You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Briggs & Stratten 20HP won't start, backfiring through exhaust and carb.

#1

N

Novo

N

Novo

Hello All.

Kinda Quick "complete" back story ,

,

This is a 8yr old Ariens 46" riding mower with Briggs 331777-2372-G5 20HP OHV INTEK single cylinder engine. Given to me after it quit running.

I suspected it had a broken rod and pulled the engine. The rod/cap was broken and no other damage to case "except" the sump cover's bearing surface for crank shaft was scored from debris.

I Cleaned the housing of old oil and debris, installed new piston, piston rod, rings and ordered new sump cover/gaskets.

When I reassembled, I was careful timing marks "dots" were correctly aligned and governor was resting correctly against tab, then tighten everything to B&S spec's.

I had also pulled the head to install new piston and inspect valves. The valves were fairly clean seated and not bent. After closing the sump cover, replacing head gasket and installing the head; I checked valve clearance and it seemed fine. "made sure correct Aluminum push rod under intake"

I reinstalled completed motor on mower and proceeded to pull the Fly wheel bolt to see if the key-way had sheared and indeed it did! Replaced key-way and reassembled.

Inspected gap on magneto coil and it seemed fine/not moved.

Tried to start it once but backfired and I quit for the day."figured to be back on it in morning"

Next day I went to start and this time it STOPPED rotating at compression stroke. I suspected I may have over looked proper valve adjustment and pulled the valve cover.

"Gasoline" came pouring out of valve area. Drained the engine sump and found all the contents of fuel tank had drain into engine over night. Read a post about this condition and pulled the anti backfire solenoid. I found it was slow to move/sticking. Cleaned the solenoid out and inspected the carburetor visually while still attached to engine. The bowl was very clean and float adjustment seemed fine. Reassembled every thing, rotated engine with new oil, drained and added new oil again.

(wanted anyone reading to have complete rebuild history)

All That to lead to this question: Battery is fully charged, engine turns over as excepted but it backfires from both carburetor and exhaust randomly no matter the throttle setting.

Never starts or runs even a little "although the engine seems to out pace the starter some times" as though it's firing some.

I have checked gas, "no water"

Checked valve clearance again. ."is good"

I checked flywheel key again "it's good"

New spark plug and is getting good arc,

Sprayed starter fluid direct in breather tube "no filter" and still just back fires.

I'm at a loss. Maybe carb needs cleaning, but I thought it would run at-least a little with starter fluid. ALL suggestions or any questions are welcome, please

Thanks in advance!

Kinda Quick "complete" back story

This is a 8yr old Ariens 46" riding mower with Briggs 331777-2372-G5 20HP OHV INTEK single cylinder engine. Given to me after it quit running.

I suspected it had a broken rod and pulled the engine. The rod/cap was broken and no other damage to case "except" the sump cover's bearing surface for crank shaft was scored from debris.

I Cleaned the housing of old oil and debris, installed new piston, piston rod, rings and ordered new sump cover/gaskets.

When I reassembled, I was careful timing marks "dots" were correctly aligned and governor was resting correctly against tab, then tighten everything to B&S spec's.

I had also pulled the head to install new piston and inspect valves. The valves were fairly clean seated and not bent. After closing the sump cover, replacing head gasket and installing the head; I checked valve clearance and it seemed fine. "made sure correct Aluminum push rod under intake"

I reinstalled completed motor on mower and proceeded to pull the Fly wheel bolt to see if the key-way had sheared and indeed it did! Replaced key-way and reassembled.

Inspected gap on magneto coil and it seemed fine/not moved.

Tried to start it once but backfired and I quit for the day."figured to be back on it in morning"

Next day I went to start and this time it STOPPED rotating at compression stroke. I suspected I may have over looked proper valve adjustment and pulled the valve cover.

"Gasoline" came pouring out of valve area. Drained the engine sump and found all the contents of fuel tank had drain into engine over night. Read a post about this condition and pulled the anti backfire solenoid. I found it was slow to move/sticking. Cleaned the solenoid out and inspected the carburetor visually while still attached to engine. The bowl was very clean and float adjustment seemed fine. Reassembled every thing, rotated engine with new oil, drained and added new oil again.

(wanted anyone reading to have complete rebuild history)

All That to lead to this question: Battery is fully charged, engine turns over as excepted but it backfires from both carburetor and exhaust randomly no matter the throttle setting.

Never starts or runs even a little "although the engine seems to out pace the starter some times" as though it's firing some.

I have checked gas, "no water"

Checked valve clearance again. ."is good"

I checked flywheel key again "it's good"

New spark plug and is getting good arc,

Sprayed starter fluid direct in breather tube "no filter" and still just back fires.

I'm at a loss. Maybe carb needs cleaning, but I thought it would run at-least a little with starter fluid. ALL suggestions or any questions are welcome, please

Thanks in advance!

#2

D

dana a

D

dana a

IT SOUNDS LIKE THE TIMING IS OFF. If timed right it will run without a carb just by spraying starting fluid in the intake. Possibly either the crank or cam shaft has 2 marks on it

#3

N

Novo

N

Novo

Dana,

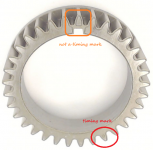

The "Cam shaft Gear" has ONLY one dot between two teeth so I'm sure that's correct!

However the crank has "best I can tell from through scratches/scaring" a "tiny" dot on one of the teeth and several teeth away, a rectangular indent.

I lined up the dots.

I agree it acts like timing issue and yeah I expected it to at least run for a sec on starter fluid if it were a fuel issue.

If no others have easier check before tomorrow morning, I will pull the engine again.

Haven't seen any definitive pics on my particular engine and the timing marks so I will post pics tomorrow when I get that far.

Thanks for responding!

The "Cam shaft Gear" has ONLY one dot between two teeth so I'm sure that's correct!

However the crank has "best I can tell from through scratches/scaring" a "tiny" dot on one of the teeth and several teeth away, a rectangular indent.

I lined up the dots.

I agree it acts like timing issue and yeah I expected it to at least run for a sec on starter fluid if it were a fuel issue.

If no others have easier check before tomorrow morning, I will pull the engine again.

Haven't seen any definitive pics on my particular engine and the timing marks so I will post pics tomorrow when I get that far.

Thanks for responding!

#4

R

Rivets

R

Rivets

Did you make sure that the crankgear was properly installed on the crankshaft. I’ve seen more than one DIY guy install it upside down. This manual will show you what the timing dots look like. https://drive.google.com/file/d/0B6NaqjIxWV1ybEN0LWo3azl6OUU/view

#5

T

Tinkerer200

T

Tinkerer200

As a side note of information, the anti-back fire solenoid on the carb has absolutely nothing to do with the possibility of the carb float not sealing and flooding gas thru the carb into crankcase. You did properly torque the flywheel nut/bolt when installing new key?

Walt Conner

Walt Conner

#8

N

Novo

N

Novo

Sorry to all that replied for my late reply! I'm in Texas and the rain has prevented me from doing any thing to the mower yet.

"Fish" I had the head off and checked the valves for sticking or bent valves. The seats were clean and they seem to function fine when engine is rotated.

"Raider820" I plan to that do that before I pull the engine again just for curiosity sake! Fairly sure it's still good though, the backfiring has been constant even though I replaced it.

"Tinkerer200" I agree if the float is stuck open, the anti-backfire solenoid won't be very effective at stopping the flow. When I took the bowl off and clean the carb some, I may have inadvertently dislodged debris in the needle seat. I did find the anti-backfire stem slow to move and cleaned as well. YES, I have torqued all bolts to manual spec's including the flywheel bolt. The new key slide in nice. However I plan to check it again before I remove the engine.

"LawnRoyalty" Thank you first for the look at manual! When I took the engine apart I removed the crank gear and inspected both sides. The side facing up "with dot" was scared from I assume debris. I laid it on a flat sharping stone and polished it as much as a could to make it smooth with out removing allot of steel. The dot was revealed when I was through. I'm certain I installed it correctly as far as which side faces the sump. Now second guessing my self if the dots were exactly lined up.

Thanks for the responses. I will be checking flywheel key then moving on to pulling engine again. Taking pics this time!

"Fish" I had the head off and checked the valves for sticking or bent valves. The seats were clean and they seem to function fine when engine is rotated.

"Raider820" I plan to that do that before I pull the engine again just for curiosity sake! Fairly sure it's still good though, the backfiring has been constant even though I replaced it.

"Tinkerer200" I agree if the float is stuck open, the anti-backfire solenoid won't be very effective at stopping the flow. When I took the bowl off and clean the carb some, I may have inadvertently dislodged debris in the needle seat. I did find the anti-backfire stem slow to move and cleaned as well. YES, I have torqued all bolts to manual spec's including the flywheel bolt. The new key slide in nice. However I plan to check it again before I remove the engine.

"LawnRoyalty" Thank you first for the look at manual! When I took the engine apart I removed the crank gear and inspected both sides. The side facing up "with dot" was scared from I assume debris. I laid it on a flat sharping stone and polished it as much as a could to make it smooth with out removing allot of steel. The dot was revealed when I was through. I'm certain I installed it correctly as far as which side faces the sump. Now second guessing my self if the dots were exactly lined up.

Thanks for the responses. I will be checking flywheel key then moving on to pulling engine again. Taking pics this time!

#9

T

Tinkerer200

T

Tinkerer200

"I'm certain I installed it correctly as far as which side faces the sump."

One side of the inside of the crankshaft timing gear is beveled making it very unlikely to be able fit the sump on properly as incorrectly installed crankshaft timing gear will hold block and sump apart.

Walt Conner

One side of the inside of the crankshaft timing gear is beveled making it very unlikely to be able fit the sump on properly as incorrectly installed crankshaft timing gear will hold block and sump apart.

Walt Conner

#11

N

Novo

N

Novo

Okay, I have to eat some "crow" here.

"Raider820" was correct to check the Key on fly wheel again!

As you can see from the pics below the flywheel was out of align again. I pulled the fly wheel and you can see the sheared key on left of third pic with new key on the right.

Thanks for suggesting to look again Raider820.

My question is:

1. is there requirement to push the key down beyond the end of the crank shaft?

2. Is backfiring capable of shearing the key again?

3. Is the key hardened at all? "looks like its not hard at all from sheared one"

Before it's asked "I would" Yes I tightened the flywheel bolt to spec's the last time.

Any guesses what sheared it? Going to reinstall new key tommarow and try to start again.

"StarTech" Your pic is exactly what mine looked like when I reinstalled it. Dots are what I lined up.

"Tinker200" What I should have said was "I'm certain I installed it correctly as far as which side faces the (BOTTOM) of the sump."

Thanks all!

"Raider820" was correct to check the Key on fly wheel again!

As you can see from the pics below the flywheel was out of align again. I pulled the fly wheel and you can see the sheared key on left of third pic with new key on the right.

Thanks for suggesting to look again Raider820.

My question is:

1. is there requirement to push the key down beyond the end of the crank shaft?

2. Is backfiring capable of shearing the key again?

3. Is the key hardened at all? "looks like its not hard at all from sheared one"

Before it's asked "I would" Yes I tightened the flywheel bolt to spec's the last time.

Any guesses what sheared it? Going to reinstall new key tommarow and try to start again.

"StarTech" Your pic is exactly what mine looked like when I reinstalled it. Dots are what I lined up.

"Tinker200" What I should have said was "I'm certain I installed it correctly as far as which side faces the (BOTTOM) of the sump."

Thanks all!

Attachments

#12

Scrubcadet10

Scrubcadet10

You did torque the flywheel bolt as well, correct?

Improperly torqued flywheel bolt/nut will cause a key to shear as well.

I'm near certain the torque spec is 100ft lbs.

Improperly torqued flywheel bolt/nut will cause a key to shear as well.

I'm near certain the torque spec is 100ft lbs.

#13

StarTech

StarTech

Need to know engine date code. It determines which steel key to use also flywheel torque was increased to 110 ft/lbs. Briggs change the crankshaft and flywheel back on July 01, 2012.

#14

N

Novo

N

Novo

Yes, Torqued to 110 ft lbs actually, which is spec I found.You did torque the flywheel bolt as well, correct?

Improperly torqued flywheel bolt/nut will cause a key to shear as well.

I'm near certain the torque spec is 100ft lbs.

#15

N

Novo

N

Novo

Not sure how to read the date StarTech.Need to know engine date code. It determines which steel key to use also flywheel torque was increased to 110 ft/lbs. Briggs change the crankshaft and flywheel back on July 01, 2012.

Attachments

#16

StarTech

StarTech

2011 Oct 18. (YYMMDD(ZD = assembly plant))

The APSI # 82 Dated Feb 2012 says to use the 593935 steel key and torque to 110 ft/lbs.

Just to note I have found a couple of these flywheels busted out in the center. And even found one just cracked. None these even had the steel key yet.

The APSI # 82 Dated Feb 2012 says to use the 593935 steel key and torque to 110 ft/lbs.

Just to note I have found a couple of these flywheels busted out in the center. And even found one just cracked. None these even had the steel key yet.

#17

S

slomo

S

slomo

The key is a soft sacrificial metal not hardened at all. Look for a flywheel crack like StarTech said.

110lbs should lock that thing down tight. Crank still have a good taper? Flywheel not tapered to match crank end?

Did someone install or is yours supposed to have a washer below the flywheel? Washer no washer? Checks parts list.

slomo

110lbs should lock that thing down tight. Crank still have a good taper? Flywheel not tapered to match crank end?

Did someone install or is yours supposed to have a washer below the flywheel? Washer no washer? Checks parts list.

slomo

#18

N

Novo

"Thanks for all the responses by the way"

"Thanks for all the responses by the way"

There is no washer on Flywheel now and none are called for in the parts list I've looked at for this engine.

I went ahead and cleaned/inspected the fly wheel for cracks and couldn't find any. Just a little scaring from previous key shears.

I assume both tapers match well because they are pretty clean and no sign of missmatch.

I installed the new key and tightened the fly wheel bolt to 110 ft lbs.

Instead of hooking up the gas line, I sprayed starter fluid in the breather tube and tried to start it. It started and ran for a few seconds and died as you would expect. "first time it's actually run since rebuild".

I figured that was the timing issue and proceeded to hook up the gas line. Tried to start it again and immediately it went back to backfiring!

After a few more try's and backfires. I stopped and pulled the flywheel bolt. The Key Is Sheared again!

I can't say whether it sheared after it ran or because it was backfiring on gas. I assume the backfiring reverse momentum is shearing it.

All the gas in the gas tank is new, I drained it a week ago and put fresh in. "no water"

I'm at a loss why it would shear so easy and why starting it from carb would make it backfire.

Any new thoughts?

Thanks again!

N

Novo

Okay, so new update2011 Oct 18. (YYMMDD(ZD = assembly plant))

The APSI # 82 Dated Feb 2012 says to use the 593935 steel key and torque to 110 ft/lbs.

Just to note I have found a couple of these flywheels busted out in the center. And even found one just cracked. None these even had the steel key yet.

There is no washer on Flywheel now and none are called for in the parts list I've looked at for this engine.

I went ahead and cleaned/inspected the fly wheel for cracks and couldn't find any. Just a little scaring from previous key shears.

I assume both tapers match well because they are pretty clean and no sign of missmatch.

I installed the new key and tightened the fly wheel bolt to 110 ft lbs.

Instead of hooking up the gas line, I sprayed starter fluid in the breather tube and tried to start it. It started and ran for a few seconds and died as you would expect. "first time it's actually run since rebuild".

I figured that was the timing issue and proceeded to hook up the gas line. Tried to start it again and immediately it went back to backfiring!

After a few more try's and backfires. I stopped and pulled the flywheel bolt. The Key Is Sheared again!

I can't say whether it sheared after it ran or because it was backfiring on gas. I assume the backfiring reverse momentum is shearing it.

All the gas in the gas tank is new, I drained it a week ago and put fresh in. "no water"

I'm at a loss why it would shear so easy and why starting it from carb would make it backfire.

Any new thoughts?

Thanks again!

#19

S

slomo

S

slomo

Amazing story. That flywheel HAS to be cracked. I bet once under torque it might show its arse. At 110ft lbs, should be down for the count.

Take it to an engine machine shop. Have them magnaflux it for cracks. Shouldn't cost a few bucks.

I've never heard of backfiring causing this. Maybe Bertsmobile1, StarTech or ILENGINE (just to name a few superstars) on here can chime in with some real wisdom.

The key is soft yes. Plausible yes. ?

slomo

Take it to an engine machine shop. Have them magnaflux it for cracks. Shouldn't cost a few bucks.

I've never heard of backfiring causing this. Maybe Bertsmobile1, StarTech or ILENGINE (just to name a few superstars) on here can chime in with some real wisdom.

The key is soft yes. Plausible yes. ?

slomo

#20

B

bertsmobile1

B

bertsmobile1

The backfiring causes the key to shear

Get some fine valve grinding paste and lap the flywheel taper to the flywheel, exactly the same as you would lap in a valve.

Make sure you clean all of the lapping paste off the top seal before refitting the flywheel.

When the taper is perfect the flywheel should seal agains the crankshaft with nothing more than thumb pressure then should be near impossible to pull back off again.

You can get really **** and go from valve grinding paste to lapping pastes getting progressively finer right down to 0.5-1.0 microns .

When we are doing drag bikes that run a sort of standard boxes or scramblers where the HP is doubled or better this is what we have to do to keep the clutch on the main shaft .

Get some fine valve grinding paste and lap the flywheel taper to the flywheel, exactly the same as you would lap in a valve.

Make sure you clean all of the lapping paste off the top seal before refitting the flywheel.

When the taper is perfect the flywheel should seal agains the crankshaft with nothing more than thumb pressure then should be near impossible to pull back off again.

You can get really **** and go from valve grinding paste to lapping pastes getting progressively finer right down to 0.5-1.0 microns .

When we are doing drag bikes that run a sort of standard boxes or scramblers where the HP is doubled or better this is what we have to do to keep the clutch on the main shaft .

#22

StarTech

StarTech

The problem partially was the design of the flywheel and crankshaft keyway. It leads to the key being sheared easily which is why Briggs went to a steel key and the new torque amount.

And yes check the flywheel for a cracks. Here is just an example of what one customer here had happen to his 310000 series and this happen with an aluminum key when the flywheel was torqued to 100 ft/lbs. I would have thought it possible with the aluminum key but here is proof that it can happen. Now of course he also had a blown head gasket. The picture is after it been sitting in my scape pile for a year.

And yes check the flywheel for a cracks. Here is just an example of what one customer here had happen to his 310000 series and this happen with an aluminum key when the flywheel was torqued to 100 ft/lbs. I would have thought it possible with the aluminum key but here is proof that it can happen. Now of course he also had a blown head gasket. The picture is after it been sitting in my scape pile for a year.

#23

N

Novo

I thought I would post some pic's so everyone could kinda see what I see. My camera sucks but it should help.

I'm not posting the pics to prove anything, just trying to help with info. I know just how hard it is to diagnose anything from words and lack of info/pics.

I've done nothing yet except inspect the the flywheel again. As you can kinda see from the pics, the mating tapers are shiny and some what polished except for scaring.

If the general opinion is to lap the two surfaces, I'm happy to do so. Happen to have some lapping paste.

I know its hard to tell from the pics, but unless there's a hair line crack, I can't find any cracks.

I'm not say there are none, I just can't see any. When I spray cleaning fluid in the tapered hole I hoped to see a tiny line show up from the crack picking up the fluid but no.

"Lawn Addict" Suggested magnaflux, but I'm not sure where I would take it for that.

"Lawn Royalty" Suggested lapping of Crank/Flywheel which I can do if more friction is needed.

Looks like the general consensuses is a cracked Flywheel or lack of friction to help the key-way do it's job and the backfiring is due to key-way shearing immediately.

My next move is to lap the flywheel/crank, buy several new key-ways and try again. The only loss is time and $2.25 key-way.

I Check this post between breaks, so looking for any other thought's.

Thank you very much Guys! Y'all have kept me from letting this sit for a year out of frustration.

N

Novo

StarTechThe problem partially was the design of the flywheel and crankshaft keyway. It leads to the key being sheared easily which is why Briggs went to a steel key and the new torque amount.

And yes check the flywheel for a cracks. Here is just an example of what one customer here had happen to his 310000 series and this happen with an aluminum key when the flywheel was torqued to 100 ft/lbs. I would have thought it possible with the aluminum key but here is proof that it can happen. Now of course he also had a blown head gasket. The picture is after it been sitting in my scape pile for a year.

View attachment 56838

I thought I would post some pic's so everyone could kinda see what I see. My camera sucks but it should help.

I'm not posting the pics to prove anything, just trying to help with info. I know just how hard it is to diagnose anything from words and lack of info/pics.

I've done nothing yet except inspect the the flywheel again. As you can kinda see from the pics, the mating tapers are shiny and some what polished except for scaring.

If the general opinion is to lap the two surfaces, I'm happy to do so. Happen to have some lapping paste.

I know its hard to tell from the pics, but unless there's a hair line crack, I can't find any cracks.

I'm not say there are none, I just can't see any. When I spray cleaning fluid in the tapered hole I hoped to see a tiny line show up from the crack picking up the fluid but no.

"Lawn Addict" Suggested magnaflux, but I'm not sure where I would take it for that.

"Lawn Royalty" Suggested lapping of Crank/Flywheel which I can do if more friction is needed.

Looks like the general consensuses is a cracked Flywheel or lack of friction to help the key-way do it's job and the backfiring is due to key-way shearing immediately.

My next move is to lap the flywheel/crank, buy several new key-ways and try again. The only loss is time and $2.25 key-way.

I Check this post between breaks, so looking for any other thought's.

Thank you very much Guys! Y'all have kept me from letting this sit for a year out of frustration.

Attachments

#24

S

slomo

S

slomo

Let's brake it down. Your FW is moving shearing keys. Bertsmobile1 had a super idea to lap it in. Do it. There's no other explanation on how or why the FW would move. You got the paste. I would finish up with toothpaste (fine abrasive) or whatever Bertsmobile1 recommends. Follow his words to the T.

Still a good idea to take it to an engine machine shop and have it Magnafluxed. My thought was under 110ft lbs of torque, the ol' girl might spread her legs shearing keys.

As you said the crank has some good scratches. Take some medium then fine grit emery paper and clean her up. Use the back side to polish. Front abrasive side to well, clean her up. Then lap her in as Bert said.

slomo

Still a good idea to take it to an engine machine shop and have it Magnafluxed. My thought was under 110ft lbs of torque, the ol' girl might spread her legs shearing keys.

As you said the crank has some good scratches. Take some medium then fine grit emery paper and clean her up. Use the back side to polish. Front abrasive side to well, clean her up. Then lap her in as Bert said.

slomo

#25

N

Novo

Just finished doing all you suggested above except the magnaflux. Filed the journal edge next to key-way on the crank back to surface level. "Was standing a bit proud" Sanded the crank journal and flywheel with 220 paper by hand. Then used lapping compound and spun the flywheel by hand. Wasn't perfect but looked allot better. "more surface touching" Then cleaned up, walked across the street to borrow a different torque wrench and reassembled. Torqued to 110 ft lbs!

Hooked up the gas line and cranked it. Eureka!!!! She STARTED!!!

Now I have a new question! lol

The motor is running away. "governor is only thing controlling speed" No idle at all.

I shut it down and restarted controlling the butterfly by hand. Idles great and speeds up like you would want but as soon as I let go of butterfly, it runs away.

When I pulled the carb off previously, all the linkage came apart. I'm pretty sure I have everything back where it was but it acts like I'm missing a spring that pulls the butterfly closed when you set throttle to idle.

I'm searching now for any diagram showing the throttle operation, linkage or parts list.

Thank you again!

N

Novo

Thank you slomo.Let's brake it down. Your FW is moving shearing keys. Bertsmobile1 had a super idea to lap it in. Do it. There's no other explanation on how or why the FW would move. You got the paste. I would finish up with toothpaste (fine abrasive) or whatever Bertsmobile1 recommends. Follow his words to the T.

Still a good idea to take it to an engine machine shop and have it Magnafluxed. My thought was under 110ft lbs of torque, the ol' girl might spread her legs shearing keys.

As you said the crank has some good scratches. Take some medium then fine grit emery paper and clean her up. Use the back side to polish. Front abrasive side to well, clean her up. Then lap her in as Bert said.

slomo

Just finished doing all you suggested above except the magnaflux. Filed the journal edge next to key-way on the crank back to surface level. "Was standing a bit proud" Sanded the crank journal and flywheel with 220 paper by hand. Then used lapping compound and spun the flywheel by hand. Wasn't perfect but looked allot better. "more surface touching" Then cleaned up, walked across the street to borrow a different torque wrench and reassembled. Torqued to 110 ft lbs!

Hooked up the gas line and cranked it. Eureka!!!! She STARTED!!!

Now I have a new question! lol

The motor is running away. "governor is only thing controlling speed" No idle at all.

I shut it down and restarted controlling the butterfly by hand. Idles great and speeds up like you would want but as soon as I let go of butterfly, it runs away.

When I pulled the carb off previously, all the linkage came apart. I'm pretty sure I have everything back where it was but it acts like I'm missing a spring that pulls the butterfly closed when you set throttle to idle.

I'm searching now for any diagram showing the throttle operation, linkage or parts list.

Thank you again!

#26

S

slomo

S

slomo

Bertsmobile1 to the rescue again.  Awesome tip on the flywheel cleanup.

Awesome tip on the flywheel cleanup.

The gov-na' closes the throttle plate or tries to. You are right, there is a small choke return spring and a throttle spring that need to be fitted proper.

Throttle linkage connects the throttle plate on one end and the other goes to the gov-na'.

Idle speed is quoted around 1750rpm. Max revs are safe at 3200rpm with the blades turning. Not a big fan of idling down a splash lube engine. Lack of lube.....

Didn't mention a file. Removes too much material or a good sharp one can. All you needed was med and fine sanding cloth/paper and a lap dance. But hey it's WORKING!!!

Does yours have the NIKKI Six carbutrator or the Ruixing?

slomo

The gov-na' closes the throttle plate or tries to. You are right, there is a small choke return spring and a throttle spring that need to be fitted proper.

Throttle linkage connects the throttle plate on one end and the other goes to the gov-na'.

Idle speed is quoted around 1750rpm. Max revs are safe at 3200rpm with the blades turning. Not a big fan of idling down a splash lube engine. Lack of lube.....

Didn't mention a file. Removes too much material or a good sharp one can. All you needed was med and fine sanding cloth/paper and a lap dance. But hey it's WORKING!!!

Does yours have the NIKKI Six carbutrator or the Ruixing?

slomo

#27

N

Novo

N

Novo

Slomo

Couldn't tell which carb I have, don't know the difference. Took pic looking down on linkage and one showing connection to the governor arm.

The choke works like it should. When you move the throttle to full, the governor arm gets stiff and the throttle butterfly arm is held open very strong.

When you set the throttle to idle, the governor arm is very easy to move and so is the throttle butterfly arm but it never moves the butterfly arm to idle.

The spring "by the way" on the governor arm is still in place.

Is it normal for the butterfly to remain full open with throttle set to idle and engine off?

Should I adjust the governor arm?

Thanks again!

Couldn't tell which carb I have, don't know the difference. Took pic looking down on linkage and one showing connection to the governor arm.

The choke works like it should. When you move the throttle to full, the governor arm gets stiff and the throttle butterfly arm is held open very strong.

When you set the throttle to idle, the governor arm is very easy to move and so is the throttle butterfly arm but it never moves the butterfly arm to idle.

The spring "by the way" on the governor arm is still in place.

Is it normal for the butterfly to remain full open with throttle set to idle and engine off?

Should I adjust the governor arm?

Thanks again!

Attachments

#28

N

Novo

N

Novo

Couldn't let it go!

I pulled the carb to make sure I had the linkage correct and it appears I did. I also found out I had not reinstalled the crank case breather tube.

Then I attempted to adjust the governor arm but it was already set correctly "no adjustment was necessary"

I reassembled it all, then started it and bingo she idled.

I then proceeded to install all the engine covers and started it again. Seemed to still idle fine.

Drove it for a little bit and started cutting some grass. Everything seemed fine except for a little surging while cutting grass but when I disengaged the blades, the engine went back to very high RPM and very little RPM change when I cut the throttle back to idle.

If I could get it to idle consistanly, I figure I've got a pretty good mower now.

Thank you to everyone for the help!

Any suggestions on the idle issue are welcome.

Thanks again all!!!

I pulled the carb to make sure I had the linkage correct and it appears I did. I also found out I had not reinstalled the crank case breather tube.

Then I attempted to adjust the governor arm but it was already set correctly "no adjustment was necessary"

I reassembled it all, then started it and bingo she idled.

I then proceeded to install all the engine covers and started it again. Seemed to still idle fine.

Drove it for a little bit and started cutting some grass. Everything seemed fine except for a little surging while cutting grass but when I disengaged the blades, the engine went back to very high RPM and very little RPM change when I cut the throttle back to idle.

If I could get it to idle consistanly, I figure I've got a pretty good mower now.

Thank you to everyone for the help!

Any suggestions on the idle issue are welcome.

Thanks again all!!!

#29

B

bertsmobile1

Engine starts on full throttle then the governor will slow it down to whatever you have set the throttle to.

It is a balance between the spring tension and the force generated by the governor bobweights.

Stationary the bob weights are of course fully in so exert no force at all .

B

bertsmobile1

YEs that is normalSlomo

Couldn't tell which carb I have, don't know the difference. Took pic looking down on linkage and one showing connection to the governor arm.

The choke works like it should. When you move the throttle to full, the governor arm gets stiff and the throttle butterfly arm is held open very strong.

When you set the throttle to idle, the governor arm is very easy to move and so is the throttle butterfly arm but it never moves the butterfly arm to idle.

The spring "by the way" on the governor arm is still in place.

Is it normal for the butterfly to remain full open with throttle set to idle and engine off?

Should I adjust the governor arm?

Thanks again!

Engine starts on full throttle then the governor will slow it down to whatever you have set the throttle to.

It is a balance between the spring tension and the force generated by the governor bobweights.

Stationary the bob weights are of course fully in so exert no force at all .

#30

StarTech

StarTech

First the carburetor looks to be a Nikki carburetor. Should have an aluminum fuel bowl on the carburetor.

As the surging try doing a static governor adjustment as there maybe a slight ply in the linkages from wear. If continues after the adjustment then the carburetor needs cleaning and probably a new main jet as the o-ring on the jet is probably gotten loose. Just to note some these Briggs engines do surge when cold as Briggs run them a little too lean. Usually adding a little choke to smooth it out indicates a lean burn condition.

Also another thing I have over the years is if the idle speed screw is set too slow the engines will surge too as the governor closes the throttle plate too much. I usually set the idle speed by holding the throttle plate closed and setting the idle speed using a tach.

As the surging try doing a static governor adjustment as there maybe a slight ply in the linkages from wear. If continues after the adjustment then the carburetor needs cleaning and probably a new main jet as the o-ring on the jet is probably gotten loose. Just to note some these Briggs engines do surge when cold as Briggs run them a little too lean. Usually adding a little choke to smooth it out indicates a lean burn condition.

Also another thing I have over the years is if the idle speed screw is set too slow the engines will surge too as the governor closes the throttle plate too much. I usually set the idle speed by holding the throttle plate closed and setting the idle speed using a tach.

#31

N

Novo

"prior" to installing the covers, but after I checked linkage/governor and started, I could watch the throttle butterfly. It did slow to an idle and rested against the idle screw. The engine was NOT (Put, Putting) as a too slow idle might be. Was generally purring as you probably would want. "lol sorry for the description but you get the idea" When I pushed to full throttle, it revved to what I would expect as a normal high RPM "Not like it was over revving" That's why I put the covers on and drove it around. After driving it around, I noticed I was no longer able to lower the throttle to a normal idle. Lastly I may should have mentioned, when I engaged the the blades, the engine didn't try to compensate speed for added load. Manually increased speed.

Is that normal?

One stupid question please: I haven't owned a riding mower in many years. Did they put a kill switch on reverse when the blades are engaged?

If so what a STUPID feature! Can't count how many times the mower died from me forgetting to disengage before backing up!

Anyways, Thank you for sticking with me!

N

Novo

BertYEs that is normal

Engine starts on full throttle then the governor will slow it down to whatever you have set the throttle to.

It is a balance between the spring tension and the force generated by the governor bobweights.

Stationary the bob weights are of course fully in so exert no force at all .

"prior" to installing the covers, but after I checked linkage/governor and started, I could watch the throttle butterfly. It did slow to an idle and rested against the idle screw. The engine was NOT (Put, Putting) as a too slow idle might be. Was generally purring as you probably would want. "lol sorry for the description but you get the idea" When I pushed to full throttle, it revved to what I would expect as a normal high RPM "Not like it was over revving" That's why I put the covers on and drove it around. After driving it around, I noticed I was no longer able to lower the throttle to a normal idle. Lastly I may should have mentioned, when I engaged the the blades, the engine didn't try to compensate speed for added load. Manually increased speed.

Is that normal?

One stupid question please: I haven't owned a riding mower in many years. Did they put a kill switch on reverse when the blades are engaged?

If so what a STUPID feature! Can't count how many times the mower died from me forgetting to disengage before backing up!

Anyways, Thank you for sticking with me!

#32

StarTech

StarTech

Yes they did on most models. And it is not so stupid as I personal know of two kids that ran over while the operator was mowing backwards. The one was a little girl that had to have part of her foot remove. Now was it really worth it to bypass that safety feature? Now that little girl will have to pay the price for the rest of her life.

Toddlers just don't realize the dangers when they want to show Daddy or Mommy something.

Plus know one used mower that previous bypass the seat switch by installing the wrong safety switch. Then operator got knock off his seat by a tree branch and mower ended up plowing into the side of his wife's new car while still cutting grass. The auto insurance almost didn't pay for the damages.

Toddlers just don't realize the dangers when they want to show Daddy or Mommy something.

Plus know one used mower that previous bypass the seat switch by installing the wrong safety switch. Then operator got knock off his seat by a tree branch and mower ended up plowing into the side of his wife's new car while still cutting grass. The auto insurance almost didn't pay for the damages.

#33

N

Novo

Indeed it has an aluminum bowl.

On the governor, "with motor off" I loosened the governor arm "throttle set to full" and tried to turn the shaft "through the motor" the same direction as full throttle on the arm. It was already as far as it could be turned. I assumed it was already correctly set. The carb linkage has "choke" on after full throttle. "No separate lever"

My mother in-law has done literally nothing to this mower in 10 years. Oil change, carb rebuild or anything else. Battery changed and garage kept, that's all.

I agree with carb rebuild.

N

Novo

StarTechFirst the carburetor looks to be a Nikki carburetor. Should have an aluminum fuel bowl on the carburetor.

As the surging try doing a static governor adjustment as there maybe a slight ply in the linkages from wear. If continues after the adjustment then the carburetor needs cleaning and probably a new main jet as the o-ring on the jet is probably gotten loose. Just to note some these Briggs engines do surge when cold as Briggs run them a little too lean. Usually adding a little choke to smooth it out indicates a lean burn condition.

Also another thing I have over the years is if the idle speed screw is set too slow the engines will surge too as the governor closes the throttle plate too much. I usually set the idle speed by holding the throttle plate closed and setting the idle speed using a tach.

Indeed it has an aluminum bowl.

On the governor, "with motor off" I loosened the governor arm "throttle set to full" and tried to turn the shaft "through the motor" the same direction as full throttle on the arm. It was already as far as it could be turned. I assumed it was already correctly set. The carb linkage has "choke" on after full throttle. "No separate lever"

My mother in-law has done literally nothing to this mower in 10 years. Oil change, carb rebuild or anything else. Battery changed and garage kept, that's all.

I agree with carb rebuild.

#34

N

Novo

My only thought was a 12v gear reduction servo could have served the same purpose to disengage the blades automatically with out user input, other than brake and selecting reverse.

As far as that goes, a rear proximity sensor could also be added to warn the user with loud buzzer for all objects. Kids, Pets, walls, fence, trees, shrubs, wife's flower garden, ect.....

I simple thought it could have been handled better and STUPID was NOT the proper word.

N

Novo

I totally agree with safety and have no intentions of by passing any switches. At 64, I too have seen many tragedies from lack of attention or bypassing safety devices.Yes they did on most models. And it is not so stupid as I personal know of two kids that ran over while the operator was mowing backwards. The one was a little girl that had to have part of her foot remove. Now was it really worth it to bypass that safety feature? Now that little girl will have to pay the price for the rest of her life.

Toddlers just don't realize the dangers when they want to show Daddy or Mommy something.

Plus know one used mower that previous bypass the seat switch by installing the wrong safety switch. Then operator got knock off his seat by a tree branch and mower ended up plowing into the side of his wife's new car while still cutting grass. The auto insurance almost didn't pay for the damages.

My only thought was a 12v gear reduction servo could have served the same purpose to disengage the blades automatically with out user input, other than brake and selecting reverse.

As far as that goes, a rear proximity sensor could also be added to warn the user with loud buzzer for all objects. Kids, Pets, walls, fence, trees, shrubs, wife's flower garden, ect.....

I simple thought it could have been handled better and STUPID was NOT the proper word.