- Joined

- Feb 19, 2020

- Threads

- 121

- Messages

- 12,883

Well lets 5 -10 min diagnostics, <15 min finding IPL and PO creation. This is where experience pays off. Doesn't take me an hour or more to figure out what is wrong with one these units.We don't waste time trying to run down parts for that type of equipment. Do you charge for the time you waste looking up the parts and freight to get it to you. To us just not worth it. Red Max is or was a quality line of equipment.

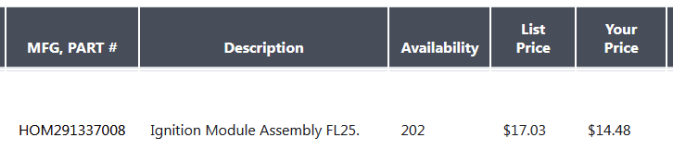

I have been working these handhelds for over 15 yrs and do know where to find the part lists and I have two very good distributors that I order regularly from. The orders are large enough that per item freight is very low or none existent. I also stock extra parts of the commonly used parts which also keep freight costs very low. I usually charge at a labor rate of 3/4 of my normal hourly rate. so that is $47.25- $52.50 depending if a senior citizen is involved or not. The current only take 1/2 hr max to change to coil including the initial diagnostics. And the coil is only $17.03 retail and the current order has the shipping at a free level. So what I breaking even and the customer is happy to bring that JD Z950M in next week for annual maintenance instead carrying to JD.

And the distributor only has 202 in stock so it be here Friday.

This Black Max trimmer was the exception as it is a line I just recently started seeing in my shop. So yes I spent a lot of extra time finding the resources needed for this project and future projects. But next it would less 15 minutes to find, setup a PO and then drop an email to my distributor's sales rep. As the work order entry the customer info is already on my system so all I got to do is enter their name and add any new equipment to the system. As pricing my already has all the part number, descriptions, and pricing so that is just a matter of entering the part number and quantity. Matter of fact normally it less time than it did to type this up to enter a work order and then bill the repair. This all thanks to some very good Auto Manager software which includes the background accounting system.

Let's say that I already know where to look up parts (which I do now) for this Black Max and I need a ignition coil. Okay sit down at the computer. Starting at 2:48 within two minutes I pull up the website, enter the equipment model number, click on the right IPL page and I have the coil PN of 291337008 and it takes another few minutes enter the PN to the work order and to pull up the PO and enter that number and click save to new pending PO if I so desired but wait I already have a $200 PO awaiting to send so I just add it to that order and email my rep. Most this is done cut and paste so there is no real typing other the initial customer work order when there is new equipment to enter.

It isn't like I have to beg a supervisor or jumping through some other hoops just order the parts.