open

BDC inlet stroke Exhaust fully closed inlet starts to close

TDC compression stroke inlet will have closed then opened a tiny amount to decompress then closed again

!/4" piston drop ( going back towards BDC is where you set & check the valve lash.

This is the fool proof method and the factory method .

The overly complicated method you picked up of face book is to allow for quietening ramps that your cam does not have and is very easy to get wrong

The IOEC method that I have to use on some of my vintage motorcycles is highly prone to error when you do not fully understand what you are doing because the inlet overlaps with the exhaust.

Apart from that the Briggs method only requires to move the piston once and you do both valves at the same time .

Standing in front of the tractor looking down on the engine and turning the engine clockwise

TDC firing stroke , both valves closed

BDC power stroke inlet remains closed, exhaust just starts to open

TDC exhaust stroke exhaust starts to close inlet starts to open

BDC inlet stroke Exhaust fully closed inlet starts to close

TDC compression stroke inlet will have closed then opened a tiny amount to decompress then closed again

!/4" piston drop ( going back towards BDC is where you set & check the valve lash.

This is the fool proof method and the factory method .

The overly complicated method you picked up of face book is to allow for quietening ramps that your cam does not have and is very easy to get wrong

The IOEC method that I have to use on some of my vintage motorcycles is highly prone to error when you do not fully understand what you are doing because the inlet overlaps with the exhaust.

Apart from that the Briggs method only requires to move the piston once and you do both valves at the same time .

#40

thesilentone

thesilentone

As it's the season of goodwill to all men, maybe try this

www.nulon.com.au

www.nulon.com.au

Start Ya Bastard Instant Engine Starter (SYB)

#41

G

gregjo1948

G

gregjo1948

I'd guess you aren't setting the valve lash correctly. Most small engines have a compression relief built into the cam. It opens the exhaust valve slightly and you may be adjusting the lash wrong.

#42

M

Mowerstevo

M

Mowerstevo

Need to check to make sure all your replacement parts are correct you used to rebuild it. Compare with the old ones…As long as the lash is set and the dots on the cam and crank are lined up, no sheared key, it’ll start. I have been down this road of sent wrong parts and key slots were off by a few degrees or timing dots were off because I was sent the wrong parts. This issue sounds like timing. If timing isn’t good then it won’t run at all or like crap.

#43

StarTech

And second the ACR does affects the intake valve. Plus Briggs says to adjust clearances at 1/4" pass TDC compression stroke. This with the piston moving down 1/4" at normal engine rotation direction. I find it is just easier to adjust each valve independently when the opposite valve is fully closed.

StarTech

First the intake valve is the one furthermost away from the flywheel, closest to the PTO end, as this engine uses a cross flow head.I'd guess you aren't setting the valve lash correctly. Most small engines have a compression relief built into the cam. It opens the exhaust valve slightly and you may be adjusting the lash wrong.

And second the ACR does affects the intake valve. Plus Briggs says to adjust clearances at 1/4" pass TDC compression stroke. This with the piston moving down 1/4" at normal engine rotation direction. I find it is just easier to adjust each valve independently when the opposite valve is fully closed.

#45

grumpyunk

grumpyunk

Did the new cam have the movable part that is spring loaded? That is the compression release that bumps the tappet/lifter when the rpms are low, and then swings out to stop bumping when rpms increase. It must be movable and also must return to rest when the engine comes to a stop. They are known to break readily and are the highest cause of cam replacement. Junk design that works for a while, and breaks on a whim. No fix except cam replacement at >$100 a pop. Extra cash and bonus for the designer...

If you read the shop instructions, the clearance is set with the piston 1/4" down from TDC(after). Or very similar. Get the book, PDF online I think.

If your compression at low speeds, with the valve clearance set at .003-.005", is more than the starter can handle, the likely the CR is not working. And it works as writ above. And means you will likely have to take it apart and inspect the cam/CR for sticky/bent/broken/?? parts.

tom

If you read the shop instructions, the clearance is set with the piston 1/4" down from TDC(after). Or very similar. Get the book, PDF online I think.

If your compression at low speeds, with the valve clearance set at .003-.005", is more than the starter can handle, the likely the CR is not working. And it works as writ above. And means you will likely have to take it apart and inspect the cam/CR for sticky/bent/broken/?? parts.

tom

#48

G

Gord Baker

G

Gord Baker

I suspected valve/cam gear timing. Since you have solved that, check the Flywheel Key to be sure it is not partially sheared.

A worn cam lobe would close valve(s) quicker so I doubt your new cam is at fault. Re set the valves per spec and check coil positioning. Perhaps you are running it too lean? Good Luck.

A worn cam lobe would close valve(s) quicker so I doubt your new cam is at fault. Re set the valves per spec and check coil positioning. Perhaps you are running it too lean? Good Luck.

#49

C

casual observer

C

casual observer

Help everyone…. Ok, this is going to be lengthy. I have completely rebuilt my Briggs and Stratton model 31C707-0026-G. It all started with a broken piston Rod arm. I figured while I was rebuilding and the engine was old I replaced multiple parts. (Cam shaft, cam shaft timing gear, tappet valves, all gaskets) I just put everything back together, started it up with out the spark plug, turned the ignition key and the flywheel spins freely. Put the spark plug in, tried to turn it over and the fly wheel doesn’t want to turn. There is a lot of resistance. The flywheel just doesn’t want to turn. I did a little research and found that it could be a valve issue. I have a Briggs and Stratton service manual and adjusted the rocker valves to the required specs. Put the valve cover back on, cranked it over and had the same results. I now have back firing out of the carb and exhaust. It’s also very hard to turn over to the point where my starter was smoking, no issues with the battery and the starter is fine. After adjusting the valves, the flywheel will spin much better when I have the throttle cable to the lowest setting. When it’s at max, flywheel barely turns. I am suspecting that something is messed up with the timing in the cam shaft even though I lined the marks up. Does anyone have any suggestions?

#50

M

mtodd101

M

mtodd101

I had similar problems with my motor. Came down to the flywheel key had sheared off and the flywheel was out of position. Fixed my motor. Good luck.

#51

C

casual observer

C

casual observer

Hi,

After reading your issue, , I think your problem is actually your starter motor circuit, could be electrical issue or a broken part or slipping part in the starter motor. A starter motor should always have enough guts to crank engine. The fact that you can turnover engine without sparkplug, but not with spark plug installed, when you get max compression, Also over tightening valves ,even slighty was letting compression out of engine, which allowed to crank.

I suggest you reset all of your original overhaul like you had it, they check out starter system, bad battery, wiring, starter motor, slipping overrunning clutch in starter motor.

If you can crank engine with starter rope, try that.

After reading your issue, , I think your problem is actually your starter motor circuit, could be electrical issue or a broken part or slipping part in the starter motor. A starter motor should always have enough guts to crank engine. The fact that you can turnover engine without sparkplug, but not with spark plug installed, when you get max compression, Also over tightening valves ,even slighty was letting compression out of engine, which allowed to crank.

I suggest you reset all of your original overhaul like you had it, they check out starter system, bad battery, wiring, starter motor, slipping overrunning clutch in starter motor.

If you can crank engine with starter rope, try that.

#53

doug9694

doug9694

Likely problem is defective decompression system. Old side valve engines had about 9 to 1 compression. OHV has much higher. Instead of putting on a stronger starter and bigger battery. Manufactures chose to add decompression schemes. Valves must be adjusted after the decompression part of the cam is past the valve stem. Or perhaps the decompression system is broke!Help everyone…. Ok, this is going to be lengthy. I have completely rebuilt my Briggs and Stratton model 31C707-0026-G. It all started with a broken piston Rod arm. I figured while I was rebuilding and the engine was old I replaced multiple parts. (Cam shaft, cam shaft timing gear, tappet valves, all gaskets) I just put everything back together, started it up with out the spark plug, turned the ignition key and the flywheel spins freely. Put the spark plug in, tried to turn it over and the fly wheel doesn’t want to turn. There is a lot of resistance. The flywheel just doesn’t want to turn. I did a little research and found that it could be a valve issue. I have a Briggs and Stratton service manual and adjusted the rocker valves to the required specs. Put the valve cover back on, cranked it over and had the same results. I now have back firing out of the carb and exhaust. It’s also very hard to turn over to the point where my starter was smoking, no issues with the battery and the starter is fine. After adjusting the valves, the flywheel will spin much better when I have the throttle cable to the lowest setting. When it’s at max, flywheel barely turns. I am suspecting that something is messed up with the timing in the cam shaft even though I lined the marks up. Does anyone have any suggestions?

#55

K

kinsler33

K

kinsler33

After you take some time away from your engine, disassemble it and re-assemble, but take an extra look at the carburetor. I'm speculating that you may have assembled something incorrectly and/or the fuel system isn't cooperating.

#56

Hammermechanicman

This thread is like a guy fell off a boat and can't swim and folks trying to tell him how to swim. Very entertaining.

Hammermechanicman

Just the whole thread in general.Was this comment directed at me

This thread is like a guy fell off a boat and can't swim and folks trying to tell him how to swim. Very entertaining.

#57

G

GDHS

G

GDHS

Methinks maybe the white smoke means something - like maybe the cylinder is flooded with oil.

And since not all of us are experienced mechanics, it would be good if writers (whose input is appreciated) would define the abbreviations they use. And we novices should try harder to use correct terminology. For example, to me, the words 'start' and 'crank' have different, distinct meanings. Like "my engine will crank but won't start". Just saying . . . .

And since not all of us are experienced mechanics, it would be good if writers (whose input is appreciated) would define the abbreviations they use. And we novices should try harder to use correct terminology. For example, to me, the words 'start' and 'crank' have different, distinct meanings. Like "my engine will crank but won't start". Just saying . . . .

#58

tew45

tew45

someone in the distant past very wisely said: For an internal combustion engine to run it must have fuel, compression, and a spark at the right time. He also said if all these were present it was beyond his expertise to repair. Apparently you do not have a spark at the right time due to cam gear misaligned or timing not right.

#59

T

Tom O'

T

Tom O'

If you have the issue with the timing and flywheel solved and your having problems with backfiring you may need to adjust the carburetor lean/rich settings. The new valves may be mixing less air than the old ones (tighter seating or gap setting or for some reason allowing more air). I'd try adjusting the fuel mixture if you think it's viable.Help everyone…. Ok, this is going to be lengthy. I have completely rebuilt my Briggs and Stratton model 31C707-0026-G. It all started with a broken piston Rod arm. I figured while I was rebuilding and the engine was old I replaced multiple parts. (Cam shaft, cam shaft timing gear, tappet valves, all gaskets) I just put everything back together, started it up with out the spark plug, turned the ignition key and the flywheel spins freely. Put the spark plug in, tried to turn it over and the fly wheel doesn’t want to turn. There is a lot of resistance. The flywheel just doesn’t want to turn. I did a little research and found that it could be a valve issue. I have a Briggs and Stratton service manual and adjusted the rocker valves to the required specs. Put the valve cover back on, cranked it over and had the same results. I now have back firing out of the carb and exhaust. It’s also very hard to turn over to the point where my starter was smoking, no issues with the battery and the starter is fine. After adjusting the valves, the flywheel will spin much better when I have the throttle cable to the lowest setting. When it’s at max, flywheel barely turns. I am suspecting that something is messed up with the timing in the cam shaft even though I lined the marks up. Does anyone have any suggestions?

#60

Appiefromholland

Appiefromholland

My first rebuild of an vanguard briggs and stratton I forgot to put the push rods in place

#61

J

Johner

J

Johner

Why did the crank break? assumed you hit something and now the key is offset on the fly wheel. Replace the key.

#62

T

The Road Warrior

The question is, why are you putting that much effort into a Briggs engine that is known as one of the cruelest jokes every perpetrated on the American consumer?

Briggs has been aware of the compression issues for many years. I scrap a truckload of these Briggs lemons annually.

Do yourself a BIG favor and scrap the headache and find a B&S 18-18.5 HP horizontally opposed, flathead engines. Lots of them out there if you know where to look. Usual cost is from free to 50 bucks.

If properly cared for, it’ll last a lifetime.

Ok everyone, give me your best shots!

T

The Road Warrior

Every time I ask this question regarding the Briggs model you’re having compression issues with, I get called out and disfellowshipped,Ok update on this… I took the whole thing apart and found that I had the cam shaft timing not lined up correctly….. smh…. Got everything back together, tried to adjust the valves again and now I have back firing out of the exhaust when I have the throttle cable at low speed. At this point I’m stumped…. Still won’t start

The question is, why are you putting that much effort into a Briggs engine that is known as one of the cruelest jokes every perpetrated on the American consumer?

Briggs has been aware of the compression issues for many years. I scrap a truckload of these Briggs lemons annually.

Do yourself a BIG favor and scrap the headache and find a B&S 18-18.5 HP horizontally opposed, flathead engines. Lots of them out there if you know where to look. Usual cost is from free to 50 bucks.

If properly cared for, it’ll last a lifetime.

Ok everyone, give me your best shots!

#63

B

bertsmobile1

I have 22 motorcycles of which 15 SV and get ridden a lot because they always go and require minimum maintenance ,

Most of the mowers I use regularly have flat head engines in them .

B

bertsmobile1

no arguement from meEvery time I ask this question regarding the Briggs model you’re having compression issues with, I get called out and disfellowshipped,

The question is, why are you putting that much effort into a Briggs engine that is known as one of the cruelest jokes every perpetrated on the American consumer?

Briggs has been aware of the compression issues for many years. I scrap a truckload of these Briggs lemons annually.

Do yourself a BIG favor and scrap the headache and find a B&S 18-18.5 HP horizontally opposed, flathead engines. Lots of them out there if you know where to look. Usual cost is from free to 50 bucks.

If properly cared for, it’ll last a lifetime.

Ok everyone, give me your best shots!

I have 22 motorcycles of which 15 SV and get ridden a lot because they always go and require minimum maintenance ,

Most of the mowers I use regularly have flat head engines in them .

#64

B

BMS

B

BMS

Sounds like a camshaft problem to me, you said you replaced them, did you do it by part number, or with used parts? Model 31 B&S singles had a lot of cam problems! Tappets were not right in a lot of the new engines when they were built. Also, the ACR arms were not hardened right at the factory. You did not post the code number, so i do not know the year it was produced. If your starter is damaged it may not crank it over, {never beat on a B&S starter it has a ceramic magnet in it for the field, if it gets a crack in the magnet the start will self-destruct and will draw the battery and have no power to turn the engine over. The ACR on the cam is very important, as the starter is not capable of turning the engine over if the compression is over 90 lbs. is the spring broken on the ACR flyweight? just some of the things that might be wrong with it, yes, i have been a B&S dealer over 50 years now, i know these engines well, my E-mail for my business is stanbms@msn.com

#65

E

Emsguy

E

Emsguy

I purchased it by part number. Still can’t get it to run.Sounds like a camshaft problem to me, you said you replaced them, did you do it by part number, or with used parts? Model 31 B&S singles had a lot of cam problems! Tappets were not right in a lot of the new engines when they were built. Also, the ACR arms were not hardened right at the factory. You did not post the code number, so i do not know the year it was produced. If your starter is damaged it may not crank it over, {never beat on a B&S starter it has a ceramic magnet in it for the field, if it gets a crack in the magnet the start will self-destruct and will draw the battery and have no power to turn the engine over. The ACR on the cam is very important, as the starter is not capable of turning the engine over if the compression is over 90 lbs. is the spring broken on the ACR flyweight? just some of the things that might be wrong with it, yes, i have been a B&S dealer over 50 years now, i know these engines well, my E-mail for my business is stanbms@msn.com

I purchased the cam shaft new by part number. Still can’t get it to run. I’ve tried everything. Code is 100916ZD. I’m going to send you an email.Sounds like a camshaft problem to me, you said you replaced them, did you do it by part number, or with used parts? Model 31 B&S singles had a lot of cam problems! Tappets were not right in a lot of the new engines when they were built. Also, the ACR arms were not hardened right at the factory. You did not post the code number, so i do not know the year it was produced. If your starter is damaged it may not crank it over, {never beat on a B&S starter it has a ceramic magnet in it for the field, if it gets a crack in the magnet the start will self-destruct and will draw the battery and have no power to turn the engine over. The ACR on the cam is very important, as the starter is not capable of turning the engine over if the compression is over 90 lbs. is the spring broken on the ACR flyweight? just some of the things that might be wrong with it, yes, i have been a B&S dealer over 50 years now, i know these engines well, my E-mail for my business is stanbms@msn.com

#66

E

Emsguy

E

Emsguy

It is a brand new cam shaft. The spring is working and the cam shaft is lined up correctly with the dot. I’ve went through every suggestion on here to set the valve lash and still get the same results. Here is a video of what it is doing…..

#67

E

Emsguy

E

Emsguy

Key has been replaced and is still intactWhy did the crank break? assumed you hit something and now the key is offset on the fly wheel. Replace the key.

#68

E

Emsguy

E

Emsguy

Ok,

Just want to update. I purchased a leak down tester last night and ran 100 PSI at TDC (compression stroke) The results were about a 15-18% leak. Hissing could be heard coming from the breather tube which was connected to the intake tube as well as hissing could be heard coming from the dipstick tube when I removed the dipstick. I took measurements of the bore from the top, middle and bottom with a telescoping gauge and measured with a dial caliper with a result of 3.563in which matches appropriately with the service manual. So at this point I’m thinking that this has to be an issue with the piston rings and causing blow by. I did purchase a new piston during this rebuild (p/n 594539) and I am fairly certain that I followed the instructions correctly with making sure the paint lines were to the right of the gap and making sure to use the correct ring for the center ring. I also made sure that no ring gaps were lined up with each other upon placing the piston back in. Did I miss something? Are the gaps suppose to be at a certain position on the piston (center ring at 2 o’clock position 8 o’clock position, etc) ?

Just want to update. I purchased a leak down tester last night and ran 100 PSI at TDC (compression stroke) The results were about a 15-18% leak. Hissing could be heard coming from the breather tube which was connected to the intake tube as well as hissing could be heard coming from the dipstick tube when I removed the dipstick. I took measurements of the bore from the top, middle and bottom with a telescoping gauge and measured with a dial caliper with a result of 3.563in which matches appropriately with the service manual. So at this point I’m thinking that this has to be an issue with the piston rings and causing blow by. I did purchase a new piston during this rebuild (p/n 594539) and I am fairly certain that I followed the instructions correctly with making sure the paint lines were to the right of the gap and making sure to use the correct ring for the center ring. I also made sure that no ring gaps were lined up with each other upon placing the piston back in. Did I miss something? Are the gaps suppose to be at a certain position on the piston (center ring at 2 o’clock position 8 o’clock position, etc) ?

#69

B

BMS

B

BMS

Did you check the exhaust seat in the head? It may be loose.Ok,

Just want to update. I purchased a leak down tester last night and ran 100 PSI at TDC (compression stroke) The results were about a 15-18% leak. Hissing could be heard coming from the breather tube which was connected to the intake tube as well as hissing could be heard coming from the dipstick tube when I removed the dipstick. I took measurements of the bore from the top, middle and bottom with a telescoping gauge and measured with a dial caliper with a result of 3.563in which matches appropriately with the service manual. So at this point I’m thinking that this has to be an issue with the piston rings and causing blow by. I did purchase a new piston during this rebuild (p/n 594539) and I am fairly certain that I followed the instructions correctly with making sure the paint lines were to the right of the gap and making sure to use the correct ring for the center ring. I also made sure that no ring gaps were lined up with each other upon placing the piston back in. Did I miss something? Are the gaps suppose to be at a certain position on the piston (center ring at 2 o’clock position 8 o’clock position, etc) ?

#70

E

Emsguy

E

Emsguy

Alright,

Here is a super exciting update. I think I have the problem figured out. When I ordered a new crank shaft, I went part number for part number. But here is the problem. The flywheel key inserts are in different locations. The crank shaft on the right is the bad one. Gotta be the wrong crank shaft that I ordered! Now for the Briggs and Stratton experts, why did the change the design of the part number?

Here is a super exciting update. I think I have the problem figured out. When I ordered a new crank shaft, I went part number for part number. But here is the problem. The flywheel key inserts are in different locations. The crank shaft on the right is the bad one. Gotta be the wrong crank shaft that I ordered! Now for the Briggs and Stratton experts, why did the change the design of the part number?

#71

StarTech

StarTech

Here is the problem. First old crankshaft still has the aluminum transfer on the rod journal which will only destroy the new rod.

Second you have now ordered the wrong crankshaft for your engine as they must be ordered per the date code. Briggs changed them and the flywheel back in 2012. Now that you have a the newer crankshaft you will also new the new flywheel and the longer key. You will also that the flywheel timing is now differently keyed. The reason for the change was that the flywheel key was shearing and destroying the flywheel due the way it was aligned in the keyway. This all explained in the APSI 89 issued by Briggs to the dealers.

The only solution now is to either return the incorrect crankshaft (if they will accept it back) and get the correct one or order a new flywheel and key the that is match to the new crankshaft.

Originally all you had to do is use some Muriatic Acid and cleaned the rod journal and lubed.

Now you can see why having all the engine's info is important as changes are made along the way.

Second you have now ordered the wrong crankshaft for your engine as they must be ordered per the date code. Briggs changed them and the flywheel back in 2012. Now that you have a the newer crankshaft you will also new the new flywheel and the longer key. You will also that the flywheel timing is now differently keyed. The reason for the change was that the flywheel key was shearing and destroying the flywheel due the way it was aligned in the keyway. This all explained in the APSI 89 issued by Briggs to the dealers.

The only solution now is to either return the incorrect crankshaft (if they will accept it back) and get the correct one or order a new flywheel and key the that is match to the new crankshaft.

Originally all you had to do is use some Muriatic Acid and cleaned the rod journal and lubed.

Now you can see why having all the engine's info is important as changes are made along the way.

#72

E

Emsguy

E

Emsguy

This is how an amateur learns from his mistakes. There was no saving the Rod journal. What’s not shown in the picture is on the other side of the journal is a huge chunk that was taken out during the blow out.Here is the problem. First old crankshaft still has the aluminum transfer on the rod journal which will only destroy the new rod.

Second you have now ordered the wrong crankshaft for your engine as they must be ordered per the date code. Briggs changed them and the flywheel back in 2012. Now that you have a the newer crankshaft you will also new the new flywheel and the longer key. You will also that the flywheel timing is now differently keyed. The reason for the change was that the flywheel key was shearing and destroying the flywheel due the way it was aligned in the keyway. This all explained in the APSI 89 issued by Briggs to the dealers.

The only solution now is to either return the incorrect crankshaft (if they will accept it back) and get the correct one or order a new flywheel and key the that is match to the new crankshaft.

Originally all you had to do is use some Muriatic Acid and cleaned the rod journal and lubed.

Now you can see why having all the engine's info is important as changes are made along the way.

#73

StarTech

Personally I don't have very deep pockets so I have to do my research before committing to things.

StarTech

See that why we images that covers all the damage but I have yet to see a crankshaft steel to be missing a chuck out the rod journal out of nearly 100 crankshaft rod failures. But I even hate to see amateur make these mistakes as it is costly at times.This is how an amateur learns from his mistakes. There was no saving the Rod journal. What’s not shown in the picture is on the other side of the journal is a huge chunk that was taken out during the blow out.

Personally I don't have very deep pockets so I have to do my research before committing to things.