You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Vanguard V-twin wiring help please

#1

F

Fabrikater

F

Fabrikater

Hello everyone.

Newly joined today in the hope that there's someone out there who can help.

I have a Vanguard 16hp V-twin engine.( Model No; 303777) I bought it used. The wiring and cables were cut off by whoever removed it from whatever it was in. I believe a ride-on mower as it is the vertical crankshaft version with a twin belt pulley. So, not having any of the original loom and having no need for a keyswitch, lights, ancillary eqiuipment or safety switches, I aim aiming to wire a simple toggle power switch, with 'kill switch' tab, and pushbutton start. I've installed a single pole solenoid and cabling for battery connections.

I need to identify the severed cables left on the motor to be able to complete the wiring for starting, running and charging.

?

Cable controls do not present a problem. Electrics have never been my favorite thing

.

.

I have attached a photo showing the cables.

The two YELLOW wires come from the recifier(?) into a connector with two matching YELLOW cables.

The cable between the above two is solid RED and continues in solid RED after the connector.

The BLACK wire to the right is from the crankcase and changes to RED with BLACK trace after connector. (I believe this is the 'kill' wire)

Apparently, one of these has a diode in it but these two connectors seen normal, as in nothing special but any comment/info would be welcome as well as confirmation that this motor is negative earth..

Well, that's what I have, any help would be much appreciated.

Ian the Fabrikater.

Newly joined today in the hope that there's someone out there who can help.

I have a Vanguard 16hp V-twin engine.( Model No; 303777) I bought it used. The wiring and cables were cut off by whoever removed it from whatever it was in. I believe a ride-on mower as it is the vertical crankshaft version with a twin belt pulley. So, not having any of the original loom and having no need for a keyswitch, lights, ancillary eqiuipment or safety switches, I aim aiming to wire a simple toggle power switch, with 'kill switch' tab, and pushbutton start. I've installed a single pole solenoid and cabling for battery connections.

I need to identify the severed cables left on the motor to be able to complete the wiring for starting, running and charging.

?

Cable controls do not present a problem. Electrics have never been my favorite thing

I have attached a photo showing the cables.

The two YELLOW wires come from the recifier(?) into a connector with two matching YELLOW cables.

The cable between the above two is solid RED and continues in solid RED after the connector.

The BLACK wire to the right is from the crankcase and changes to RED with BLACK trace after connector. (I believe this is the 'kill' wire)

Apparently, one of these has a diode in it but these two connectors seen normal, as in nothing special but any comment/info would be welcome as well as confirmation that this motor is negative earth..

Well, that's what I have, any help would be much appreciated.

Ian the Fabrikater.

Attachments

#2

R

Rivets

R

Rivets

This manual should help you identify where each wire goes. https://www.briggsandstratton.com/c...a/en_us/Files/FAQs/alternator_replacement.pdf

#3

F

Fabrikater

BTW ... I am also a useless non qualfied, old school no nothing. Wierd isn't it.

Cheers and thanks again.

F

Fabrikater

Many thanks Rivets, willingness to help is still a welcome response. I'll delve into the manual later but it is likely I have already done that. The solution to a knowledgable person is definately in there somewhere but all manuals assume that the motor is in a 'normal' location as in a mower. Getting rid of unwanted curcuits would be easy enough if I had removed the motor myself but as it is I can't identify the purpose or estination for these 3 wires.This manual should help you identify where each wire goes. https://www.briggsandstratton.com/c...a/en_us/Files/FAQs/alternator_replacement.pdf

BTW ... I am also a useless non qualfied, old school no nothing. Wierd isn't it.

Cheers and thanks again.

#4

F

Fabrikater

F

Fabrikater

Hi Rivets. I have seen this manual before. None of the diagrams show or describe the wiring I have exactly. The regulator / rectifier I have is shown on page 16 but the 'one red lead' is described as 'connector output lead' and that it connects to ....'the equipment harness'. So not alot of help really as where on 'the harness' that connection is made is not stated.

FYI ..before posting my request for help I ended up asking Briggs and Stratton directly. Without going into details .... it was a complete, and frustrating waste of time.

FYI ..before posting my request for help I ended up asking Briggs and Stratton directly. Without going into details .... it was a complete, and frustrating waste of time.

#5

R

Rivets

R

Rivets

Your post is very confusing, as I assume you were asking how to wire a motor into your tractor. The manual I posted tells you where each of the engine wires is plugged into the tractor wiring. What I now think you are asking is, does anyone have a wiring diagram of my tractor, so I can wire in a different engine. If I am correct, this is totally different than your original post. I you are looking for a wiring diagram for you tractor we are going to need a tractors model and serial numbers, as each manufacturer uses their own systems. They are not universal. Also, with your extremely limited knowledge of electrical wiring on these types of units, it will be hard to explain to you which wire goes where, plus wiring color codes on small equipment are constantly being changed, which drives even experienced techs to drink.

#7

F

Fabrikater

F

Fabrikater

I'm sorry that you find my post confusing. Perhaps you will let me clarify.

The motor, I believe, is originally from a mower, as it is a vertical shaft model with a double belt pulley. (as I said).

I have no way of knowing what the original make or model of mower it was. (to find a wiring diagram)

Imagine for yourself that a friend gave you a motor that was running when removed and you want to use it for a gokart for example.

I am not installing it in another mower. I won't be using a 5 or 6 pole key switch, nor lights, horn, or any safety switches.

Referring to the diagram in your reply, would you agree that if the wires shown as being connected to terminals 4 (black) & 5 )red) on the keyswitch were connected to a toggle switch there would be a viable circuit for ignition and starter. The red cable is easily visible in my photo and I think the one with a black trace id for lights etc. My lack of knowledge leaves me unaware as to whether that is all that will be required to ensure charging once running.

Sorry again for being such a dumbass non-electrician, I was feeling I was one amongst many who needed a bit of specialist help and experience. Maybe I'm dumber than I thunk I wos.

The motor, I believe, is originally from a mower, as it is a vertical shaft model with a double belt pulley. (as I said).

I have no way of knowing what the original make or model of mower it was. (to find a wiring diagram)

Imagine for yourself that a friend gave you a motor that was running when removed and you want to use it for a gokart for example.

I am not installing it in another mower. I won't be using a 5 or 6 pole key switch, nor lights, horn, or any safety switches.

Referring to the diagram in your reply, would you agree that if the wires shown as being connected to terminals 4 (black) & 5 )red) on the keyswitch were connected to a toggle switch there would be a viable circuit for ignition and starter. The red cable is easily visible in my photo and I think the one with a black trace id for lights etc. My lack of knowledge leaves me unaware as to whether that is all that will be required to ensure charging once running.

Sorry again for being such a dumbass non-electrician, I was feeling I was one amongst many who needed a bit of specialist help and experience. Maybe I'm dumber than I thunk I wos.

#8

R

Rivets

R

Rivets

Ok, as a retired instructor I have to give this one more try, to lead this child through the electrical forest of how to wire an engine into a circuit. I know I’m going to get $./#@ for doing it this way, but at th end those that hate me go to the back of the line. You’re not alone.

First I’m going to make some assumptions which will probably come back to bite me.

1. This person has very little or no clue how engine electrical circuits work.

2. This person is going to question any suggests or answers because he’s made his assumptions fact.

3. This person wants to do as little as possible on his own to figure out the problem.

4. This engine was removed from another piece of equipment.

5. We have no clue why this person wants to wire in a starting and charging systems only.

6. In the picture this person provided, it looks like there is a three terminal starter solenoid mounted to the frame.

7. From all information I can glean from this person’s posts the battery will not be mounted on the framer that the solenoid is mounted to. If I am wrong these instructions will NOT solve the problem, so DO NOT use my instructions.

8. Finally, I hope this person can follow instructions.

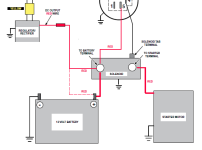

To the OP, I hope that I can dummy this down enough for your brain to understand. I have provided a manual (which is probably too technical for you brain) to help you identify the components you will be working with. Star has provided you a diagram of how to wire in the basic starting and charging circuits. Steps to accomplish this task.

1. Seeing that you don’t like the key switch system Star posted, you will need to purchase and have on hand the following components, connectors, and tools.

A. 6 or 8 gauge battery cables, negative and positive with terminal ends the same size as the large solenoid terminals. You will also need a short cable this size to go from the starter solenoid to the starter.

B. One small spool each of red or black 12 gauge stranded wire.

C. Various wire connectors to attach wire to components.

D. One spring loaded SPST switch to install in the starting circuit.

E, One SPST switch to install in the kill circuit.

F. An electrical crimping tool.

Lets get started with the kill circuit.

1. Remove the shroud and trace the black wire to a component. I’m assuming it will be the coil, but you need to verify.

2. Disconnect the bullet connector from the black wire.

3. Install a new small black wire with the appropriate bullet connector on one end to this wire.

4. On the other end of this wire attach an appropriate connector so it can be attached to the kill switch.

5. Make a second small black wire with appropriate connectors to connect between the kill switch and the frame. Attach this setup and you have completed the kill system.

Now the starting circuit. Refer to the illustration Star provided.

1. Attach the positive battery cable to one of the large terminals on the starting solenoid.

2. Make a 12 gauge red wire lead to go from the large terminal on the solenoid you attached the positive battery wire to the SPST spring loaded switch. Will have a bullet connector on one end and a spade or ring connector on the other.

3. Make up a second red wire lead to go from the starter switch to the small terminal on the starter solenoid, with appropriate connectors. See Star’s diagram.

Now the charging circuit.

1. Disconnect the red bullet connector from the the red wire on the voltage regulator, look at your picture.

2. Make up a second red wire lead to go from the volt regulator connector to the large terminal on the starter solenoid where you attach the positive battery cable, with appropriate connectors. See Star’s diagram.

Now attach the negative battery cable to the frame you have mounted the engines to. Your wiring should now look like the diagram Star post, with the addition of a kill circuit because you don’t lke a key switch.

Hopefully you can handle this, but I have my reservations. Personally I would not attempt doing this with your limited knowledge of electrical systems and circuitry, but unless I posted what it involves you would have just blown it off. WARNING, not understanding how these circuits work together or incorrect wiring can result in blown components and/or injury. You can starter hating and insulting me now.

First I’m going to make some assumptions which will probably come back to bite me.

1. This person has very little or no clue how engine electrical circuits work.

2. This person is going to question any suggests or answers because he’s made his assumptions fact.

3. This person wants to do as little as possible on his own to figure out the problem.

4. This engine was removed from another piece of equipment.

5. We have no clue why this person wants to wire in a starting and charging systems only.

6. In the picture this person provided, it looks like there is a three terminal starter solenoid mounted to the frame.

7. From all information I can glean from this person’s posts the battery will not be mounted on the framer that the solenoid is mounted to. If I am wrong these instructions will NOT solve the problem, so DO NOT use my instructions.

8. Finally, I hope this person can follow instructions.

To the OP, I hope that I can dummy this down enough for your brain to understand. I have provided a manual (which is probably too technical for you brain) to help you identify the components you will be working with. Star has provided you a diagram of how to wire in the basic starting and charging circuits. Steps to accomplish this task.

1. Seeing that you don’t like the key switch system Star posted, you will need to purchase and have on hand the following components, connectors, and tools.

A. 6 or 8 gauge battery cables, negative and positive with terminal ends the same size as the large solenoid terminals. You will also need a short cable this size to go from the starter solenoid to the starter.

B. One small spool each of red or black 12 gauge stranded wire.

C. Various wire connectors to attach wire to components.

D. One spring loaded SPST switch to install in the starting circuit.

E, One SPST switch to install in the kill circuit.

F. An electrical crimping tool.

Lets get started with the kill circuit.

1. Remove the shroud and trace the black wire to a component. I’m assuming it will be the coil, but you need to verify.

2. Disconnect the bullet connector from the black wire.

3. Install a new small black wire with the appropriate bullet connector on one end to this wire.

4. On the other end of this wire attach an appropriate connector so it can be attached to the kill switch.

5. Make a second small black wire with appropriate connectors to connect between the kill switch and the frame. Attach this setup and you have completed the kill system.

Now the starting circuit. Refer to the illustration Star provided.

1. Attach the positive battery cable to one of the large terminals on the starting solenoid.

2. Make a 12 gauge red wire lead to go from the large terminal on the solenoid you attached the positive battery wire to the SPST spring loaded switch. Will have a bullet connector on one end and a spade or ring connector on the other.

3. Make up a second red wire lead to go from the starter switch to the small terminal on the starter solenoid, with appropriate connectors. See Star’s diagram.

Now the charging circuit.

1. Disconnect the red bullet connector from the the red wire on the voltage regulator, look at your picture.

2. Make up a second red wire lead to go from the volt regulator connector to the large terminal on the starter solenoid where you attach the positive battery cable, with appropriate connectors. See Star’s diagram.

Now attach the negative battery cable to the frame you have mounted the engines to. Your wiring should now look like the diagram Star post, with the addition of a kill circuit because you don’t lke a key switch.

Hopefully you can handle this, but I have my reservations. Personally I would not attempt doing this with your limited knowledge of electrical systems and circuitry, but unless I posted what it involves you would have just blown it off. WARNING, not understanding how these circuits work together or incorrect wiring can result in blown components and/or injury. You can starter hating and insulting me now.

#9

F

Fabrikater

F

Fabrikater

What were you an instructor of? Was it incivility with an added course on discourtesy? I'm amazed that you could be motivated to write all that you have making a point of taking every opportunity to be rude and insulting. You're probably too set in your ways to learn that we can't all be experts in everything as you obviously believe yourself to be. It's a shame that such a site can be marred by coming across somebody like you. If there is a moderator then you should be barred. I wouldn't follow your guidance now as, given your disclaimer, it wouldn't surprise me if you have designed in a fault to damage one of the components. I can't think what you are actually on this site for ... maybe you miss instructing people and being listened to. Sad really.

#10

F

Fabrikater

Hello, I am sorry for not noticing that the diagram had come from you. As there was no message it looked like it was at the end of Rivets reply. If you are following this post you will see the latest communications with Rivets.

True to say that your diagram is the most useful piece of information I have received. Due to Rivets abusive tone I will not be pursuing this matter further on this site. Thanks for your help.

F

Fabrikater

Hello, I am sorry for not noticing that the diagram had come from you. As there was no message it looked like it was at the end of Rivets reply. If you are following this post you will see the latest communications with Rivets.

True to say that your diagram is the most useful piece of information I have received. Due to Rivets abusive tone I will not be pursuing this matter further on this site. Thanks for your help.

#11

StarTech

StarTech

Well with over different 303777 out there it kinda hard to know if it has a carburetor solenoid (which most likely it does). With this in mind a three position five terminal key switch would the easiest way to wire this up. As you need to power the carb solenoid during start up and running but only need the ground out the ignition coil to stop.

The problem I don't know which OEM PN would be the Indak 4G463A switch which is the smallest profile switch.

The problem I don't know which OEM PN would be the Indak 4G463A switch which is the smallest profile switch.

#12

R

Rivets

R

Rivets

I taught automotive and small engine repair for 30+ years, plus have worked on small engine for 50+ years, I think I know what I’m talking about. I assure you I would never put anything in my procedures which will intentionally harm anyone or equipment. I expected the reply you posted, because I knew you. Wanted someone to take your hand and do the work for you. Your limited understanding of electricity and attitude impedes your ability to accomplish this project. The moderators do not bar members for posting the truth and you are not the first to say I’m full of ——— and shouldn’t be allowed n this site, because they can’t get the exact information they want. Most of the time it is DIY guys who think they know enough about electricity to be dangerous. The experienced techs have enough work in their businesses, that they don’t have time to step by step lead you through a solution. Star and I have given you more than enough information to solve your problem, it’s up to you as to how you use it. As I say to my wife, “You are right again, I’ll be in the shop if you need me”. Bye, bye bye.

#13

F

Fabrikater

I do understand that each wiring circuit will be specific to the particular model. Are the other details from the engine plate (Type & Code) any use?

From Youtube images it does not appear to have a carb solenoid and no other wires than those in my photo. Others, again on Youtube, have removed the original harness from a tractor or mower and wired a system exactly as I want to. Unfortunalely non of then are exactly the same as mine.

As far as a 'kill' swith goes, I have a toggle switch for the power (ignition) with a cover that has to be lifted to switch on and cuts the power when pushed back down. (very common).

FYI. In preparing the cables I can tell that the soolid red wire from the rectifier is a heavier cable than the red with black trace so most likely power and lighting.

This project is to power a machine, not a vehicle.. Already built and proven but bogged down with an 8hp so I need more power. When I've got this motor in it I'll post a video (if that's possible).

Thanks again.

F

Fabrikater

Hi Star Tech. Thanks for 'staying with me'.Well with over different 303777 out there it kinda hard to know if it has a carburetor solenoid (which most likely it does). With this in mind a three position five terminal key switch would the easiest way to wire this up. As you need to power the carb solenoid during start up and running but only need the ground out the ignition coil to stop.

The problem I don't know which OEM PN would be the Indak 4G463A switch which is the smallest profile switch.

I do understand that each wiring circuit will be specific to the particular model. Are the other details from the engine plate (Type & Code) any use?

From Youtube images it does not appear to have a carb solenoid and no other wires than those in my photo. Others, again on Youtube, have removed the original harness from a tractor or mower and wired a system exactly as I want to. Unfortunalely non of then are exactly the same as mine.

As far as a 'kill' swith goes, I have a toggle switch for the power (ignition) with a cover that has to be lifted to switch on and cuts the power when pushed back down. (very common).

FYI. In preparing the cables I can tell that the soolid red wire from the rectifier is a heavier cable than the red with black trace so most likely power and lighting.

This project is to power a machine, not a vehicle.. Already built and proven but bogged down with an 8hp so I need more power. When I've got this motor in it I'll post a video (if that's possible).

Thanks again.

#14

F

Fabrikater

F

Fabrikater

I taught automotive and small engine repair for 30+ years, plus have worked on small engine for 50+ years, I think I know what I’m talking about. I assure you I would never put anything in my procedures which will intentionally harm anyone or equipment. I expected the reply you posted, because I knew you. Wanted someone to take your hand and do the work for you. Your limited understanding of electricity and attitude impedes your ability to accomplish this project. The moderators do not bar members for posting the truth and you are not the first to say I’m full of ——— and shouldn’t be allowed n this site, because they can’t get the exact information they want. Most of the time it is DIY guys who think they know enough about electricity to be dangerous. The experienced techs have enough work in their businesses, that they don’t have time to step by step lead you through a solution. Star and I have given you more than enough information to solve your problem, it’s up to you as to how you use it. As I say to my wife, “You are right again, I’ll be in the shop if you need me”. Bye, bye bye.

As I say to my wife, “You are right again,.......... " So your wife was right about something?? and you acknowledged it ?

#15

R

Rivets

R

Rivets

Yes, she says “don’t let dummies stop you from helping those who are willing to say I’m in over my head. They will assume that those trying to help are smarter than they are. Not questioning what they are told.”

#16

F

Fabrikater

F

Fabrikater

Strange that you feel comfortable admitting and ask folk to make allowances, with a disclaimer, that you are "not a professional mechanic" even though you claim to have been an instructor and teaching a skill you were not qualified for, you will not forgive my admission in my first post saying; "Electrics have never been my favorite thing

"

"