You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Battery Bolt Corrosion

#1

M

mzdrati

M

mzdrati

Hi- I am having a problem with corrosion on the positive battery terminal on my low-hour Hustler Raptor SD. I'm guessing that this is more of a general question, and likely does not pertain to the specific make or model of my mower, but I put it here just in case. The mower is 2 years old, and has about 25 hours on it. It is stored in my shed when not in use, is never used in the rain or n wet grass, and is cleaned after each use.

I have noticed that a few times, the mower will not start (nothing happens when I turn the key). In both instances, I inspected the battery terminals and discovered that the positive terminal was rather severely corroded. So much so that it made more sense to discard the bolt than try to clean it up. I had the same issue today when trying to start the mower... I made sure all of the safety switches switch conditions were met, turned the key, and only a faint buzzing sound. I Checked all of the connections, then noticed that the battery again had a significant amount of corrosion on it (only the positive side, not the negative side at all). I cleaned all of the contacts with a wire brush, replaced the nut and bolt with new ones, and it started just fine- but just looking for suggestions on how to prevent this moving forward.

I have noticed that a few times, the mower will not start (nothing happens when I turn the key). In both instances, I inspected the battery terminals and discovered that the positive terminal was rather severely corroded. So much so that it made more sense to discard the bolt than try to clean it up. I had the same issue today when trying to start the mower... I made sure all of the safety switches switch conditions were met, turned the key, and only a faint buzzing sound. I Checked all of the connections, then noticed that the battery again had a significant amount of corrosion on it (only the positive side, not the negative side at all). I cleaned all of the contacts with a wire brush, replaced the nut and bolt with new ones, and it started just fine- but just looking for suggestions on how to prevent this moving forward.

#2

ILENGINE

ILENGINE

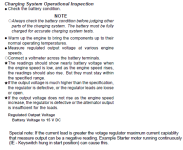

They make anticorrosion spray for battery terminals, but i would also be checking what the voltage is at the battery with the engine running full rpm with a volt meter to make sure that it isn't overcharging the battery which can also cause the issue that you are having. If the charge voltage at the battery is over 14 volts DC would be checking into a faulty voltage regulator.

#3

sgkent

sgkent

Cover it with some Vaseline after you clean it. Also check to see if battery acid is seeping out near the post. It is a problem batteries have had for a hundred years or more.

#5

Hammermechanicman

Hammermechanicman

I bought a handful of stainless bolts and nuts that I switch out on customer units when I find corroded battery bolts.

#7

B

bertsmobile1

B

bertsmobile1

Remember back in high school, in physics you were taught about GALVANIC CELLS

Well in the real world a galvanic cell creates some thing called galvanic corrosion and it is why they bold zinc or aluminium blocks to the sides of steel ships .

IT is why galvanise iron is called Galvanised iron & not zinc dipped steel like we use Tin Plate to describe steel covered by tin.

It is why your steel hot water tank has that aluminium-zinc alloy anode that you are supposed to replaces every 6 to 10 years if you want your tank to last for 50 + years

And also why electricians install them where there is not enough space to do it so you will be forced to buy a new system every 5 years because the tank has rusted through .

So for those of you who were asleep during high school science , or went to a school where they taught creationism in place of science .

Whenever you have 2 metals that are different touching each other and a path for electrons to flow between them other than the contact surfaces then you have a GALVANIC CELL and the net result will be GALVANIC CORROSION .

In galvanic corrosion the metal with the highest energy of creation will oxidize in an attempt to go to a lower energy state ( first law of thermodynamics ) thus will crumble away to nothing.

However there are some things that rock the boat and one of them is the permeability of the oxide coating , yes permeability affects more things than fuel lines .

So in the case of Hammers stainless bolts, they start to corrode, but the oxide coating is very tough and very dense and has a very low permeability which is why stainless things remain bright & shinny for a very long time but eventually go dull .

Now how does this affect your battery terminal ?

Well you have a galvanic smorgasbord there , where you have from the nut to the bolt , steel bolt, steel nut ,steel washer, lead terminal, tin, copper, tin,on the wire terminal steel washer & steel bolt

So all that needs is enough moisture for a conductive path and you have word war III happening on top of your battery

Add oxygen from the air and it is on for young and old

I could complicate it even more by stating that you get galvanic cells in a single metal where 2 or more parts are at different energy levels ( call it stress if that makes it easier to visualise ) so at the head of a roll formed bolt you have a cell between the unthreaded portion of the shank and the upset forged head ( actually there are several in the head ) plus another between the rolled thread & the unthreaded section of the shank, the washer has 2 galvanic cells between the inner & outer edges and the middle where no deformation happened , a folded tin plated copper cable terminal has cells both between the tin & copper + internally here the hole is punched where the sides are rolled around and the edges where it was sheared out of the sheet , then because it is a different alloy to the cable itself between it and the cable plus internally at the crimp

The lead battery terminal is cast so has no galvanic potential other than between everything else that is in contact with it

If you touch your corroded terminal you will feel that it is sightly damp and it is that dampness that is creating the cells.

Thus you need to prevent the whole shooting match getting damp

Hence, terminal grease, terminal spray, vaseline or my favourite liquid electrical tape

Those felt washers adsorb moisture and prevent surface cell between the + & - battery posts created by moisture on the top of the battery .

IF your eyes have not glazed over yet you might remember lead plated battery bolts at one time which work if and only if they are done up & never undone as tightening them scratches off the soft lead coating however the pig ignorant have banned these bolts because lead as we all know is the devils metal and just looking at it will cause your testicles to fall off , your children to grow 2 heads and your women folk to become infertile then die .

Now what I do

I use 1.5" coach bolts with wing nuts some times I have to grind down the wings a bit because battery posts are getting shorter .

First I do them up very tight to turn the round hole in the battery post square .

Then undo the nut, slip the cable over it, tighten the nut then paint the whole shooting match over with Liquid Electrical Tape .

This has to be complete top sides & bottom.

Having done this air & moisture are now excluded so the galvanic cells can not be completed, thus no corrosion.

The big trick is to leave 1/2" of the end of the bolt unpainted so voltage readings can be taken or there is a place to connect jumper leads to if & when needed .

Because the liquid electrical tape dries to a plastic finish, no washers, spring or flat are needed and the nut can not vibrate loose while the coating is soft enough that you can easily unscrew the wing nut if needed .

Once done up like this they are never touched again and there are a lot of my customers running the batteries that I treated this way up to 13 years ago

Well in the real world a galvanic cell creates some thing called galvanic corrosion and it is why they bold zinc or aluminium blocks to the sides of steel ships .

IT is why galvanise iron is called Galvanised iron & not zinc dipped steel like we use Tin Plate to describe steel covered by tin.

It is why your steel hot water tank has that aluminium-zinc alloy anode that you are supposed to replaces every 6 to 10 years if you want your tank to last for 50 + years

And also why electricians install them where there is not enough space to do it so you will be forced to buy a new system every 5 years because the tank has rusted through .

So for those of you who were asleep during high school science , or went to a school where they taught creationism in place of science .

Whenever you have 2 metals that are different touching each other and a path for electrons to flow between them other than the contact surfaces then you have a GALVANIC CELL and the net result will be GALVANIC CORROSION .

In galvanic corrosion the metal with the highest energy of creation will oxidize in an attempt to go to a lower energy state ( first law of thermodynamics ) thus will crumble away to nothing.

However there are some things that rock the boat and one of them is the permeability of the oxide coating , yes permeability affects more things than fuel lines .

So in the case of Hammers stainless bolts, they start to corrode, but the oxide coating is very tough and very dense and has a very low permeability which is why stainless things remain bright & shinny for a very long time but eventually go dull .

Now how does this affect your battery terminal ?

Well you have a galvanic smorgasbord there , where you have from the nut to the bolt , steel bolt, steel nut ,steel washer, lead terminal, tin, copper, tin,on the wire terminal steel washer & steel bolt

So all that needs is enough moisture for a conductive path and you have word war III happening on top of your battery

Add oxygen from the air and it is on for young and old

I could complicate it even more by stating that you get galvanic cells in a single metal where 2 or more parts are at different energy levels ( call it stress if that makes it easier to visualise ) so at the head of a roll formed bolt you have a cell between the unthreaded portion of the shank and the upset forged head ( actually there are several in the head ) plus another between the rolled thread & the unthreaded section of the shank, the washer has 2 galvanic cells between the inner & outer edges and the middle where no deformation happened , a folded tin plated copper cable terminal has cells both between the tin & copper + internally here the hole is punched where the sides are rolled around and the edges where it was sheared out of the sheet , then because it is a different alloy to the cable itself between it and the cable plus internally at the crimp

The lead battery terminal is cast so has no galvanic potential other than between everything else that is in contact with it

If you touch your corroded terminal you will feel that it is sightly damp and it is that dampness that is creating the cells.

Thus you need to prevent the whole shooting match getting damp

Hence, terminal grease, terminal spray, vaseline or my favourite liquid electrical tape

Those felt washers adsorb moisture and prevent surface cell between the + & - battery posts created by moisture on the top of the battery .

IF your eyes have not glazed over yet you might remember lead plated battery bolts at one time which work if and only if they are done up & never undone as tightening them scratches off the soft lead coating however the pig ignorant have banned these bolts because lead as we all know is the devils metal and just looking at it will cause your testicles to fall off , your children to grow 2 heads and your women folk to become infertile then die .

Now what I do

I use 1.5" coach bolts with wing nuts some times I have to grind down the wings a bit because battery posts are getting shorter .

First I do them up very tight to turn the round hole in the battery post square .

Then undo the nut, slip the cable over it, tighten the nut then paint the whole shooting match over with Liquid Electrical Tape .

This has to be complete top sides & bottom.

Having done this air & moisture are now excluded so the galvanic cells can not be completed, thus no corrosion.

The big trick is to leave 1/2" of the end of the bolt unpainted so voltage readings can be taken or there is a place to connect jumper leads to if & when needed .

Because the liquid electrical tape dries to a plastic finish, no washers, spring or flat are needed and the nut can not vibrate loose while the coating is soft enough that you can easily unscrew the wing nut if needed .

Once done up like this they are never touched again and there are a lot of my customers running the batteries that I treated this way up to 13 years ago

#8

M

mzdrati

M

mzdrati

Thank you all! There's a shocking amount of experienced and well-thought-out information here- from simple advice to a thorough recap of a science lesson.

THANK YOU!

I cleaned the connections thoroughly, replaced both bolts with new ones, tightened the connections (without over tightening them) and coated each terminal and bolt assembly with CRC Battery Terminal Protector:

www.crcindustries.com

www.crcindustries.com

I will report back as to how this works. My next course of action will be what Bert recommends, but I did not go that route simply because I could NOT find "Liquid Electrical Tape" anywhere locally, so the CRC product application is just temporary. Can you suggest a specific product and advise where you purchased it?

Thank you all again!

THANK YOU!

I cleaned the connections thoroughly, replaced both bolts with new ones, tightened the connections (without over tightening them) and coated each terminal and bolt assembly with CRC Battery Terminal Protector:

CRC® Battery Terminal Protector, 7.5 wt oz

Don’t let corrosion compromise your battery’s health. Ready to give your battery the protection it deserves? This specially engineered formula is designed to shield battery terminals from the dreaded corrosion that often leads to hard starting and unexpected battery failures. This protector is a...

I will report back as to how this works. My next course of action will be what Bert recommends, but I did not go that route simply because I could NOT find "Liquid Electrical Tape" anywhere locally, so the CRC product application is just temporary. Can you suggest a specific product and advise where you purchased it?

Thank you all again!

#9

R

Rivets

R

Rivets

This is the product I use, should be available at big box building stores, like Home Depot. https://www.gardnerbender.com/en/p/LTB-400/Liquid-Electrical-Tape-Werpro-Seal

#10

B

bertsmobile1

A lot of lifes problems can be understood if you just remember all that "useless" stuff that got crammed into your head at school .

All corrosion is galvanic and once you get your head around this then preventing , or at best slowing it down becomes an easy job.

When we bought our new electric hot water system I moved the tank outdoors where there was head space to replace the 4' long anode and I bought 5 new anodes which were wrapped in shrink fit pallet wrapping and stored behind it .

Well that was over 30 years ago and the new owners are still using our tank they have been replacing the anodes every 10 years.

Now that tank was $ 600 ( aus ) so those $ 300 worth of anodes have saved $ 1800 to $ 2400 worth of replacement hot water tanks .

Most builders place the tank as close to the bathroom as possible so the water runs hot quickly and the anodes are impossible to replace without removing the tank , a task that most home owners are reluctant to do .

B

bertsmobile1

Same product, different can .This is the product I use, should be available at big box building stores, like Home Depot. https://www.gardnerbender.com/en/p/LTB-400/Liquid-Electrical-Tape-Werpro-Seal

A lot of lifes problems can be understood if you just remember all that "useless" stuff that got crammed into your head at school .

All corrosion is galvanic and once you get your head around this then preventing , or at best slowing it down becomes an easy job.

When we bought our new electric hot water system I moved the tank outdoors where there was head space to replace the 4' long anode and I bought 5 new anodes which were wrapped in shrink fit pallet wrapping and stored behind it .

Well that was over 30 years ago and the new owners are still using our tank they have been replacing the anodes every 10 years.

Now that tank was $ 600 ( aus ) so those $ 300 worth of anodes have saved $ 1800 to $ 2400 worth of replacement hot water tanks .

Most builders place the tank as close to the bathroom as possible so the water runs hot quickly and the anodes are impossible to replace without removing the tank , a task that most home owners are reluctant to do .

#11

sgkent

sgkent

all I know is that besides changing tires, cleaning corroded battery bolts and putting Vaseline on them is the third job most mechanics did in their life. Maybe the world has changed.

#12

B

bertsmobile1

B

bertsmobile1

Sealed batteries ended a lot of that as no more acid fume to condense on the battery top

And yes a std service item done at every service .

And yes a std service item done at every service .

#13

B

Born2Mow

B

Born2Mow

You are correct about galvanic corrosion. Two opposite metals in close proximity, with an electrolyte. In the case of battery posts, it's usually the difference between the battery post (Lead) and the electrical strap (Brass). Usually most new battery straps AND the clamping fasteners will be Lead plated, but the plating can be short lived. Electrolyte is supplied by humidity in the air, from wash water, and/or seepage from around the battery posts. Each is easy to come by; pick one. The chart below shows the compatibility of metals....

If "2 dissimilar metals and an electrolyte" sound like a battery, then you're correct. What's happening is that a tiny battery is formed. So the "corrosion" is the result of an electrical process. Of course, the additional presence of an acid (if your post is leaking) doesn't help one bit.

Prevention is easy: exclude the electrolyte. This can be done by coating the post and terminal with any type of thick grease. This could be a specialized battery post protector grease or a bulk automotive grease. If your posts are leaking then the felt battery post protectors can help.

If "2 dissimilar metals and an electrolyte" sound like a battery, then you're correct. What's happening is that a tiny battery is formed. So the "corrosion" is the result of an electrical process. Of course, the additional presence of an acid (if your post is leaking) doesn't help one bit.

Prevention is easy: exclude the electrolyte. This can be done by coating the post and terminal with any type of thick grease. This could be a specialized battery post protector grease or a bulk automotive grease. If your posts are leaking then the felt battery post protectors can help.

#14

B

bertsmobile1

B

bertsmobile1

Actually the metals do not even have to be dissimilar

When you bend a metal cold you create a stress in the lattice & that stress will form a galvanic cell between itself

If you have some old nails you will notice they always start rusting at the head & tip first .

As for mower batteries, I use a longer bolt and a shortened wing nut

When assembled the entire assembly gets painted over with a product called "Liquid Electrical Tape " leaving about 1/2" of thread uncoated so I can take measurements or clip on jumper leads .

Just done a mower I last serviced in 2014 and the LET was still in place & the battery was still fine

When you bend a metal cold you create a stress in the lattice & that stress will form a galvanic cell between itself

If you have some old nails you will notice they always start rusting at the head & tip first .

As for mower batteries, I use a longer bolt and a shortened wing nut

When assembled the entire assembly gets painted over with a product called "Liquid Electrical Tape " leaving about 1/2" of thread uncoated so I can take measurements or clip on jumper leads .

Just done a mower I last serviced in 2014 and the LET was still in place & the battery was still fine

#16

7394

7394

Common 'baking soda' put on the corrosion areas & add a lil water, will clean it like new.

Then replace what is deemed shot.. Then add a coating to prevent this fun time again.

Then replace what is deemed shot.. Then add a coating to prevent this fun time again.