You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Briggs and Stratton 190cc throttle not working

#1

nicknsw

nicknsw

Hi there.

I have a Briggs and Stratton 190cc 4-stroke push mower. It starts fine, but runs excessively as if the throttle does not work regardless of where the throttle lever is between rabbit and turtle.

So, when the throttle is open the engine runs at 100%, as if the mixture is too rich.

When the throttle is fully closed the engine cuts out, which is what is expected.

However, when the throttle is anywhere in between open and closed it continues to run at 100% (rabbit), there is no varied speed/control from the throttle lever to the engine.

The three images below shows throttle open, halfway, and closed.

Using the above image, when the throttle is halfway or closed, the plastic part marked (2) which controls the valve in the carburetor doesn't move. When the engine is running, either fully open (rabbit) or reduced throttle, and I manually rotate/pivot part (2) it causes the engine to slow and even stop when fully rotated. It's as if the component marked (2) is missing a second governor spring that pulls/pivots the part from left to right as the governor arm moves back (right to left in the pic).

The other parts marked in the picture, includes (1) governor spring attached to the throttle which appears to be correctly placed, and (3) showing the positioning of the throttle mechanism when closed and the engine cuts off - again, this appears to work fine.

Details about the engine below.

It's got me stumped and I would welcome your help. Thank you in advance.

I have a Briggs and Stratton 190cc 4-stroke push mower. It starts fine, but runs excessively as if the throttle does not work regardless of where the throttle lever is between rabbit and turtle.

So, when the throttle is open the engine runs at 100%, as if the mixture is too rich.

When the throttle is fully closed the engine cuts out, which is what is expected.

However, when the throttle is anywhere in between open and closed it continues to run at 100% (rabbit), there is no varied speed/control from the throttle lever to the engine.

The three images below shows throttle open, halfway, and closed.

Using the above image, when the throttle is halfway or closed, the plastic part marked (2) which controls the valve in the carburetor doesn't move. When the engine is running, either fully open (rabbit) or reduced throttle, and I manually rotate/pivot part (2) it causes the engine to slow and even stop when fully rotated. It's as if the component marked (2) is missing a second governor spring that pulls/pivots the part from left to right as the governor arm moves back (right to left in the pic).

The other parts marked in the picture, includes (1) governor spring attached to the throttle which appears to be correctly placed, and (3) showing the positioning of the throttle mechanism when closed and the engine cuts off - again, this appears to work fine.

Details about the engine below.

It's got me stumped and I would welcome your help. Thank you in advance.

#3

B

bertsmobile1

B

bertsmobile1

How the system works

On the end of the rod that the spring is connected to is the governor

The governor pulls the rod backwards to make the engine go slow against the spring that stretches when you set the mower to full speed

So it is a tug-O-war between the spring & the governor.

The faster the engine spins the stronger the governor should be pulling that rod back to slow the engine down .

To check if it is working start the engine, set the control to 1/2 speed then work the throttle plate ( red 2 ) with your finger on the loop that the spring connects to.

The faster the engine spins the stronger the rod should be pulling back against your finger trying to close the throttle.

If not then you have a governor failure .

The numbers on the sticker that you posted are EPA numbers and not the engine number.

The real engine number will be stamped into the engine and on that model should be in the heat shield on top of the muffler .

IT should start with 12 unless you bought it from Bunnings where it could be a cheaper engine .

To access the governor linkages you have to remover the shroud on top of the engine .

Some times crud like twigs can get stuck under the shroud which prevent the governor from working.

That is the Tornado model designed by graduate industrial designers who have zero idea about lawn mowers.

It is pressed from very thin steel and highly prone to failure at the left side handle bar mount

Make sure you keep the bolt tight & keep the space around the mounting plate and the top bend very clean

I scrap around 20 to 30 of them every year and where possible fit the engines to earlier bases that are far stronger

On the end of the rod that the spring is connected to is the governor

The governor pulls the rod backwards to make the engine go slow against the spring that stretches when you set the mower to full speed

So it is a tug-O-war between the spring & the governor.

The faster the engine spins the stronger the governor should be pulling that rod back to slow the engine down .

To check if it is working start the engine, set the control to 1/2 speed then work the throttle plate ( red 2 ) with your finger on the loop that the spring connects to.

The faster the engine spins the stronger the rod should be pulling back against your finger trying to close the throttle.

If not then you have a governor failure .

The numbers on the sticker that you posted are EPA numbers and not the engine number.

The real engine number will be stamped into the engine and on that model should be in the heat shield on top of the muffler .

IT should start with 12 unless you bought it from Bunnings where it could be a cheaper engine .

To access the governor linkages you have to remover the shroud on top of the engine .

Some times crud like twigs can get stuck under the shroud which prevent the governor from working.

That is the Tornado model designed by graduate industrial designers who have zero idea about lawn mowers.

It is pressed from very thin steel and highly prone to failure at the left side handle bar mount

Make sure you keep the bolt tight & keep the space around the mounting plate and the top bend very clean

I scrap around 20 to 30 of them every year and where possible fit the engines to earlier bases that are far stronger

#5

nicknsw

nicknsw

Thanks bertsmobile1, appreciate your points. Like the comment about the Tornado designers! I'll go through your steps and post here my findings.

#6

nicknsw

nicknsw

When you say "throttle plate wide open" is this figure (3) in the diagram, the plate which pivots from being open and closed? THanks for your input.Is the throttle plate wide open with the engine dead ? It should be .

#8

S

SeniorCitizen

At about 5:10 in the vid he shows a throttle plate .

S

SeniorCitizen

No , #3 may operate it but it's the round disk valve down inside the carburetor throat below the round choke plate . May need a head lamp / flashlight to see it .When you say "throttle plate wide open" is this figure (3) in the diagram, the plate which pivots from being open and closed? THanks for your input.

At about 5:10 in the vid he shows a throttle plate .

#9

nicknsw

nicknsw

thank you all for your tips and input. Hopefully, this is one item I can save following the floods. I'll post back here at the weekend after going through each. Appreciate it

#10

nicknsw

nicknsw

Thank you all for your assistance. I am grateful.

Bunnings model, Victa Tornado. 625 series.

@bertsmobile1, you suggested I check the governor. I did this, as suggested at half throttle, and the throttle plate (2) does not pivot when I move the governor loop with the throttle lever. Note, when I pivot the plate manually with my fingers waggling the governor, the engine performs as it should, speeding up and down accordingly. See video link below.

I removed the shroud and cleaned out the debris that collected.

@senorcitizen. I'm pretty sure the throttle plate inside the carburetor operates as it should seeing as the speed of the engine does vary when I waggle the governor. See video.

@StarTech

Governor adjust bolt tightened as per instructions, and the area is now clean of debris.

Videos that better highlights my problem, one showing the unit with the shroud off, and another starting it up after your advice here. Any other tips grateful. My thanks

Bunnings model, Victa Tornado. 625 series.

@bertsmobile1, you suggested I check the governor. I did this, as suggested at half throttle, and the throttle plate (2) does not pivot when I move the governor loop with the throttle lever. Note, when I pivot the plate manually with my fingers waggling the governor, the engine performs as it should, speeding up and down accordingly. See video link below.

I removed the shroud and cleaned out the debris that collected.

@senorcitizen. I'm pretty sure the throttle plate inside the carburetor operates as it should seeing as the speed of the engine does vary when I waggle the governor. See video.

@StarTech

Governor adjust bolt tightened as per instructions, and the area is now clean of debris.

Videos that better highlights my problem, one showing the unit with the shroud off, and another starting it up after your advice here. Any other tips grateful. My thanks

#11

B

bertsmobile1

With the throttle set at 1/2 speed the engine speed should increase when you push that loop towards the spring

The further you push the loop the harder the governor should be pushing back against your finger

Is this happening ?

B

bertsmobile1

Not quite with you here@bertsmobile1, you suggested I check the governor. I did this, as suggested at half throttle, and the throttle plate (2) does not pivot when I move the governor loop with the throttle lever. Note, when I pivot the plate manually with my fingers waggling the governor, the engine performs as it should, speeding up and down accordingly. See video link below.

I removed the shroud and cleaned out the debris that collected.

With the throttle set at 1/2 speed the engine speed should increase when you push that loop towards the spring

The further you push the loop the harder the governor should be pushing back against your finger

Is this happening ?

#12

nicknsw

When I start it up it runs at 100% power.

I turn the throttle to halfway and it still runs at 100% power... no change.

The only change to power is when the throttle is in the off position - the engine comes to a standstill.

Any position the throttle is in, other than off, the machine is running at 100%.

When I manually move the loop that the governor spring is attached to, towards the rear of the machine, the engine slows (go to 0:50 onwards in the video of the mower running), and eventually stops.

The problem is not the spring pulling the governor arm towards the front of the machine (which you have correctly surmised by the arm pushing against my finger), which makes it go faster, the problem is pushing the arm/loop to slow the speed. There is no tension, or pulling power on the arm for it to slow.

nicknsw

Sorry, let me try again.Not quite with you here

With the throttle set at 1/2 speed the engine speed should increase when you push that loop towards the spring

The further you push the loop the harder the governor should be pushing back against your finger

Is this happening ?

When I start it up it runs at 100% power.

I turn the throttle to halfway and it still runs at 100% power... no change.

The only change to power is when the throttle is in the off position - the engine comes to a standstill.

Any position the throttle is in, other than off, the machine is running at 100%.

When I manually move the loop that the governor spring is attached to, towards the rear of the machine, the engine slows (go to 0:50 onwards in the video of the mower running), and eventually stops.

The problem is not the spring pulling the governor arm towards the front of the machine (which you have correctly surmised by the arm pushing against my finger), which makes it go faster, the problem is pushing the arm/loop to slow the speed. There is no tension, or pulling power on the arm for it to slow.

#13

B

bertsmobile1

B

bertsmobile1

There has to be some governing force because without it the engine will race away at an uncontrollable speed then blow up

The normal full speed is 3500 rpm at around 5000 rpm the engine explodes because the con rod is not strong enough to go that quick.

As your engine has not blown up I have to assume that the governor is in fact working but I would like a short video of it running so we can hear the speed

If you can set your camera ( better than a phone ) on a stand or some bricks so it is not bouncing around the shoot the top of the carb from full throttle while you slowly throttle down to stop

The sort of angle you took the still from would be great

We really need to hear the engine running .

It could be the spring is too strong , the governor is not working properly or the controls are bent

This engine layout is very easily buggered by pushing the mower under low shrubs and having branches bend the levers & rods out of position.

B & S has put some better protection on your model but it is still pathetic which is why the 2 strokes had the throttle cables running through the snorkel so they can not get damaged by colliding with branches, low walls car bumpers etc etc etc .

The normal full speed is 3500 rpm at around 5000 rpm the engine explodes because the con rod is not strong enough to go that quick.

As your engine has not blown up I have to assume that the governor is in fact working but I would like a short video of it running so we can hear the speed

If you can set your camera ( better than a phone ) on a stand or some bricks so it is not bouncing around the shoot the top of the carb from full throttle while you slowly throttle down to stop

The sort of angle you took the still from would be great

We really need to hear the engine running .

It could be the spring is too strong , the governor is not working properly or the controls are bent

This engine layout is very easily buggered by pushing the mower under low shrubs and having branches bend the levers & rods out of position.

B & S has put some better protection on your model but it is still pathetic which is why the 2 strokes had the throttle cables running through the snorkel so they can not get damaged by colliding with branches, low walls car bumpers etc etc etc .

#14

sgkent

sgkent

does the governor assembly work all the way to the back, meaning are all the components connected all the way to the governor shaft? If so it sounds like the governor inside the engine has failed.

#15

nicknsw

nicknsw

Hi Bert, thanks again. Did you not see the video I posted yesterday afternoon, attached link to the mower running.There has to be some governing force because without it the engine will race away at an uncontrollable speed then blow up

The normal full speed is 3500 rpm at around 5000 rpm the engine explodes because the con rod is not strong enough to go that quick.

As your engine has not blown up I have to assume that the governor is in fact working but I would like a short video of it running so we can hear the speed

If you can set your camera ( better than a phone ) on a stand or some bricks so it is not bouncing around the shoot the top of the carb from full throttle while you slowly throttle down to stop

The sort of angle you took the still from would be great

We really need to hear the engine running .

It could be the spring is too strong , the governor is not working properly or the controls are bent

This engine layout is very easily buggered by pushing the mower under low shrubs and having branches bend the levers & rods out of position.

B & S has put some better protection on your model but it is still pathetic which is why the 2 strokes had the throttle cables running through the snorkel so they can not get damaged by colliding with branches, low walls car bumpers etc etc etc .

#16

nicknsw

https://photos.app.goo.gl/cCCUJLzWLGwCWJQu7

nicknsw

Hi Sgkent, I believe the governor assembly, which I've assumed is the connection from the throttle plate at the front of the machine, all the way to the back of the machine via the governor arm is what you are referring to, is connected as it should be. It certainly appears to the the case when the shroud has been taken off (the first video shows this I believe: https://photos.app.goo.gl/WhjB51JQVhUxa6Uc6 ), but I cannot confirm this when the cover is back on as the assembly is hidden from view when the machine is started. If you watch the same video I shared with Bert from 0:50 onwards you can see and hear the engine slowing when I manually move the governor arm, which in turn must be moving the linkage at the back of the machine because the engine slows and eventually cuts out - as it should.does the governor assembly work all the way to the back, meaning are all the components connected all the way to the governor shaft? If so it sounds like the governor inside the engine has failed.

https://photos.app.goo.gl/cCCUJLzWLGwCWJQu7

#17

B

bertsmobile1

I missed the video

Your governor is not working

That engine is chronically over reving & you are lucky it has not gone bang already

Double check that the governor is adjusted properly

If it is adjusted properly then the governor internally is buggered

They are not expensive just a PIA to pull the engine apart to replace .

B

bertsmobile1

OKHi Bert, thanks again. Did you not see the video I posted yesterday afternoon, attached link to the mower running.

I missed the video

Your governor is not working

That engine is chronically over reving & you are lucky it has not gone bang already

Double check that the governor is adjusted properly

If it is adjusted properly then the governor internally is buggered

They are not expensive just a PIA to pull the engine apart to replace .

#18

nicknsw

nicknsw

Thanks for your help. I'll make a start on pulling the engine apart at the weekend, find the part and source something online, assuming it's within my skillset! Appreciate your helpOK

I missed the video

Your governor is not working

That engine is chronically over reving & you are lucky it has not gone bang already

Double check that the governor is adjusted properly

If it is adjusted properly then the governor internally is buggered

They are not expensive just a PIA to pull the engine apart to replace .

#19

sgkent

sgkent

My question came because you moved the arm right at the throttle. What I wanted t to know was if you moved it all the way at the very back where it comes out of the engine, does that movement relay properly all the way to the front?

#20

nicknsw

nicknsw

Yes it does when I move the arm manuallyMy question came because you moved the arm right at the throttle. What I wanted t to know was if you moved it all the way at the very back where it comes out of the engine, does that movement relay properly all the way to the front?

#21

nicknsw

nicknsw

Hi @bertsmobile1, @sgkent, @StarTech, @SeniorCitizen,

I'd like to thank each of you all for your help, but with the last snippet of advice from Bertsmobile1 regarding the "internal governor" I think I have come to the end of my skillset to take the engine apart. To be honest, other than moving the valve in the carburetor I don't know what I'd be looking for. Everything has been through trial and error

I have double checked the governor arm, and the assembly nut, the entire rig (assembly arm + governor arm + throttle plate) moved freely when I move the arm manually. Further, I can also see the valve in the carburetor opening and closing, there is no friction there, it doesn't stick. So, I'm inclined to take Berts advice that the "internal governor" is not working, although I do not know what this does beyond opening and closing the valve in the carburetor.

Last ditch effort with my latest video to show the governor assembly the the internal "knocking" sound it makes, which is performed freely, no friction.

https://photos.app.goo.gl/LKP9WevR2WZ4GRTB7

If I was to take it to a mechanic to look and fix how much time do you think it would take to fix? Time is better than asking what it costs... that I can work out with the former. Again, thank you everyone.

I'd like to thank each of you all for your help, but with the last snippet of advice from Bertsmobile1 regarding the "internal governor" I think I have come to the end of my skillset to take the engine apart. To be honest, other than moving the valve in the carburetor I don't know what I'd be looking for. Everything has been through trial and error

I have double checked the governor arm, and the assembly nut, the entire rig (assembly arm + governor arm + throttle plate) moved freely when I move the arm manually. Further, I can also see the valve in the carburetor opening and closing, there is no friction there, it doesn't stick. So, I'm inclined to take Berts advice that the "internal governor" is not working, although I do not know what this does beyond opening and closing the valve in the carburetor.

Last ditch effort with my latest video to show the governor assembly the the internal "knocking" sound it makes, which is performed freely, no friction.

https://photos.app.goo.gl/LKP9WevR2WZ4GRTB7

If I was to take it to a mechanic to look and fix how much time do you think it would take to fix? Time is better than asking what it costs... that I can work out with the former. Again, thank you everyone.

#22

S

slomo

S

slomo

Slow the revs down. Engine is way over rev'ing. You need about half the revs that engine was singing with.

Guessing the governor is set backwards or broken internally. You can set the gov backwards and it will do as your video shows.

Guessing the governor is set backwards or broken internally. You can set the gov backwards and it will do as your video shows.

#23

S

slomo

S

slomo

Sounds spot on as usual mate.Either the governor is out adjustment or the governor/oil slinger has failed. Try doing a static governor adjustment to see if this corrects the problem. If it don't then it is time to go in.

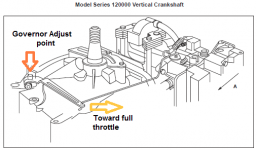

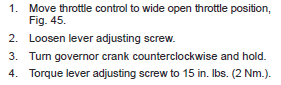

View attachment 60318

View attachment 60317

#24

nicknsw

nicknsw

Thanks @slomo, I took the advice from @StarTech and setup the governor as per the instructions.

After starting the engine, and with the revs too high as indicated here, I can slow those revs down by moving the governor arm backwards (towards the rear of the machine) with my fingers. To the point that if I hold the governor arm as far back as it will go the engine slows then eventually comes to a stop. It is only when I let go of the governor, does the engine rev up to that undesirable speed.

I wouldn't know what to look for if I was to "go in" and source the internal governor. Even getting into the damn things looks harder than breaking into a bank vault.

Can you please elaborate on what you mean when you say "You can set the gov backwards and it will do as your video shows."?

After starting the engine, and with the revs too high as indicated here, I can slow those revs down by moving the governor arm backwards (towards the rear of the machine) with my fingers. To the point that if I hold the governor arm as far back as it will go the engine slows then eventually comes to a stop. It is only when I let go of the governor, does the engine rev up to that undesirable speed.

I wouldn't know what to look for if I was to "go in" and source the internal governor. Even getting into the damn things looks harder than breaking into a bank vault.

Can you please elaborate on what you mean when you say "You can set the gov backwards and it will do as your video shows."?

#25

S

slomo

Double check what you have done in setting this governor nut/arm up and GENTLY snugged down. No impact guns are required here. If you are right handed, used your left hand with open fingers (to lower torque) when you torque that nut down.

I'm sure the directions that StarTech sent are proper. Just know if you loosen the nut and move the gov arm the "other" way, you get max revs all the time. The gov will not work proper.

Engine off, throttle plate should be WIDE OPEN. Engine on, the gov pushes against the linkages to CLOSE the throttle plate down.

S

slomo

If you loosen the gov arm nut on the shaft that sticks up out of the block, and move the gov arm the wrong way in regards to the throttle plate opening, you will have an engine that is at max revs ALL the time. Gov and linkage arm can be set backwards.Can you please elaborate on what you mean when you say "You can set the gov backwards and it will do as your video shows."?

Double check what you have done in setting this governor nut/arm up and GENTLY snugged down. No impact guns are required here. If you are right handed, used your left hand with open fingers (to lower torque) when you torque that nut down.

I'm sure the directions that StarTech sent are proper. Just know if you loosen the nut and move the gov arm the "other" way, you get max revs all the time. The gov will not work proper.

Engine off, throttle plate should be WIDE OPEN. Engine on, the gov pushes against the linkages to CLOSE the throttle plate down.

#26

nicknsw

nicknsw

Hi @slomo and thanks. Only just seen your post. I'll try this again at the weekend and let you all know. again, my sincere thanks

#28

nicknsw

nicknsw

Hi @slomo. Despite checking the setup of the gov arm, as per the instructions here, the engine is still over revving. I'm at a loss and rather than spend any more time on it I'll take it in to be repaired, and keep my fingers the bill doesn't give me something else to worry about! I'll let you know. THanks again mate.

#29

dougmacm

dougmacm

Your 1st picture shows a BENT rod connecting the throttle cable pivot to the carb linkage.

I've got a similar linkage set up on a 190cc B&S powered 1996 Lawn Boy and the same linkage rod on mine is STRAIGHT.

If your linkage rod is supposed to be straight as well, this could definitely be the problem ... see pic.

Until I saw this thread, I had no clue WHY my mower had this rod and 2nd control cable position (thought my mower was missing a cable, but what it did I had no clue !!).

Doug

I've got a similar linkage set up on a 190cc B&S powered 1996 Lawn Boy and the same linkage rod on mine is STRAIGHT.

If your linkage rod is supposed to be straight as well, this could definitely be the problem ... see pic.

Until I saw this thread, I had no clue WHY my mower had this rod and 2nd control cable position (thought my mower was missing a cable, but what it did I had no clue !!).

Doug