You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Bobbing oil dip stick?

#1

PTmowerMech

PTmowerMech

Briggs 44S777-0016-G1 23hp

On a Husqvarna Z346

Ok, I've been had. Good one fella's. Jokes on me. Har har.

That thing that was posted about how a oil dip stick will flop around if it's got a bad head gasket, well I tried it on this one, and it did just that. But I also tried it on another piece of equipment that I knew for a fact didn't have a bad head gasket, and it did the same exact thing.

So I'm wondering, maybe who ever said that meant that the dip stick would bobble more than this. Here's a video to show how much it's bobbing.

What this engine is doing, 90% of the time is surging. (all the way until filming this) But choking it doesn't level it out. So that tells me it's an air problem. Which could be a head gasket.

On a Husqvarna Z346

Ok, I've been had. Good one fella's. Jokes on me. Har har.

That thing that was posted about how a oil dip stick will flop around if it's got a bad head gasket, well I tried it on this one, and it did just that. But I also tried it on another piece of equipment that I knew for a fact didn't have a bad head gasket, and it did the same exact thing.

So I'm wondering, maybe who ever said that meant that the dip stick would bobble more than this. Here's a video to show how much it's bobbing.

What this engine is doing, 90% of the time is surging. (all the way until filming this) But choking it doesn't level it out. So that tells me it's an air problem. Which could be a head gasket.

#4

Scrubcadet10

Scrubcadet10

If you think about it, the piston is displacing air, when you open the dipstick tube, its going to suck air and push air out of the tube.

#5

StarTech

StarTech

Now Scrub you know everything on YouTube is the gospel truth. So don't try on overtax PT's brain. <LOL> Just pulling you leg PT.

#6

StarTech

StarTech

And I just got in an engine that runs for about 3-4 rounds on the customer's lawn and then starts to act up. Well he tried fixing the carb himself. Don't know what else is wrong yet. But bowl gasket was damaged and it was new when he installed it. The wrong inlet tube o-ring. And of all things the main jet is awol. So I thinking he has at least a carburetor problem but I might be wrong too.

#7

B

bertsmobile1

B

bertsmobile1

Stop & have a little think

As the pistons descend the crankcase is pressurised .

Air will take the path of least resistance so it is simply a case that lifting the weight of the dip stick requires less energy than opening the breather valve .

Next time you get one in with a known blown gasket, try the same thing & you should see that dip stick lift several inches if not get blown right out of the tube .

As the pistons descend the crankcase is pressurised .

Air will take the path of least resistance so it is simply a case that lifting the weight of the dip stick requires less energy than opening the breather valve .

Next time you get one in with a known blown gasket, try the same thing & you should see that dip stick lift several inches if not get blown right out of the tube .

#8

PTmowerMech

Hey now, that's me in the video.

PTmowerMech

That's what make sense. The piston alone can cause a dipstick to do this.If you think about it, the piston is displacing air, when you open the dipstick tube, its going to suck air and push air out of the tube.

Now Scrub you know everything on YouTube is the gospel truth. So don't try on overtax PT's brain. <LOL> Just pulling you leg PT.

Hey now, that's me in the video.

#9

PTmowerMech

Where does the extra pressure come from, since the only way from the combustion chamber to the sump is either through the valve guides or passed the rings.

PTmowerMech

Stop & have a little think

As the pistons descend the crankcase is pressurised .

Air will take the path of least resistance so it is simply a case that lifting the weight of the dip stick requires less energy than opening the breather valve .

Next time you get one in with a known blown gasket, try the same thing & you should see that dip stick lift several inches if not get blown right out of the tube .

Where does the extra pressure come from, since the only way from the combustion chamber to the sump is either through the valve guides or passed the rings.

#10

StarTech

StarTech

Glad I don't watch YouTube videos lately as my welding helmet is broken. Everytime I get near a camera I break it. Even the mirrors turn their backs to me.That's what make sense. The piston alone can cause a dipstick to do this.

Hey now, that's me in the video.

#11

PTmowerMech

PTmowerMech

The fuel is a little mirky and seems have a bit of water it in. Also the fuel solenoid was bad.

#12

StarTech

Was the fuel solenoid actually bad or was it just needing a good ultrasonic cleaning?

StarTech

You are forgetting the push galley on OHV engines that pass right the head gaskets. Briggs OHV Inteks are one that regularly blows the head gasket between the cylinder and the push rod galley.Where does the extra pressure come from, since the only way from the combustion chamber to the sump is either through the valve guides or passed the rings.

Was the fuel solenoid actually bad or was it just needing a good ultrasonic cleaning?

#13

Scrubcadet10

Scrubcadet10

Stop & have a little think

As the pistons descend the crankcase is pressurised .

Air will take the path of leat resistance so it is simply a case that lifting the weight of the dip stick requires less energy .

The extra pressure comes from the crankcase area decreasing because the piston is traveling back down.Where does the extra pressure come from, since the only way from the combustion chamber to the sump is either through the valve guides or passed the rings.

#14

PTmowerMech

Probably just a good cleaning. It would move a little both ways, by turning the key off and on.

As far as the head gasket goes, I'd better do a leakdown before I start tearing into this. I bought the tool a few years ago, and have only used it once or twice.

PTmowerMech

You are forgetting the push galley on OHV engines that pass right the head gaskets. Briggs OHV Inteks are one that regularly blows the head gasket between the cylinder and the push rod galley.

Was the fuel solenoid actually bad or was it just needing a good ultrasonic cleaning?

Probably just a good cleaning. It would move a little both ways, by turning the key off and on.

As far as the head gasket goes, I'd better do a leakdown before I start tearing into this. I bought the tool a few years ago, and have only used it once or twice.

#15

PTmowerMech

I'm talking about what Bert said about how one with a blown head gasket will make a dipstick jump several inches, if not all the way out the tube. This one is bobbing only a couple of inches. Same as the other one, that doesn't have a bad headgasket.

Plus something else I did, mowed for about 10 minutes. Killed it and pulled the dipstick. No smoke from the oil fill tube.

PTmowerMech

The extra pressure comes from the crankcase area decreasing because the piston is traveling back down.

I'm talking about what Bert said about how one with a blown head gasket will make a dipstick jump several inches, if not all the way out the tube. This one is bobbing only a couple of inches. Same as the other one, that doesn't have a bad headgasket.

Plus something else I did, mowed for about 10 minutes. Killed it and pulled the dipstick. No smoke from the oil fill tube.

#16

7394

7394

A blown head gasket will allow the crankcase to inhale much more air thru the leak on down stroke, so more crankcase pressure is developed.

#17

B

bertsmobile1

B

bertsmobile1

In theory when the piston rises, it creates a low pressure zone ( vacuum ) in the crank case and when the piston falls it creates a high pressure zone in the crank case that vents via the breather

In practice air gets sucked in past all of the seals , you get blow by on compression and a lot more on exhaust that will rush into the low pressure zone in the crank case

If the engine was in fact airtight then you would not need a breather .

The more the number of cylinders the less this effect and it becomes zero on horizontally opposed crankshafts

On race engines , particualry single cylinder ones you can get a couple of extra Hp by fitting a flow through crankcase venting system with a crank case inlet & outlet both fitted with one way check valves so less energy is lost through pulling a vacuum on up strokes and compressing on the down stroke

Piston rings do not create a seal

The oil gets behind them and on the upstroke pushes the ring into the cylinder wall

To do this the air above the piston has to be under pressure as is the case on the compression stroke

However on the exhaust stroke there is very little pressure because the exhaust valve is open thus the rings do not get forced hard onto the cylinder wall and you get blow by

In practice air gets sucked in past all of the seals , you get blow by on compression and a lot more on exhaust that will rush into the low pressure zone in the crank case

If the engine was in fact airtight then you would not need a breather .

The more the number of cylinders the less this effect and it becomes zero on horizontally opposed crankshafts

On race engines , particualry single cylinder ones you can get a couple of extra Hp by fitting a flow through crankcase venting system with a crank case inlet & outlet both fitted with one way check valves so less energy is lost through pulling a vacuum on up strokes and compressing on the down stroke

Piston rings do not create a seal

The oil gets behind them and on the upstroke pushes the ring into the cylinder wall

To do this the air above the piston has to be under pressure as is the case on the compression stroke

However on the exhaust stroke there is very little pressure because the exhaust valve is open thus the rings do not get forced hard onto the cylinder wall and you get blow by

#18

PTmowerMech

PTmowerMech

Also, there is no oil around the fuel pump vent.

I mowed for about another 20 minutes, and during this time, I choked it a little at a time until the choke lever was in full position. This time, it did clear up the surging. Not sure why it didn't clear up the other two times I did it (even using my hand).

In the morning, after everything has settled, I'm going to drain out some gas. 1 quart at time, until it clears up. Then ad some fresh, high octane to it. I may also remove the float bowl and see what it looks like inside.

I mowed for about another 20 minutes, and during this time, I choked it a little at a time until the choke lever was in full position. This time, it did clear up the surging. Not sure why it didn't clear up the other two times I did it (even using my hand).

In the morning, after everything has settled, I'm going to drain out some gas. 1 quart at time, until it clears up. Then ad some fresh, high octane to it. I may also remove the float bowl and see what it looks like inside.

#19

PTmowerMech

Briggs don't normally fail from edges leading to the outside. I've only seen them leak between the valves and the opening to the push rods.

PTmowerMech

That is IF it's blown around the edge, leading to the outside of the engine, right? Because the pressure inside the sump won't increase a whole lot, if it's an internal gasket leak. Will it?A blown head gasket will allow the crankcase to inhale much more air thru the leak on down stroke, so more crankcase pressure is developed.

Briggs don't normally fail from edges leading to the outside. I've only seen them leak between the valves and the opening to the push rods.

#20

Tiger Small Engine

Suspected bad head gasket:

While at idle, quickly push throttle to WOT, then at WOT quickly go down to idle, waiting a few seconds in between. Does a puff of smoke come out? After running a bit, open dipstick and look for a little smoke coming out. Neither are definitive tests. Now perform a compression test and leak down test, watching for air escaping out of cylinder head with valve cover off. Just did one yesterday with 40% loss. Anything under 20% is acceptable. Single cylinder Briggs (ie: 31P677) is very common for bad head gasket.

Tiger Small Engine

Get an extractor (if you don’t already have one) and suck all that old bad cloudy fuel out, and blow out tank.That is IF it's blown around the edge, leading to the outside of the engine, right? Because the pressure inside the sump won't increase a whole lot, if it's an internal gasket leak. Will it?

Briggs don't normally fail from edges leading to the outside. I've only seen them leak between the valves and the opening to the push rods.

Suspected bad head gasket:

While at idle, quickly push throttle to WOT, then at WOT quickly go down to idle, waiting a few seconds in between. Does a puff of smoke come out? After running a bit, open dipstick and look for a little smoke coming out. Neither are definitive tests. Now perform a compression test and leak down test, watching for air escaping out of cylinder head with valve cover off. Just did one yesterday with 40% loss. Anything under 20% is acceptable. Single cylinder Briggs (ie: 31P677) is very common for bad head gasket.

#21

7394

7394

Valid point Sir..That is IF it's blown around the edge, leading to the outside of the engine, right? Because the pressure inside the sump won't increase a whole lot, if it's an internal gasket leak. Will it?

Briggs don't normally fail from edges leading to the outside. I've only seen them leak between the valves and the opening to the push rods.

#22

PTmowerMech

So I took the fuel line loose from the pump (tank side, and drained about 6oz. This was after it had been sitting all night. And it was clear as a bell. So I put that line back on and pulled the fuel line off the carb , and pumped out about 1/2 quart, and it was milky, had tiny fragments in it and still a little more water. So I replaced the fuel pump and pumped a few oz and it was clear.

I removed the bowl and it wasn't just real bad. But you could tell had been coated in water. Kind of chalking film over it.

I have the carb apart now and in the USC, looking for a rebuild kit.

I sure wished the Stens 520-024 was for this model.

PTmowerMech

Get an extractor (if you don’t already have one) and suck all that old bad cloudy fuel out, and blow out tank.

Suspected bad head gasket:

While at idle, quickly push throttle to WOT, then at WOT quickly go down to idle, waiting a few seconds in between. Does a puff of smoke come out? After running a bit, open dipstick and look for a little smoke coming out. Neither are definitive tests. Now perform a compression test and leak down test, watching for air escaping out of cylinder head with valve cover off. Just did one yesterday with 40% loss. Anything under 20% is acceptable. Single cylinder Briggs (ie: 31P677) is very common for bad head gasket.

So I took the fuel line loose from the pump (tank side, and drained about 6oz. This was after it had been sitting all night. And it was clear as a bell. So I put that line back on and pulled the fuel line off the carb , and pumped out about 1/2 quart, and it was milky, had tiny fragments in it and still a little more water. So I replaced the fuel pump and pumped a few oz and it was clear.

I removed the bowl and it wasn't just real bad. But you could tell had been coated in water. Kind of chalking film over it.

I have the carb apart now and in the USC, looking for a rebuild kit.

I sure wished the Stens 520-024 was for this model.

#23

F

Forest#2

F

Forest#2

I've seen them dual throat Nikki's do some weird things when they get upset.

Do You see a Nikki carb number on the side of yours?

Is that the Aluminum bowl or the Steel bowl Nikki? The reason I ask is the Aluminum bowl kit is different than the steel bowl Nikki and the steel bowl type has two different kit's.

One size does not fit all on the Nikki's, close but no cigar.

If it has a Nikki name on the carb I would try to re-kit before going the Clone route is another reason I ask.

Do You see a Nikki carb number on the side of yours?

Is that the Aluminum bowl or the Steel bowl Nikki? The reason I ask is the Aluminum bowl kit is different than the steel bowl Nikki and the steel bowl type has two different kit's.

One size does not fit all on the Nikki's, close but no cigar.

If it has a Nikki name on the carb I would try to re-kit before going the Clone route is another reason I ask.

#24

PTmowerMech

Yes is an aluminum bowl nikki.

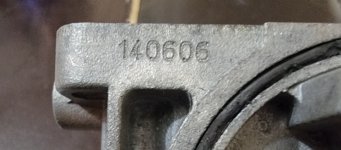

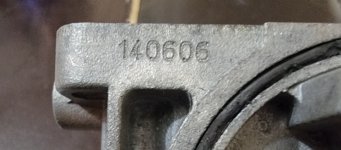

number on top

590851 266

4818 5B

Bottom

The Partstree diagram looks like the right one.

One difference I do see is the choke shaft. The one I have, the shaft goes all the way through and has a screw on the other end that secures a washer to keep it from sliding out.

PTmowerMech

I've seen them dual throat Nikki's do some weird things when they get upset.

Do You see a Nikki carb number on the side of yours?

Is that the Aluminum bowl or the Steel bowl Nikki? The reason I ask is the Aluminum bowl kit is different than the steel bowl Nikki and the steel bowl type has two different kit's.

One size does not fit all on the Nikki's, close but no cigar.

If it has a Nikki name on the carb I would try to re-kit before going the Clone route is another reason I ask.

Yes is an aluminum bowl nikki.

number on top

590851 266

4818 5B

Bottom

The Partstree diagram looks like the right one.

44S777-0016-G1 - Briggs & Stratton Vertical Engine Carburetor, Fuel Supply Parts Diagram

One difference I do see is the choke shaft. The one I have, the shaft goes all the way through and has a screw on the other end that secures a washer to keep it from sliding out.

#26

PTmowerMech

I did get lucky and find a few things I'd bought before, that got lost in the move.

I do have one question, that I think pertains to the main jets. Do they have anything to do with the L & R that's stamped on the carb body? As in two different size jets that are particular about being L or R? Partstree only listed 1 jet (other than high altitude).

PTmowerMech

Rebuild parts ordered. Now just waiting to see what I either forgot to order, or what wrong part I did order. lolOne thing to check with being a Nikki twin barrel is loose main jets.

I did get lucky and find a few things I'd bought before, that got lost in the move.

I do have one question, that I think pertains to the main jets. Do they have anything to do with the L & R that's stamped on the carb body? As in two different size jets that are particular about being L or R? Partstree only listed 1 jet (other than high altitude).

#27

F

Forest#2

F

Forest#2

Here is some info about your later model Nikki BRIGGS aluminum bowl CARB that I have on file for reference. This info will answer some of your questions about the Briggs Nikki's. Note the L in your first picture, that is the left side reference for the jets location. The texture of that carb appears that maybe it has been in the Usonic few times before the pictures. The steel bowl Nikki's are the older models and are of at least two different designs. I do not have a very good track record of trying to use the China clone replacement Nikki's although I have taken parts from the clones such as o rings, etc and installed into the real Nikki and get a good run. Amazon Prime has a free refund policy if their carbs don't work correctly so that is usually where I get Clones for testing.

I have tested the Nikki carb using both of the jets as the larger size and got a good run. I've drilled the smaller to same size as the larger jet. I also use a gasket and RTV with good results at the intake instead of trusting the O-ring. Sometimes the intake two intake gaskets come in a kit, but if not I just make them.

These are rebuild links to assisting in cleaning, kitting, and where to find parts

AT A REASONABLE PRICE.

Try using Google Chrome as the browser for these links. Sometimes Microsoft edge will 404 out.

Tip: When looking up Nikki carb kit numbers use Briggs ahead of the part number INSTEAD of Nikki

Nikki carb rebuild links, videos and also a parts supplier on ebay.

Google Chrome will have to be used to access these links. Microsoft edge will not work.

https://bgsupply.weebly.com/helpful-videos.html

to look at parts, kit, jet, etc to go to different part number, etc click on the 3 bars menu in the upper left corner. You will have to choose Briggs and Stratton to see the Nikkii carb parts

https://sawzillaparts.com/carburetor-kits/briggs-stratton/

and another link to repairing the Nikki’s plus others

This is the steel bowl with the BLACK emulsion tube. Pay attention to the jet holes after you remove the top plate for cleaning them.

Your aluminum bowl is the later model and slightly different but some good tips here.

https://outdoorpowerinfo.com/repairs/

I have tested the Nikki carb using both of the jets as the larger size and got a good run. I've drilled the smaller to same size as the larger jet. I also use a gasket and RTV with good results at the intake instead of trusting the O-ring. Sometimes the intake two intake gaskets come in a kit, but if not I just make them.

These are rebuild links to assisting in cleaning, kitting, and where to find parts

AT A REASONABLE PRICE.

Try using Google Chrome as the browser for these links. Sometimes Microsoft edge will 404 out.

Tip: When looking up Nikki carb kit numbers use Briggs ahead of the part number INSTEAD of Nikki

Nikki carb rebuild links, videos and also a parts supplier on ebay.

Google Chrome will have to be used to access these links. Microsoft edge will not work.

https://bgsupply.weebly.com/helpful-videos.html

to look at parts, kit, jet, etc to go to different part number, etc click on the 3 bars menu in the upper left corner. You will have to choose Briggs and Stratton to see the Nikkii carb parts

https://sawzillaparts.com/carburetor-kits/briggs-stratton/

and another link to repairing the Nikki’s plus others

This is the steel bowl with the BLACK emulsion tube. Pay attention to the jet holes after you remove the top plate for cleaning them.

Your aluminum bowl is the later model and slightly different but some good tips here.

https://outdoorpowerinfo.com/repairs/

#28

PTmowerMech

PTmowerMech

Thank you for that. I'm going to save that Sawsilla website. Looks like they've got good prices.Here is some info about your later model Nikki BRIGGS aluminum bowl CARB that I have on file for reference. This info will answer some of your questions about the Briggs Nikki's. Note the L in your first picture, that is the left side reference for the jets location. The texture of that carb appears that maybe it has been in the Usonic few times before the pictures. The steel bowl Nikki's are the older models and are of at least two different designs. I do not have a very good track record of trying to use the China clone replacement Nikki's although I have taken parts from the clones such as o rings, etc and installed into the real Nikki and get a good run. Amazon Prime has a free refund policy if their carbs don't work correctly so that is usually where I get Clones for testing.

I have tested the Nikki carb using both of the jets as the larger size and got a good run. I've drilled the smaller to same size as the larger jet. I also use a gasket and RTV with good results at the intake instead of trusting the O-ring. Sometimes the intake two intake gaskets come in a kit, but if not I just make them.

These are rebuild links to assisting in cleaning, kitting, and where to find parts

AT A REASONABLE PRICE.

Try using Google Chrome as the browser for these links. Sometimes Microsoft edge will 404 out.

Tip: When looking up Nikki carb kit numbers use Briggs ahead of the part number INSTEAD of Nikki

Nikki carb rebuild links, videos and also a parts supplier on ebay.

Google Chrome will have to be used to access these links. Microsoft edge will not work.

https://bgsupply.weebly.com/helpful-videos.html

to look at parts, kit, jet, etc to go to different part number, etc click on the 3 bars menu in the upper left corner. You will have to choose Briggs and Stratton to see the Nikkii carb parts

https://sawzillaparts.com/carburetor-kits/briggs-stratton/

and another link to repairing the Nikki’s plus others

This is the steel bowl with the BLACK emulsion tube. Pay attention to the jet holes after you remove the top plate for cleaning them.

Your aluminum bowl is the later model and slightly different but some good tips here.

https://outdoorpowerinfo.com/repairs/

#29

7394

7394

Firefox works as well, just saying..Google Chrome will have to be used to access these links. Microsoft edge will not work.

#30

PTmowerMech

PTmowerMech

I use Brave. There's no commercials on Youtube.Firefox works as well, just saying..

#31

T

TobyU

T

TobyU

Not a good test at all. Most do that and lots of blown head gaskets do no

no worst. Never had one blow the strick out hard.

Many will start to smoke if you open dipstick.

Best test I have found (because comp tester etc should be left in toolbox for autos lol) is to get it warm and then go in three tight circles to the right, then three to the left, then three to the right again...

If you don't fall off..... Look for your house through the thick blue/white smoke!

If no smoke....gasket isn't that bad bad.....yet.

no worst. Never had one blow the strick out hard.

Many will start to smoke if you open dipstick.

Best test I have found (because comp tester etc should be left in toolbox for autos lol) is to get it warm and then go in three tight circles to the right, then three to the left, then three to the right again...

If you don't fall off..... Look for your house through the thick blue/white smoke!

If no smoke....gasket isn't that bad bad.....yet.

#32

F

Forest#2

I ordered some Nikki Briggs stuff recently from them and shipping was only like $3.50 and tracking # provided and a fast shipper to me.

Tip about replacing the itty bitty jet o rings.

install the jet on a wire such as a straightened out paper clip and then take a needle nose plier (so you do not stab yourself with the sharp o ring pick) use a o ring pick and break the old o ring off then lube the replacement ring and use back of finger nail to get one side caught in the groove and then just roll it on around using back of finger nail.

I bought some Nikki Briggs jet o rings from this guy before and they work great, seem tougher than the ones in the kit and fit the jet grooves good). Some of the kit jet o-rings are too fat for the jet groove and emulsion tube.

When installing the jets I also use the paper clip wire to guide the jet onto the tube then I use a small nut driver that is little smaller in diameter than the jet and hand press into place. (nut driver is hollow inside so the guide wire goes up inside as a alignment guide for the little jet)

F

Forest#2

I just recently stumbled across that sawzilla site.Thank you for that. I'm going to save that Sawsilla website. Looks like they've got good prices.

I ordered some Nikki Briggs stuff recently from them and shipping was only like $3.50 and tracking # provided and a fast shipper to me.

Tip about replacing the itty bitty jet o rings.

install the jet on a wire such as a straightened out paper clip and then take a needle nose plier (so you do not stab yourself with the sharp o ring pick) use a o ring pick and break the old o ring off then lube the replacement ring and use back of finger nail to get one side caught in the groove and then just roll it on around using back of finger nail.

I bought some Nikki Briggs jet o rings from this guy before and they work great, seem tougher than the ones in the kit and fit the jet grooves good). Some of the kit jet o-rings are too fat for the jet groove and emulsion tube.

When installing the jets I also use the paper clip wire to guide the jet onto the tube then I use a small nut driver that is little smaller in diameter than the jet and hand press into place. (nut driver is hollow inside so the guide wire goes up inside as a alignment guide for the little jet)

#33

PTmowerMech

The old o-rings disintegrated. The nut driver is a good idea. I have used an extra 2 cycle carb adjusting tool, lubed with

BTW, "erbay?" You mean ebay, right?

PTmowerMech

I just recently stumbled across that sawzilla site.

I ordered some Nikki Briggs stuff recently from them and shipping was only like $3.50 and tracking # provided and a fast shipper to me.

Tip about replacing the itty bitty jet o rings.

install the jet on a wire such as a straightened out paper clip and then take a needle nose plier (so you do not stab yourself with the sharp o ring pick) use a o ring pick and break the old o ring off then lube the replacement ring and use back of finger nail to get one side caught in the groove and then just roll it on around using back of finger nail.

I bought some Nikki Briggs jet o rings from this guy before and they work great, seem tougher than the ones in the kit and fit the jet grooves good). Some of the kit jet o-rings are too fat for the jet groove and emulsion tube.

When installing the jets I also use the paper clip wire to guide the jet onto the tube then I use a small nut driver that is little smaller in diameter than the jet and hand press into place. (nut driver is hollow inside so the guide wire goes up inside as a alignment guide for the little jet)

The old o-rings disintegrated. The nut driver is a good idea. I have used an extra 2 cycle carb adjusting tool, lubed with

BTW, "erbay?" You mean ebay, right?

#34

T

TobyU

A lot of times I find this is put in from the bottom and not from the top..

Apparently this happens from the factory because I have had multiple ones where people swear it's never been worked on or serviced but yet it's stuck in the bottom which can fall out and be sitting in the bowl so that's why I feel it's a bad way to install the jet. But it will work either way.

T

TobyU

Sounds like you're installing the Jets the same way I do which is kind of hard to describe but if you're holding the carburetor and it's normal orientation you would be dropping them down the middle too. You just have to make sure that they go in properly and you seat them in the hole..I just recently stumbled across that sawzilla site.

I ordered some Nikki Briggs stuff recently from them and shipping was only like $3.50 and tracking # provided and a fast shipper to me.

Tip about replacing the itty bitty jet o rings.

install the jet on a wire such as a straightened out paper clip and then take a needle nose plier (so you do not stab yourself with the sharp o ring pick) use a o ring pick and break the old o ring off then lube the replacement ring and use back of finger nail to get one side caught in the groove and then just roll it on around using back of finger nail.

I bought some Nikki Briggs jet o rings from this guy before and they work great, seem tougher than the ones in the kit and fit the jet grooves good). Some of the kit jet o-rings are too fat for the jet groove and emulsion tube.

When installing the jets I also use the paper clip wire to guide the jet onto the tube then I use a small nut driver that is little smaller in diameter than the jet and hand press into place. (nut driver is hollow inside so the guide wire goes up inside as a alignment guide for the little jet)

A lot of times I find this is put in from the bottom and not from the top..

Apparently this happens from the factory because I have had multiple ones where people swear it's never been worked on or serviced but yet it's stuck in the bottom which can fall out and be sitting in the bowl so that's why I feel it's a bad way to install the jet. But it will work either way.

#35

A

awkerper

A

awkerper

Piston rings don't make a perfect seal, so there's always a certain amount of "blow by" gas that sneaks past the rings. This is why the engine has some kind of ventilation system - on automotive engines, it's called the PCV valve (positive crankcase ventilation). If this vent is obstructed, the pressure can be enough to lift the dipstick out of the tube.Where does the extra pressure come from, since the only way from the combustion chamber to the sump is either through the valve guides or passed the rings.

#36

PTmowerMech

Right. I get all that. Located under the flywheels. But that's only to relieve the pressure in the crankcase. Pressure in the head gets pushed down into the crankcase when the headgasket between the valves and the push rod valley, upon explosion in the combustion chamber.

This is more than the PCV can exhaust.

So with a bad headgasket it'll come out the PCV, the vented fuel filter and anywhere else it can find. As Bert noted, if the oil cap isn't secured, that's the least amount of resistance, so it's going to go there.

The video I posted, I'm almost positive is normal. To make sure, I did the same thing on an engine I knew had good head gaskets.

My confusing was just how much bobbling the oil cap would do with or without a blown head gasket. Bert says it would jump a lot more than what mine is doing if the headgasket was bad. Which makes sense, since the explosion is contained inside the head, and the only bobbing the oil cap is doing is just the normal pressure of the pistons up and down stroke.

PTmowerMech

Piston rings don't make a perfect seal, so there's always a certain amount of "blow by" gas that sneaks past the rings. This is why the engine has some kind of ventilation system - on automotive engines, it's called the PCV valve (positive crankcase ventilation). If this vent is obstructed, the pressure can be enough to lift the dipstick out of the tube.

Right. I get all that. Located under the flywheels. But that's only to relieve the pressure in the crankcase. Pressure in the head gets pushed down into the crankcase when the headgasket between the valves and the push rod valley, upon explosion in the combustion chamber.

This is more than the PCV can exhaust.

So with a bad headgasket it'll come out the PCV, the vented fuel filter and anywhere else it can find. As Bert noted, if the oil cap isn't secured, that's the least amount of resistance, so it's going to go there.

The video I posted, I'm almost positive is normal. To make sure, I did the same thing on an engine I knew had good head gaskets.

My confusing was just how much bobbling the oil cap would do with or without a blown head gasket. Bert says it would jump a lot more than what mine is doing if the headgasket was bad. Which makes sense, since the explosion is contained inside the head, and the only bobbing the oil cap is doing is just the normal pressure of the pistons up and down stroke.

#37

PTmowerMech

I knew something was up when I removed the bowl and the jets went laying in the bottom of it. They're supposed to snap in. Give a little click when inserted properly.

The guy who showed me this first, said to install them before putting the tube onto the carb, as to not smash the rubber gasket below it.

That rubber gasket was almost none existent when I removed the tube.

I think the problems this engine had were no less than 2. Water that had collected in the fuel pump. (probably from pressure washing after each mowing, because it's stored inside the garage at all times) And the bad internal gaskets. Which may have also been caused by the water.

But the bowl, even though it had a little water in it, didn't have the white corrosion that most do that's been water contaminated.

PTmowerMech

Sounds like you're installing the Jets the same way I do which is kind of hard to describe but if you're holding the carburetor and it's normal orientation you would be dropping them down the middle too. You just have to make sure that they go in properly and you seat them in the hole..

A lot of times I find this is put in from the bottom and not from the top..

Apparently this happens from the factory because I have had multiple ones where people swear it's never been worked on or serviced but yet it's stuck in the bottom which can fall out and be sitting in the bowl so that's why I feel it's a bad way to install the jet. But it will work either way.

I knew something was up when I removed the bowl and the jets went laying in the bottom of it. They're supposed to snap in. Give a little click when inserted properly.

The guy who showed me this first, said to install them before putting the tube onto the carb, as to not smash the rubber gasket below it.

That rubber gasket was almost none existent when I removed the tube.

I think the problems this engine had were no less than 2. Water that had collected in the fuel pump. (probably from pressure washing after each mowing, because it's stored inside the garage at all times) And the bad internal gaskets. Which may have also been caused by the water.

But the bowl, even though it had a little water in it, didn't have the white corrosion that most do that's been water contaminated.

#38

PTmowerMech

PTmowerMech

I posted this on the wrong thread. So here it is on the right thread.

Just incase things don't work out with the rebuild, I got a new carb from Briggs. I probably should've went with the Stens and just swapped out the jets, if need be. It was about $80 cheaper. But the owner of this is a multi millionaire. And has kept my brother in work for over a decade now. Plus this mowers home is about 2hrs away. It's gotta be right the very first time. And stay that way.

Briggs has an online store now. I may start getting a few things from them also, just to try them out.

Briggs online store.

Just incase things don't work out with the rebuild, I got a new carb from Briggs. I probably should've went with the Stens and just swapped out the jets, if need be. It was about $80 cheaper. But the owner of this is a multi millionaire. And has kept my brother in work for over a decade now. Plus this mowers home is about 2hrs away. It's gotta be right the very first time. And stay that way.

Briggs has an online store now. I may start getting a few things from them also, just to try them out.

Briggs online store.

#39

F

Forest#2

Yes I've seen some that go in from the opposite direction. the emulsion tube has to be off the carb for them.

If they are laying in the bowl or gone (sticking to tyhe bottom of your shoes) they went in from the bottom. (and you did not see them fall on the floor)

F

Forest#2

I have the plastic emulsion tube in my hand or on the workbench, not on the carb when installing the jets. Using the little hollow tube nut driver and the wire allows for straightening a crooked press if watched or looked at afterwards closely. Some will want to seat slightly cocked sometimes.Sounds like you're installing the Jets the same way I do which is kind of hard to describe but if you're holding the carburetor and it's normal orientation you would be dropping them down the middle too. You just have to make sure that they go in properly and you seat them in the hole..

A lot of times I find this is put in from the bottom and not from the top..

Apparently this happens from the factory because I have had multiple ones where people swear it's never been worked on or serviced but yet it's stuck in the bottom which can fall out and be sitting in the bowl so that's why I feel it's a bad way to install the jet. But it will work either way.

Yes I've seen some that go in from the opposite direction. the emulsion tube has to be off the carb for them.

If they are laying in the bowl or gone (sticking to tyhe bottom of your shoes) they went in from the bottom. (and you did not see them fall on the floor)

#40

F

Forest#2

F

Forest#2

You asked me???

BTW, "erbay?" You mean ebay, right?

Not sure of your question, I do not see the typo

sometimes referred to as flea bay or FLEECE bay.

BTW, "erbay?" You mean ebay, right?

Not sure of your question, I do not see the typo

sometimes referred to as flea bay or FLEECE bay.

#41

PTmowerMech

Here's the link you posted. https://www.erbay.com/itm/163674198748

That's erbay. I've never heard of that. I clicked on it, and even the crappy security I have on my computer didn't like it.

Ok, scratch all that. I used that same link, without the r, and it went to the o-rings.

It's all good now.

PTmowerMech

You asked me???

BTW, "erbay?" You mean ebay, right?

Not sure of your question, I do not see the typo

sometimes referred to as flea bay or FLEECE bay.

Here's the link you posted. https://www.erbay.com/itm/163674198748

That's erbay. I've never heard of that. I clicked on it, and even the crappy security I have on my computer didn't like it.

Ok, scratch all that. I used that same link, without the r, and it went to the o-rings.

It's all good now.

#42

F

Forest#2

F

Forest#2

This is a strange one for a copy and paste error????? erbay

My computer might be getting a lisp or stutter????????????

My computer might be getting a lisp or stutter????????????