You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Burning oil, Tear Down Time.

#1

E

ESully

E

ESully

I have a 19 year old Craftsman 42" Lawn Tractor with a Briggs & Stratton Model 407777 Type 0167E1 Code 020311YG engine.

It has done well over the years, but oil usage tells me it's time to open it up. I'm thinking it will need at least a new set of rings, but of course I won't know for sure till I open it up.

Currently it has about 160 psi compression on both cyclinders. It tends to run ok if I keep the oil at the low mark on the dip stick, but if I bring it above that oil usage goes up quite a bit.

I have rebuilt a few car and motorcycle engines over the years, but never a lawn mower engine. I was wondering if anyone could guide me on where to find torque specs and a good source for parts. Also if anyone has a link for a good rebuild link or video.

Thanks, Ed

It has done well over the years, but oil usage tells me it's time to open it up. I'm thinking it will need at least a new set of rings, but of course I won't know for sure till I open it up.

Currently it has about 160 psi compression on both cyclinders. It tends to run ok if I keep the oil at the low mark on the dip stick, but if I bring it above that oil usage goes up quite a bit.

I have rebuilt a few car and motorcycle engines over the years, but never a lawn mower engine. I was wondering if anyone could guide me on where to find torque specs and a good source for parts. Also if anyone has a link for a good rebuild link or video.

Thanks, Ed

#2

B

bertsmobile1

B

bertsmobile1

Service manuals for B & S engines are all over the web

Broken down into side valve or OHV & Single or twin so get the right one for your engine

At worst you can buy used manuals on evilpay or craigs List .

If you have done a motorcycle then you can do a mower.

Only real trick is the con rod can only go in one way or it will foul on the case.

If your engine has a counterweight then always replace the bolt that holds the halves together

Broken down into side valve or OHV & Single or twin so get the right one for your engine

At worst you can buy used manuals on evilpay or craigs List .

If you have done a motorcycle then you can do a mower.

Only real trick is the con rod can only go in one way or it will foul on the case.

If your engine has a counterweight then always replace the bolt that holds the halves together

#3

S

slomo

S

slomo

Are the valves set proper? 160 psi sounds like the head is full of carbon or the valves are really loose??

What oil are you using?

Pull the head/s and decarbon the head and valves.

Clean the cooling fins while you are at it.

What oil are you using?

Pull the head/s and decarbon the head and valves.

Clean the cooling fins while you are at it.

#4

E

ESully

E

ESully

I'm sure there is carbon buildup, which is why I think it is time for new rings.

I use Rotella 30wt.

I use Rotella 30wt.

#5

E

ESully

E

ESully

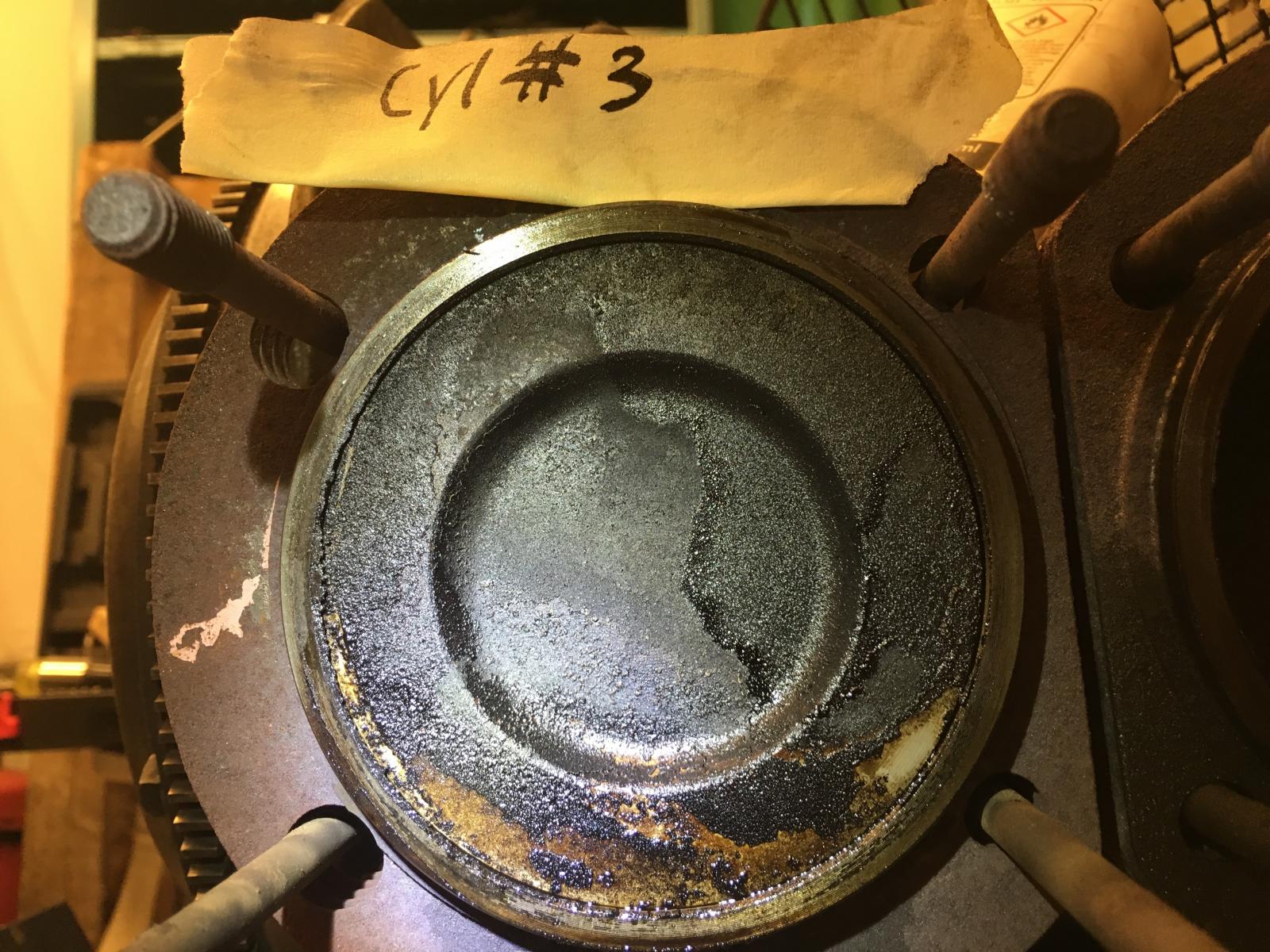

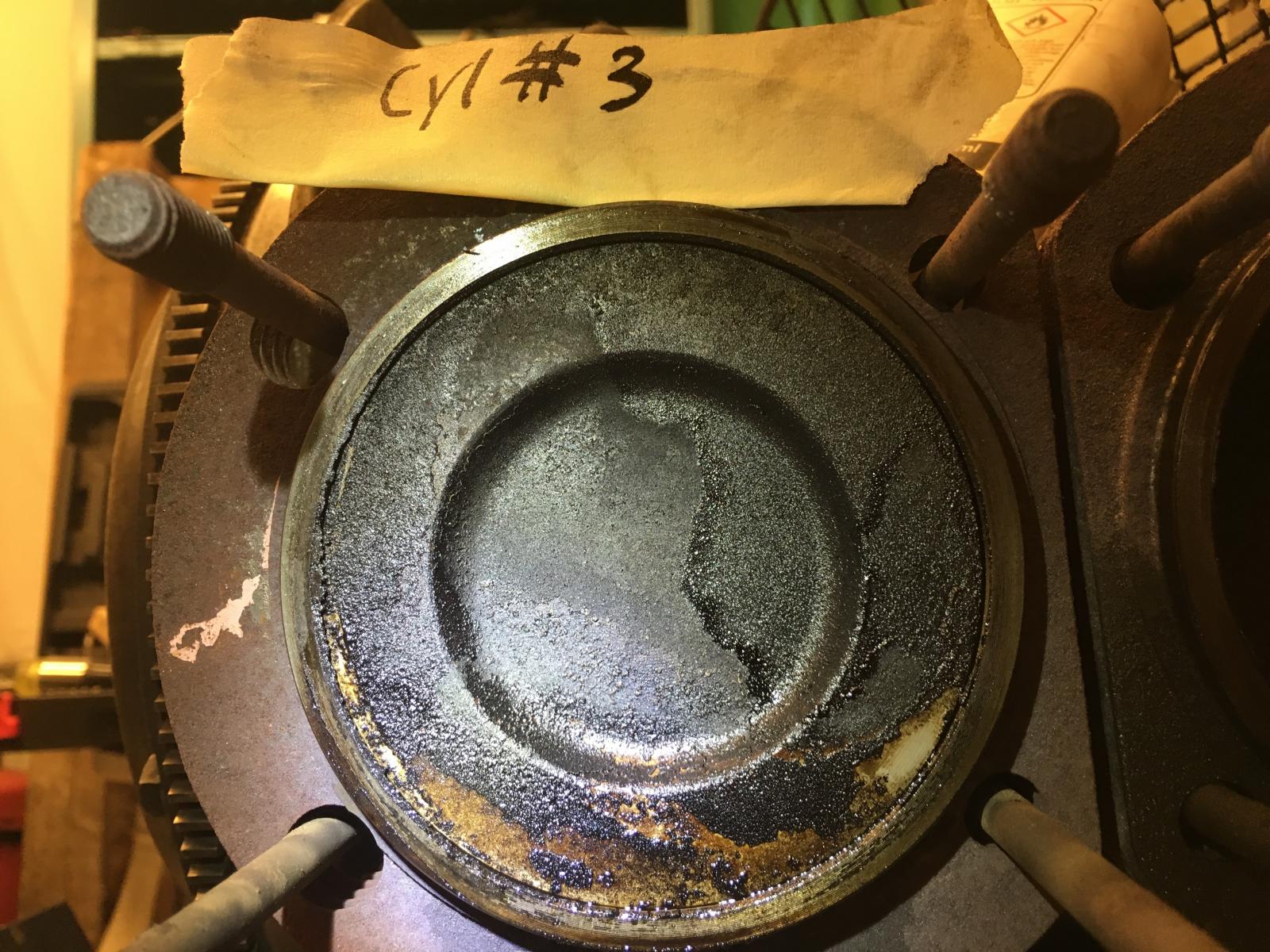

I finally finished using the mower for the season, so it was time for a tear-down. I removed the majority of gunk from the engine, with a little further clean up to go. Before I pulled it, I added BG engine cleaner to the oil and some Wurth intake cleaner through the carburetor throats. Prior to this, the plugs were carboned up enough for one cylinder to quit. Internals look very nice after 19 years of 1 1/2 hours a week, with a good patch of carbon on the pistons. Intake valve was great, exhaust had some minor build up. I forgot to take pictures of heads before I went home. The cylinder walls are nice and shiny with some crosshatch still left, reflecting the piston top nicely.

I was planning to hone the cylinders and new rings, along with lapping the valves and new seals on the intake valves.

I was planning to hone the cylinders and new rings, along with lapping the valves and new seals on the intake valves.

#6

E

ESully

E

ESully

I finally had a bit of warm weather last week and gave the mower a break in run. After a nice run I drained the oil. It was of course quite dirty from assembly lube and ring seating.

I gave it fresh oil and this week used it for an hour with the trailer hauling debris from my spring yard cleanup. The new rings and valve guide seals seem to have worked. It's running great, no oil burning, and the oil looks clean. I'll pull the valve covers soon and check the valve clearances, but overall I'm very happy with how it turned out.

I gave it fresh oil and this week used it for an hour with the trailer hauling debris from my spring yard cleanup. The new rings and valve guide seals seem to have worked. It's running great, no oil burning, and the oil looks clean. I'll pull the valve covers soon and check the valve clearances, but overall I'm very happy with how it turned out.

#7

sgkent

sgkent

the clean areas on the edge of the piston are caused by oil washing over the rings. If the carbon was all the way to the piston edge it would not be coming by the rings. The detergents in the oil dissolve the carbon. That is one way we could always determine where oil was coming from as we took engines apart to machine them. That piston photo shows that a lot of oil has been coming by the rings.

#8

B

bertsmobile1

Never have

Never will

DETERGENTS Carry away foreign particles and prevent them joining together to form a sludge

Some of the really sofisticated ones will allow a small number of foreign particles to join till it gets to a particular size to make filtering more efficient .

SOLVENTS dissolve which is why they are called SOLVENTS

Unfortunately the fluid under the sink is mislabeled as detergent and it cleans your dishes so to the drug addled brain ( or what was left of it ) of an advertising agency creative if washing u detergent cleans his cocain impliments then a detergent oil must clean your engine .

From then on it sank into peoples minds and stayed there with all the other trash like a dewatering solution is the same as a penetrating fluid

A detergent is a dispersant of sorts although on a molecular level they work slightly differently .

B

bertsmobile1

DETERGENTS DO NOT DISSOLVE ANYTHINGthe clean areas on the edge of the piston are caused by oil washing over the rings. If the carbon was all the way to the piston edge it would not be coming by the rings. The detergents in the oil dissolve the carbon. That is one way we could always determine where oil was coming from as we took engines apart to machine them. That piston photo shows that a lot of oil has been coming by the rings.

Never have

Never will

DETERGENTS Carry away foreign particles and prevent them joining together to form a sludge

Some of the really sofisticated ones will allow a small number of foreign particles to join till it gets to a particular size to make filtering more efficient .

SOLVENTS dissolve which is why they are called SOLVENTS

Unfortunately the fluid under the sink is mislabeled as detergent and it cleans your dishes so to the drug addled brain ( or what was left of it ) of an advertising agency creative if washing u detergent cleans his cocain impliments then a detergent oil must clean your engine .

From then on it sank into peoples minds and stayed there with all the other trash like a dewatering solution is the same as a penetrating fluid

A detergent is a dispersant of sorts although on a molecular level they work slightly differently .

#9

sgkent

sgkent

I worked for a guy who built among others, Al Unser Jr's winning engines. He also built winning FI engines and Indy engines. The oil washing over the piston tops container additives that the oil industry calls "detergents" as in a generic term, that wash the carbon away. That is a fact. I don't wish to argue with you but if you insist go pick on someone else.

#10

R

Rivets

R

Rivets

The detergents that are put in oil to hold contaminants in suspension until they can be removed from the engine. As Bert said they are not cleaners. In a properly tuned engine the amount of carbon above the piston head should be negligible as the extremely small of oil which is not scrapped down by the oil ring is burned away during normal operation. If you really want to get picky, carbon is a solid which there is not known solvent for. The detergent holds it in suspension until you change the oil. What most people call carbon in a cylinder is really oil in a non fluid state, which can be dissolved with a solvent.

#11

sgkent

sgkent

y'all are wrong again. This GM Top Cyl cleaner will dissolve carbon/coke in an engine. I did a test of about 10 -15 different cleaners on some hard carbon that had deposited on some CJ7 valves 30 some years ago. This is the only stuff that worked. It turned the rock hard coked up deposits into like toothpaste over night.

If you look at his photos you will see one of his piston. Carbon is only in the center. That is because the oil washed the carbon away. I bored and rebuilt maybe 3,600 engines as a machinist. I do know what I am talking about here. In fact, y'all should get stuck cleaning up an old block from the 30's that used non-detergent oil. You'll need long drills and things like that to get the packed dirt out of the passages. Just awful. Modern oils do a good job of carrying carbon deposits away. If you ever get a chance to work on a used hydrogen engine - the oil is as clean 50,000 miles later as it was on the day it was put in because there is no C in the H2 unlike Hydro Carbons that are full of C.

If you look at his photos you will see one of his piston. Carbon is only in the center. That is because the oil washed the carbon away. I bored and rebuilt maybe 3,600 engines as a machinist. I do know what I am talking about here. In fact, y'all should get stuck cleaning up an old block from the 30's that used non-detergent oil. You'll need long drills and things like that to get the packed dirt out of the passages. Just awful. Modern oils do a good job of carrying carbon deposits away. If you ever get a chance to work on a used hydrogen engine - the oil is as clean 50,000 miles later as it was on the day it was put in because there is no C in the H2 unlike Hydro Carbons that are full of C.

Attachments

#12

R

Rivets

R

Rivets

Seeing that I’m on the other side of 70 I do know about non detergent oils. I’ve pulled oil pans with two inches of crud on the bottom, from engines run with non detergent oil. When the oil companies started adding additives such as detergents/dispersants to oil it changed how clean an engine will run. What do the oil companies say they do?

DETERGENTS

Detergents are designed to keep your engine running clean by removing deposits from engine parts and preventing rust. Detergents neutralize oil impurities and acids created during oxidation. Because detergents keep engine oil deposits and impurities soluble, these types of oil additives are crucial for preventing oil sludge in your vehicle’s engine.

DISPERSANTS

A partner to detergents, dispersants help prevent deposition and sludge by suspending solid particles in your engine oil. Dispersants keep your engine clean by preventing particles and impurities from settling on metal components. Dispersants also help maintain the viscosity of your engine oil for reliable performance at any temperature.

DETERGENTS

Detergents are designed to keep your engine running clean by removing deposits from engine parts and preventing rust. Detergents neutralize oil impurities and acids created during oxidation. Because detergents keep engine oil deposits and impurities soluble, these types of oil additives are crucial for preventing oil sludge in your vehicle’s engine.

DISPERSANTS

A partner to detergents, dispersants help prevent deposition and sludge by suspending solid particles in your engine oil. Dispersants keep your engine clean by preventing particles and impurities from settling on metal components. Dispersants also help maintain the viscosity of your engine oil for reliable performance at any temperature.

#13

sgkent

sgkent

yawn. Sorry, was putting me to sleep, discussing irrelevant things. This is caused by oil washing past the rings, and a lot of it.

#14

B

bertsmobile1

B

bertsmobile1

I am not trying to be a nit picker nor start arguements for the fun of it

I taught an introduction to lubricants to TAFE students back in the 70's & 80's .

And again it is the solvents ionizers & oxadizers that do the cleaning, not the detergents

The Ph adjusters also play a big part

In a lot of diesel engines you do not want to disturb the ridge ring of carbon at the top of the cylinder as it take a lot of the punishment off the fire ring .

And yes I have pulled down my fair share of old engines, rolling mills and other gear that uses sludging oils with settling tanks as part of the oil management system apart

And yes badly designed / poorly maintained ones needed the oil galleries drilled out

And I have been riding and repairing British motorcycles since I was 13 and like Rivets I am on the wrong side of 70 as well

From Friday to Tuesday I will be out riding one of my 90 + year old motorcycles running non- detergent oil, in fact the first BSA model to have a recirculating oil system, ignoring the brief experiment with sumps & oil flingers .

As for soaking parts in oil and having them soften the deposit not relevent as it never happens inside an engine but handy to know when it comes to cleaning them.

When people who know some thing is wrong it is their duty to correct it

The misnomer that detegents clean is wide spread

There are detergent oils that do not clean but these are rarely used in engines.

Whe I say some thing that is wrong, I expect others who know it is wrong to correct me as well which has happened here on more than one occasion.

Before the internet a lie tol a million times was still a lie

However now days a lie posted 500 times becomes an undisputable fact .

I taught an introduction to lubricants to TAFE students back in the 70's & 80's .

And again it is the solvents ionizers & oxadizers that do the cleaning, not the detergents

The Ph adjusters also play a big part

In a lot of diesel engines you do not want to disturb the ridge ring of carbon at the top of the cylinder as it take a lot of the punishment off the fire ring .

And yes I have pulled down my fair share of old engines, rolling mills and other gear that uses sludging oils with settling tanks as part of the oil management system apart

And yes badly designed / poorly maintained ones needed the oil galleries drilled out

And I have been riding and repairing British motorcycles since I was 13 and like Rivets I am on the wrong side of 70 as well

From Friday to Tuesday I will be out riding one of my 90 + year old motorcycles running non- detergent oil, in fact the first BSA model to have a recirculating oil system, ignoring the brief experiment with sumps & oil flingers .

As for soaking parts in oil and having them soften the deposit not relevent as it never happens inside an engine but handy to know when it comes to cleaning them.

When people who know some thing is wrong it is their duty to correct it

The misnomer that detegents clean is wide spread

There are detergent oils that do not clean but these are rarely used in engines.

Whe I say some thing that is wrong, I expect others who know it is wrong to correct me as well which has happened here on more than one occasion.

Before the internet a lie tol a million times was still a lie

However now days a lie posted 500 times becomes an undisputable fact .

#15

StarTech

When I was a lot younger I was told to use automatic transmission fluid to de coke an engine. Smokes like a freight train engine climbing a hill. It supposedly mixed with carbon and burn off burn both.

Well anyway the engine needs to check for wear of the bore and since it is a Briggs v-twin especially the #2 cylinder as I have seen several where #1 was fine but #2 be worn oval and tapered. Just a person observation here. In the picture it does looks like the top ring is out spec end gap wise.

If worn tapered then a rebuild with OS pistons and rings if it can OS to 0.020 OS but I had seen a couple that went over that and since Briggs no longer supply pistons that 0.030 OS it kills a rebuild.

As for oil used all we can do is to used the best oil we can and hope it manufacture has done their job on blending it with good additives. I currently switching most of my customer over to synthetics due our high Summer air temps to increase the maximum operating temp range.

StarTech

Or when it gets filtered out on engines with good oil filters.The detergents that are put in oil to hold contaminants in suspension until they can be removed from the engine. As Bert said they are not cleaners. In a properly tuned engine the amount of carbon above the piston head should be negligible as the extremely small of oil which is not scrapped down by the oil ring is burned away during normal operation. If you really want to get picky, carbon is a solid which there is not known solvent for. The detergent holds it in suspension until you change the oil. What most people call carbon in a cylinder is really oil in a non fluid state, which can be dissolved with a solvent.

When I was a lot younger I was told to use automatic transmission fluid to de coke an engine. Smokes like a freight train engine climbing a hill. It supposedly mixed with carbon and burn off burn both.

Well anyway the engine needs to check for wear of the bore and since it is a Briggs v-twin especially the #2 cylinder as I have seen several where #1 was fine but #2 be worn oval and tapered. Just a person observation here. In the picture it does looks like the top ring is out spec end gap wise.

If worn tapered then a rebuild with OS pistons and rings if it can OS to 0.020 OS but I had seen a couple that went over that and since Briggs no longer supply pistons that 0.030 OS it kills a rebuild.

As for oil used all we can do is to used the best oil we can and hope it manufacture has done their job on blending it with good additives. I currently switching most of my customer over to synthetics due our high Summer air temps to increase the maximum operating temp range.

#16

E

ESully

E

ESully

Interesting discussion. One issue with using my picture though, as I mentioned earlier I added BG EPR® Engine Performance Restoration® to the oil, and put Wurth Engine Cleaner/Conditioner through the intake. These 2 products removed quite a bit of the build up inside the engine and combustion chamber prior to disassembly.

I believe it would have looked more like another of my engines I rebuilt if I had not used these products first. A bit more carbon at the outside of the pistons from burning oil.

I believe it would have looked more like another of my engines I rebuilt if I had not used these products first. A bit more carbon at the outside of the pistons from burning oil.

Attachments

#17

sgkent

sgkent

the removal of oil first at the outside of the piston shows that is where the oil was washing over the rings. If the cleaners you added in the fuel or thru the carb were solely responsible then the removal would be a different pattern. The point is that as the oil and anything you put in it washes past the rings, it attacks carbon in the areas it comes into contact with first. In your photos it doesn't surprise me you were burning oil and that the engine was smoking. If the carbon had been even all across the piston then I would have suspected a valve guide as the cause. Here is an example of a VW engine where the pistons are leaking oil at the bottom of the piston.You can see where the carbon is being washed away. I use it as an example.

#18

sgkent

sgkent

you are making mountains out of molehills and saying things I never said. The oil in the crankcase contains additives that the oil industry marketing calls a generic word, "detergents," that wash away the carbon on the pistons tops where it is in excess. I am sure a molecular scientist could explain the process. All I know is that when I see it, I know that oil has been getting past the rings. If the oil doesn't exist in a quantity to wash away the carbon, then it solidifies into a hard black carbon. If the heat continues on it, it turns to almost a coke. If water has been getting into an engine it also will leave the pistons clean, and sometimes with a white coating. GM had a process for years to knock carbon off a piston when it was dieseling, by drizzling water into the carb and letting it turn to steam at low speed and knock the carbon off. My 1992 Acura had trouble with carbon fouling of the pistons and rings. Acura's published solution was to drizzle GM Top Cylinder cleaner into the engine at a fast idle and then run the engine hard for a minute, then change the oil. There are things that remove carbon from an engine but none leave it spotless. Nothing that I know of will remove carbon that has built up to 1/4 to 1/2" like it used to on the CJ7 intake valves, other than pulling the intake manifold or head off and physically knocking the carbon off. I've seen spark plugs malformed by getting hit with a large piece of carbon like that which broke off a valve. As to non-detergent oil, I spent two days with long drill bits, pieces of wire cable, brushes etc., cleaning oil galleries on a 1939 Buick once for a customer. Some of the passages were completely clogged with rock like deposits. EGR valves also plug up with carbon that can be very hard.I am not trying to be a nit picker nor start arguements for the fun of it

I taught an introduction to lubricants to TAFE students back in the 70's & 80's .

And again it is the solvents ionizers & oxadizers that do the cleaning, not the detergents

The Ph adjusters also play a big part

In a lot of diesel engines you do not want to disturb the ridge ring of carbon at the top of the cylinder as it take a lot of the punishment off the fire ring .

And yes I have pulled down my fair share of old engines, rolling mills and other gear that uses sludging oils with settling tanks as part of the oil management system apart

And yes badly designed / poorly maintained ones needed the oil galleries drilled out

And I have been riding and repairing British motorcycles since I was 13 and like Rivets I am on the wrong side of 70 as well

From Friday to Tuesday I will be out riding one of my 90 + year old motorcycles running non- detergent oil, in fact the first BSA model to have a recirculating oil system, ignoring the brief experiment with sumps & oil flingers .

As for soaking parts in oil and having them soften the deposit not relevent as it never happens inside an engine but handy to know when it comes to cleaning them.

When people who know some thing is wrong it is their duty to correct it

The misnomer that detegents clean is wide spread

There are detergent oils that do not clean but these are rarely used in engines.

Whe I say some thing that is wrong, I expect others who know it is wrong to correct me as well which has happened here on more than one occasion.

Before the internet a lie tol a million times was still a lie

However now days a lie posted 500 times becomes an undisputable fact .

#19

E

ESully

E

ESully

Lets just say oil has additives and call a truce  . The old Xerox- Copy argument. Detergent is a generic name.

. The old Xerox- Copy argument. Detergent is a generic name.

From the Interweb

"Engine oil always has additives added to its base stock. Base stock or base oil is the primary component of engine oil resulting from petroleum or chemical processing. The base stock is typically 80% to 90% of engine oil.

Additives are chemical compounds that are added to the base stock to improve the performance of engine oil. Additives make up about 10% to 20% of engine oil.

Additives include detergents, corrosion inhibitors, antiwear additives, alkalis, friction modifiers, foam inhibitors, etc.

Detergents or dispensers are used to clean and neutralize impurities in the oil, which usually cause deposits or sludge on engine components.

Detergents ensure that these impurities and foreign objects remain in suspension so that the filtration system can remove these impurities.

Along with these functions, detergent additives play an important role in the performance of motor or engine oil. A non-detergent oil, which does not contain any detergent, will not have these functions."

From the Interweb

"Engine oil always has additives added to its base stock. Base stock or base oil is the primary component of engine oil resulting from petroleum or chemical processing. The base stock is typically 80% to 90% of engine oil.

Additives are chemical compounds that are added to the base stock to improve the performance of engine oil. Additives make up about 10% to 20% of engine oil.

Additives include detergents, corrosion inhibitors, antiwear additives, alkalis, friction modifiers, foam inhibitors, etc.

Detergents or dispensers are used to clean and neutralize impurities in the oil, which usually cause deposits or sludge on engine components.

Detergents ensure that these impurities and foreign objects remain in suspension so that the filtration system can remove these impurities.

Along with these functions, detergent additives play an important role in the performance of motor or engine oil. A non-detergent oil, which does not contain any detergent, will not have these functions."

#20

B

bertsmobile1

B

bertsmobile1

Adding water to clean coke deposits off engines has been happening since Scent Spray started making carburettors in 1902

Period motor magazines are full of "easy way to decoke" methods and the bulk of them use water .

In the 80's there was a machine that was popular amongst workshops that did a programmed water injection .

It became a big money earner till some people who actually understand the physics of combustion in confined spaces debunked the "miracle power increaser"

And FWIW cleaning this way removes the ridge ring of carbon which is important on a lot of older engines that use plain grey iron rings not so important with steel rings and a disaster with plated rings .

Most of the premium lubricating oils are blended from Australian crude as we have the lowest ash content of any crude on the planet ( make crap petrol by the way ).

So ashless oil has been around for a lot longer than most would believe .

The big problem with oils is unlike what Castrol spent a fortune trying to make us believe, "oils is just oils,, Sol" there is 5/8 of sfa difference in equivalent grades of oil from one brand to another .

So in order to sell more than the competitor they all spend a massive amount on advertising in order to brainwash us that their product is vastly superiour where as in reality any difference is marginal at most .But because of all of the BS that we have been subjected to ( like detergents clean ) it is near impossible for any person to think objectively about oil because what most of us think we know is actually the BS advertisers have implanted .

And to quote a very close friend , now deceased who was an oil technican & blender

"The best oil for your engine is the oil you just drained out and the more of it the better it is "

The distinctive pattern you showed us in your photo is caused by the heat & pressure of combustion and the direction of flame propergation on oil that has entered the cylinder and deposited upon the piston crown . You generally get a similar pattern on the head from the plug hole radiating out .

The oil should be around 80 deg C and the piston top should be around 300 C so will tend to burn just the same as you pouring cooking oil into a hot frying pan ( synthetics are much more resistant to this ) .

The volatile fraction ( oil smell ) will boil off leaving a paste layer ( layer is only a couple of molecules thick ) which will either be blown across the piston crown by the force of the combustion or burned by the heat then compacted by the pressure .

Period motor magazines are full of "easy way to decoke" methods and the bulk of them use water .

In the 80's there was a machine that was popular amongst workshops that did a programmed water injection .

It became a big money earner till some people who actually understand the physics of combustion in confined spaces debunked the "miracle power increaser"

And FWIW cleaning this way removes the ridge ring of carbon which is important on a lot of older engines that use plain grey iron rings not so important with steel rings and a disaster with plated rings .

Most of the premium lubricating oils are blended from Australian crude as we have the lowest ash content of any crude on the planet ( make crap petrol by the way ).

So ashless oil has been around for a lot longer than most would believe .

The big problem with oils is unlike what Castrol spent a fortune trying to make us believe, "oils is just oils,, Sol" there is 5/8 of sfa difference in equivalent grades of oil from one brand to another .

So in order to sell more than the competitor they all spend a massive amount on advertising in order to brainwash us that their product is vastly superiour where as in reality any difference is marginal at most .But because of all of the BS that we have been subjected to ( like detergents clean ) it is near impossible for any person to think objectively about oil because what most of us think we know is actually the BS advertisers have implanted .

And to quote a very close friend , now deceased who was an oil technican & blender

"The best oil for your engine is the oil you just drained out and the more of it the better it is "

The distinctive pattern you showed us in your photo is caused by the heat & pressure of combustion and the direction of flame propergation on oil that has entered the cylinder and deposited upon the piston crown . You generally get a similar pattern on the head from the plug hole radiating out .

The oil should be around 80 deg C and the piston top should be around 300 C so will tend to burn just the same as you pouring cooking oil into a hot frying pan ( synthetics are much more resistant to this ) .

The volatile fraction ( oil smell ) will boil off leaving a paste layer ( layer is only a couple of molecules thick ) which will either be blown across the piston crown by the force of the combustion or burned by the heat then compacted by the pressure .

#21

E

ESully

E

ESully

I figured it was time for a mid July update.

The mower was initially running well. A couple of weeks ago it developed a small backfire. It got progressively worse, and the right cylinder was not firing well. I decided to give it a going over and checked and reset all the valve and coil clearances, along with another oil change and new set of spark plugs. I had good spark and 155lbs compression on both cylinders. It has not used any noticeable amount of oil since the new rings finished seating.

While I had the covers off, I figured I would give the carburetor a complete tear down and cleaning. Originally I had only pulled the float bowl and sprayed everything with carburetor cleaner. This time I took it completely apart and scrubbed everything.

On first start, it ran on both cylinders, but needed a bit of choke to run well. I couldn't figure why it seemed to be running lean, so off came the carburetor again. It seems as though I had misplaced a small gasket. I thought about ordering it, but being me and in a hurry I decided to get a small piece of gasket material and make it myself.

I just gave the mower a run in low 90 degree temperatures and it's running great again. Initial issue must have been some carbon blocking the flow to the right cylinder jet, and the second issue was the missing gasket allowing excess air in leaning the mixture. I'm now hoping for a few years of trouble free mowing.

The mower was initially running well. A couple of weeks ago it developed a small backfire. It got progressively worse, and the right cylinder was not firing well. I decided to give it a going over and checked and reset all the valve and coil clearances, along with another oil change and new set of spark plugs. I had good spark and 155lbs compression on both cylinders. It has not used any noticeable amount of oil since the new rings finished seating.

While I had the covers off, I figured I would give the carburetor a complete tear down and cleaning. Originally I had only pulled the float bowl and sprayed everything with carburetor cleaner. This time I took it completely apart and scrubbed everything.

On first start, it ran on both cylinders, but needed a bit of choke to run well. I couldn't figure why it seemed to be running lean, so off came the carburetor again. It seems as though I had misplaced a small gasket. I thought about ordering it, but being me and in a hurry I decided to get a small piece of gasket material and make it myself.

I just gave the mower a run in low 90 degree temperatures and it's running great again. Initial issue must have been some carbon blocking the flow to the right cylinder jet, and the second issue was the missing gasket allowing excess air in leaning the mixture. I'm now hoping for a few years of trouble free mowing.