You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Stuck tire

#1

T

T.H. Hill

T

T.H. Hill

I'm having an issue with my T1200 craftsman mower. It started with it not wanting to go in to reverse and it eventually got to the point where I had no brakes and when I put it into gear it would start to creep forward even with the clutch/ brake pedal down. I think I've isolated the problem to where the clutch/ brake linkage engage behind the right rear tire. So..... the problem I have now is that I can't seem to get that tire off. I've tried everything from spraying it down with penetrating oil to beating on the back of the rim with a piece of angle iron and a heavy hammer and it won't budge. It looks like it had a keeper on the rim at one time but it's been replaced with just a washer. Any ideas on how to get the rim off so I can get a better look at what's going on with the linkage?

Attachments

#2

StarTech

StarTech

Okay penetrating oil will not work period. The oil swells the dirt and rust forming a seal off area.

Try this instead provided you have not beating beating the shaft where the screw goes.

Try this instead provided you have not beating beating the shaft where the screw goes.

- Get a schedule 40 3/4 PCV coupler.

- Cut it nearly in nearly leaving leave the center stop intact.

- Now here is the tricky and heat maybe needed, drive the end with the stop ring on the rim standoff. Heat will soften the plastic but use no more necessary. You are wanting a very tight fit.

- Turn rim and if necessary the mower up where this becomes a cup.

- Fill with with 2 cycle fuel mix and let soak in. You may need to refill the cup a few times.

- This usually loosen the rust up.

- If this don't work the last resort is to try Muriatic Acid. It will eat away the rust. Just got get the past swelled rust area. Careful don't breathe the fumes. It can take your breathe away. Also don't get it on anything aluminum. Once the rim is off neutralize the acid with water and immediately oil things to prevent flash rusting.

#3

sgkent

sgkent

If you can find an inexpensive replacement rim, you can always Sawzall the wheel to make a slit, then pry to widen the slit and pull it off.

As to your original problem. Have you checked the brake pads and cable / bar tension? Lots of mowers use a pad that wears, and when it does the belt geometry and behavior changes. Sometimes it will cause slippage, sometimes it will fail to brake the pulleys.

As to your original problem. Have you checked the brake pads and cable / bar tension? Lots of mowers use a pad that wears, and when it does the belt geometry and behavior changes. Sometimes it will cause slippage, sometimes it will fail to brake the pulleys.

#4

A

Auto Doc's

You already have another posting for this same machine. Why a new posting? That creates confusion for the folks trying to help you.

Please try to show continuity by only having one posting per machine you need help with.

On to the reply....

A homemade solvent mix I have used for year as a technician is a 50/50 mix of transmission fluid and Acetone.

You mix it in a small steel container with a screw on top and only use a little at a time. Acetone evaporates quickly by itself, but when mixed with transmission fluid it slows down the evaporation and thins the transmission fluid so it can creep into the tightest rusted parts easily.

This shop "mixture" was around long before the convenient trash they sell in spray cans today.

A

Auto Doc's

Hello T.,I'm having an issue with my T1200 craftsman mower. It started with it not wanting to go in to reverse and it eventually got to the point where I had no brakes and when I put it into gear it would start to creep forward even with the clutch/ brake pedal down. I think I've isolated the problem to where the clutch/ brake linkage engage behind the right rear tire. So..... the problem I have now is that I can't seem to get that tire off. I've tried everything from spraying it down with penetrating oil to beating on the back of the rim with a piece of angle iron and a heavy hammer and it won't budge. It looks like it had a keeper on the rim at one time but it's been replaced with just a washer. Any ideas on how to get the rim off so I can get a better look at what's going on with the linkage?

You already have another posting for this same machine. Why a new posting? That creates confusion for the folks trying to help you.

Please try to show continuity by only having one posting per machine you need help with.

On to the reply....

A homemade solvent mix I have used for year as a technician is a 50/50 mix of transmission fluid and Acetone.

You mix it in a small steel container with a screw on top and only use a little at a time. Acetone evaporates quickly by itself, but when mixed with transmission fluid it slows down the evaporation and thins the transmission fluid so it can creep into the tightest rusted parts easily.

This shop "mixture" was around long before the convenient trash they sell in spray cans today.

#5

StarTech

And use anti seize when installing either the removed rim or a new rim. They can get sticky too but once the mixture get in there and dissolved the grease part of the anti seize they come off fairly easy.

StarTech

Even using the 50/50 mix you got to it in there which the coupler cup I describe would do as you need very, very, deep penetration. This is because these rims can be rusted all the way front to back.Hello T.,

You already have another posting for this same machine. Why a new posting? That creates confusion for the folks trying to help you.

Please try to show continuity by only having one posting per machine you need help with.

On to the reply....

A homemade solvent mix I have used for year as a technician is a 50/50 mix of transmission fluid and Acetone.

You mix it in a small steel container with a screw on top and only use a little at a time. Acetone evaporates quickly by itself, but when mixed with transmission fluid it slows down the evaporation and thins the transmission fluid so it can creep into the tightest rusted parts easily.

This shop "mixture" was around long before the convenient trash they sell in spray cans today.

And use anti seize when installing either the removed rim or a new rim. They can get sticky too but once the mixture get in there and dissolved the grease part of the anti seize they come off fairly easy.

#6

T

T.H. Hill

T

T.H. Hill

If you can find an inexpensive replacement rim, you can always Sawzall the wheel to make a slit, then pry to widen the slit and pull it off.

As to your original problem. Have you checked the brake pads and cable / bar tension? Lots of mowers use a pad that wears, and when it does the belt geometry and behavior changes. Sometimes it will cause slippage, sometimes it will fail to brake the pulleys.

#7

T

T.H. Hill

T

T.H. Hill

I've only had the mower for a couple of weeks so I don't know much about it. It started by having issues trying to shift from forward to reverse then progressed to where I had no brakes and it would creep forward when it was in gear. After looking at it, it looked like the issue was with the linkage that runs from the clutch/ brake peddle back to the transmission. Now I'm stuck because I can't get the rear tire off to see what's going on. I don't want to ruin a rim if I can help it. I might check with a local parts store to see if they have something that can loosen the rust. I've also seen where an 8" gear can be used to pry the wheel off but that involves taking all of the air out of the tire in order to get the gear puller on.

#8

T

T.H. Hill

T

T.H. Hill

Even using the 50/50 mix you got to it in there which the coupler cup I describe would do as you need very, very, deep penetration. This is because these rims can be rusted all the way front to back.

And use anti seize when installing either the removed rim or a new rim. They can get sticky too but once the mixture get in there and dissolved the grease part of the anti seize they come off fairly easy.

#9

T

T.H. Hill

T

T.H. Hill

Sorry but the new posting was about a different problem I was having with that mower. I thought that might be less confusing

#10

StarTech

Just one warning leave the wife's acetone alone and get your own or its a frying pan up aside your head.

StarTech

I agree that most of the so call penetrating sprays are just junk. I tried many of claiming to remove rust and none as far works as advertise. And I do have more success with the 50/50 acetone and transmission mix. The problem with acetone it will damage paint. Currently trying a highly recommend Kroil but on first few projects it has failed to live up to its advertising too. So far it has been a waste of $35. Now on mildly struck screws it works works better than the others I tried.A homemade solvent mix I have used for year as a technician is a 50/50 mix of transmission fluid and Acetone.

You mix it in a small steel container with a screw on top and only use a little at a time. Acetone evaporates quickly by itself, but when mixed with transmission fluid it slows down the evaporation and thins the transmission fluid so it can creep into the tightest rusted parts easily.

This shop "mixture" was around long before the convenient trash they sell in spray cans today.

Just one warning leave the wife's acetone alone and get your own or its a frying pan up aside your head.

#11

R

Rivets

R

Rivets

I’ve had success with a mixture of kerosene and antifreeze. Was shown to me by my grandfather on the farm. Don’t know why it works, but you have to soak it for about 6 hours.

#13

T

T.H. Hill

T

T.H. Hill

LOL soooooo on to my next installment of the process to fix this thing. After failed attempts to get the back wheel off, I started to look forward to where the clutch/ brake linkage connects to the peddle. As soon as I got this thing I noticed the clutch peddle was really far forward and difficult to reach. I'm 5'8" so I'm sure Craftsman (or whoever makes these things) intended for someone my height could use these and not someone 6'2". So I started thinking maybe there is an adjustment up front and no need to mess with the rear wheel at this time. I found two bolts under the clutch peddle and it looked like I could make an adjustment from there. I loosened the two bolts and tried to maneuver the plate behind the bolts as best I could (of course I have no idea what I'm doing) I started the mower, put it in gear and rode around the yard and I'm able the shift a bit better but, I don't have either a main brake or an emergency brake. I feel like I'm getting closer to solving the problem... I just need to get over the hump. Looking at where the clutch comes up from under the frame It seems to me that it should be closer to my feet.

Attachments

#14

T

T.H. Hill

T

T.H. Hill

soooooo on to my next installment of the process to fix this thing. After failed attempts to get the back wheel off, I started to look forward to where the clutch/ brake linkage connects to the peddle. As soon as I got this thing I noticed the clutch peddle was really far forward and difficult to reach. I'm 5'8" so I'm sure Craftsman (or whoever makes these things) intended for someone my height could use these and not someone 6'2". So I started thinking maybe there is an adjustment up front and no need to mess with the rear wheel at this time. I found two bolts under the clutch peddle and it looked like I could make an adjustment from there. I loosened the two bolts and tried to maneuver the plate behind the bolts as best I could (of course I have no idea what I'm doing) I started the mower, put it in gear and rode around the yard and I'm able the shift a bit better but, I don't have either a main brake or an emergency brake. I feel like I'm getting closer to solving the problem... I just need to get over the hump. Looking at where the clutch comes up from under the frame It seems to me that it should be closer to my feet.If you can find an inexpensive replacement rim, you can always Sawzall the wheel to make a slit, then pry to widen the slit and pull it off.

As to your original problem. Have you checked the brake pads and cable / bar tension? Lots of mowers use a pad that wears, and when it does the belt geometry and behavior changes. Sometimes it will cause slippage, sometimes it will fail to brake the pulleys.

Attachments

#15

StarTech

StarTech

I can't prove by it my results and that's what counts to me....Of course people swear by JB Weld too and I have try them and they fail to live up to hype.

#16

sgkent

sgkent

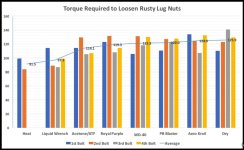

Trash? A mentor, who was engineer and machinist known for building winning Formula One and Indy engines, once suggested I try Liquid Wrench on some exhaust studs that were frozen solid. I laughed but tried it. I had already snapped one double nutted. Came back the next morning and all but one unscrewed by finger. The other one took a grab with a pair of pliers. Here is what Project Farm discovered in his testing of Penetrating Oils.

#17

StarTech

StarTech

Now that is more believable when actually someone took time to do the testing head to head but just how rusty were the fasteners. And also proves that the home brew works better than most of commercial penetrating fluids. As shown heat is still the best for many applications. Probably why I still use a torch at times.

I give Liquid Wench a try as there got to be something that actually halfway works but I won't be holding my breathe until I prove it myself. I have had to use Muriatic Acid on steel on steel and Sulfuric Acid to remove steel fasteners out of aluminum. And I have even used Sulfuric Acid to clean some carburetors.

Whatever anyone does DON'T use Muriatic Acid on anything aluminum or you won't have it long.

I give Liquid Wench a try as there got to be something that actually halfway works but I won't be holding my breathe until I prove it myself. I have had to use Muriatic Acid on steel on steel and Sulfuric Acid to remove steel fasteners out of aluminum. And I have even used Sulfuric Acid to clean some carburetors.

Whatever anyone does DON'T use Muriatic Acid on anything aluminum or you won't have it long.

#18

T

T.H. Hill

T

T.H. Hill

Thanks for the heads up on Kroil I'll pick some up the next time I'm at Lowes

Now that is more believable when actually someone took time to do the testing head to head but just how rusty were the fasteners. And also proves that the home brew works better than most of commercial penetrating fluids. As shown heat is still the best for many applications. Probably why I still use a torch at times.

I give Liquid Wench a try as there got to be something that actually halfway works but I won't be holding my breathe until I prove it myself. I have had to use Muriatic Acid on steel on steel and Sulfuric Acid to remove steel fasteners out of aluminum. And I have even used Sulfuric Acid to clean some carburetors.

Whatever anyone does DON'T use Muriatic Acid on anything aluminum or you won't have it long.

I can't prove by it my results and that's what counts to me....Of course people swear by JB Weld too and I have try them and they fail to live up to hype.

#19

F

Freddie21

F

Freddie21

Taryl gives ideas....https://www.lawnmowerforum.com/threads/stuck-tire.80470/?utm_source=email&utm_campaign=trending

#20

P

Peva

P

Peva

Regarding whacking the backside of a rim with a hammer, angle iron, or whatever to break it loose from the hub, I did that one time, and instead of the rim breaking loose, the retaining ring on the tip of the axle rod in the gear inside the transmission pulled out of its groove - so the entire axle rod-hub-wheel assembly slid out of the transmission.  So I had to partially disassemble the transmission to retrieve the retainer ring and put a new retainer ring in.

So I had to partially disassemble the transmission to retrieve the retainer ring and put a new retainer ring in.

#22

T

T.H. Hill

T

T.H. Hill

Good to know... I've pretty much given up on trying to get that wheel off for now. I've been making some progress in figuring out why the mower is so hard to shift from forward to reverse and it seems to be connected to the adjustment for the brakes behind the right rear tire. I can make that adjustment without removing the wheel, although it would be easier with the wheel off.Regarding whacking the backside of a rim with a hammer, angle iron, or whatever to break it loose from the hub, I did that one time, and instead of the rim breaking loose, the retaining ring on the tip of the axle rod in the gear inside the transmission pulled out of its groove - so the entire axle rod-hub-wheel assembly slid out of the transmission.So I had to partially disassemble the transmission to retrieve the retainer ring and put a new retainer ring in.

#23

T

T.H. Hill

T

T.H. Hill

The other day I decided to try and adjust what I thought was the brake behind the right rear wheel. As I was adjusting the nut inward, I thought I was adjusting the brake pad but instead found that it was also adjusting the tension on the drive belt as well. At one point I checked to see how the transmission was shifting, and was working perfectly. Then I though great, all I have to do now is tighten the nut all the way down and the messed everything up again. Before the adjustment it was very easy to depress the clutch/brake peddle down and after turning the nut clockwise the peddle became much harder to depress. Since this mower is different than my previous one, I'm having to re-learn how everything works on this one.

#24

R

Red Good

R

Red Good

Been bugging me for a bit . From the 2 pics early in this thread , is the wheel further on the shaft than it is supposed to be ? Or is the flats for different models ?

#25

StarTech

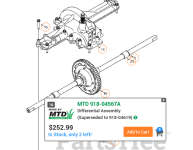

Here is one here. It is suppose to be flush.

The OP problem is all this rust highlighted in this image and likely it worst than it looks.

StarTech

Just an optical illusion.Been bugging me for a bit . From the 2 pics early in this thread , is the wheel further on the shaft than it is supposed to be ? Or is the flats for different models ?

Here is one here. It is suppose to be flush.

The OP problem is all this rust highlighted in this image and likely it worst than it looks.

#26

TiIngot

From the rear using a long sharp end bar (my jack handle) I put it against the rear side rim center shaft and hit the bar with a hammer, rotating the wheel and repeatedly hitting the rim shaft. Also, I hit the edge of the rim near the tire as I rotated the tire. It took about 10 minutes but it slowly moved and slid off. No heat or oil needed and the Craftsman is 28 years old with original tires until now.

TiIngot

I just had the same problem today. I jacked up the right side allowing the left rear tire to remain grounded.I've only had the mower for a couple of weeks so I don't know much about it. It started by having issues trying to shift from forward to reverse then progressed to where I had no brakes and it would creep forward when it was in gear. After looking at it, it looked like the issue was with the linkage that runs from the clutch/ brake peddle back to the transmission. Now I'm stuck because I can't get the rear tire off to see what's going on. I don't want to ruin a rim if I can help it. I might check with a local parts store to see if they have something that can loosen the rust. I've also seen where an 8" gear can be used to pry the wheel off but that involves taking all of the air out of the tire in order to get the gear puller on.

From the rear using a long sharp end bar (my jack handle) I put it against the rear side rim center shaft and hit the bar with a hammer, rotating the wheel and repeatedly hitting the rim shaft. Also, I hit the edge of the rim near the tire as I rotated the tire. It took about 10 minutes but it slowly moved and slid off. No heat or oil needed and the Craftsman is 28 years old with original tires until now.

#27

T

T.H. Hill

T

T.H. Hill

OK so, I'm still trying to figure this out. For now I've decided to work on getting the brakes and the drive belt tension figured out. After making an adjustment behind the right rear wheel, the mower seems to shift just fine now. The problem I had was I kept turning the adjustment nut clockwise until to get to the point that the belt tension was too tight. I noticed there is also an adjustment nut just like the one behind the rear wheel... can I make an adjustment up by the brake/ clutch shown in the picture? Also, thank you for sending the attachment showing how to check the gap on the brake pad adjustment with feeler gauge. If I can get this working properly, I'll move on to the much harder task of getting that rear tire off but for now it's fine the way it is unless I have to fix a flat tire at some point.Just an optical illusion.

Here is one here. It is suppose to be flush.

View attachment 72409

The OP problem is all this rust highlighted in this image and likely it worst than it looks.

View attachment 72412

Attachments

#28

StarTech

StarTech

I am confused apparently. Isn't this an Auto Drive model? If so there is no way to adjust the belts at the transaxle. Or is it one with multiple speed control?

Now rear tires can be repaired while the rims are still on the mower, just a lot hardier but easier to do than 5" or 6" rim version that I had to do on a go cart.

And as noted many time on this and other forums MTD CVT drive requires MTD belts and not aftermarket belts. These are of an unique design both height and width. Common B belts just won't work right.

Now rear tires can be repaired while the rims are still on the mower, just a lot hardier but easier to do than 5" or 6" rim version that I had to do on a go cart.

And as noted many time on this and other forums MTD CVT drive requires MTD belts and not aftermarket belts. These are of an unique design both height and width. Common B belts just won't work right.

#29

S

slomo

S

slomo

Funny how the acetone and Kroil did the worst.

Unless there is some void that allows the miracle juice to penetrate the threads, no spray on Earth will help. A nut and stud rusted over lacks these voids.

Saying that, I still fog it down usually waiting a couple weeks to allow the "wonder spray of the week" working time.

Unless there is some void that allows the miracle juice to penetrate the threads, no spray on Earth will help. A nut and stud rusted over lacks these voids.

Saying that, I still fog it down usually waiting a couple weeks to allow the "wonder spray of the week" working time.

#30

StarTech

StarTech

You got it. That why I suggested Muriatic Acid with soaking cup as a last resort. Even that has to fight the penetrating oils. Its is about the only thing that dissolve rust as it penetrate and does minor to the good parts; unless it is aluminum then it destroys it. Just have to do it outside with a breeze.Funny how the acetone and Kroil did the worst.

Unless there is some void that allows the miracle juice to penetrate the threads, no spray on Earth will help. A nut and stud rusted over lacks these voids.

Saying that, I still fog it down usually waiting a couple weeks to allow the "wonder spray of the week" working time.

#31

O

oldntired55

O

oldntired55

just to comment on Kroil, when i was a mechanic many yrs ago, a faithful cusomer brought his 47 Willys in for all new spring shackles. he also brought a can of Kroil from the maintenance shop at his factory. he was in no hurry for the Willys back...he said to "wire brush the thick rust off the bolts, spray the Kroil on and let it sit for 2 or 3 days." much to my amazement... every nut & bolt spun off . great stuff i think!I agree that most of the so call penetrating sprays are just junk. I tried many of claiming to remove rust and none as far works as advertise. And I do have more success with the 50/50 acetone and transmission mix. The problem with acetone it will damage paint. Currently trying a highly recommend Kroil but on first few projects it has failed to live up to its advertising too. So far it has been a waste of $35. Now on mildly struck screws it works works better than the others I tried.

Just one warning leave the wife's acetone alone and get your own or its a frying pan up aside your head.

#32

StarTech

StarTech

My problem is usually the customers are on my back to get things back quickly which I had to find better ways of getting thing done.

But everybody has different experiences in different situations. I just use what works best for me.

But everybody has different experiences in different situations. I just use what works best for me.

#33

F

Forest#2

And then I usually have to heat the rear of the rims collar with a torch and maybe use a HF puller and 3/8 bolts through the 2 holes in the outer part of the rim. Protect the end of the axle from being mush roomed

Do not beat on the rear of the rim or you can ruin your transaxle. (axle keepers inside the xmission)

I've had to just cut off some of them rim and then use a bearing type separator on the rims collar and install a new rim and antisieze.. Let the air out of the tire BEFORE using any heat.

The hydrostatic have a N adjust usually located under the right rear fender.

And when they won't go into N with the pull rod push them with one rear wheel off the ground.

Not a fun job when rims are rusted to the axle.

F

Forest#2

After the plastic pipe is warmed and pressed onto the rim I use shoe goo to seal the pipe to the rim and then install a 90 degree plastic fitting onto the end of the pipe. the 90 does not need to be glued. Fill the 90 to hold the penetrating oil. heat behind the rim to help the penetrating oiul flow into the rim's rusty collar/axle area.Okay penetrating oil will not work period. The oil swells the dirt and rust forming a seal off area.

Try this instead provided you have not beating beating the shaft where the screw goes.

Note this may or may not work but is worth a try.

- Get a schedule 40 3/4 PCV coupler.

- Cut it nearly in nearly leaving leave the center stop intact.

- Now here is the tricky and heat maybe needed, drive the end with the stop ring on the rim standoff. Heat will soften the plastic but use no more necessary. You are wanting a very tight fit.

- Turn rim and if necessary the mower up where this becomes a cup.

- Fill with with 2 cycle fuel mix and let soak in. You may need to refill the cup a few times.

- This usually loosen the rust up.

- If this don't work the last resort is to try Muriatic Acid. It will eat away the rust. Just got get the past swelled rust area. Careful don't breathe the fumes. It can take your breathe away. Also don't get it on anything aluminum. Once the rim is off neutralize the acid with water and immediately oil things to prevent flash rusting.

And then I usually have to heat the rear of the rims collar with a torch and maybe use a HF puller and 3/8 bolts through the 2 holes in the outer part of the rim. Protect the end of the axle from being mush roomed

Do not beat on the rear of the rim or you can ruin your transaxle. (axle keepers inside the xmission)

I've had to just cut off some of them rim and then use a bearing type separator on the rims collar and install a new rim and antisieze.. Let the air out of the tire BEFORE using any heat.

The hydrostatic have a N adjust usually located under the right rear fender.

And when they won't go into N with the pull rod push them with one rear wheel off the ground.

Not a fun job when rims are rusted to the axle.

#35

F

Forest#2

F

Forest#2

On some similar rims that are rusted to the axle I've taken a very large threaded nut and welded to the rim and use a large bolt threaded into the nut to push off the rim.