You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

18 HP B&S Charging System

#1

G

GoHardrGoHome

G

GoHardrGoHome

I have a 18 HP (M/N 422447 Type 1216 01 Code 90121132) Briggs & Stratton engine on a Grasshopper riding mower with a charging system issue. Note that this stator is the single-wire version. I had to replace the diode in the harness due to damage. Got one from a local B&S dealer that lasted a couple weeks. Went to another more reputable dealer for another...same result. They seem to rectify the AC voltage (~28 vAC) to ~14 vDC current for a short time and then the meter readings are jumping all over the place. I've had it with the diode system! Can someone tell me if I can put a regulator rectifier in the system in place of the diode? If so, what is the P/N for the regulator rectifier? FYI, I ordered from Amazon what I thought would be the correct unit but it is for a 2-wire stator, so I don't think I can make this work without burning something up!

#2

R

Richard Milhous

R

Richard Milhous

I don't know about this particular system but typically a rectifier includes capacitance to help level the voltage.

#4

G

GoHardrGoHome

G

GoHardrGoHome

I suspect that if someone knew the specs of the diode I need, I would put it in and forget about it. B&S lists the diode as part of the stator wiring and doesn't provide the specs on the diode. The dealerships I've dealt with, suspected they were giving me the correct diode. I think not.

#5

G

GoHardrGoHome

G

GoHardrGoHome

Can't pull up your engine code. There is a 121602 but no 121601.

Can't pull up your engine code. There is a 121602 but no 121601

I keep the everything clean. I've recently had the covers off and there was very little debris in there. Code is correct. See attached.Can't pull up your engine code. There is a 121602 but no 121601.

Attachments

#6

R

Richard Milhous

R

Richard Milhous

If your tester is reading 28V AC off the stator, your peak voltage is 40V each direction. The diode will have to take that voltage, and whatever peak current the stator can push into the battery - could be pretty large.

#8

S

slomo

S

slomo

Great pic. In future posts start with that. We need engine and mower numbers to help.

Still I can't pull it up on the Briggs site.

Still I can't pull it up on the Briggs site.

#9

S

slomo

S

slomo

Take it to an auto parts store. They can load test for free. Make sure it's a load test and not those internal resistance testers.Agreed! I think I may have already fried a cell in my battery!

#10

StarTech

or use this link https://www.jackssmallengines.com/j...699999-series/422400-to-422499/422447-1216-01

StarTech

Must be using the wrong site then because that engine does exist on Power Portal. Keep looking.Great pic. In future posts start with that. We need engine and mower numbers to help.

Still I can't pull it up on the Briggs site.

or use this link https://www.jackssmallengines.com/j...699999-series/422400-to-422499/422447-1216-01

#11

R

Richard Milhous

R

Richard Milhous

I'm curious under what conditions the 28 and 14V were measured - with or without any load connected? Did you try taking an AC reading downstream from the diode?

#12

S

slomo

www.briggsandstratton.com

www.briggsandstratton.com

S

slomo

You have dealer access, I don't. I use the Briggs engine info site below.Must be using the wrong site then because that engine does exist on Power Portal. Keep looking.

View attachment 58354

or use this link https://www.jackssmallengines.com/j...699999-series/422400-to-422499/422447-1216-01

Find Manual & Parts List | Briggs & Stratton

Whether you are putting your equipment away for the season or needing to replace a part, locate your equipment or engine manual to get the information specific to your product.

#13

G

GoHardrGoHome

G

GoHardrGoHome

I included all the numbers in the original post.Must be using the wrong site then because that engine does exist on Power Portal. Keep looking.

View attachment 58354

or use this link https://www.jackssmallengines.com/j...699999-series/422400-to-422499/422447-1216-01

#14

S

slomo

S

slomo

Confirmed but the Briggs site I use didn't pull it up. StarTech has a cool dealer power portal site he uses.I included all the numbers in the original post.

#15

G

GoHardrGoHome

G

GoHardrGoHome

I had the wire disconnected before the diode and measured the stator's output at 28VAC. When I reconnected it and test at the battery for DC voltage, I was getting about 14.2 VDC. Now that the diode is not functioning properly and likely shorted my battery out, the DC voltage at the battery goes from 3 to, I think it was 18 VDC! I need to rectify the voltage before I get a new battery!I'm curious under what conditions the 28 and 14V were measured - with or without any load connected? Did you try taking an AC reading downstream from the diode?

#16

R

Richard Milhous

R

Richard Milhous

The battery might still be good. I'm more interested in figuring out what the multimeter is actually measuring, honestly. If the open-circuit stator is pumping 28V sinusoidal AC and the battery is fully charged, diode functional, the RMS voltage at the battery should be about 22V (assuming this is a single-winding stator with no parts other than the coils).

To solve your problem (without knowing anything about this charging system!) my advice is: Make sure there isn't supposed to be a capacitor somewhere in it. Use a diode with at least 45V rating and as much current rating as you can find. Avoid running the machine with a bad diode, or you could damage something that ain't damaged yet.

To solve your problem (without knowing anything about this charging system!) my advice is: Make sure there isn't supposed to be a capacitor somewhere in it. Use a diode with at least 45V rating and as much current rating as you can find. Avoid running the machine with a bad diode, or you could damage something that ain't damaged yet.

#17

B

bertsmobile1

B

bertsmobile1

Just to get a handle on your problem

1) have you owned this mower from new ?

2) is this the original engine ?

3) Dose the mower have an electric clutch ?

a single wire diode will not be able to keep up with the power requirements of an electric clutch and recharge the battery

It will overheat & burn out .

The stators that have a single wire with diode are only for recharging the battery , usually on a walk behind mower

1) have you owned this mower from new ?

2) is this the original engine ?

3) Dose the mower have an electric clutch ?

a single wire diode will not be able to keep up with the power requirements of an electric clutch and recharge the battery

It will overheat & burn out .

The stators that have a single wire with diode are only for recharging the battery , usually on a walk behind mower

#18

S

slomo

S

slomo

At minimum, use a double rated or more, amperage diode than what the charging coil puts out.

Charging coil puts out 6 amps for example. Diode needs to be 12 to 50 amp rated. Most have 2 diodes to share the amperage load I think. If you have 2 diodes in there, they should be wired in parallel or installed next to each other so to say.

Charging coil puts out 6 amps for example. Diode needs to be 12 to 50 amp rated. Most have 2 diodes to share the amperage load I think. If you have 2 diodes in there, they should be wired in parallel or installed next to each other so to say.

#19

G

GoHardrGoHome

G

GoHardrGoHome

I've had this mower for 17 years! I purchased it used. Everything looked to be stock, including the engine. Yes, the mower utilizes an electric clutch. It worked fine for many years with the single-wire stator and diode until the diode was damaged physically.Just to get a handle on your problem

1) have you owned this mower from new ?

2) is this the original engine ?

3) Dose the mower have an electric clutch ?

a single wire diode will not be able to keep up with the power requirements of an electric clutch and recharge the battery

It will overheat & burn out .

The stators that have a single wire with diode are only for recharging the battery , usually on a walk behind mower

#20

G

GoHardrGoHome

G

GoHardrGoHome

Richard, I'm going to test a few things and get back to you with results. I'm not too concerned about running it without the wire connected since I've seen in the past where the diode wire connection unplugged due to vibration while I was mowing. I didn't see anything that failed...plugged it back in and I got >14 volts DC at the battery.The battery might still be good. I'm more interested in figuring out what the multimeter is actually measuring, honestly. If the open-circuit stator is pumping 28V sinusoidal AC and the battery is fully charged, diode functional, the RMS voltage at the battery should be about 22V (assuming this is a single-winding stator with no parts other than the coils).

To solve your problem (without knowing anything about this charging system!) my advice is: Make sure there isn't supposed to be a capacitor somewhere in it. Use a diode with at least 45V rating and as much current rating as you can find. Avoid running the machine with a bad diode, or you could damage something that ain't damaged yet.

#21

G

GoHardrGoHome

G

GoHardrGoHome

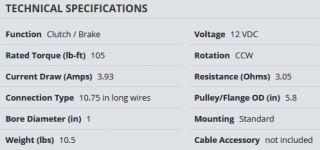

Ok, I went out and stripped back the shrink tube on the wiring and actually found two diodes connected in series. One very near the engine and the other about one foot away.

With the engine off, I checked both diodes individually and they only allow current in the direction of the battery. I tried to identify the diodes but only found numbers on Diode No. 2 (see attached diagram). With engine running at about 1/2 throttle, I then checked the voltage at the battery.

On the DC scale it was fluctuating between 2 and 15.5 VDC. I then decided to check it on AC scale just out of curiosity... 34 to 190 VAC!!

After running for about 5 minutes the diodes were very warm to the touch.

With the engine off, I checked both diodes individually and they only allow current in the direction of the battery. I tried to identify the diodes but only found numbers on Diode No. 2 (see attached diagram). With engine running at about 1/2 throttle, I then checked the voltage at the battery.

On the DC scale it was fluctuating between 2 and 15.5 VDC. I then decided to check it on AC scale just out of curiosity... 34 to 190 VAC!!

After running for about 5 minutes the diodes were very warm to the touch.

Attachments

#23

R

Richard Milhous

R

Richard Milhous

I'm no electrical engineer but I'm guessing at least one diode is fried like an egg. Keep in mind you can test them for resistance at 9V or whatever your tester supplies but the response may be non-linear. I.e., it looks fine on the tester but the 40V peak from the stator might blow right through.

I don't really know how meters measure AC or modulated DC voltage, but it's not simple to measure the effective (RMS) voltage. AC meter measurements on a non-sinusoidal or DC-biased voltage might be worthless.

It is quite possible the diodes are meant to dissipate a lot of heat, so that might be normal - but heat also reduces their service life.

I dunno for sure why this was designed to produce 28V AC RMS, but it's not improbable that a diode (or maybe even something else) has a dampening function: non-linear resistance, clamping, or more likely just ballast resistance. Otherwise the system is effectively operating at 22V RMS with the battery charged. Which is a lot, and might be to ensure the battery doesn't run dead if the engine is running slowly.

Why I think the diodes might be taking a lot of heat: Below is a graph of different theoretical systems. Each is offset by 30° for comparison. The black line shows a sinusoidal voltage at 28V RMS (approximately what your stator is cranking). The blue line shows the same curve interrupted by a perfect diode (infinite resistance in one direction, zero resistance in the other) with nothing else connected. The green line shows the voltage you would see from the same curve connected to a fully charged battery. The red line shows the same with the instantaneous voltage capped at 16.5V, which would produce a RMS voltage of 14.2 (I don't know how effective a multimeter is at reading RMS voltage for a pulsed DC circuit though).

The unlimited green curve would deliver about 27x the heat to a charged battery as the limited red curve, and about quadruple the power to a static load. My supposition is that something (probably one of the diodes) is supposed to limit the effective voltage.

If there are two diodes in series, there's a reason. Could this be aftermarket work? Or is it because they needed two diodes to handle the 40V peak voltage, and if one is fried the other will soon follow?

I don't really know how meters measure AC or modulated DC voltage, but it's not simple to measure the effective (RMS) voltage. AC meter measurements on a non-sinusoidal or DC-biased voltage might be worthless.

It is quite possible the diodes are meant to dissipate a lot of heat, so that might be normal - but heat also reduces their service life.

I dunno for sure why this was designed to produce 28V AC RMS, but it's not improbable that a diode (or maybe even something else) has a dampening function: non-linear resistance, clamping, or more likely just ballast resistance. Otherwise the system is effectively operating at 22V RMS with the battery charged. Which is a lot, and might be to ensure the battery doesn't run dead if the engine is running slowly.

Why I think the diodes might be taking a lot of heat: Below is a graph of different theoretical systems. Each is offset by 30° for comparison. The black line shows a sinusoidal voltage at 28V RMS (approximately what your stator is cranking). The blue line shows the same curve interrupted by a perfect diode (infinite resistance in one direction, zero resistance in the other) with nothing else connected. The green line shows the voltage you would see from the same curve connected to a fully charged battery. The red line shows the same with the instantaneous voltage capped at 16.5V, which would produce a RMS voltage of 14.2 (I don't know how effective a multimeter is at reading RMS voltage for a pulsed DC circuit though).

The unlimited green curve would deliver about 27x the heat to a charged battery as the limited red curve, and about quadruple the power to a static load. My supposition is that something (probably one of the diodes) is supposed to limit the effective voltage.

If there are two diodes in series, there's a reason. Could this be aftermarket work? Or is it because they needed two diodes to handle the 40V peak voltage, and if one is fried the other will soon follow?

Attachments

#24

G

GoHardrGoHome

G

GoHardrGoHome

Thanks very much for your input, Richard. If you're not an electrical engineer, you are definitely way above my pay grade on all of this!

I had the unit at a shop once to have a look at the issue and I don't know if they added an extra diode or what they did. I questioned them about it but the guy who worked on the mower doesn't work there anymore

I tried contacting B&S about the issue but was directed back to my local dealer. In the parts manual it only shows one diode so that is what is confusing me since the shop must have added a second one to the harness.

This is why, if there is a way to replace the diodes with a regulator rectifier, I would jump at the opportunity to buy one!

.... or, if someone could confidently direct me to exactly what was needed for diode(s) and tell me if they should be hooked up in series or parallel if more than one is required, then I'd buy some and get them installed.

B&S don't sell the diode as a separate part and I don't want to have to order a new stator in order to get the diode!

Thanks to all for your input

I had the unit at a shop once to have a look at the issue and I don't know if they added an extra diode or what they did. I questioned them about it but the guy who worked on the mower doesn't work there anymore

I tried contacting B&S about the issue but was directed back to my local dealer. In the parts manual it only shows one diode so that is what is confusing me since the shop must have added a second one to the harness.

This is why, if there is a way to replace the diodes with a regulator rectifier, I would jump at the opportunity to buy one!

.... or, if someone could confidently direct me to exactly what was needed for diode(s) and tell me if they should be hooked up in series or parallel if more than one is required, then I'd buy some and get them installed.

B&S don't sell the diode as a separate part and I don't want to have to order a new stator in order to get the diode!

Thanks to all for your input

#25

S

slomo

S

slomo

Someone needs to find the spec on the charging coil. Looking for rated amperage output spec.

That IN5406 diode is only rated at 3 amps of current. Hope this doesn't have disco headlights and ghetto blaster boom boxes on it.

Sounds like the wire protection is removed. Follow the charge wire with your fingers and your eyes. See if there is any form of wire damage.

I would keep any shrink wrap, plastic wire loom or electrical tape away from the diodes. Any covering will insulate the parts causing over heats leading to early parts failure.

Example. Someone finds the coil puts out 4 amps. Get an 8-15 amp rated diode.

Only need one or can parallel to keep part size down and handle more current.

That IN5406 diode is only rated at 3 amps of current. Hope this doesn't have disco headlights and ghetto blaster boom boxes on it.

Sounds like the wire protection is removed. Follow the charge wire with your fingers and your eyes. See if there is any form of wire damage.

I would keep any shrink wrap, plastic wire loom or electrical tape away from the diodes. Any covering will insulate the parts causing over heats leading to early parts failure.

Example. Someone finds the coil puts out 4 amps. Get an 8-15 amp rated diode.

Only need one or can parallel to keep part size down and handle more current.

#26

B

bertsmobile1

B

bertsmobile1

Well the current draw for a flat battery and an electric clutch would be well over 3 Amps .

However once again why?

Now one could strip & rewind a B & S stator if one was desperate but for all pracical purposes it is a waste of time.

It either works or it does not work.'The labour charge for faffing around, pulling a stator off, finding the short / broken wire then making a good repair is around 3 times the replacemnt part price .

We could break up the potting mix & repair all of the dead magneto coils as nearly all of them would have failed because the trigger was toasted but again 3 hours work to avaoid replacing a $ 20 part .

While it would be good for the environment ( if we disposed of the waste properly ) to repair them, it is not economically fesible .

Right now I have a box full of Power Torq coils that I am debating stripping down to fix because B & S jacked up the price to $ 180 wholesale to force people to toss out their old mowers & buy new ones .

However once again why?

Now one could strip & rewind a B & S stator if one was desperate but for all pracical purposes it is a waste of time.

It either works or it does not work.'The labour charge for faffing around, pulling a stator off, finding the short / broken wire then making a good repair is around 3 times the replacemnt part price .

We could break up the potting mix & repair all of the dead magneto coils as nearly all of them would have failed because the trigger was toasted but again 3 hours work to avaoid replacing a $ 20 part .

While it would be good for the environment ( if we disposed of the waste properly ) to repair them, it is not economically fesible .

Right now I have a box full of Power Torq coils that I am debating stripping down to fix because B & S jacked up the price to $ 180 wholesale to force people to toss out their old mowers & buy new ones .

#27

R

Richard Milhous

R

Richard Milhous

Unless this is a $100 part (and maybe even if it is), Bertsmobile is right. You don't know what the specs on the diode are supposed to be. I think there is probably supposed to be something moderating that voltage, and it's quite likely in the diode. Or could there be some other component buried in the stator that has failed? You could make it work by using a higher amp diode or putting a few in parallel like Slomo suggested, but if it fails you will be getting dirty voltage through your system.

A wiring diagram would be useful to see if there is supposed to be a ballast resistor somewhere.

A wiring diagram would be useful to see if there is supposed to be a ballast resistor somewhere.

#28

K

kh0432

K

kh0432

I replaced my in line diode with a regulator for a 5-9a charging system. Part # 491546. You can find them as cheap as $13 in aftermarket. I had installed a digital voltmeter on my mower and saw that the voltage would climb as high as 17V which I feel would be enough to eventually boil the battery dry. Most lawn mower batteries are maintenance free now and don't have caps to check the water. Maybe that's why they don't last long. Since putting on the regulator my voltage never goes above 14.1V. Keep in mind that the voltage is controlled by dumping some of the current to ground when the battery is fully charged. If you mount the regulator to something plastic make sure to run a ground wire from the mounting bolt to engine ground.

#29

T

Telesis

T

Telesis

A couple of things.... Based on the info you've provided, I believe your engine likely has the stator for a Tri-Circuit type alternator. I say this because it puts out 28VAC and has to provide more than 3A. If it was just the simple DC 3amp output type, as Bert said, this couldn't be used on a machine with an electric clutch PTO. The Tri-Circuit system puts out a total of 9-10 amps, but typically uses two 5amp circuits. The single black wire from the stator goes to a connector. The other side of the connector goes to 2 diodes. Each diode powers part of the total load, hence keeping things manageable. Having said that, how does this relate to what you actually have?

First, I am unaware of a single B&S alternator system that ever uses diodes in series. Clearly someone has "fat fingered" your system. The only time one ever puts diodes in series is to double the voltage rating. It does nothing for the current rating. No need for this in a small engine environment as higher PIV(peak inverse voltage) diodes are readily available. Also for those that mentioned it, NEVER place diodes in parallel unless a series dropping resistor is used in series with each diode. (This is because the voltage drop across a conducting silicon diode is approximately 0.6 volts and rarely are two diodes exactly the same. The one with the higher drop will 'fight' the other one, kind of like connecting two batteries with different voltages in parallel) You'll never have to do this in the small engine world! [I am an electrical engineer FWIW :-]

Your original post asked the question about replacing the diode(s) with a regulator. Well you can with Briggs part number 794360 regulator/rectifier. Knock-offs on Amazon are < $20. Better choice than a diode for heat sinking reasons(not electrical reasons). [take a look at the B&S Engine Alternator Repower Guide to learn everything you'll need to know and then some about their various stator and alternator types, color codes, specs, etc. I find it invaluable!]

(Richard, these small engine systems don't use caps for 'smoothing' like a conventional linear power supply. They rely on the fact that the battery itself behaves like big fat cap. Likewise, there are no ballast resistors or other components like that. These systems are simple. AC voltage is sourced from the stator that may be used directly or rectified by a diode or rectified/regulated by a 'module'. That's it. Take a look at the Repower Guide I mentioned above. It's a great resource!)

Good luck!

First, I am unaware of a single B&S alternator system that ever uses diodes in series. Clearly someone has "fat fingered" your system. The only time one ever puts diodes in series is to double the voltage rating. It does nothing for the current rating. No need for this in a small engine environment as higher PIV(peak inverse voltage) diodes are readily available. Also for those that mentioned it, NEVER place diodes in parallel unless a series dropping resistor is used in series with each diode. (This is because the voltage drop across a conducting silicon diode is approximately 0.6 volts and rarely are two diodes exactly the same. The one with the higher drop will 'fight' the other one, kind of like connecting two batteries with different voltages in parallel) You'll never have to do this in the small engine world! [I am an electrical engineer FWIW :-]

Your original post asked the question about replacing the diode(s) with a regulator. Well you can with Briggs part number 794360 regulator/rectifier. Knock-offs on Amazon are < $20. Better choice than a diode for heat sinking reasons(not electrical reasons). [take a look at the B&S Engine Alternator Repower Guide to learn everything you'll need to know and then some about their various stator and alternator types, color codes, specs, etc. I find it invaluable!]

(Richard, these small engine systems don't use caps for 'smoothing' like a conventional linear power supply. They rely on the fact that the battery itself behaves like big fat cap. Likewise, there are no ballast resistors or other components like that. These systems are simple. AC voltage is sourced from the stator that may be used directly or rectified by a diode or rectified/regulated by a 'module'. That's it. Take a look at the Repower Guide I mentioned above. It's a great resource!)

Good luck!

#30

StarTech

StarTech

Oh well I reckon I didn't repair an Ariens Zoom 34 last year with Warner 5219-120 electric PTO that had a 3 amp dual circuit stator then. But yes 3 amp stator can be used with an electric PTO; just depends PTO amp draw. Actually the Ariens was also powering the anti fire solenoid at the same time too.as Bert said, this couldn't be used on a machine with an electric clutch PTO.

#31

D

dave.cooper40

D

dave.cooper40

Hello, Diodes rarely act like you're describing. They either work or don't work. What your describing could be a loose connection or intermittent short like a wire touching the frame. The coil could also have an intermittent short that happens when it gets hot.

#32

T

Telesis

T

Telesis

Oh I believe you did Star. I'm curious based on what you've seen in your shop, if you see that as the exception more than the rule. IOW, do you see many low (3A) alternator systems on machines with PTOs? That PTO is spec'd at 3 ohms which means it's pulling 4 amps@12v(fuel solenoid is a fraction of that). That is at the high end of the alternator's capability. Amazing that that machine can charge the battery and power the PTO effectively at the same time (that pesky Kirchoff's current law) but it does! I believe it's because it charges the battery during the peak of the half cycle where the alternator is supplying both charging current INTO the battery and current OUT to the PTO and the moment the voltage drops back down to a certain point close to the battery voltage, the battery current reverses and it outputs current to the PTO. So the stator and diode are not continuously supplying 4amps and you can push the limits. I would appreciate a design with a little more headroom! <since I've gotten flamed for this before, I'm talking conventional current flow!>

FWIW....

FWIW....

#33

R

Richard Milhous

Ruh Roh. I am planning to do that on a trailer brake controller powered by the brake light circuit. I realized I needed a bypass (don't want to lose the brakes if the brakelight switch fails) and that if the brake lights had a short it would just blow the fuse on the bypass and... oops. I figured to isolate the circuits with two diodes in parallel for redundancy because I also don't want even a momentary unexpected brake fail if a diode gives up.

Would it work to match the diodes by their voltage drop at a known current?

R

Richard Milhous

Also for those that mentioned it, NEVER place diodes in parallel unless a series dropping resistor is used in series with each diode. (This is because the voltage drop across a conducting silicon diode is approximately 0.6 volts and rarely are two diodes exactly the same. The one with the higher drop will 'fight' the other one, kind of like connecting two batteries with different voltages in parallel)

Ruh Roh. I am planning to do that on a trailer brake controller powered by the brake light circuit. I realized I needed a bypass (don't want to lose the brakes if the brakelight switch fails) and that if the brake lights had a short it would just blow the fuse on the bypass and... oops. I figured to isolate the circuits with two diodes in parallel for redundancy because I also don't want even a momentary unexpected brake fail if a diode gives up.

Would it work to match the diodes by their voltage drop at a known current?

#34

G

GoHardrGoHome

G

GoHardrGoHome

Slomo, I've tried to identify the stator I have from the B&S Alternator Specifications sheet. I know it only has one wire, but to positively identify it from the B&S sheet is a bit confusing! Even the dealer wasn't positive.

Richard,... as I stated earlier, this engine is in a Grasshopper zero turn mower. Grasshopper doesn't have a very good wiring diagram for the electrical system. It does however show a single wire coming from the stator, going to a diode and then directly back to a fuse panel that is connected to the battery. It does not show any other regulating device in the diagram.

Telesis, thanks for your input. It likely annoys you to read how DIYer's like myself are trying to fix something they know little about, but I've already had the unit to a shop and spent money on labor and "experimental parts" that they recommended!

Telesis, I will take your advise and order the regulator/rectifier and post back with the results.

Glad to see that my posts have intrigued everyone to contribute. I really do appreciate your input.

Richard,... as I stated earlier, this engine is in a Grasshopper zero turn mower. Grasshopper doesn't have a very good wiring diagram for the electrical system. It does however show a single wire coming from the stator, going to a diode and then directly back to a fuse panel that is connected to the battery. It does not show any other regulating device in the diagram.

Telesis, thanks for your input. It likely annoys you to read how DIYer's like myself are trying to fix something they know little about, but I've already had the unit to a shop and spent money on labor and "experimental parts" that they recommended!

Telesis, I will take your advise and order the regulator/rectifier and post back with the results.

Glad to see that my posts have intrigued everyone to contribute. I really do appreciate your input.

#35

StarTech

But some reason the Warner actually pulls less than the spec'd amount and had a resistance closer to 4 ohms.

As for PTO operation I believe they using the battery on valleys and letting stator recharge on the peaks pulses. It seems to work fine as the average DC current is with specs of the stator. With 1800 pulses per minutes (30 per sec) the magnetic field doesn't seen to drop out too much as it take less hold the clutch engaged once it engaged much like a relay can have less holding current and still stay pulled in.

StarTech

You and me both as I like at least a 50% surplus but that is what Ariens supplied with that mower. So it is possible but not recommended. Most PTO systems I see usually have at least a 10 amp rated stator.Oh I believe you did Star. I'm curious based on what you've seen in your shop, if you see that as the exception more than the rule. IOW, do you see many low (3A) alternator systems on machines with PTOs? That PTO is spec'd at 3 ohms which means it's pulling 4 amps@12v(fuel solenoid is a fraction of that). That is at the high end of the alternator's capability. Amazing that that machine can charge the battery and power the PTO effectively at the same time (that pesky Kirchoff's current law) but it does! I believe it's because it charges the battery during the peak of the half cycle where the alternator is supplying both charging current INTO the battery and current OUT to the PTO and the moment the voltage drops back down to a certain point close to the battery voltage, the battery current reverses and it outputs current to the PTO. So the stator and diode are not continuously supplying 4amps and you can push the limits. I would appreciate a design with a little more headroom! <since I've gotten flamed for this before, I'm talking conventional current flow!>

FWIW....

But some reason the Warner actually pulls less than the spec'd amount and had a resistance closer to 4 ohms.

As for PTO operation I believe they using the battery on valleys and letting stator recharge on the peaks pulses. It seems to work fine as the average DC current is with specs of the stator. With 1800 pulses per minutes (30 per sec) the magnetic field doesn't seen to drop out too much as it take less hold the clutch engaged once it engaged much like a relay can have less holding current and still stay pulled in.

#36

Boudreaux In Eunice La.

Boudreaux In Eunice La.

Star Tech has put the correct diode info on here ..... Some 1 wire units use the 1 amp Such as 1N4002 and then the larger stators use the 3 amp as shown in the DATA sheet which would be the 1N5401........ If your diodes keep blowing then something is wrong in the stator or your coils .....

#37

T

Telesis

T

Telesis

GoHard, what color is the wire from the stator? If it is a 3A DC system then the wire color would be red(usually) and the original wire would have had the diode in line right at the connector and the connector itself would(usually) be red. If it's one of the higher current output stators(5A, 9A, TriCircuit) then (usually) the wire from the stator is black with a green connector. I realize given the age of your machine that the original connector may be long gone!

Finally, when you replaced the diode due to damage(from your first post), did you identify and repair the cause of the original damage? Diodes rarely fail on their own. Typical failure mode is short or open due to overcurrent.

Let us know!

Finally, when you replaced the diode due to damage(from your first post), did you identify and repair the cause of the original damage? Diodes rarely fail on their own. Typical failure mode is short or open due to overcurrent.

Let us know!

#38

G

GoHardrGoHome

G

GoHardrGoHome

The wire from the stator is black and used to have a green connector. When I originally said it was "damaged", I didn't elaborate on the whole story....the damn connector kept coming apart for me so I decided to fix it. I cut out the old one and soldered in a new connector not realizing that I threw away a diode! The loose connector problem only escalated when I decided to fix it!

The second diode was installed by a local shop that was supposed to have more knowledge on this than I have

I've got a regulator rectifier on order.

The second diode was installed by a local shop that was supposed to have more knowledge on this than I have

I've got a regulator rectifier on order.

#39

VRR.DYNDNS>BIZ

VRR.DYNDNS>BIZ

No, The opposite. The Battery is frying the system. Batteries can have an intermittent internal single cell short. Additionally, the fuse might be over rated. The output is protected by a fuse that will protect the diode. The only other option is a short on the way to the fuse. An ac pressure on the battery does it good, not harm as it vibrates ions loose to improve battery condition as long as the reverse polarity due to a shorted diode, rather than an open diode, and the fuse protect the system from high current. This sometimes will cause the fuse to repeatedly fail, then people put in a higher fuse. The current output of the charging stator has a rating, and fuse should protect for that level if I were designing it, however, the parts list will usually tell the appropriate size. Replace your battery, replace the diode wire, insure the fuse is good, check the wires for shorts, and go mow.Agreed! I think I may have already fried a cell in my battery!

#40

G

GoHardrGoHome

G

GoHardrGoHome

The correct fuse is in place. The diode has been replaced twice. The battery was replaced this spring. I'm mowing but the charging system is not operating the way it was designed.No, The opposite. The Battery is frying the system. Batteries can have an intermittent internal single cell short. Additionally, the fuse might be over rated. The output is protected by a fuse that will protect the diode. The only other option is a short on the way to the fuse. An ac pressure on the battery does it good, not harm as it vibrates ions loose to improve battery condition as long as the reverse polarity due to a shorted diode, rather than an open diode, and the fuse protect the system from high current. This sometimes will cause the fuse to repeatedly fail, then people put in a higher fuse. The current output of the charging stator has a rating, and fuse should protect for that level if I were designing it, however, the parts list will usually tell the appropriate size. Replace your battery, replace the diode wire, insure the fuse is good, check the wires for shorts, and go mow.

#41

T

Telesis

T

Telesis

The good news is you have a 9 amp stator. The reg/rect you ordered will work fine with this stator. As said previously, just make sure when you mount it, you make a good ground connection with its case. Obviously, remove both diodes there now when you install it!

#43

G

GoHardrGoHome

G

GoHardrGoHome

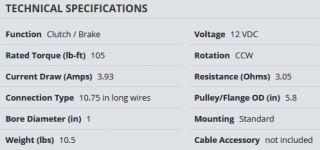

Amazon finally delivered the regulator rectifier. I would have at least expected a simple explanation of which wire goes to the stator! I assume the Red wire connects to battery power and the Yellow wire connects to the stator. Can anyone confirm this for me?

Attachments

#45

G

GoHardrGoHome

G

GoHardrGoHome

Thanks for the confirmation. Now I can get it installed and tested when I have a free moment.

#46

G

GoHardrGoHome

G

GoHardrGoHome

I got the regulator rectifier installed today. It works as it should. Normal voltage charging is happening! Thanks again for all the assistance.