You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Adjust play in brake linkage rod

#1

J

JimP2014

Here is a short video of this rake linkage rod that I think has too much play in it so basically the brake is off + I believe that rod should not slide the way it does even when the spring is attached it slides the same amount as if there's a way to stop that motion the spring itself seems to be a little bit too long I wonder what anybody knows about how to get rid of that play in that rod? Craftsman lt2000 2019.5 horsepower engine 42-in cutting width.

Thankks,

Jim

J

JimP2014

Here is a short video of this rake linkage rod that I think has too much play in it so basically the brake is off + I believe that rod should not slide the way it does even when the spring is attached it slides the same amount as if there's a way to stop that motion the spring itself seems to be a little bit too long I wonder what anybody knows about how to get rid of that play in that rod? Craftsman lt2000 2019.5 horsepower engine 42-in cutting width.

Thankks,

Jim

#2

J

JimP2014

J

JimP2014

So there's this very long spring and it connects to this plate that controls the brake pads. The plate where this long spring hooks into has One large hole and that's where the spring should go but behind that there's a smaller hole and I wonder what that's for if anyone knows seems like if I use that smaller hole somehow then the current setup will be more tight. So that long spring which really is not the problem there's nothing wrong with it it's just resting on top of that metal plate the other thing is where that long linkage rod goes towards the front of the mower you can't get in there you probably have to take out the engine but maybe there's nothing to service on the front end of that long metal linkage rod so it doesn't matter.

Jim

Jim

Attachments

#3

J

JimP2014

J

JimP2014

So I took off that spring it's known as an elongated spring which I never really knew but one side of the spring is elongated and the other side is just like the closed loop. The spring is 5.5in Long and it has an outside diameter I believe 3/8 of an inch but in any case, it's fairly easy to find a spring that's 5 and 1/2 in Long it's more difficult to find one which is 5 and 1/4 in long which is what I figure I need so I decided that they two makes springs 5 and 1/4 in long except both ends are elongated I don't think that's a big deal the only thing you have to worry about is making sure the elongated side does not slip off of the linkage rod which would not be hard to figure out. That linkage rod itself should actually have an adjustment setup built into it so it's a metal rod going into some sort of adjustment setup and then from there it goes out to metal rod again so in the middle some place you can adjust it to loosen it or tighten it that's the way that linkage rod should be built.

Jim

Jim

#4

F

Forest#2

F

Forest#2

????

I would probably search for a download a owners manual and parts list and review if the brake does not operate. Owners manuals usually have pictures and adjustment procedures. (and brakes are usually wimpy operating on LT Models)Brakes just kinda slow down the LT machine when on flat ground if they are of the small puck type..

If the brake works Ok I would live with it.

I would probably search for a download a owners manual and parts list and review if the brake does not operate. Owners manuals usually have pictures and adjustment procedures. (and brakes are usually wimpy operating on LT Models)Brakes just kinda slow down the LT machine when on flat ground if they are of the small puck type..

If the brake works Ok I would live with it.

#5

J

JimP2014

your foot is fully depressing the brake pedal. So now when you take your foot off the brake the machine shoots forward like a rocket.

My latest idea since I do not weld ( I saw where someone cut that linkage rod and welded a long threaded steel screw to the end that eventually attaches to the brake disc area ) but my idea is to get an elongated spring and instead of 5.5" overall length, get one that is say 2" long and then on this spring closest to the front of the machine loop a steel cable somehow and get it taught so the end result is that brass colored rod has zero play in it when the brake is "off". My other idea is use the same much shorter spring and then add a, "Adjustable Hook with Ring Stainless Steel Turnbuckle Hook" and this could be used inline to take up the slack in the linkage rod.

Jim

P.S. If I do nothing and put everything back the way it is the only real problem is jack rabbit starts when the foot comes off the brake, even slowly.

J

JimP2014

Forest thanks for your reply. I have it 'all apart' right now I could just reassemble the right rear tire/brake linkage and everything will run. But with the brake pedal not depressed at all, I have found that linkage rod ( brass color ) has some play in it. If I could shorten the distance which is basically the length of the spring by maybe a 1/4" to 1/2" and put the spring back where it attaches to the metal plate ( it sits over the brake rotor ) and then it attaches to the brass colored linkage rod the shorter length of the spring will remove the play in the horizontal movement of the linkage rod. I think this is the reason when you are running the machine and depress the brake it takes slightly longer to stop, no big deal here but now????

I would probably search for a download a owners manual and parts list and review if the brake does not operate. Owners manuals usually have pictures and adjustment procedures. (and brakes are usually wimpy operating on LT Models)Brakes just kinda slow down the LT machine when on flat ground if they are of the small puck type..

If the brake works Ok I would live with it.

your foot is fully depressing the brake pedal. So now when you take your foot off the brake the machine shoots forward like a rocket.

My latest idea since I do not weld ( I saw where someone cut that linkage rod and welded a long threaded steel screw to the end that eventually attaches to the brake disc area ) but my idea is to get an elongated spring and instead of 5.5" overall length, get one that is say 2" long and then on this spring closest to the front of the machine loop a steel cable somehow and get it taught so the end result is that brass colored rod has zero play in it when the brake is "off". My other idea is use the same much shorter spring and then add a, "Adjustable Hook with Ring Stainless Steel Turnbuckle Hook" and this could be used inline to take up the slack in the linkage rod.

Jim

P.S. If I do nothing and put everything back the way it is the only real problem is jack rabbit starts when the foot comes off the brake, even slowly.

#6

F

Forest#2

F

Forest#2

I felt your pain about those neck jerking, wheel standing jack rabbit starts with several of the Lawn tractors models as the brake/clutch pedal is let off. Really aggravating and just the nature of the beast on some.

What I've noticed it's USUALLY not the brake releasing quickly but is the motion drive belt instantly grabbing. with the correct size belt installed and all the pulleys ok.

On some models I have not found a good solution.

I can confirm it being the motion drive belt grabbing by wetting the drive belt or even smearing little bit of oil or vaseline onto the belt. The oil/water will wear off quickly. This just helps confirm quickly that it's the drive belt grabbing by allowing the belt to slip for a softer start when the clutch/brake is released.

What I've noticed it's USUALLY not the brake releasing quickly but is the motion drive belt instantly grabbing. with the correct size belt installed and all the pulleys ok.

On some models I have not found a good solution.

I can confirm it being the motion drive belt grabbing by wetting the drive belt or even smearing little bit of oil or vaseline onto the belt. The oil/water will wear off quickly. This just helps confirm quickly that it's the drive belt grabbing by allowing the belt to slip for a softer start when the clutch/brake is released.

#7

J

JimP2014

Jim

J

JimP2014

So I see where you say it's a drive belt and that's a really easy quick solution what you're talking about but I believe the problem is that linkage rod has too much play in it you don't think that's true just curious?I felt your pain about those neck jerking, wheel standing jack rabbit starts with several of the Lawn tractors models as the brake/clutch pedal is let off. Really aggravating and just the nature of the beast on some.

What I've noticed it's USUALLY not the brake releasing quickly but is the motion drive belt instantly grabbing. with the correct size belt installed and all the pulleys ok.

On some models I have not found a good solution.

I can confirm it being the motion drive belt grabbing by wetting the drive belt or even smearing little bit of oil or vaseline onto the belt. The oil/water will wear off quickly. This just helps confirm quickly that it's the drive belt grabbing by allowing the belt to slip for a softer start when the clutch/brake is released.

Jim

#8

F

Forest#2

F

Forest#2

I'm just saying that those wheel standing, neck jerking, jack rabbit starts on some riding lawn mowers is the drive belt instantly grabbing even as the clutch/brake is slowly released, not the brake releasing all at once.

You can either do as I suggested to the drive belt or completely disconnect the brake linkage so the brake does not even apply and test and see if you still have the wheel standing clutch grabbing type issue. You might be correct in it being the brake but I've never seen such cause the instant clutch grab issue for jack rabbit starts.

I see this jack rabbit issue most often on the manual shift models that have the spring loaded zig-zag idler pulleys as the clutch drive engauge/disengauge.

Post up the complete model number from under the seat of your LT2000.

You can either do as I suggested to the drive belt or completely disconnect the brake linkage so the brake does not even apply and test and see if you still have the wheel standing clutch grabbing type issue. You might be correct in it being the brake but I've never seen such cause the instant clutch grab issue for jack rabbit starts.

I see this jack rabbit issue most often on the manual shift models that have the spring loaded zig-zag idler pulleys as the clutch drive engauge/disengauge.

Post up the complete model number from under the seat of your LT2000.

#10

J

JimP2014

Husqvarna 532197296 Hg3000/3500 Brake Spring <--- and it is 5.5" long and has worked well for years, just not so much this year - mainly due to "jack rabbit starts".

It does stop the machine. Another thing I noticed is you have to press the brake very far down in order for the ignition to crank the starter, this seems new also. In the past the brake did not need to be pressed down so hard. So the actual pedal travel in the horiz and forward direction seems like it is say 2" more than it was and this is for starting.

Jim

J

JimP2014

I am not sure of what the Sears parts has for a spring, their catalog depicts a spring that is say 2" long. But The one that this machine has is this one;917289070 Craftsman Lawn Tractor <--- I am using this for parts

Husqvarna 532197296 Hg3000/3500 Brake Spring <--- and it is 5.5" long and has worked well for years, just not so much this year - mainly due to "jack rabbit starts".

It does stop the machine. Another thing I noticed is you have to press the brake very far down in order for the ignition to crank the starter, this seems new also. In the past the brake did not need to be pressed down so hard. So the actual pedal travel in the horiz and forward direction seems like it is say 2" more than it was and this is for starting.

Jim

#11

J

JimP2014

J

JimP2014

It just occured to me, since this LT2000 is about 15 years old or more, it should have the problem where things are loose, like the belt for example or some other issue involving the pulleys BUT the problem is things are to tight! I did take the advice of Forest and not much changed. So instead of the ground drive belt becoming to loose ( this really should happen after 15 yrs.) it is now tighter. This makes no sense. It is as if I need to take the drive belt and stretch it a bit or buy one that is slightly longer.

Jim

Jim

#12

J

JimP2014

J

JimP2014

I stand corrected the pedal has to much play in it - I wish I could just fix this.It just occured to me, since this LT2000 is about 15 years old or more, it should have the problem where things are loose, like the belt for example or some other issue involving the pulleys BUT the problem is things are to tight! I did take the advice of Forest and not much changed. So instead of the ground drive belt becoming to loose ( this really should happen after 15 yrs.) it is now tighter. This makes no sense. It is as if I need to take the drive belt and stretch it a bit or buy one that is slightly longer.

Jim

#13

F

Forest#2

The reason the clutch has lots of slack/play is the drive belt is worn which results in the clutching idler have to move too far to take up the slack. The more the clutch idler moves to take up the BELT slack the more forward the clutch/brake pedal will be for travel engauge disengauge. You might also have worn pulleys idle AND the top drive pulley worn on the sides allowing the belt travel too deep in the pulley.

It's quite a job to replace the drive belt and also properly inspect the pulleys. for example remove the deck, remove the front drive stack pulley or slide it down, carefully route the new belt and re-install all. After replacing this type drive belt I leave the deck off and test the drive BEFORE re-installing the deck. The mower will also have to elevated in the front. Quite a learning experience the first time doing such.

It's quite common for them type drive systems to have jack rabbit starts even with a new belt, might even be worse with a new belt.

Stay safe if under the mower. I use a chain hoist for such to make the job more user friendly.

Would be worth while to get an estimate for such from a shop.

F

Forest#2

See pg 24 of your owners manual. Here is a link to download a owners manual for that rig.I stand corrected the pedal has to much play in it - I wish I could just fix this.

The reason the clutch has lots of slack/play is the drive belt is worn which results in the clutching idler have to move too far to take up the slack. The more the clutch idler moves to take up the BELT slack the more forward the clutch/brake pedal will be for travel engauge disengauge. You might also have worn pulleys idle AND the top drive pulley worn on the sides allowing the belt travel too deep in the pulley.

It's quite a job to replace the drive belt and also properly inspect the pulleys. for example remove the deck, remove the front drive stack pulley or slide it down, carefully route the new belt and re-install all. After replacing this type drive belt I leave the deck off and test the drive BEFORE re-installing the deck. The mower will also have to elevated in the front. Quite a learning experience the first time doing such.

It's quite common for them type drive systems to have jack rabbit starts even with a new belt, might even be worse with a new belt.

Stay safe if under the mower. I use a chain hoist for such to make the job more user friendly.

Would be worth while to get an estimate for such from a shop.

#14

J

JimP2014

Jim

J

JimP2014

Forest thank you very much for the detailed explanation! I now understand how the parts all work together.See pg 24 of your owners manual. Here is a link to download a owners manual for that rig.

The reason the clutch has lots of slack/play is the drive belt is worn which results in the clutching idler have to move too far to take up the slack. The more the clutch idler moves to take up the BELT slack the more forward the clutch/brake pedal will be for travel engauge disengauge. You might also have worn pulleys idle AND the top drive pulley worn on the sides allowing the belt travel too deep in the pulley.

It's quite a job to replace the drive belt and also properly inspect the pulleys. for example remove the deck, remove the front drive stack pulley or slide it down, carefully route the new belt and re-install all. After replacing this type drive belt I leave the deck off and test the drive BEFORE re-installing the deck. The mower will also have to elevated in the front. Quite a learning experience the first time doing such.

It's quite common for them type drive systems to have jack rabbit starts even with a new belt, might even be worse with a new belt.

Stay safe if under the mower. I use a chain hoist for such to make the job more user friendly.

Would be worth while to get an estimate for such from a shop.

Jim

#16

J

JimP2014

J

JimP2014

Forest you speak the truth. I just grabbed hold of that drive belt and lo and behold it pulls back the brake pedal. I stand corrected it pulls it Forward towards the front wheels.

Jim

Jim

#17

J

JimP2014

J

JimP2014

The other thing I noticed is when you pull the brake pedal all the way back towards the rear of the riding mower the belt seems very tight I would think it is supposed to be loose?Forest you speak the truth. I just grabbed hold of that drive belt and lo and behold it pulls back the brake pedal. I stand corrected it pulls it Forward towards the front wheels.

Jim

#18

J

JimP2014

I don't know the way this moves back and forth I can't see it being the belt or the linkage rod it's some other thing it has to be it's right somehow in the the metal rod from the brake pedal going back to wherever it goes to on the other side of the riding mower that's what it seems like to me like that needs to be fixed and nothing else?

Jim

J

JimP2014

The other thing I noticed is when you pull the brake pedal all the way back towards the rear of the riding mower the belt seems very tight I would think it is supposed to be loose?

I don't know the way this moves back and forth I can't see it being the belt or the linkage rod it's some other thing it has to be it's right somehow in the the metal rod from the brake pedal going back to wherever it goes to on the other side of the riding mower that's what it seems like to me like that needs to be fixed and nothing else?

Jim

#19

F

Forest#2

F

Forest#2

As the clutch is depressed towards the front the drive belt slacks.

As the clutch comes back the motion drive belt tension increases. (because the spring loaded clutch idler pulley moves into the belt)

Agree that in your video something appears too loose or to much slop in the clutch/brake swivel rod, but I do not know what?????

The video is not good enough to determine just what is upset. (maybe bolts loose or bushings worn?????

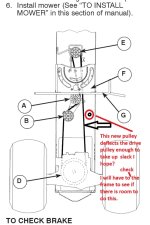

I added that additional pulley in red to that type mower. It kept the long run in the belt from flopping and less likely to jump off the pulleys.

As the clutch comes back the motion drive belt tension increases. (because the spring loaded clutch idler pulley moves into the belt)

Agree that in your video something appears too loose or to much slop in the clutch/brake swivel rod, but I do not know what?????

The video is not good enough to determine just what is upset. (maybe bolts loose or bushings worn?????

I added that additional pulley in red to that type mower. It kept the long run in the belt from flopping and less likely to jump off the pulleys.

#20

J

JimP2014

Jim

J

JimP2014

I hear you on you don't know what it is because that whole setup is like the freaking Bermuda triangle trying to get in there you got to take everything apart I'll see if I can take the mower deck off and then I got to get a lift for the front end of it see exactly what's going on there's just no other way to do it it seems but thanks for replying and you have no idea what's going on there and I don't either but there's some sort of slop.As the clutch is depressed towards the front the drive belt slacks.

As the clutch comes back the motion drive belt tension increases. (because the spring loaded clutch idler pulley moves into the belt)

Agree that in your video something appears too loose or to much slop in the clutch/brake swivel rod, but I do not know what?????

The video is not good enough to determine just what is upset. (maybe bolts loose or bushings worn?????

I added that additional pulley in red to that type mower. It kept the long run in the belt from flopping and less likely to jump off the pulleys.

Jim

#22

F

Forest#2

F

Forest#2

Just something to think about: (food for thought $ wise also_

15 year old mower and still has same belts, pulleys, deck spindles, etc.

If this is the only mower you have and grass is growing while you are working on the old rig you might want to think about limping it until mowing season is over. It will at least need all belts replaced and YOU WILL FIND OTHER THINGS THAT need attention.

You might even find you need $$$ ($) to find a replacement mower or a hay baler.

More attention can be given to re-furbishing a OLD mowing rig when it's not really needed and the weather is cooler.

15 year old mower and still has same belts, pulleys, deck spindles, etc.

If this is the only mower you have and grass is growing while you are working on the old rig you might want to think about limping it until mowing season is over. It will at least need all belts replaced and YOU WILL FIND OTHER THINGS THAT need attention.

You might even find you need $$$ ($) to find a replacement mower or a hay baler.

More attention can be given to re-furbishing a OLD mowing rig when it's not really needed and the weather is cooler.

#23

J

JimP2014

J

JimP2014

No I actually have another machine it's a Yard machine is the hydrostatic transmission but there's no reason why this one the celty 2000 can't get back the way it was lt2000 so I've been using the Yard machine cut the lawn and as it turns out the grass around here is brown every place so you're basically cutting dirt but I just really would like to get this back and it wasn't tip top shape as far as I'm turnedJust something to think about: (food for thought $ wise also_

15 year old mower and still has same belts, pulleys, deck spindles, etc.

If this is the only mower you have and grass is growing while you are working on the old rig you might want to think about limping it until mowing season is over. It will at least need all belts replaced and YOU WILL FIND OTHER THINGS THAT need attention.

You might even find you need $$$ ($) to find a replacement mower or a hay baler.

More attention can be given to re-furbishing a OLD mowing rig when it's not really needed and the weather is cooler.

#24

J

JimP2014

J

JimP2014

So a few days ago and I'm getting around to this now for a post I engaged the blades and I saw Sparks coming from underneath the mower deck so I don't remember that being a problem but now it is a problem so the blade one of them is hitting the mower deck I don't know what's going on with it it wasn't happening before but I guess take the mower deck off again spin the blades and see what's hitting what maybe the deck is bent I'm not sure what's going on.

Jim

Jim

#25

F

Forest#2

F

Forest#2

It happens. Murphy has woke up.

You say grass is brown and dirty in your area. Must not be close to Oklahoma.

If the grass is brown you need to watch that sparking deck and not start a forest fire.

You say grass is brown and dirty in your area. Must not be close to Oklahoma.

If the grass is brown you need to watch that sparking deck and not start a forest fire.

#26

J

JimP2014

Jim

Who's Murphy?

J

JimP2014

I am thinking about what you're saying and that is true I'm in Connecticut and maybe maybe we are elevated fire danger level I'm not sure but it happens every year certain areas of the yard that are exposed to direct sunlight turn brown it happens with numerous lawns unless people are spending couple hundred dollars a day to keep their lawn watered but I'm now trying to make sure that the Sparks are flying from underneath the deck and not the deck pulleys for example but this will be done later today when it's a lot cooler out.It happens. Murphy has woke up.

You say grass is brown and dirty in your area. Must not be close to Oklahoma.

If the grass is brown you need to watch that sparking deck and not start a forest fire.

Jim

Who's Murphy?

#28

J

JimP2014

J

JimP2014

I got you. The only thing I could think of that I did is I adjusted the The mechanism on the left side of the mower that controls the height of the deck but I did that couple weeks ago.You asked:

Who's Murphy?

search: Murphy"s Law on-line

#29

J

JimP2014

So I try to make a video of the Sparks flying and I'm pretty sure they're coming from the front of the mower deck below it that is but no luck however I've been trying to get some audio of this ringing noise that is pretty much constant when I'm cutting the grass I just wonder if anybody could identify with this ringing noise is?

Thank you very much,

Jim

J

JimP2014

I got you. The only thing I could think of that I did is I adjusted the The mechanism on the left side of the mower that controls the height of the deck but I did that couple weeks ago.

So I try to make a video of the Sparks flying and I'm pretty sure they're coming from the front of the mower deck below it that is but no luck however I've been trying to get some audio of this ringing noise that is pretty much constant when I'm cutting the grass I just wonder if anybody could identify with this ringing noise is?

Thank you very much,

Jim

#30

J

JimP2014

J

JimP2014

I just replaced idler pulley and it's the larger of the two so it has that carriage bolt and then from there you have that belt guide and then on top of that you put that idler pulley and then on top of that you put a washer and then on top of that you tighten it down with the nut.

I don't have a video for this but once you tighten it down you can take the pulley and just wobble it in any direction + the belt guide you can slide it back and forth.

So the question is is this the way it's supposed to mount wobbly pulley and a belt guide that slides back and forth.

Jim

I don't have a video for this but once you tighten it down you can take the pulley and just wobble it in any direction + the belt guide you can slide it back and forth.

So the question is is this the way it's supposed to mount wobbly pulley and a belt guide that slides back and forth.

Jim

#31

J

JimP2014

So I found this video from repair clinic and they're referring to it as a large deck pulley which makes sense it's the larger one so I have done exactly what this guy has done but what I'm saying is that once everything's all tightened up the whole deck pulley wobbles there's no way to get it tighter in his video I don't see him trying to make the large deck pulley wobble but that's what the one I have is doing.

Jim

J

JimP2014

I just replaced idler pulley and it's the larger of the two so it has that carriage bolt and then from there you have that belt guide and then on top of that you put that idler pulley and then on top of that you put a washer and then on top of that you tighten it down with the nut.

I don't have a video for this but once you tighten it down you can take the pulley and just wobble it in any direction + the belt guide you can slide it back and forth.

So the question is is this the way it's supposed to mount wobbly pulley and a belt guide that slides back and forth.

Jim

So I found this video from repair clinic and they're referring to it as a large deck pulley which makes sense it's the larger one so I have done exactly what this guy has done but what I'm saying is that once everything's all tightened up the whole deck pulley wobbles there's no way to get it tighter in his video I don't see him trying to make the large deck pulley wobble but that's what the one I have is doing.

Jim

#32

J

JimP2014

J

JimP2014

The only thing I could think of is the socket that I'm using is somehow messing up the ability to tighten it really tight I don't know for sure but when I get done tightening it there's a noticeable Gap between the frame and where the shaft for the pulley maybe like an eighth of an inch r as tight as it's going to be The only thing I could think of is just getting an adjustable wrench and put it on that nut and just keep tightening it and see if it closes up the Gap between the bottom shaft of the large pulley and the deck frame and of course the belt guide is in between and that is wobbling as well but more side to side maybe the problem is I need to use like I said an adjustable wrench

So I found this video from repair clinic and they're referring to it as a large deck pulley which makes sense it's the larger one so I have done exactly what this guy has done but what I'm saying is that once everything's all tightened up the whole deck pulley wobbles there's no way to get it tighter in his video I don't see him trying to make the large deck pulley wobble but that's what the one I have is doing.

Jim

#33

J

JimP2014

J

JimP2014

I'm not sure how this information can help someone else but for large pulley on the lt2000 mower deck you might have to use an adjustable wrench to get the thing locked down really tight once you do that then there's no more wobble with that large pulley if you don't do this all the time and I don't even though I probably had this part like 20 times you wouldn't know it but that's what you have to do use an adjustable wrench if you don't have long sockets tighten it down until the pulley has no wiggle in it it rotates without any sort of wobble and hopefully this stops this ringing noise when the mower deck is engaged.

Jim

Jim

#34

J

JimP2014

J

JimP2014

This question would be for anyone who maybe work as a small engine mechanic or owns a repair shop or both but as of yesterday all the spindles all of the pulleys plus a brand new belt which is actually roughed up on the outside all this stuff is new. So when I engaged the blades everything seems okay except I'm still getting this ringing noise and it's coming from you there the mower deck somehow r the drive belt or drive belt pulleys all that but here's a question would be for people who have experience.

If if you start the riding mower up and you run it and run it at full throttle there is no ringing noise and when the blades are engaged is when the ringing noise starts so my conclusion is it has something to do with the mower deck but this is a question for people who have seen this before is it possible when I engage the mower deck that is putting some sort of extra stress on the drive belt plus those pulleys and so those are the problem r or it can never happen that way.

Thanks,

Jim

If if you start the riding mower up and you run it and run it at full throttle there is no ringing noise and when the blades are engaged is when the ringing noise starts so my conclusion is it has something to do with the mower deck but this is a question for people who have seen this before is it possible when I engage the mower deck that is putting some sort of extra stress on the drive belt plus those pulleys and so those are the problem r or it can never happen that way.

Thanks,

Jim

#35

F

Forest#2

F

Forest#2

Have you had the deck off of the machine and thourghly/closely inspected the spindles bearings,idler pulleys, my doing a manual feel/listen as you rotate things manually.

Might be good time to also remove ALL the spindle bearing/inspect and re-pack them.

If not this needs to be done as a starter.

You might try posting up a video of the noise.

Might be good time to also remove ALL the spindle bearing/inspect and re-pack them.

If not this needs to be done as a starter.

You might try posting up a video of the noise.

#36

J

JimP2014

Jim

J

JimP2014

Forest these spindles are all brand new I can't imagine about repacking anything it's all everything two brand new spindles and two brand new pulleys one is a larger pulley but all that stuff's brand new and the belt brand new also checked it ended up getting scuffed up on the outside of it I'm not sure of whatever caused that is still a problem. But really the question is if every time you engage the mower deck blades you hear a ringing noise this is entirely possible that it has nothing to do with the mower deck that's really I'm hoping someone knows the answer to that one .Have you had the deck off of the machine and thourghly/closely inspected the spindles bearings,idler pulleys, my doing a manual feel/listen as you rotate things manually.

Might be good time to also remove ALL the spindle bearing/inspect and re-pack them.

If not this needs to be done as a starter.

You might try posting up a video of the noise.

Jim

#37

F

Forest#2

F

Forest#2

You might get more responses if you start a new thread about your latest NEW issue instead of using the brake adjust rod playpost.

If you start a new thread post up the Complete model number of your mower from the model tag and the deck size.

Usually if back side of a belt is getting scuffed the belt keepers need to be inspected.

If you start a new thread post up the Complete model number of your mower from the model tag and the deck size.

Usually if back side of a belt is getting scuffed the belt keepers need to be inspected.

#38

J

JimP2014

J

JimP2014

You might get more responses if you start a new thread about your latest NEW issue instead of using the brake adjust rod playpost.

If you start a new thread post up the Complete model number of your mower from the model tag and the deck size.

Usually if back side of a belt is getting scuffed the belt keepers need to be inspected. My phone is acting up but I did see what you said Forest about another thread

#40

F

Forest#2

Also maybe a video of the you are hearing.

Back side of belt scuffed can also be a flat idler not spinning good.

Belt will get hot and a new belt might have a slight chip or belt scream when belt is cold and tone change as belt heats.

Might have to get someone to watch the belt when it operating. STAY SAFE.

See if it's jumping or vibrating. Ringing sound is usually a dry bearing and I've seen lots of NEW spindles now days that new bearings are dry, no grease.

Also let it operate little while and then kill the engine and feel of the belt and see if it's hot. If the belt is not hot it's probably a spindle bearing and most likely a upper one.

F

Forest#2

Post up a link to your new post here also and we will get a heads up about such.Starting another threat tomorrow morning good idea

Also maybe a video of the you are hearing.

Back side of belt scuffed can also be a flat idler not spinning good.

Belt will get hot and a new belt might have a slight chip or belt scream when belt is cold and tone change as belt heats.

Might have to get someone to watch the belt when it operating. STAY SAFE.

See if it's jumping or vibrating. Ringing sound is usually a dry bearing and I've seen lots of NEW spindles now days that new bearings are dry, no grease.

Also let it operate little while and then kill the engine and feel of the belt and see if it's hot. If the belt is not hot it's probably a spindle bearing and most likely a upper one.

#41

J

JimP2014

Jim

J

JimP2014

Forest thanks for the additional information there's no way in hell any person who's not in the business or does it all the time would ever know any of this I would do this you suggest with more videos alsoPost up a link to your new post here also and we will get a heads up about such.

Also maybe a video of the you are hearing.

Back side of belt scuffed can also be a flat idler not spinning good.

Belt will get hot and a new belt might have a slight chip or belt scream when belt is cold and tone change as belt heats.

Might have to get someone to watch the belt when it operating. STAY SAFE.

See if it's jumping or vibrating. Ringing sound is usually a dry bearing and I've seen lots of NEW spindles now days that new bearings are dry, no grease.

Also let it operate little while and then kill the engine and feel of the belt and see if it's hot. If the belt is not hot it's probably a spindle bearing and most likely a upper one.

Jim

#42

J

JimP2014

J

JimP2014

I will be checking forest's suggestion start a new thread but I am including one more image. I mean the only thing I could think of for new thread is I've had the mower deck away from the riding mower at least a dozen times + I guess the thread will be starting from scratch even though that's not true. Couple things I did notice the last time I slid the mower deck underneath the frame somehow the whole mower deck ended up closer to the rear tires so I had to adjust that rod that attaches to the front of the mower deck never did that before.

I replaced the large pulley I noticed a large pulley has some wobble in it so I tighten it as tight as I could and I removed the wobble and now the wobble is back I don't know if the wobble is supposed to be there.

This belt is only maybe a month old I'm sure if I buy another belt it only takes a few times for it to get all screwed up.

And the reason I believe besides the obvious belt problem but there's something wrong is when you engage the blades there's this constant ringing noise and I can't figure out what is coming from I'm assuming it's the mower deck because that's the only time it appears but who knows.

And when I engage the blades and I have that constant ringing noise I think I'm going to blow another head gasket on the machine it just seems like that's going to be the next thing to happen and then I go back to the engine and replace the head gasket.

In the photo you might notice a very strange belt angle and that's because the mower deck is right on the ground normally it's pretty much horizontal.

Jim

I replaced the large pulley I noticed a large pulley has some wobble in it so I tighten it as tight as I could and I removed the wobble and now the wobble is back I don't know if the wobble is supposed to be there.

This belt is only maybe a month old I'm sure if I buy another belt it only takes a few times for it to get all screwed up.

And the reason I believe besides the obvious belt problem but there's something wrong is when you engage the blades there's this constant ringing noise and I can't figure out what is coming from I'm assuming it's the mower deck because that's the only time it appears but who knows.

And when I engage the blades and I have that constant ringing noise I think I'm going to blow another head gasket on the machine it just seems like that's going to be the next thing to happen and then I go back to the engine and replace the head gasket.

In the photo you might notice a very strange belt angle and that's because the mower deck is right on the ground normally it's pretty much horizontal.

Jim