You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Briggs 16HP Vanguard carb / fuel problem

#1

W

Wurzel

W

Wurzel

Hello All - am hoping the knowledge bank here may be able help. I'm resurrecting a John Deere LT166 lawn tractor with 16HP Briggs engine. It has sat for 2-3 years but was running fine, save for a snapped deck belt, previously. I've stripped and cleaned the carb and got it started, driving and mowing, but not very well. It basically won't run properly without choke. I've double checked the jets in the carb. I can just about get it to tick over without choke by adjusting the fuel screw, but it won't rev and it's obviously running far too rich. In any other position it won't even idle, or only for 10-15 secs before stuttering and dying. With choke it will rev, but is maybe at 30% power and clearly not running as it should. Oddly it can manage forwards, but reverse pretty much kills it.

Have I missed something on the Aisan carb? I thought maybe a fuel pump issue but if it runs at full revs, albeit it badly, it can't be? I've checked the tank cap breather as well. It has clean fuel, albeit mixed with whatever small amount of bad might have previously been in the tank, but I think it was bone dry. Is there a hidden jet anywhere on those carbs?

Thanks in advance...!

Have I missed something on the Aisan carb? I thought maybe a fuel pump issue but if it runs at full revs, albeit it badly, it can't be? I've checked the tank cap breather as well. It has clean fuel, albeit mixed with whatever small amount of bad might have previously been in the tank, but I think it was bone dry. Is there a hidden jet anywhere on those carbs?

Thanks in advance...!

#2

S

slomo

Have you checked and cleaned the emulsion tube?

I would pull and flush the fuel tank. Most likely full of dirt and grass which hinders flow.

S

slomo

Engine wants more fuel.It basically won't run properly without choke.

Even the sometimes hidden or hard to reach pilot jet?I've double checked the jets in the carb

Have you checked and cleaned the emulsion tube?

Is the choke stuck on?I can just about get it to tick over without choke by adjusting the fuel screw, but it won't rev and it's obviously running far too rich.

I would say yes. Sitting for a couple years, the carb needs to be COMPLETELY opened up and probably boiled out. You've missed something inside. Or buy a new carb. Done deal.Have I missed something on the Aisan carb?

Have you pulled the hose AT the carb fuel bowl inlet? Verified good steady flow from tank? Drain into a glass jar so you can see what is going on.I thought maybe a fuel pump issue but if it runs at full revs, albeit it badly, it can't be?

I would pull and flush the fuel tank. Most likely full of dirt and grass which hinders flow.

Please explain this procedure? Curious......I've checked the tank cap breather as well.

Dump the tank completely. Get fresh today fuel in there, no E-10 if possible. Fuel stabilizer is your friend. Let's see, when did I get mower gas last??? I personally forgot what I had for dinner last night.It has clean fuel, albeit mixed with whatever small amount of bad might have previously been in the tank, but I think it was bone dry.

I covered this above. Yes there is.Is there a hidden jet anywhere on those carbs?

#3

W

Wurzel

W

Wurzel

Thanks for your pointers @slomo !

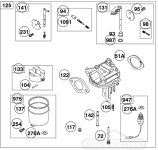

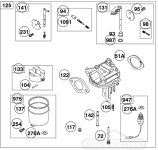

I'll double check fuel supply and also drain and refresh the tank so can be sure there - I've run with the tank cap on and off as well. Choke definitely not stuck on, I'm watching it at the carb. I'll take the carb apart a third time and make a note of each jet, tube and valve cleaned, my slight concern is that emulsion tube. I can't remember if I've done it as looking at the diagram (142), it looks like it's in the tube next to the main jet tube which is under a welch plug? If it is, I definitely haven't.

I'll double check fuel supply and also drain and refresh the tank so can be sure there - I've run with the tank cap on and off as well. Choke definitely not stuck on, I'm watching it at the carb. I'll take the carb apart a third time and make a note of each jet, tube and valve cleaned, my slight concern is that emulsion tube. I can't remember if I've done it as looking at the diagram (142), it looks like it's in the tube next to the main jet tube which is under a welch plug? If it is, I definitely haven't.

#4

Tiger Small Engine

Tiger Small Engine

It is running lean if carburetor needs choke. Clean the carburetor again. Every passage poke with tiny wire, carburetor cleaner and compressed air. Get the emulsion tube out if it is removable. If that doesn’t work, order an aftermarket carburetor by model number.

#5

S

slomo

S

slomo

142 is the emulsion tube. It has super tiny holes so be thorough. Use a magnifying glass and fishing line to verify holes are open. Start saving bread ties. They have small gauge wire under that plastic coating. I found a couple that work great for this. You might have to use a radiator hose angled pic tool to get the emulsion tube out.

Wear safety glasses when spraying carb cleaner. Face shield even better. That stuff burns the eyes let me tell you.

Wear safety glasses when spraying carb cleaner. Face shield even better. That stuff burns the eyes let me tell you.

#6

F

Forest#2

F

Forest#2

Your carb appears to be maybe a Walbro LMT and Briggs quit using it and went to the Nikki and ruxing carbs.

It's worth your effort to try to stay with the Walbro LMT because it's the most user friendly carb to repair and the smoothest running when all is correct.

I'll post below couple links, one is how to repair a Warlbo LMT link and the other is to view one for sale on flea bay. You have to keep a heads up because some call the Nikki carbs and kits Walbro just to trick you into buying the Nikki stuff.

Their are two type of them Walbro LMT's for attempting to remove the emulsion tube. One has a little main brass jet in the side of the that must be removed first. This type usually have the solenoid on bottom of bowl. The other type does not use this main jet on the side.

It's very important to use a correct fitting Hollow ground screwdriver (gunsmith's type screwdriver) when attempting to remove the emulsion tube and some of them have to be reduced in width on their sides so as to fit down inside the hole by grinding. If too wide the screwdriver will ruin the threads in the hole as it's turned A regular tapered screwdriver will usually ruin the screwdriver slot and the emulsion tube cannot be removed.

If a emulsion tube is stuck and cannot be removed I have as a last attempt effort to get the carb to run is use a Ultrasonic with heater water and white vinegar then high pressure air. The emulsion tube has several tiny holes and if any are clogged the carb no go. when re-installing a emulsion tube just get it snug, then back off and re-snug.

You can get a Nikki China clone as replacement for around $15, but getting one to run correctly is usually a roll the dice. If you have Amazon Prime you can use a free return if it don't run correctly.

Engine model, type, and code will be good for us to reference for more detail.

Carb repair link

https://outdoorpowerinfo.com/repairs/

Walbro LMT on fleece bay

It's worth your effort to try to stay with the Walbro LMT because it's the most user friendly carb to repair and the smoothest running when all is correct.

I'll post below couple links, one is how to repair a Warlbo LMT link and the other is to view one for sale on flea bay. You have to keep a heads up because some call the Nikki carbs and kits Walbro just to trick you into buying the Nikki stuff.

Their are two type of them Walbro LMT's for attempting to remove the emulsion tube. One has a little main brass jet in the side of the that must be removed first. This type usually have the solenoid on bottom of bowl. The other type does not use this main jet on the side.

It's very important to use a correct fitting Hollow ground screwdriver (gunsmith's type screwdriver) when attempting to remove the emulsion tube and some of them have to be reduced in width on their sides so as to fit down inside the hole by grinding. If too wide the screwdriver will ruin the threads in the hole as it's turned A regular tapered screwdriver will usually ruin the screwdriver slot and the emulsion tube cannot be removed.

If a emulsion tube is stuck and cannot be removed I have as a last attempt effort to get the carb to run is use a Ultrasonic with heater water and white vinegar then high pressure air. The emulsion tube has several tiny holes and if any are clogged the carb no go. when re-installing a emulsion tube just get it snug, then back off and re-snug.

You can get a Nikki China clone as replacement for around $15, but getting one to run correctly is usually a roll the dice. If you have Amazon Prime you can use a free return if it don't run correctly.

Engine model, type, and code will be good for us to reference for more detail.

Carb repair link

https://outdoorpowerinfo.com/repairs/

Walbro LMT on fleece bay

Carburetor for Briggs & Stratton 696179 Original Walbro LMT Replaces Nikki Carb | eBay

Find many great new & used options and get the best deals for Carburetor for Briggs & Stratton 696179 Original Walbro LMT Replaces Nikki Carb at the best online prices at eBay! Free shipping for many products!

www.ebay.com

#7

S

slomo

S

slomo

Love the gunsmith screwdriver mention. Make sure the slot fits snug and doesn't hurt the threads.

Take a sanding roll and make your own if you don't have a good fitting flat blade. Use a larger driver than required. Sand away the tip in a parallel fashion. Then grind the sides off to fit the hole.

Take a sanding roll and make your own if you don't have a good fitting flat blade. Use a larger driver than required. Sand away the tip in a parallel fashion. Then grind the sides off to fit the hole.

#8

W

Wurzel

W

Wurzel

So have had the carb out again, also emulsion tube out this time as well, but it was already clean. I found three tiny holes just on the air side of the fuel screw hole which I thought might have been blocked, but they're clean as well. All back together and same problem - it will tick over without choke but won't rev at all. I haven't dumped the fuel yet, that's next but it is revving Ok with choke so will see if it has an effect.

@Forest#2 it says it's as Aisan carb, are they rebranded Walbro LMTs? It has the solenoid that also keeps the bowl on, and the little jet on the side perpendicular to the main jet, pics attached (jets removed).

@Forest#2 it says it's as Aisan carb, are they rebranded Walbro LMTs? It has the solenoid that also keeps the bowl on, and the little jet on the side perpendicular to the main jet, pics attached (jets removed).

Attachments

#9

S

slomo

S

slomo

Still no details on the pilot circuit. Even at mid and higher revs, it still pulls fuel combined with the main jet. Does yout carb have a pilot screw of either fuel or air for adjustments?

Your engine wants more fuel. Revs better with the choke on from what you are saying. Find out why you lack fuel delivery.

What does your float height look like? Put the float back in and take some pictures.

Verify you have a good flow of fuel AT the carb inlet pipe.

Lastly IF the carb says Aisan and OEM is a Walbro, something is off there.

There's more to it than a clean main jet and emulsion tube. I would enrichen the pilot circuit.

Your engine wants more fuel. Revs better with the choke on from what you are saying. Find out why you lack fuel delivery.

What does your float height look like? Put the float back in and take some pictures.

Verify you have a good flow of fuel AT the carb inlet pipe.

Lastly IF the carb says Aisan and OEM is a Walbro, something is off there.

There's more to it than a clean main jet and emulsion tube. I would enrichen the pilot circuit.

#10

W

Wurzel

W

Wurzel

@slomo thanks and agreed I can find no pilot jet and there's no evidence of one on the diagram above, so I don't know how the pilot circuit works on this carb. It has a fuel mixture screw which I've checked and the tip and seat it sits in are good. It does seem to be ticking over a touch better without choke now than previously, but I can't find a mixture setting that allows it to rev without choke, I've started from half a turn right out to three turns or more.

When I do try to rev without choke the carb chucks fuel forward out of the air side and kills the engine straight away.

Can't take a pic of float height as bowl would be on? Or have I misunderstood? Float is on in the above pic but I can turn it over and support it at closed level if that's what you mean?

Will un-attach fuel inlet with engine running to check the pump is pulling fuel up from the tank, as you mentioned earlier.

I should add this is a UK, not US machine, in case that accounts for the Aisan carb - Googling indicates they were fitted to a few. The engine is model 303777.

Starting to think it might be easier to find an aftermarket carb and hope it works - grass is growing!

When I do try to rev without choke the carb chucks fuel forward out of the air side and kills the engine straight away.

Can't take a pic of float height as bowl would be on? Or have I misunderstood? Float is on in the above pic but I can turn it over and support it at closed level if that's what you mean?

Will un-attach fuel inlet with engine running to check the pump is pulling fuel up from the tank, as you mentioned earlier.

I should add this is a UK, not US machine, in case that accounts for the Aisan carb - Googling indicates they were fitted to a few. The engine is model 303777.

Starting to think it might be easier to find an aftermarket carb and hope it works - grass is growing!

#11

F

Forest#2

F

Forest#2

I've never seen anything like that carb as being a Walbro.. (in the USA and your engine model number is USA strange. Make sure you do not have a intake manifold air leak. The chole and throttle is slightly different on the USA LMT Walbro's.

Can you post up the complete Model, type and code of your engine?

Dopes it say Briggs on the engine or ????

Can you post up the complete Model, type and code of your engine?

Dopes it say Briggs on the engine or ????

#12

W

Wurzel

W

Wurzel

Am now wondering what it is! It looks like a Vanguard, but is branded John Deere, code plate below and Briggs plate from the other side also pictured.

Will check manifold leak with carb spray but it's pretty snug. I'm struggling with it running flat out on choke, evidently getting enough fuel, then dying when the choke restriction is removed. It actually smells rich the whole time to me but that doesn't make sense.

Will check manifold leak with carb spray but it's pretty snug. I'm struggling with it running flat out on choke, evidently getting enough fuel, then dying when the choke restriction is removed. It actually smells rich the whole time to me but that doesn't make sense.

Attachments

#14

S

slomo

S

slomo

THAT is the pilot either fuel or air screw. In THAT circuit, sounds as it's clogged. You mentioned half a turn to 3 turns, does nothing. That told me it was not working as it should. REMOVE the pilot screw. Spray carb cleaner in there. Spray compressed air in there. Rod the hole out with fishing line or bread tie. Try to seal the hole with your air nozzle to really force the clog out. Research welch plugs on carbs. You might need to remove one or more to get BEHIND them to get the carb clean.It has a fuel mixture screw which I've checked

What does the flywheel key look like? Are the valves set proper? Remember there are 2 TDC strokes on a 4 cycle engine. Could be set on the wrong stroke. Flywheel key needs to be unmolested and aligned straight up, perfectly. CLEAN the block cooling fins while you are there.When I do try to rev without choke the carb chucks fuel forward out of the air side and kills the engine straight away.

YES, your 3rd picture from the left. Now flip the carb upside down. Look at the float and the mounting surface for the bowl. Float should be parallel to the bowl mounting area. Not hang below nor above.Can't take a pic of float height as bowl would be on? Or have I misunderstood? Float is on in the above pic but I can turn it over and support it at closed level if that's what you mean?

Easy does it there. Try and get this one going.Starting to think it might be easier to find an aftermarket carb and hope it works - grass is growing!

#15

S

slomo

S

slomo

That is a Briggs engine.

shop.briggsandstratton.com

shop.briggsandstratton.com

Carb is no longer available per Jacks Small Engines.

Some of the others here might can find a superseded carb part number??????

Parts Lookup

Carb is no longer available per Jacks Small Engines.

Some of the others here might can find a superseded carb part number??????

#16

S

slomo

S

slomo

Make sure you have full battery voltage AT the carb solenoid wires, key on. That thing "could" be limiting fuel flow into the carb, could be sticking. I always snip those plungers off so as to never have a fuel delivery issue again.

#17

F

Forest#2

F

Forest#2

Did you look on the top of BOTH valve covers for complete engine info?

sometimes someone will install a valve cover up side down and the info is not visible.

Also if you decide to remove the welch plugs as a final attempt for good cleaning/rodding of the passages, I've removed welch plugs and re-used the same ones by very carefully drilling a tiny hole in the center, I use a drill stop so as to drill through only the welch plug, then I can carefully pull it out with a o ring pick or a awl then re-form the welch plug on a piece of leather and to seal the hole I have some slow drying two part epoxy that I use AFTER the welch plug is re-installed on the carb. My epoxy is the consistency of majarine or soft butter and will not flow through the hole and I coat the complete welch plug out to it's edges and smooth it out with finger before it completely dries. It's actually Brownells acraglass gel.

Do as slomo says about using high volume compressed air. That is type carb that high pressure air can be used with no concerns about damaging the internals the internals. I sometimes place screen wire cage around a carb before injecting high pressure air so as to catch welch plug if they blow out and become lost.

Here is a link that shows two different carbs and parts list for a 303777 1147-E1

The latter cab 807639 and it's parts kit 807962 is very expensive type.

The earlier 808728 is more reasonable one but they go by engine code numbers for the two different carbs.

https://jackssmallengines.com/jacks...arburetor-fuel-supply-kit-carburetor-overhaul

sometimes someone will install a valve cover up side down and the info is not visible.

Also if you decide to remove the welch plugs as a final attempt for good cleaning/rodding of the passages, I've removed welch plugs and re-used the same ones by very carefully drilling a tiny hole in the center, I use a drill stop so as to drill through only the welch plug, then I can carefully pull it out with a o ring pick or a awl then re-form the welch plug on a piece of leather and to seal the hole I have some slow drying two part epoxy that I use AFTER the welch plug is re-installed on the carb. My epoxy is the consistency of majarine or soft butter and will not flow through the hole and I coat the complete welch plug out to it's edges and smooth it out with finger before it completely dries. It's actually Brownells acraglass gel.

Do as slomo says about using high volume compressed air. That is type carb that high pressure air can be used with no concerns about damaging the internals the internals. I sometimes place screen wire cage around a carb before injecting high pressure air so as to catch welch plug if they blow out and become lost.

Here is a link that shows two different carbs and parts list for a 303777 1147-E1

The latter cab 807639 and it's parts kit 807962 is very expensive type.

The earlier 808728 is more reasonable one but they go by engine code numbers for the two different carbs.

https://jackssmallengines.com/jacks...arburetor-fuel-supply-kit-carburetor-overhaul

#18

W

Wurzel

The fuel screw was doing little previously, but now if I lean it off too much it stalls, so is working at the least in part.

Flywheel - haven't got in that far yet, will check and also do fins if clogged. Valve clearances likewise.

Will also check float level. Disconnecting the solenoid kills the engine, but I'll check the voltage to see if constant. I'm twisting the carb once it's off the engine to unscrew the bowl, as I can't see a way to easily disconnect the solenoid wiring at the solenoid. Twisting the solenoid will have twisted the wire and stressed the connection over time / previous owners I'm sure.

@Forest#2 was there info missing from my last? I will check tomorrow in daylight again. Noted re welch plugs, thanks for the tip!

Appreciate your continued help!

W

Wurzel

I haven't fired compressed air through there yet but it has had a load of carb cleaner through. I'll also try compressed air in case the carb cleaner hasn't moved something, plus a wire guitar string I've found works well. I've pictured the fuel screw port in the venturi below, what do those three just visible (hard to get phone to focus!) behind do? They're connected to 72 in the diagram via a channel (showing in pic 1 top of carb) in the carb body - again all blasted through with carb cleaner and apparently clear.THAT is the pilot either fuel or air screw. In THAT circuit, sounds as it's clogged. You mentioned half a turn to 3 turns, does nothing. That told me it was not working as it should. REMOVE the pilot screw. Spray carb cleaner in there. Spray compressed air in there. Rod the hole out with fishing line or bread tie. Try to seal the hole with your air nozzle to really force the clog out. Research welch plugs on carbs. You might need to remove one or more to get BEHIND them to get the carb clean.

The fuel screw was doing little previously, but now if I lean it off too much it stalls, so is working at the least in part.

Flywheel - haven't got in that far yet, will check and also do fins if clogged. Valve clearances likewise.

Will also check float level. Disconnecting the solenoid kills the engine, but I'll check the voltage to see if constant. I'm twisting the carb once it's off the engine to unscrew the bowl, as I can't see a way to easily disconnect the solenoid wiring at the solenoid. Twisting the solenoid will have twisted the wire and stressed the connection over time / previous owners I'm sure.

@Forest#2 was there info missing from my last? I will check tomorrow in daylight again. Noted re welch plugs, thanks for the tip!

Appreciate your continued help!

Attachments

#19

F

Forest#2

F

Forest#2

Just to give you a brief idea of their use:

Those ports in the carb throat are called something like transistion ports.

You can re-view such on-line. One is located on the air intake throat above the butterfly of the carb and its the idle port. Air rushing through the throat sucks gas through which ever port the butterfly has opened towards. On the high speed port below the butterfly or engine side when the butterfly is wide open all three will be providing gas by the suction of air rushing past the port/ports.

One of the other two is on the engine side of the butterfly and it's the High speed port that sucks more gas into the engine as the butterfly opens.

The one in the middle might be a trasistion between the high and low butterfly opening.

They all have to be open and yes hard to get to. You have to be careful and not break off a wire in them or you will be SOL. No way of getting the wire/rod back out. One goes to the idle circuit and meets up with others channels under a welch plug. The metering circuits and jets are located inside the carb to regulate the proper amount of gas coming out those posts per the butterfly opening amount and jets sized per HP of the engine, etc. Do not damage those ports.

A hint where this idle welch plug is is it's usually close to the idle jet area if the carb has a adjustable idle jet. I have some long different size needle tips that I can put on my air nozzle gun so as to blow high pressure air back through those ports. The air nozzle kit I have came with a air nozzle and about 6 different screw on tips. It looks similar to this one.

Those ports in the carb throat are called something like transistion ports.

You can re-view such on-line. One is located on the air intake throat above the butterfly of the carb and its the idle port. Air rushing through the throat sucks gas through which ever port the butterfly has opened towards. On the high speed port below the butterfly or engine side when the butterfly is wide open all three will be providing gas by the suction of air rushing past the port/ports.

One of the other two is on the engine side of the butterfly and it's the High speed port that sucks more gas into the engine as the butterfly opens.

The one in the middle might be a trasistion between the high and low butterfly opening.

They all have to be open and yes hard to get to. You have to be careful and not break off a wire in them or you will be SOL. No way of getting the wire/rod back out. One goes to the idle circuit and meets up with others channels under a welch plug. The metering circuits and jets are located inside the carb to regulate the proper amount of gas coming out those posts per the butterfly opening amount and jets sized per HP of the engine, etc. Do not damage those ports.

A hint where this idle welch plug is is it's usually close to the idle jet area if the carb has a adjustable idle jet. I have some long different size needle tips that I can put on my air nozzle gun so as to blow high pressure air back through those ports. The air nozzle kit I have came with a air nozzle and about 6 different screw on tips. It looks similar to this one.

#20

S

slomo

S

slomo

Make sure you have full battery voltage AT the carb solenoid wires, key on. That thing "could" be limiting fuel flow into the carb, could be sticking. I always snip those plungers off so as to never have a fuel delivery issue again.

#21

F

Forest#2

F

Forest#2

Right about the ABF (anti back fire) solenoid plunger.

I've heard rumors that they can be tested on the work bench with a good 9v xistor radio battery but I always just use 12v. Make sure the plunger is fully retracting. I have cleaned up sticking plungers by using a oil and just keep on operating the plunger by hand, but if it's sticking just give her the clip/snip.

I've heard rumors that they can be tested on the work bench with a good 9v xistor radio battery but I always just use 12v. Make sure the plunger is fully retracting. I have cleaned up sticking plungers by using a oil and just keep on operating the plunger by hand, but if it's sticking just give her the clip/snip.

#22

W

Wurzel

W

Wurzel

With workshop facilities still under construction for a couple of weeks I'm a little limited, but nonetheless I did get a bit more done this evening.

Carb: Had the carb off again and got into the transition ports and idle port with fine wire, plus compressed air. I can see clearly through the idle port, but it's impossible to say if one or another of the transition ports may remain partially blocked. I was however able to get plenty of air from the top of 72 (with screw 955 removed), in the diagram below through to the idle port and also out an air side port.

Carb back on and problem remains, however while blowing compressed air, I did see the welch plug above the transition jets (which looks to have been got at before), has a small air leak - which won't be helping. Rudimentarily I've put my finger over it while the engine is running and there's no difference, but even so it will need replacing. Also still need to properly check for any more substantial vaccuum leaks at the manifold.

Fuel: I'm getting a steady 12v at the fuel solenoid and good flow at the carb inlet. I haven't been able to bench test the solenoid yet. Float level checked and good. However having had a better look at the tank there's quite a lot of fuel in it, which means more of it will be old. Once I've found the drain plug, I will drain and refresh - so definitely some hope there.

Mechanical: I haven't seen the fly wheel yet or checked valve clearances, I'll get to those once I've changed the fuel / am not working off a concrete floor!

Carb: Had the carb off again and got into the transition ports and idle port with fine wire, plus compressed air. I can see clearly through the idle port, but it's impossible to say if one or another of the transition ports may remain partially blocked. I was however able to get plenty of air from the top of 72 (with screw 955 removed), in the diagram below through to the idle port and also out an air side port.

Carb back on and problem remains, however while blowing compressed air, I did see the welch plug above the transition jets (which looks to have been got at before), has a small air leak - which won't be helping. Rudimentarily I've put my finger over it while the engine is running and there's no difference, but even so it will need replacing. Also still need to properly check for any more substantial vaccuum leaks at the manifold.

Fuel: I'm getting a steady 12v at the fuel solenoid and good flow at the carb inlet. I haven't been able to bench test the solenoid yet. Float level checked and good. However having had a better look at the tank there's quite a lot of fuel in it, which means more of it will be old. Once I've found the drain plug, I will drain and refresh - so definitely some hope there.

Mechanical: I haven't seen the fly wheel yet or checked valve clearances, I'll get to those once I've changed the fuel / am not working off a concrete floor!

#23

S

slomo

S

slomo

Typically the pilot circuit works at idle and off idle. Not mid and full throttle. It still draws fuel and air through that circuit when at full revs. Adjusting the pilot screw should either stumble the engine or smooth it out. That is if it's working as it should at low revs.

Old fuel and possible water contamination are definitely something to address first. Stop all testing until you have fresh (non E-10 if possible) gas. Get some Stabil fuel stabilizer and add it to your fuel can. Shake it well. Never worry about bad fuel again.

I would snip the anti-backfire solenoid plunger off. Just idle down the revs and turn the key off. You still might get a pop but it doesn't harm anything. Never worry about starting issues again.

So carb upside down, the float was hanging level with the bowl mating surface? If so that is good.

You might have to strip the carb down and boil it. Is that the OEM original carb, to that engine, you are working with?

Old fuel and possible water contamination are definitely something to address first. Stop all testing until you have fresh (non E-10 if possible) gas. Get some Stabil fuel stabilizer and add it to your fuel can. Shake it well. Never worry about bad fuel again.

I would snip the anti-backfire solenoid plunger off. Just idle down the revs and turn the key off. You still might get a pop but it doesn't harm anything. Never worry about starting issues again.

So carb upside down, the float was hanging level with the bowl mating surface? If so that is good.

You might have to strip the carb down and boil it. Is that the OEM original carb, to that engine, you are working with?

#24

W

Wurzel

W

Wurzel

Having that much old fuel in the tank (turned out to be about 4l) was a massive oversight given I only put a little fresh in - so I was convinced that would be the issue. But alas after dropping the tank, draining the fuel line and hooking it up to a fresh fuel source, it's made no difference. I do recall at least smelling the tank before I started and it was fine, plus the old fuel had a very red (not brown), tinge - so I think it must have had stabiliser in it.

So I'm back where I started, full revs with choke is no issue, but I can't past a quarter without. It feels like it's getting plenty of fuel without choke though, as it sprays unburnt fuel forward back out the carb as it starts to splutter and die? Fuel screw works at idle, too lean and it stumbles, then it stops having an effect too far the other way, but won't rev at all if too rich. It still doesn't start too well without choke though.

The float valve closes about parallel with the mating service, but upside down IIRC it rests beyond parallel, there's a little slack in float hinge. I will snip the plunger, but that would likely be affecting it with choke as well.

I don't have an ultrasonic cleaner but I think my last option is too boil the carb, maybe it will move something if that's the issue. As far as I can ascertain, it is the OEM carb for that engine, it's exactly as @Forest#2 's diagram on the link above.

I did accidentally leave screw and washer 955 off the carb a couple days ago and started it up. Needless to say there was a massive vaccuum leak and it ran very badly - but it seemed like the same problem but worse. So am wondering if there somehow could be a vaccuum leak somewhere - more testing there. I should add, I'm doing this without the air filter fitted, but it would be a long shot to say that's leaning it out too much?

So I'm back where I started, full revs with choke is no issue, but I can't past a quarter without. It feels like it's getting plenty of fuel without choke though, as it sprays unburnt fuel forward back out the carb as it starts to splutter and die? Fuel screw works at idle, too lean and it stumbles, then it stops having an effect too far the other way, but won't rev at all if too rich. It still doesn't start too well without choke though.

The float valve closes about parallel with the mating service, but upside down IIRC it rests beyond parallel, there's a little slack in float hinge. I will snip the plunger, but that would likely be affecting it with choke as well.

I don't have an ultrasonic cleaner but I think my last option is too boil the carb, maybe it will move something if that's the issue. As far as I can ascertain, it is the OEM carb for that engine, it's exactly as @Forest#2 's diagram on the link above.

I did accidentally leave screw and washer 955 off the carb a couple days ago and started it up. Needless to say there was a massive vaccuum leak and it ran very badly - but it seemed like the same problem but worse. So am wondering if there somehow could be a vaccuum leak somewhere - more testing there. I should add, I'm doing this without the air filter fitted, but it would be a long shot to say that's leaning it out too much?

#25

F

Forest#2

F

Forest#2

You say:

It feels like it's getting plenty of fuel without choke though, as it sprays unburnt fuel forward back out the carb as it starts to splutter and die?

Tell us more about what you are saying here??????????

Is this as it's running fast with choke or what are you trying to indicate????

Reason I ask is I'm suspicious of something else as a issue, like maybe you have more than one problem with that engine???????????????

It feels like it's getting plenty of fuel without choke though, as it sprays unburnt fuel forward back out the carb as it starts to splutter and die?

Tell us more about what you are saying here??????????

Is this as it's running fast with choke or what are you trying to indicate????

Reason I ask is I'm suspicious of something else as a issue, like maybe you have more than one problem with that engine???????????????

#26

W

Wurzel

W

Wurzel

No that's only if it's running fast with choke and i take the choke off, or when I try to rev it more than it wants to go, without choke. It's like a carb backfire. I'll get a video tomorrow to demonstrate!

#27

F

Forest#2

F

Forest#2

your Briggs twin Intek engine parts list.

You can also get a service manual for that engine if desired for around $25 TO30. (you might find a freebie download somewhere)

Look for a Briggs Twin OHV, part number might be 273521.

You have a problem with that engine that is not JUST the carb.

I've seen other things very similar to yours make me think it was the carb when it was ignition, timing, bad valves, etc.

You need to check elsewhere.

What I would start checking.

I would install new spark plugs NGK 6130 or champion RC12YC gapped properly.

First I would make sure that the valves on both heads are adjusted properly per specs and I would also look at the valve lift (compare the valve lift to each other) to make sure you do not have a flat or worn cam lobe.

I would make sure the flywheel key is good.

I've seen the single cylinder Briggs engines act like that due to the intake valve lobe worn down and the valve lash even though adjusted properly would not allow the engine to take gas properly. The valve lift should be same on both the exhaust and the intake valves.

Also I would confirm by using a Ohmmeter that both of the diodes in the kill wire harness going to the magnetos are Ok. (one not shorted) You can check on line how to ohm the diodes.

Those are isolation diodes and if one is shorted the ignition will be erratic at different rpms. While checking the diodes check the air gap on both magnetos as at .010-.012.

also make sure the engine is not running on just one cylinder. You can do this by grounding one spark plug wire at a time on each cylinder.

after doing the valve lash I would compare the compression on cylinder 1 to cylinder 2 and see if they are balanced.

You can also get a service manual for that engine if desired for around $25 TO30. (you might find a freebie download somewhere)

Look for a Briggs Twin OHV, part number might be 273521.

You have a problem with that engine that is not JUST the carb.

I've seen other things very similar to yours make me think it was the carb when it was ignition, timing, bad valves, etc.

You need to check elsewhere.

What I would start checking.

I would install new spark plugs NGK 6130 or champion RC12YC gapped properly.

First I would make sure that the valves on both heads are adjusted properly per specs and I would also look at the valve lift (compare the valve lift to each other) to make sure you do not have a flat or worn cam lobe.

I would make sure the flywheel key is good.

I've seen the single cylinder Briggs engines act like that due to the intake valve lobe worn down and the valve lash even though adjusted properly would not allow the engine to take gas properly. The valve lift should be same on both the exhaust and the intake valves.

Also I would confirm by using a Ohmmeter that both of the diodes in the kill wire harness going to the magnetos are Ok. (one not shorted) You can check on line how to ohm the diodes.

Those are isolation diodes and if one is shorted the ignition will be erratic at different rpms. While checking the diodes check the air gap on both magnetos as at .010-.012.

also make sure the engine is not running on just one cylinder. You can do this by grounding one spark plug wire at a time on each cylinder.

after doing the valve lash I would compare the compression on cylinder 1 to cylinder 2 and see if they are balanced.

#28

S

slomo

If the engine is puking gas out of the carb, we are talking cam timing issues right? Been a while on that trick for my memory. Like a 2 stroke? Or it is a valve adjustment needed? Having a senior moment here...... LOL Flat cam lobe?? Going with a bad cam lobe for 20 bucks Alex.

S

slomo

Nope. Needs to be exactly parallel, to the bowl mating flange. Not about parallel nor close to parallel. These little tricks can cause grief. Too low a fuel level will starve the engine. Too high, well you get the email.The float valve closes about parallel with the mating service, but upside down IIRC it rests beyond parallel

Go to the hardware store. Get a small bolt, SAME threads as the carb solenoid. Just something to attach the carb bowl on for testing. We are temporarily eliminating the carb solenoid. See if this changes anything. If not, reinstall the solenoid if you want to.I will snip the plunger, but that would likely be affecting it with choke as well.

I myself, am not impressed with ultra sonic cleaners for carbs. Maybe some guys have better luck. Now the wife's dishwasher, greatest parts washer on the planet, yes. Good ol' pot scrubber cycle works great. Boiling carbs I feel is the best way to really get inside and do some good. As you can see, the carb is dunked in cleaning solution and the heat loosens gunk up. Strip all plastic parts out first. Lay the jets and emulsion tube in the pan. Bertsmobile1 has shared this tip with us. Summation don't sweat not having an ultra sonic cleaner for this.I don't have an ultrasonic cleaner but I think my last option is too boil the carb,

If the engine is puking gas out of the carb, we are talking cam timing issues right? Been a while on that trick for my memory. Like a 2 stroke? Or it is a valve adjustment needed? Having a senior moment here...... LOL Flat cam lobe?? Going with a bad cam lobe for 20 bucks Alex.

#29

S

slomo

S

slomo

Pull the valve cover/s and sparky plug/s. Rotate the engine by hand. Watch the rocker arms. Rockers should move roughly the same depth INTO the block. Might have a second small bump on the EX valve for compression release.

#30

W

Wurzel

W

Wurzel

So a couple of videos, the first showing it running flat out with about 80% choke, then the effect of removing choke, shown at the carb, where it starts stumbling and dies. The second is it starting at idle with no choke, then trying to gradually introduce revs.

Full revs to no choke: https://youtube.com/shorts/qQAejaOIz8E?feature=share

No choke idle to revs: https://youtube.com/shorts/mOj3QcGQN7k?feature=share

Poorly video'd on my phone so apologies for sound...

Had ocnfirmed by another this evening that it was running OK only a year ago, so I'm struggling to make the jump to a mechanical issue. I'm just bolting and unbolting the carb, will take the shroud off tomorrow and have a clean, is there potential for a vaccuum leak further in than the manifold / carb mating surface?

Full revs to no choke: https://youtube.com/shorts/qQAejaOIz8E?feature=share

No choke idle to revs: https://youtube.com/shorts/mOj3QcGQN7k?feature=share

Poorly video'd on my phone so apologies for sound...

Had ocnfirmed by another this evening that it was running OK only a year ago, so I'm struggling to make the jump to a mechanical issue. I'm just bolting and unbolting the carb, will take the shroud off tomorrow and have a clean, is there potential for a vaccuum leak further in than the manifold / carb mating surface?

#31

F

Forest#2

F

Forest#2

Hard to tell for sure but I seem to detect that it's only running on one cylinder sometimes maybe. (or one cylinder is weaker) You can judge such by rpm drop as each cylinder is disabled, comparing one to the other.

You can easily confirm such by sliding back the rubber boots on both spark plugs so as to see the metal ends while on the spark plug and while the engine is running at idle ground each spark plug wire one at a time using a long blade screwdriver. If grounding one spark plug wire immediately starts killing the engine that is the ONE CYLINDER that it's using to run.

The cylinder that makes no difference when it's spark plug wire is grounded is the dead or weak cylinder.

Lightly lubing the spark plug wire itself just above the boot helps when sliding the boot back. (another way is to allow a small solid wire to stick out of the boot and ground the wire while it's running.

Just because you see a spark at both plugs IS NOT sure indicator that both cylinders are actually producing power. The other way is to use a fuse puller and momentarily pull the spark plug wire off the plug. I do not like to pull a plug wire for testing while running, I prefer grounding but sometimes I have no other choice.

You can easily confirm such by sliding back the rubber boots on both spark plugs so as to see the metal ends while on the spark plug and while the engine is running at idle ground each spark plug wire one at a time using a long blade screwdriver. If grounding one spark plug wire immediately starts killing the engine that is the ONE CYLINDER that it's using to run.

The cylinder that makes no difference when it's spark plug wire is grounded is the dead or weak cylinder.

Lightly lubing the spark plug wire itself just above the boot helps when sliding the boot back. (another way is to allow a small solid wire to stick out of the boot and ground the wire while it's running.

Just because you see a spark at both plugs IS NOT sure indicator that both cylinders are actually producing power. The other way is to use a fuse puller and momentarily pull the spark plug wire off the plug. I do not like to pull a plug wire for testing while running, I prefer grounding but sometimes I have no other choice.

#32

R

RevB

R

RevB

Are those composite floats or just really crusty brass floats? The composite floats are sometimes like the Bing composite floats and they absorb gas after the surface sealing fails making the float too heavy and the needle never closes. Thus, too rich as you say it appears to be.Hello All - am hoping the knowledge bank here may be able help. I'm resurrecting a John Deere LT166 lawn tractor with 16HP Briggs engine. It has sat for 2-3 years but was running fine, save for a snapped deck belt, previously. I've stripped and cleaned the carb and got it started, driving and mowing, but not very well. It basically won't run properly without choke. I've double checked the jets in the carb. I can just about get it to tick over without choke by adjusting the fuel screw, but it won't rev and it's obviously running far too rich. In any other position it won't even idle, or only for 10-15 secs before stuttering and dying. With choke it will rev, but is maybe at 30% power and clearly not running as it should. Oddly it can manage forwards, but reverse pretty much kills it.

Have I missed something on the Aisan carb? I thought maybe a fuel pump issue but if it runs at full revs, albeit it badly, it can't be? I've checked the tank cap breather as well. It has clean fuel, albeit mixed with whatever small amount of bad might have previously been in the tank, but I think it was bone dry. Is there a hidden jet anywhere on those carbs?

Thanks in advance...!

#33

G

Gord Baker

G

Gord Baker

The wires on a Wire Brush work well for poking through these holes. Some jets on the bottom of the float bowl have a very tiny hold on an angle in the threads.142 is the emulsion tube. It has super tiny holes so be thorough. Use a magnifying glass and fishing line to verify holes are open. Start saving bread ties. They have small gauge wire under that plastic coating. I found a couple that work great for this. You might have to use a radiator hose angled pic tool to get the emulsion tube out.

Wear safety glasses when spraying carb cleaner. Face shield even better. That stuff burns the eyes let me tell you.

#35

S

STEVES

S

STEVES

Narrow (thin, flat) 1/2" wrench fits at the top of solenoid at bottom of bowl to removeI haven't fired compressed air through there yet but it has had a load of carb cleaner through. I'll also try compressed air in case the carb cleaner hasn't moved something, plus a wire guitar string I've found works well. I've pictured the fuel screw port in the venturi below, what do those three just visible (hard to get phone to focus!) behind do? They're connected to 72 in the diagram via a channel (showing in pic 1 top of carb) in the carb body - again all blasted through with carb cleaner and apparently clear.

The fuel screw was doing little previously, but now if I lean it off too much it stalls, so is working at the least in part.

Flywheel - haven't got in that far yet, will check and also do fins if clogged. Valve clearances likewise.

Will also check float level. Disconnecting the solenoid kills the engine, but I'll check the voltage to see if constant. I'm twisting the carb once it's off the engine to unscrew the bowl, as I can't see a way to easily disconnect the solenoid wiring at the solenoid. Twisting the solenoid will have twisted the wire and stressed the connection over time / previous owners I'm sure.

@Forest#2 was there info missing from my last? I will check tomorrow in daylight again. Noted re welch plugs, thanks for the tip!

Appreciate your continued help!

#36

F

ft_motors

F

ft_motors

If it's running rich, most likely the air jets are plugged.Hello All - am hoping the knowledge bank here may be able help. I'm resurrecting a John Deere LT166 lawn tractor with 16HP Briggs engine. It has sat for 2-3 years but was running fine, save for a snapped deck belt, previously. I've stripped and cleaned the carb and got it started, driving and mowing, but not very well. It basically won't run properly without choke. I've double checked the jets in the carb. I can just about get it to tick over without choke by adjusting the fuel screw, but it won't rev and it's obviously running far too rich. In any other position it won't even idle, or only for 10-15 secs before stuttering and dying. With choke it will rev, but is maybe at 30% power and clearly not running as it should. Oddly it can manage forwards, but reverse pretty much kills it.

Have I missed something on the Aisan carb? I thought maybe a fuel pump issue but if it runs at full revs, albeit it badly, it can't be? I've checked the tank cap breather as well. It has clean fuel, albeit mixed with whatever small amount of bad might have previously been in the tank, but I think it was bone dry. Is there a hidden jet anywhere on those carbs?

Thanks in advance...!

#37

S

S.A.P.

Probably got full of thum grass clippings and oil, and ran too hot.

Once the covers been removed of course, things can be observed, flywheel magnet, coil, and any foreign matter trapped in the cooling fins. Some compressed air, or (pressure washing) works, (remove the coil first) to get the gunk off.

S

S.A.P.

Sounds like a head gasket issue.Hello All - am hoping the knowledge bank here may be able help. I'm resurrecting a John Deere LT166 lawn tractor with 16HP Briggs engine. It has sat for 2-3 years but was running fine, save for a snapped deck belt, previously. I've stripped and cleaned the carb and got it started, driving and mowing, but not very well. It basically won't run properly without choke. I've double checked the jets in the carb. I can just about get it to tick over without choke by adjusting the fuel screw, but it won't rev and it's obviously running far too rich. In any other position it won't even idle, or only for 10-15 secs before stuttering and dying. With choke it will rev, but is maybe at 30% power and clearly not running as it should. Oddly it can manage forwards, but reverse pretty much kills it.

Have I missed something on the Aisan carb? I thought maybe a fuel pump issue but if it runs at full revs, albeit it badly, it can't be? I've checked the tank cap breather as well. It has clean fuel, albeit mixed with whatever small amount of bad might have previously been in the tank, but I think it was bone dry. Is there a hidden jet anywhere on those carbs?

Thanks in advance...!

Probably got full of thum grass clippings and oil, and ran too hot.

Once the covers been removed of course, things can be observed, flywheel magnet, coil, and any foreign matter trapped in the cooling fins. Some compressed air, or (pressure washing) works, (remove the coil first) to get the gunk off.

#38

B

barny57

B

barny57

Hello All - am hoping the knowledge bank here may be able help. I'm resurrecting a John Deere LT166 lawn tractor with 16HP Briggs engine. It has sat for 2-3 years but was running fine, save for a snapped deck belt, previously. I've stripped and cleaned the carb and got it started, driving and mowing, but not very well. It basically won't run properly without choke. I've double checked the jets in the carb. I can just about get it to tick over without choke by adjusting the fuel screw, but it won't rev and it's obviously running far too rich. In any other position it won't even idle, or only for 10-15 secs before stuttering and dying. With choke it will rev, but is maybe at 30% power and clearly not running as it should. Oddly it can manage forwards, but reverse pretty much kills it.

Have I missed something on the Aisan carb? I thought maybe a fuel pump issue but if it runs at full revs, albeit it badly, it can't be? I've checked the tank cap breather as well. It has clean fuel, albeit mixed with whatever small amount of bad might have previously been in the tank, but I think it was bone dry. Is there a hidden jet anywhere on those carbs?

Thanks in advance...!

A new carb kids only from 10 to 15 bucks I just replace the partsHello All - am hoping the knowledge bank here may be able help. I'm resurrecting a John Deere LT166 lawn tractor with 16HP Briggs engine. It has sat for 2-3 years but was running fine, save for a snapped deck belt, previously. I've stripped and cleaned the carb and got it started, driving and mowing, but not very well. It basically won't run properly without choke. I've double checked the jets in the carb. I can just about get it to tick over without choke by adjusting the fuel screw, but it won't rev and it's obviously running far too rich. In any other position it won't even idle, or only for 10-15 secs before stuttering and dying. With choke it will rev, but is maybe at 30% power and clearly not running as it should. Oddly it can manage forwards, but reverse pretty much kills it.

Have I missed something on the Aisan carb? I thought maybe a fuel pump issue but if it runs at full revs, albeit it badly, it can't be? I've checked the tank cap breather as well. It has clean fuel, albeit mixed with whatever small amount of bad might have previously been in the tank, but I think it was bone dry. Is there a hidden jet anywhere on those carbs?

Thanks in advance...!

#39

F

Freddie21

F

Freddie21

I have the exact problem with a Kohler SV590 19hp. The governor brackets were previously adjusted and I think I got them close. Almost idles with choke partically on, spits fuel out when throttle increased. More than one OEM carb and one China carb. Mine does have a mixture screw, but little affect. For the cheap price, try another carb and see if problem changes. Like mentioned, Amazon will take the return.

#40

W

Wurzel

W

Wurzel

Having some trouble finding a compatible one, the linkages are top mounted on most of the ones that claim to be replacements...A new carb kids only from 10 to 15 bucks I just replace the parts

#41

W

Wurzel

W

Wurzel

Yep next job, hopefully notSounds like a head gasket issue.

Probably got full of thum grass clippings and oil, and ran too hot.

Once the covers been removed of course, things can be observed, flywheel magnet, coil, and any foreign matter trapped in the cooling fins. Some compressed air, or (pressure washing) works, (remove the coil first) to get the gunk off.

#42

W

Wurzel

W

Wurzel

Not yet, will do but have good flow at carb inletI hope you changed out the Fuel Filter.

#43

W

Wurzel

W

Wurzel

Could be a thing, they're compositeAre those composite floats or just really crusty brass floats? The composite floats are sometimes like the Bing composite floats and they absorb gas after the surface sealing fails making the float too heavy and the needle never closes. Thus, too rich as you say it appears to be.

#44

T

TobyU

T

TobyU

Whatever happened with this? I'm a little confused if I conflicting statements in the first post. Says they think it's obviously too rich but then when they give it choke it smooths out and runs better but only has 30% power.

Sounds to me like it's actually lean and even with the choke it's not getting enough.

It always irritates me when people , well actually customers, say they cleaned out the carburetor.. blah blah blah, as most people don't really know how to clean out a carburetor properly or don't no what the actual crucial part is to clean.

I got a feeling this carburetor is still gummed up and that's the problem. So where does it stand now?

Sounds to me like it's actually lean and even with the choke it's not getting enough.

It always irritates me when people , well actually customers, say they cleaned out the carburetor.. blah blah blah, as most people don't really know how to clean out a carburetor properly or don't no what the actual crucial part is to clean.

I got a feeling this carburetor is still gummed up and that's the problem. So where does it stand now?

#45

F

Forest#2

F

Forest#2

From your post #24

You say

as it sprays unburnt fuel forward back out the carb as it starts to splutter and die? Fuel screw works at idle, too lean and it stumbles,.

Did you ever check to see if the engine will idle/run using only one cylinder doing the cylinder comparison test suggested previously?

Listening to your video in post #30 you could easily do such with the engine idling.

Also

Did you ever check the valve lash?

If you remove the shroud keep a heads up and do not run the engine long enough to overheat

How many times have we heard the story, it was running good when I parked it, therefore the engine will run great when a battery is installed, trust me.

You say

as it sprays unburnt fuel forward back out the carb as it starts to splutter and die? Fuel screw works at idle, too lean and it stumbles,.

Did you ever check to see if the engine will idle/run using only one cylinder doing the cylinder comparison test suggested previously?

Listening to your video in post #30 you could easily do such with the engine idling.

Also

Did you ever check the valve lash?

If you remove the shroud keep a heads up and do not run the engine long enough to overheat

How many times have we heard the story, it was running good when I parked it, therefore the engine will run great when a battery is installed, trust me.

#46

S

slomo

Remove the main jet. Look for a jet number on it and see if your parts schematic lists any jet sizes. You might have to SLIGHTLY open up that main jet. Just a little bit at a time.

I would verify no vacuum leaks prior to enlarging the main jet size.

S

slomo

Your videos indicated it ran fine at idle and low revs. Pilot circuit seemed okay there. Just when you increased throttle is ran short on fuel. So the main jet is to be looked at. You need choke for higher revs. That also confirms you are shy on fuel from the main jet.So a couple of videos, the first showing it running flat out with about 80% choke, then the effect of removing choke, shown at the carb, where it starts stumbling and dies. The second is it starting at idle with no choke, then trying to gradually introduce revs.

Full revs to no choke: https://youtube.com/shorts/qQAejaOIz8E?feature=share

No choke idle to revs: https://youtube.com/shorts/mOj3QcGQN7k?feature=share

Poorly video'd on my phone so apologies for sound...

Had ocnfirmed by another this evening that it was running OK only a year ago, so I'm struggling to make the jump to a mechanical issue. I'm just bolting and unbolting the carb, will take the shroud off tomorrow and have a clean, is there potential for a vaccuum leak further in than the manifold / carb mating surface?

Remove the main jet. Look for a jet number on it and see if your parts schematic lists any jet sizes. You might have to SLIGHTLY open up that main jet. Just a little bit at a time.

I would verify no vacuum leaks prior to enlarging the main jet size.

#47

S

slomo

S

slomo

His engine is starving for fuel. He has to choke it to smooth it out in high revs.Are those composite floats or just really crusty brass floats? The composite floats are sometimes like the Bing composite floats and they absorb gas after the surface sealing fails making the float too heavy and the needle never closes. Thus, too rich as you say it appears to be.

#48

S

slomo

S

slomo

Feel or measure the temps from both exhaust pipes directly off the heads. Both should be hot.Hard to tell for sure but I seem to detect that it's only running on one cylinder sometimes maybe. (or one cylinder is weaker) You can judge such by rpm drop as each cylinder is disabled, comparing one to the other.

You can easily confirm such by sliding back the rubber boots on both spark plugs so as to see the metal ends while on the spark plug and while the engine is running at idle ground each spark plug wire one at a time using a long blade screwdriver. If grounding one spark plug wire immediately starts killing the engine that is the ONE CYLINDER that it's using to run.

The cylinder that makes no difference when it's spark plug wire is grounded is the dead or weak cylinder.

Lightly lubing the spark plug wire itself just above the boot helps when sliding the boot back. (another way is to allow a small solid wire to stick out of the boot and ground the wire while it's running.

Just because you see a spark at both plugs IS NOT sure indicator that both cylinders are actually producing power. The other way is to use a fuse puller and momentarily pull the spark plug wire off the plug. I do not like to pull a plug wire for testing while running, I prefer grounding but sometimes I have no other choice.

#49

F

Forest#2

F

Forest#2

From your post #24

You say

as it sprays unburnt fuel forward back out the carb as it starts to splutter and die? Fuel screw works at idle, too lean and it stumbles,.

Did you ever check to see if the engine will still idle using only one cylinder doing the cylinder comparison test suggested.

Listening to your video in post #30 you could easily do such with the engine idling.

Did you ever check the valve lash?

You say

as it sprays unburnt fuel forward back out the carb as it starts to splutter and die? Fuel screw works at idle, too lean and it stumbles,.

Did you ever check to see if the engine will still idle using only one cylinder doing the cylinder comparison test suggested.

Listening to your video in post #30 you could easily do such with the engine idling.

Did you ever check the valve lash?

#50

F

Forest#2

F

Forest#2

Feel or measure the temps from both exhaust pipes directly off the heads. Both should be hot.

I've got a IR thermometer that is really good for fast checking for a cold dead cylinde or comparing cylinder temps..

I've got a IR thermometer that is really good for fast checking for a cold dead cylinde or comparing cylinder temps..

#51

W

Wurzel

W

Wurzel

Progress at last thanks to your pointers, it's only running on one cylinder, #1 is down.

The plugs are in a very different condition, the one on #1 cylinder having done little to no work. Swapped the plugs with each other and #1 still not firing, tested and confirmed no spark on #1.

Checked #1 magneto and the gap was too big, set correctly but still no spark. Have now run out of light, but initial tests with multimeter suggest the kill diode on #1 magneto is open. Will test properly tomorrow to confirm - thanks again for all your help!

The plugs are in a very different condition, the one on #1 cylinder having done little to no work. Swapped the plugs with each other and #1 still not firing, tested and confirmed no spark on #1.

Also I would confirm by using a Ohmmeter that both of the diodes in the kill wire harness going to the magnetos are Ok. (one not shorted) You can check on line how to ohm the diodes.

Those are isolation diodes and if one is shorted the ignition will be erratic at different rpms. While checking the diodes check the air gap on both magnetos as at .010-.012.

Checked #1 magneto and the gap was too big, set correctly but still no spark. Have now run out of light, but initial tests with multimeter suggest the kill diode on #1 magneto is open. Will test properly tomorrow to confirm - thanks again for all your help!

#52

T

TobyU

T

TobyU

The coil Gap is pretty forgiving on those. Just use a business card or whatever but most of them will fire just fine even at the widest position and it's more important to make sure it doesn't rub on the flywheel but a few thousands here or there is not going to cause a no spark condition.

If you actually have no spark jumping from The wire to the engine block or on a good known plug where it won't jump the plug gap then you certainly need to figure out the no spark condition for that one.

If you actually have no spark jumping from The wire to the engine block or on a good known plug where it won't jump the plug gap then you certainly need to figure out the no spark condition for that one.

#53

F

Forest#2

F

Forest#2

Just couple tips:

A OPEN diode will not keep the magneto from firing. A shorted or low resistance diode will result in erratic/misfire operation. The diodes purpose is as isolation diodes, isolating one mag from the other when the engine is running. I've replaced those diodes with a 1N4007, 1 amp, 1000PIV (peak inverse voltage) buying them dirt cheap on fleece bay. I just cut the wire leads on the old ones out of the wire loom, solder or crimp in the replacements and use heat shrink tubing over the replacements instead of buying the Briggs diode harness. If that diode is burned open or charred it's due to voltage getting onto the kill wire and on mowers that have been setting long time outside water gets into the ignition switch and rust inside will allow cross tracking of voltage. If you loose the/a magneto again later you will need to replace the ign switch. Be sure you get the polarity correct on the replacement diode when installing (the white line ring or cathode will go towards the magneto)

Those magnetos can be found for less than $20. I've had good luck with the ones from Amazon and fleece bay. I try to keep a spare magneto around. I've have previously bought the $70 Napa mag replacements and have them fail within a years time.

I would at the very least replace both magnetos, set the air gap at .010-.012 (most plastic cards are too thick at .015) Air gap is not real critical just make sure you have clearance to the magnet after setting by turning the flywheel by hand. Save the one that's firing as a spare maybe.

Then replace the one diode or wire harness. Be careful BEFORE trying to turn out the 5/16 machine screws holding the mags. That is steel screws into aluminum and they will twist off easily, FIRST slightly/lightly peck on their head with a small hammer and the vibration will loosen the corrosion. Make sure you get them just good snug when going back. I sometimes use little bit of Anti-seize on their threads.

You cannot make any logical ohmmeter tests on those mags because their is electronic sealed inside. The real test is to use a old spark plug and set the gap at approx .060 and look at the spark in shade or a darkened room.

I would also pull both valve covers and check the valve lash before ordering parts. Might need valve cover gaskets after doing so. You can find specs for such on-line.

BUT before jumping in and buying mag's and diodes even though you do not see spark. I would compare compression on each cylinder. Most likely ok but now is the time to test such. You will be mainly checking to see if valves and valve seats are Ok. The heads on some of those Briggs OHV's will bite the dust in a surprise way and no or weak compression.

It appears you had two issues going in, clogged carb and a weak or dead cylinder, maybe.

But it was running good when stored. (Murphy's law strikes again)

A OPEN diode will not keep the magneto from firing. A shorted or low resistance diode will result in erratic/misfire operation. The diodes purpose is as isolation diodes, isolating one mag from the other when the engine is running. I've replaced those diodes with a 1N4007, 1 amp, 1000PIV (peak inverse voltage) buying them dirt cheap on fleece bay. I just cut the wire leads on the old ones out of the wire loom, solder or crimp in the replacements and use heat shrink tubing over the replacements instead of buying the Briggs diode harness. If that diode is burned open or charred it's due to voltage getting onto the kill wire and on mowers that have been setting long time outside water gets into the ignition switch and rust inside will allow cross tracking of voltage. If you loose the/a magneto again later you will need to replace the ign switch. Be sure you get the polarity correct on the replacement diode when installing (the white line ring or cathode will go towards the magneto)

Those magnetos can be found for less than $20. I've had good luck with the ones from Amazon and fleece bay. I try to keep a spare magneto around. I've have previously bought the $70 Napa mag replacements and have them fail within a years time.

I would at the very least replace both magnetos, set the air gap at .010-.012 (most plastic cards are too thick at .015) Air gap is not real critical just make sure you have clearance to the magnet after setting by turning the flywheel by hand. Save the one that's firing as a spare maybe.

Then replace the one diode or wire harness. Be careful BEFORE trying to turn out the 5/16 machine screws holding the mags. That is steel screws into aluminum and they will twist off easily, FIRST slightly/lightly peck on their head with a small hammer and the vibration will loosen the corrosion. Make sure you get them just good snug when going back. I sometimes use little bit of Anti-seize on their threads.

You cannot make any logical ohmmeter tests on those mags because their is electronic sealed inside. The real test is to use a old spark plug and set the gap at approx .060 and look at the spark in shade or a darkened room.

I would also pull both valve covers and check the valve lash before ordering parts. Might need valve cover gaskets after doing so. You can find specs for such on-line.

BUT before jumping in and buying mag's and diodes even though you do not see spark. I would compare compression on each cylinder. Most likely ok but now is the time to test such. You will be mainly checking to see if valves and valve seats are Ok. The heads on some of those Briggs OHV's will bite the dust in a surprise way and no or weak compression.

It appears you had two issues going in, clogged carb and a weak or dead cylinder, maybe.

But it was running good when stored. (Murphy's law strikes again)

#54

B

bertsmobile1

B

bertsmobile1

Just to clarify things

The magnetos have a Hall Effect Trigger chip in them which is what makes them work

They have a kill wire attached to stop them working when you shut down .

On twin cylinder engines you get a ripple down the kill wire that can interfear with the other magneto so they put diodes in there to clamp this signal.

On B & S engines the diode is usually in the kill wires and quite obvious.

Thses can be replaced for a few cents or the sub loom can be replaced for a lot of dollars .

The chip inside the magneto coil is neither repairable nor replaceable ( I have pulled a few apart ) .

So you test the coils by removing the kill wire

No spark with the kill wire removed = dead coil that has to be replaced

The magnetos have a Hall Effect Trigger chip in them which is what makes them work

They have a kill wire attached to stop them working when you shut down .

On twin cylinder engines you get a ripple down the kill wire that can interfear with the other magneto so they put diodes in there to clamp this signal.

On B & S engines the diode is usually in the kill wires and quite obvious.

Thses can be replaced for a few cents or the sub loom can be replaced for a lot of dollars .

The chip inside the magneto coil is neither repairable nor replaceable ( I have pulled a few apart ) .

So you test the coils by removing the kill wire

No spark with the kill wire removed = dead coil that has to be replaced

#55

W

Wurzel

Removed the kill wire to that cylinder and it's still not firing, so am assuming a dead coil - happily they're fairly cheap to replace.

W

Wurzel

Just to clarify things

The magnetos have a Hall Effect Trigger chip in them which is what makes them work

They have a kill wire attached to stop them working when you shut down .

On twin cylinder engines you get a ripple down the kill wire that can interfear with the other magneto so they put diodes in there to clamp this signal.

On B & S engines the diode is usually in the kill wires and quite obvious.

Thses can be replaced for a few cents or the sub loom can be replaced for a lot of dollars .

The chip inside the magneto coil is neither repairable nor replaceable ( I have pulled a few apart ) .

So you test the coils by removing the kill wire

No spark with the kill wire removed = dead coil that has to be replaced

Removed the kill wire to that cylinder and it's still not firing, so am assuming a dead coil - happily they're fairly cheap to replace.

#56

B

bertsmobile1

Now if the kill wires have diodes in them then test them as well lest they lead to a very short service life for the replacement coil.

And make sure you get the correct one or the engine will never run properly

Also test the kill wire for voltage

It is a ground wire so should only ever be ground ( engine off ) or open ( engine on )

A problem that had me going mad ended up being corrosion in the socket of a parking brake switch that allowed a tiny voltage to pass down the kill wire if you had your foot flat on the brake when cranking the engine, but not if the brake was on the latch.

That mower came back more times than a black fellas boomerang .

B

bertsmobile1

Yep stone deadRemoved the kill wire to that cylinder and it's still not firing, so am assuming a dead coil - happily they're fairly cheap to replace.

Now if the kill wires have diodes in them then test them as well lest they lead to a very short service life for the replacement coil.

And make sure you get the correct one or the engine will never run properly

Also test the kill wire for voltage

It is a ground wire so should only ever be ground ( engine off ) or open ( engine on )

A problem that had me going mad ended up being corrosion in the socket of a parking brake switch that allowed a tiny voltage to pass down the kill wire if you had your foot flat on the brake when cranking the engine, but not if the brake was on the latch.

That mower came back more times than a black fellas boomerang .

#57

S

slomo

Make sure you LOOK at the new coil. Some say UP and some other mounting tips on them. Summation, it is possible to mount one back to front or front to back depending on your coil.

She sure idles down nice with one dead cylinder (from your videos). You should of verified spark several pages ago. Get a cheap inline spark tester. Or just ground a plug out......

S

slomo

TIPRemoved the kill wire to that cylinder and it's still not firing, so am assuming a dead coil - happily they're fairly cheap to replace.

Make sure you LOOK at the new coil. Some say UP and some other mounting tips on them. Summation, it is possible to mount one back to front or front to back depending on your coil.

She sure idles down nice with one dead cylinder (from your videos). You should of verified spark several pages ago. Get a cheap inline spark tester. Or just ground a plug out......

#58

T

TobyU

T

TobyU

From all of this I think we've learned one thing and it goes back to what I always tell everyone when troubleshooting a mower...

Always start by making sure the machine is getting enough fuel especially on the no starts because well over 85% of the time that is the case..

After you have confirmed it is getting fuel or it's running, if a twin engine, always cancel out each cylinder to make sure it will run on both.

This is most easily done with a towel or a glove and popping the spark plug wires off one at a time with it running at a medium speed. No reason to have it going full speed but don't have it idling either.

In this situation this would have quickly determined that it was only running on one cylinder and we could have moved away from even talking about fuel for the time being.