You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

B&S - Vanguard v-twin 16hp static power to power managed

#1

Sparkanen

Sparkanen

Hello Guys, I am looking for an advice.

Is it possible to make a power(throttle) managed motor from static RPM motor? I have 16 HP Vanguard v-Twin carburator. And want somehow to use it in self-build tractor. But first I have to figure out how to change it to power managed motor... Otherwise I cant use it ...

I would be very greatefull to anyone providing any help...

I am thinking about few scenarios. Worst one is to remove governor and use static throttle This should work but without warranty of not breaking motor. So I would like some safe way to use it....

This should work but without warranty of not breaking motor. So I would like some safe way to use it....

Is it possible to make a power(throttle) managed motor from static RPM motor? I have 16 HP Vanguard v-Twin carburator. And want somehow to use it in self-build tractor. But first I have to figure out how to change it to power managed motor... Otherwise I cant use it ...

I would be very greatefull to anyone providing any help...

I am thinking about few scenarios. Worst one is to remove governor and use static throttle

Attachments

#2

B

bertsmobile1

B

bertsmobile1

Want to expand on a "power managed motor"

Because a governed engine is a power managed engine as the throttle opens wider as more load is applied .

Because a governed engine is a power managed engine as the throttle opens wider as more load is applied .

#3

Sparkanen

Sparkanen

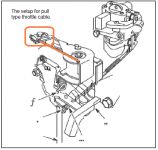

In true state it is power managed motor. Thank you for that correction. But RPM are static, right? So can I just remove static throttle adjustment and attach the throttle cable and it will do the work? I have settings like on the picture.Want to expand on a "power managed motor"

Because a governed engine is a power managed engine as the throttle opens wider as more load is applied .

Attachments

#4

StarTech

StarTech

Note: The OP has an engine that appears to be built for generator use. To usable even the tapered crankshaft would need to changed out, unless, he can find a custom built pulley with a taper fit. But answer the question it is fairly easy to convent to a throttle control engine. Just the throttle setup off the same engine series.

In order to research this we would need the model and type numbers off the current engine so we have base to go from.

In order to research this we would need the model and type numbers off the current engine so we have base to go from.

#5

Sparkanen

Engine number: 305477-0116-B1.

Yes, Tapered crankshaft is another challenge I already have a custom made attachment to Torque converter Comet Magnum 44.

I already have a custom made attachment to Torque converter Comet Magnum 44.

I am sorry for my english - I am not native speaker/writer

Sparkanen

Hello, coooool that's light at the end of the tunnelNote: The OP has an engine that appears to be built for generator use. To usable even the tapered crankshaft would need to changed out, unless, he can find a custom built pulley with a taper fit. But answer the question it is fairly easy to convent to a throttle control engine. Just the throttle setup off the same engine series.

In order to research this we would need the model and type numbers off the current engine so we have base to go from.

Engine number: 305477-0116-B1.

Yes, Tapered crankshaft is another challenge

I am sorry for my english - I am not native speaker/writer

#6

ILENGINE

ILENGINE

Should be able to just remove the fixed part of the throttle, IE the screw that holds the bracket with the thumb nut to the engine and remove the bracket, throttle fixing screw and the rod to the throttle control and , install a throttle cable clamp and throttle cable and make that part usable. Sounds like the pulley situation may already be figured out.

Should work with a throttle cable setup for a variable speed operation unless Briggs used a fixed throttle style carb then it will still operate as a variable throttle but may surge and run poorly at low speeds.

Should work with a throttle cable setup for a variable speed operation unless Briggs used a fixed throttle style carb then it will still operate as a variable throttle but may surge and run poorly at low speeds.

#7

Sparkanen

Sparkanen

Hmm, It sounds like a plan... What about idle RPM/Throttle ... do I need to set up some spring tension up to just remove the fixed part of the throttle? I hope for idle RPM somewhere around 1000 RPM. Hopefully motor will not strike me to my but, what I am doing with himShould be able to just remove the fixed part of the throttle, IE the screw that holds the bracket with the thumb nut to the engine and remove the bracket, throttle fixing screw and the rod to the throttle control and , install a throttle cable clamp and throttle cable and make that part usable. Sounds like the pulley situation may already be figured out.

Should work with a throttle cable setup for a variable speed operation unless Briggs used a fixed throttle style carb then it will still operate as a variable throttle but may surge and run poorly at low speeds.

#8

Mower King

Mower King

B&S likes their engines to idle around 1750 but, you can set both WOT and idle RPM at your own discretion and actual application. WOT is usually around 3600 but, that's not set in stone either.Hmm, It sounds like a plan... What about idle RPM/Throttle ... do I need to set up some spring tension up to just remove the fixed part of the throttle? I hope for idle RPM somewhere around 1000 RPM. Hopefully motor will not strike me to my but, what I am doing with him

#10

Sparkanen

Sparkanen

Cool guys, I will try to remove static throttle first and see on what RPM will it run. I have ordered RPM measurer, as motor doesn't have its own. I am looking forward to do this! So excited.

thank you very much for advices, I will post the result.

thank you very much for advices, I will post the result.

#11

B

bertsmobile1

B

bertsmobile1

Peak torque on these engines is usually around 3000 rpm

The engines are balanced for 3600 rpm ( roughly ) and at speeds above 4000 rpm can shake very badly

Connecting rods are weak and most will break when you try to run them above 5000 rpm.

If you disconnect the governor , leave the governor arm in place & hook a spring onto something to hold the arm back.

Inside the engine the governor mechanism can fall apart if there is no load working against the bob weights .

When these engines are converted for racing or go carts the crankcases are pulled apart & the entire governor is removed but the oil splash paddle wheel ( If fitted ) must be retained .

If you are going to use this engine for some sort of tractor then setting it up for normal governed control with a throttle over ride is the best way to go , not a direct throttle

Most tractor attachments are designed to run at either 3600 rpm or 1750 rpm and this has been the case world wide for at least 60 years.

Please tell us exactly what you want the engine to drive & what the machine will be needed to do .

I think all that you will really need is a couple of different springs to allow the engine to rev slower and a throttle cable with a lever at the dash board .

I gather you get this engine cheap and want to use it to power a tractor of some sort to do some farm work of some sort .

If this is the case there is no use making the engine go faster than 3600 in fact it will run bad use a lot of fuel and do a poor job.

The exception is if you want a faster road speed where there is little load on the engine but even then a higher gear to go faster with the engine spinning at 3000 rpm is better than making the engine spin at 4000 rpm .

The engines are balanced for 3600 rpm ( roughly ) and at speeds above 4000 rpm can shake very badly

Connecting rods are weak and most will break when you try to run them above 5000 rpm.

If you disconnect the governor , leave the governor arm in place & hook a spring onto something to hold the arm back.

Inside the engine the governor mechanism can fall apart if there is no load working against the bob weights .

When these engines are converted for racing or go carts the crankcases are pulled apart & the entire governor is removed but the oil splash paddle wheel ( If fitted ) must be retained .

If you are going to use this engine for some sort of tractor then setting it up for normal governed control with a throttle over ride is the best way to go , not a direct throttle

Most tractor attachments are designed to run at either 3600 rpm or 1750 rpm and this has been the case world wide for at least 60 years.

Please tell us exactly what you want the engine to drive & what the machine will be needed to do .

I think all that you will really need is a couple of different springs to allow the engine to rev slower and a throttle cable with a lever at the dash board .

I gather you get this engine cheap and want to use it to power a tractor of some sort to do some farm work of some sort .

If this is the case there is no use making the engine go faster than 3600 in fact it will run bad use a lot of fuel and do a poor job.

The exception is if you want a faster road speed where there is little load on the engine but even then a higher gear to go faster with the engine spinning at 3000 rpm is better than making the engine spin at 4000 rpm .

#12

S

SamB

S

SamB

An engine not long for this world? I simply meant the engine may not last long in an application it's not meant for.Peak torque on these engines is usually around 3000 rpm

The engines are balanced for 3600 rpm ( roughly ) and at speeds above 4000 rpm can shake very badly

Connecting rods are weak and most will break when you try to run them above 5000 rpm.

If you disconnect the governor , leave the governor arm in place & hook a spring onto something to hold the arm back.

Inside the engine the governor mechanism can fall apart if there is no load working against the bob weights .

When these engines are converted for racing or go carts the crankcases are pulled apart & the entire governor is removed but the oil splash paddle wheel ( If fitted ) must be retained .

If you are going to use this engine for some sort of tractor then setting it up for normal governed control with a throttle over ride is the best way to go , not a direct throttle

Most tractor attachments are designed to run at either 3600 rpm or 1750 rpm and this has been the case world wide for at least 60 years.

Please tell us exactly what you want the engine to drive & what the machine will be needed to do .

I think all that you will really need is a couple of different springs to allow the engine to rev slower and a throttle cable with a lever at the dash board .

I gather you get this engine cheap and want to use it to power a tractor of some sort to do some farm work of some sort .

If this is the case there is no use making the engine go faster than 3600 in fact it will run bad use a lot of fuel and do a poor job.

The exception is if you want a faster road speed where there is little load on the engine but even then a higher gear to go faster with the engine spinning at 3000 rpm is better than making the engine spin at 4short life for this engine? :-D

#13

B

bertsmobile1

It is a brand new Vabguard and if not abuse will last for a very long time .

However people do not understand that they are governed engines designed to run within a fixed rev range and not a automotive engine designed to be throttle controlled.

Run them too slow and they will not oil enough and overheat

Run them too fast & the con rods break or the pistons split .

There is a good reason why a 2 cylinder motorcycle engine is twice the price of a 2 cylinder mower engine and delivers 4 times the Hp/cc as a mower engine.

Now horizontal shaft engines are designed to run about 10 times as long as a vertical shaft engine will but they do have limits and using them outside those limits can result in a very short service life .

Sparkenen has already mentioned English is not his first language one might assume he is from some where in South America where engines are hard to come by & very expensive .

So he has gotten his hands on whatever cheap engine he can find & id trying to use it outside of it's intended use.

We really need to know exactly what he is trying to do.

If it is going into a skid steer, waml behind tractor or farm tractor of some kind then it should remain governed .

B

bertsmobile1

REad the whole thread.An engine not long for this world? Just asking. :-D

It is a brand new Vabguard and if not abuse will last for a very long time .

However people do not understand that they are governed engines designed to run within a fixed rev range and not a automotive engine designed to be throttle controlled.

Run them too slow and they will not oil enough and overheat

Run them too fast & the con rods break or the pistons split .

There is a good reason why a 2 cylinder motorcycle engine is twice the price of a 2 cylinder mower engine and delivers 4 times the Hp/cc as a mower engine.

Now horizontal shaft engines are designed to run about 10 times as long as a vertical shaft engine will but they do have limits and using them outside those limits can result in a very short service life .

Sparkenen has already mentioned English is not his first language one might assume he is from some where in South America where engines are hard to come by & very expensive .

So he has gotten his hands on whatever cheap engine he can find & id trying to use it outside of it's intended use.

We really need to know exactly what he is trying to do.

If it is going into a skid steer, waml behind tractor or farm tractor of some kind then it should remain governed .

#14

Sparkanen

Sparkanen

Hello I am from Slovakia, reach enough to buy new tractor  I have one Zetor 6245 older but very effective tractor for farm. So my story is... My father already past away and I have an old small homemade tractor from him with broken motor from Jawa 500 OHC motorcycle. I am an IT guy and tell myself, I am quite good in hand working, practical enough and have some basic info around motors. Also as IT guy, I am learning fast and with combination of Internet ... it is enough to do something what will create little happiness in my life

I have one Zetor 6245 older but very effective tractor for farm. So my story is... My father already past away and I have an old small homemade tractor from him with broken motor from Jawa 500 OHC motorcycle. I am an IT guy and tell myself, I am quite good in hand working, practical enough and have some basic info around motors. Also as IT guy, I am learning fast and with combination of Internet ... it is enough to do something what will create little happiness in my life  So yes, this is my hobby. Do something else than watching TV series as I am 8 hours daily in front of PC, I consider it is enough, and I am trying to do something different activity.

So yes, this is my hobby. Do something else than watching TV series as I am 8 hours daily in front of PC, I consider it is enough, and I am trying to do something different activity.

This motor cost me 750euro which might be something arround 800-900 dolars. This is half the price you can buy it in the shop. It is brand new, thats perfect. But I did a mistake and bought it without investigation... Tapered shaft ... static throttle, without muffler and without any informations for what those engines are supposed to work...

So I bought it and now I have it... and I am trying to do some miracles. I understand why there is governor, I am clever for this enough, at least I hope I am. In my first post I wrote this is last solution to do that as I know it can harm the motor itself.

Purpose of small tractor: It is size of normal garden tractor and will do small work in our garden behind the house. You can see the picture of the forgotten tractor below as well as CVT white papers and my tapered adapter for the tapered shaft.

as well as CVT white papers and my tapered adapter for the tapered shaft.

So here we are now:

- I have removed static throttle and looks like it is working (I don't know if motor is running OK or not... I have no practice and can't hear it, especially without a muffler

)

)

- I have observed, when I shut down the motor and start it immediately it start... but when I let it be for 10-20 seconds and want to start it again I always have to open a choke, otherwise it will not start. Right after start I can close the choke and it is running like on the video.

Hello, if you want to see how it did at "final" state, you can check it here on the link below. I have mounted a CVT just to to test if it reacts quite good on RPM motor has now.

Check the video HERE

Next step is to buy or engineer a muffler for this monster.

This motor cost me 750euro which might be something arround 800-900 dolars. This is half the price you can buy it in the shop. It is brand new, thats perfect. But I did a mistake and bought it without investigation... Tapered shaft ... static throttle, without muffler and without any informations for what those engines are supposed to work...

So I bought it and now I have it... and I am trying to do some miracles. I understand why there is governor, I am clever for this enough, at least I hope I am. In my first post I wrote this is last solution to do that as I know it can harm the motor itself.

Purpose of small tractor: It is size of normal garden tractor and will do small work in our garden behind the house. You can see the picture of the forgotten tractor below

So here we are now:

- I have removed static throttle and looks like it is working (I don't know if motor is running OK or not... I have no practice and can't hear it, especially without a muffler

- I have observed, when I shut down the motor and start it immediately it start... but when I let it be for 10-20 seconds and want to start it again I always have to open a choke, otherwise it will not start. Right after start I can close the choke and it is running like on the video.

Hello, if you want to see how it did at "final" state, you can check it here on the link below. I have mounted a CVT just to to test if it reacts quite good on RPM motor has now.

Check the video HERE

Next step is to buy or engineer a muffler for this monster.

Attachments

#15

B

bertsmobile1

B

bertsmobile1

Excellent now we are all reading from the same book we can all work together

So you will need to get some sort of throttle cable to hook up to the control as Illengine mentioned back in post # 6 and Star showed in post # 9

The governor assembly virtually prevents the engine reving way too far as the circular plate you attach the control cable to has a very limited range of movement.

You might need to replace the governor springs to get the engine to run smoothly from idle to full speed ( around 3600 rpm )

Mufflers are usually not part of the engine because they have to be made to fit around the body of what the engine is powering

You can have some fun here and fit 2 motorcycle mufflers going strait up so it looks like a big truck . If the head is not threaded you can thread it to take steel water pipe and make an exhaust from that which is what a lot of the smaller single cylinder engines have or even get 2 single cylinder pepper pot style mufflers , one for each side .

So where does the engine fit ?

Under the fuel tank or in the space between the tank & the drivers seat ?

Does the engine power anything directly or does it just hook up to the pump and everything runs off the pump oil ?

In theory you should not need to choke a hot engine to start but more than 1 have worked on would only start with the choke on regardless of how hot the engine was .

So you will need to get some sort of throttle cable to hook up to the control as Illengine mentioned back in post # 6 and Star showed in post # 9

The governor assembly virtually prevents the engine reving way too far as the circular plate you attach the control cable to has a very limited range of movement.

You might need to replace the governor springs to get the engine to run smoothly from idle to full speed ( around 3600 rpm )

Mufflers are usually not part of the engine because they have to be made to fit around the body of what the engine is powering

You can have some fun here and fit 2 motorcycle mufflers going strait up so it looks like a big truck . If the head is not threaded you can thread it to take steel water pipe and make an exhaust from that which is what a lot of the smaller single cylinder engines have or even get 2 single cylinder pepper pot style mufflers , one for each side .

So where does the engine fit ?

Under the fuel tank or in the space between the tank & the drivers seat ?

Does the engine power anything directly or does it just hook up to the pump and everything runs off the pump oil ?

In theory you should not need to choke a hot engine to start but more than 1 have worked on would only start with the choke on regardless of how hot the engine was .

#16

Sparkanen

- Yes, engine is going to be in the middle between fuel tank and rider. Still I have to figure out exact position, because there have to be also place for the CVT driven pulley.

- Motor will power transmission which is under the driver seat reached by chain links. Here is the picture of the chain links and ratios which I made just by hand. I still have to figure out the 2nd-ary jackshaft chain wheel. I suppose it have to be 9 teeth sprocket. However I am counting the ratios aaand it is still too fast for such tractor. Maybe you can help here as well.

- It also can hook up and power the oil pump to get back hydraulics working.

- Tractor has also chain sprocket for back accessories which can be powered by chain.

- regarding the muffler, exactly I am thinking about some motorcycle exhaust attached to self-made exhaust pipes. Head is not threaded, and I think I will not do this, just to not damage the head. Original Muffler costs 300euros... it is too much But maybe at the end I will spare the money for it, if I will decide to based on time and other things...

But maybe at the end I will spare the money for it, if I will decide to based on time and other things...

Sparkanen

Hello, do you know exact setup of governor springs? There is no idle spring at the moment.Excellent now we are all reading from the same book we can all work together

So you will need to get some sort of throttle cable to hook up to the control as Illengine mentioned back in post # 6 and Star showed in post # 9

The governor assembly virtually prevents the engine reving way too far as the circular plate you attach the control cable to has a very limited range of movement.

You might need to replace the governor springs to get the engine to run smoothly from idle to full speed ( around 3600 rpm )

Mufflers are usually not part of the engine because they have to be made to fit around the body of what the engine is powering

You can have some fun here and fit 2 motorcycle mufflers going strait up so it looks like a big truck . If the head is not threaded you can thread it to take steel water pipe and make an exhaust from that which is what a lot of the smaller single cylinder engines have or even get 2 single cylinder pepper pot style mufflers , one for each side .

So where does the engine fit ?

Under the fuel tank or in the space between the tank & the drivers seat ?

Does the engine power anything directly or does it just hook up to the pump and everything runs off the pump oil ?

In theory you should not need to choke a hot engine to start but more than 1 have worked on would only start with the choke on regardless of how hot the engine was .

- Yes, engine is going to be in the middle between fuel tank and rider. Still I have to figure out exact position, because there have to be also place for the CVT driven pulley.

- Motor will power transmission which is under the driver seat reached by chain links. Here is the picture of the chain links and ratios which I made just by hand. I still have to figure out the 2nd-ary jackshaft chain wheel. I suppose it have to be 9 teeth sprocket. However I am counting the ratios aaand it is still too fast for such tractor. Maybe you can help here as well.

- It also can hook up and power the oil pump to get back hydraulics working.

- Tractor has also chain sprocket for back accessories which can be powered by chain.

- regarding the muffler, exactly I am thinking about some motorcycle exhaust attached to self-made exhaust pipes. Head is not threaded, and I think I will not do this, just to not damage the head. Original Muffler costs 300euros... it is too much

Attachments

#17

StarTech

StarTech

When you remove the items circled in post #3 the engine should go straight to idle when the engine is started; unless, you have a throttle cable attached. This is how a governed engine works. The governor spring on the control will pull the governed speed up as tension is applied.

Originally the engine was setup for generator which would have a governed speed of 3150 rpm [50hz] or 3750 rpm [60hz] and was prevented from going to idle speed. The only time an idle spring is used is for governed idle speeds which some Briggs do use.

Originally the engine was setup for generator which would have a governed speed of 3150 rpm [50hz] or 3750 rpm [60hz] and was prevented from going to idle speed. The only time an idle spring is used is for governed idle speeds which some Briggs do use.