When considering why a lawn mower crankshaft bends, it's first helpful to consider how much energy actually exists in the rotating blades. A 21-inch lawn mower blade tip moves at nearly 200 miles per hour! The mass of the blades rotating at 51 revolutions per second contains a substantial amount of energy. In fact, the kinetic energy of the rotating blades is roughly the same as dropping a 50 pound weight from a height of 17 feet. The problem comes when the blades contact an immovable object and are forced to stop suddenly. All this kinetic energy must dissipate, similar to the way it does when a race car hits a wall. Something is going to bend!

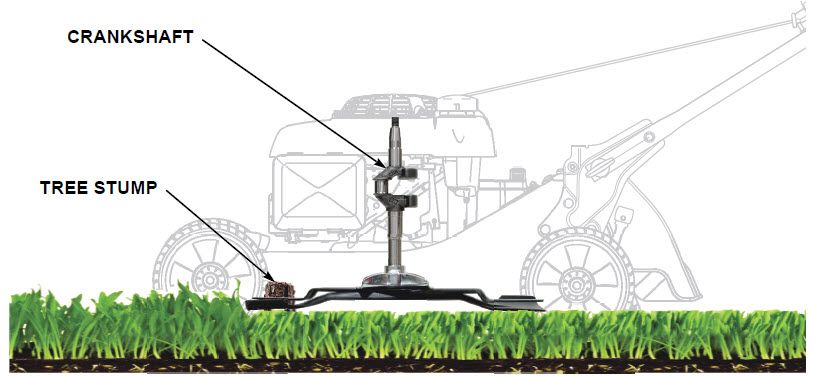

In the lawn mower's case, the energy is dissipated through the blades and the crankshaft. When the impact occurs, the crankshaft twists, but it also bends because the distance between the bottom of the engine and the lower end of the crankshaft creates a lever effect (moment arm), resulting in the torque that bends the crankshaft. This is important to consider because it means the crankshaft would still bend, even if the lawn mower were equipped with a shear key.

Incidents do occur, which is why the crankshaft and blades are designed to be strong and to withstand impact without breaking. But considering the amount of energy involved, it's simply not realistic to expect these components to incur no damage when impacting a solid or immovable object. Lawn mowers are designed to cut grass lawns not sprinklers, stumps, rocks, pipes, curbs, and other immovable objects. So prevent unfortunate incidents by taking some time before mowing to mark the location of any hidden immovable objects in the lawn. Also, be careful around curbs and terracing wall edges where a wheel of the mower could suddenly drop. We suggest that you push the mower around these obstructions and not use the drive control.