You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Snapper series 6 Briggs model 191707 type 251501 Having trouble removing drive pulley .

#1

S

Snapper series 6 1987

S

Snapper series 6 1987

Trying to remove the drive pulley and wondering if the pulley has to be unscrewed or just removed by heat and tapping. There are threads visible inside the bottom of the pulley but nothing I can find says it has to be unscrewed. There is no bolt from the bottom. Possibly it fell off but it's an old machine so not sure. Thank you for any information. Penumbra75@aol.com is my email.

#2

ILENGINE

ILENGINE

The disc should unscrew from the shaft collar. The shaft collar is held on by if I remember correctly 2 set screws, and then should slide off if not stuck to the shaft.

#3

S

Snapper series 6 1987

S

Snapper series 6 1987

The two set screws came out so easily I thought I had it made. Been trying all the usual sprays (ATF, WD 40 etc) heated it up and tried driving the shaft while the motor was suspended with 2x4's under the pulley. Initially I figured there had been a retaining bolt from underneath but none show up on the diagrams or videos. I'll see if it will unscrew and then heat it up with MAP or acetylene if I can find someone with a torch. All the shops around here (Mandeville , LA) are gone and the dealers only want to sell me one of those $4000 zero turns that must weigh 500 lbs or more. Thank you for the tip. When I saw those threads starting to chip off inside the collar I figured I better ask to see if anyone has dealt with this specific drive pulley. I'm an old disabled jarhead and I really need to get this "ole reliable" going again. Thank you again for helping. Let's see if it works!!!

#4

S

slomo

S

slomo

Guessing she is rusted onto the crankshaft. Two set screws are all I know about securing it on the crank. I couldn't get mine off either.

There is an adjustment needs to be made. The depth of the steel drive disk TO the rubber ring, driven disk. If yours doesn't pull a hill then you need more contact here.

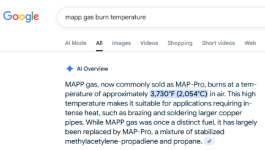

Several ways to remove it. Candle wax and a propane torch. MAP gas is no longer made. It was only 50 degrees F hotter anyway. Everyone swore by MAP gas LOL. Basically the same burn temp as propane. Air hammer if you can get on it. Soak it in PB Blaster for a couple weeks no joke. Spray it down daily.

There is an adjustment needs to be made. The depth of the steel drive disk TO the rubber ring, driven disk. If yours doesn't pull a hill then you need more contact here.

Several ways to remove it. Candle wax and a propane torch. MAP gas is no longer made. It was only 50 degrees F hotter anyway. Everyone swore by MAP gas LOL. Basically the same burn temp as propane. Air hammer if you can get on it. Soak it in PB Blaster for a couple weeks no joke. Spray it down daily.

#5

S

Snapper series 6 1987

S

Snapper series 6 1987

Thank you for the tips. If the pulley is not screwed onto the shaft that makes things easier. I've been soaking it and every now and then giving it a whack with a socket on the end. I've tried the candle wax but I think I put the flame too near the crankshaft so it was also hot.

Also very helpful to know about the MAP gas. A torch with one tank is $70 , I've got several propane tips so I can save the $70 for a mere 50 degrees hotter. It's actually moved a little , what stopped me was seeing those metal shards inside the opening. I've got the engine hanging upside down with the weight on the pully via 2 2x4's.

The main reason I put up the post this morning was to ask about weather the pulley was screwed onto the crankshaft. I have compressed air so I can hammer it as well. Thank you again.

Also very helpful to know about the MAP gas. A torch with one tank is $70 , I've got several propane tips so I can save the $70 for a mere 50 degrees hotter. It's actually moved a little , what stopped me was seeing those metal shards inside the opening. I've got the engine hanging upside down with the weight on the pully via 2 2x4's.

The main reason I put up the post this morning was to ask about weather the pulley was screwed onto the crankshaft. I have compressed air so I can hammer it as well. Thank you again.

#6

H

hlw49

H

hlw49

Snapper had a special puller to remove the drive disc off the engine. Use to have one but can't find it now

#7

Its Me

Its Me

Snapper, I still have the puller, and it screws into the Disk and a solid thread bolt contacts the crankshaft and pushes the adaptor off, I can send a pic, what you do is unscrew the disk, that will only leave the color, remove the set screws, LPS in the holes and get a wheel puller two jar put you a blot in the end and pull if off, course you probably know to set it in neutral.

#8

S

Snapper series 6 1987

S

Snapper series 6 1987

I sure wish I had known about this forum before I started. I have a Briggs and Stratton Service and repair manual (copyright 1992) I got 20 years ago and it's been a great resource. Chapter 13 has all the special tools down to shop towels , washers and nuts. No mention anywhere of this puller that only after reading your message did I know one for this specific engine existed. Glad I stopped pounding on the shaft since It was starting to chip away threads. I think I stopped in time. If you can please put up a picture of the puller/bolt that would be very helpful. Bolt size and tread info would be fantastic. Not one video , article , podcast or manual mentions this puller for the series 6 mower. I watch all the tarydactyl , donnie boy, chickacanic videos and no one mentions a puller for possibly this one crankshaft pulley. None of the others says anything about those threads or a bolt to get it off with. I'm going to dig in my parts barrel and see if I have anything that matches that thread. I do have a lot of taps and dies and might have one that matches this.

* the only bolt puller I can find in this chapter 13 is on page 13-4 part number# 19238. I'll copy that page and put the picture up on here.

I have the Snapper parts manual #06082 with a drawing of the pulley on page 24 but no mention of a puller or how to remove it.

* the only bolt puller I can find in this chapter 13 is on page 13-4 part number# 19238. I'll copy that page and put the picture up on here.

I have the Snapper parts manual #06082 with a drawing of the pulley on page 24 but no mention of a puller or how to remove it.

#9

S

slomo

S

slomo

Once you get the pulley off the crankshaft, please glob the snot out of the end of the crank with anti-seize goo. Next guy will thank you upon removal.

Same goes for those rear hubs on those machines. Anti-sneeze the crap out of those axle hub pieces.

Same goes for those rear hubs on those machines. Anti-sneeze the crap out of those axle hub pieces.

#10

S

Snapper series 6 1987

S

Snapper series 6 1987

Will do if ever I can get this thing to let go. It's like a Lousiana tick...just burrows in deeper. The information in both Briggs and Snapper manuals and parts diagrams offer no ideas on how to remove it. Tons of pages about carbs though.Once you get the pulley off the crankshaft, please glob the snot out of the end of the crank with anti-seize goo. Next guy will thank you upon removal.

Same goes for those rear hubs on those machines. Anti-sneeze the crap out of those axle hub pieces.

#12

S

Snapper series 6 1987

S

Snapper series 6 1987

Again, thank you to everyone. I wound up having to use wax, wd40, ATF, Blaster, propane, 3 lb mall, soaking over night several times. Hitting a socket resting on top the crank shaft until it was almost mashed by 50%....and FINALLY IT CAME OFF!!! The shaft was completely covered in rust. First time it's been off since 1987. The shaft was not damaged since the socket was softer metal and in the beginning 20 strikes would give a 2 hundredths of an inch of travel. Not fun, but it's off.

#13

A

Auto Doc's

A

Auto Doc's

Don't expect the puller to be in the Briggs and Stratton manual, they did not build the mower, just the basic engine.

The manual that Snapper has basically showed operating and basic maintenance along with exploded view parts diagrams.

As I recall from being in an actual small engine shop back then, many tools were usually fabricated by the repair shops.

We used to remove the 2 set screws and then place a bolt in the center hole so it would contact the tip of the engine crankshaft. From there a 3-jaw puller would be used to apply light pressure. If there was rust, it took patience and lots of soaking to work them off.

Clean the crankshaft end then apply anti seize to the crankshaft end during reassembly.

These do have a height sitting for them to work correctly and work properly. I will see if I can locate my old repair information and/or a Jim Jackson you tube video that I watched not long ago.

Jim Jackson has a hobby/business working on these:

The manual that Snapper has basically showed operating and basic maintenance along with exploded view parts diagrams.

As I recall from being in an actual small engine shop back then, many tools were usually fabricated by the repair shops.

We used to remove the 2 set screws and then place a bolt in the center hole so it would contact the tip of the engine crankshaft. From there a 3-jaw puller would be used to apply light pressure. If there was rust, it took patience and lots of soaking to work them off.

Clean the crankshaft end then apply anti seize to the crankshaft end during reassembly.

These do have a height sitting for them to work correctly and work properly. I will see if I can locate my old repair information and/or a Jim Jackson you tube video that I watched not long ago.

Jim Jackson has a hobby/business working on these:

#14

S

Snapper series 6 1987

S

Snapper series 6 1987

I did see some of Jim's videos and quite a few others. I did find a Briggs manual and got a few ideas from that as well. It just took a lot of "all the above" to finally get it loose. As it turns out I think the intake valve may have been sticking since it was really covered with carbon. Gonna polish the crankshaft ends and put a lot of anti seize on them. Valves and camshaft look fine, got lucky on that. Had to order a valve spring compression tool, it seemed too risky to try to pry the caps out so I went ahead and spent the $. The whole idea is to not have to buy one of those zero turn monster mowers. No one makes anything like the Snapper and the least expensive Zero Turn was $4000 and up. They did the same thing with riding mowers they did with "pick up" trucks. This forum has been a great resource. Wish I had known about it years ago. I did take some very exacting measurements on where the pulley was on the shaft. One thing I did notice after the pulley was off...it looks like none of the sprays or wax I drenched it with got more than a few 32nds of an inch below the surface. Probably if I had used acetylene torch it would have gone faster. We don't have anyone within 50 miles of here who work on these old Snappers. All the dealers want to do is sell one of these "land tank mowers" that all weigh more than 600 lbs. Thank you for your help!!

#15

S

slomo

S

slomo

Honestly penetrating lube, does nothing but lighten your wallet. As you found, most of the time, it doesn't get past the rust. Those induction heaters for stud removal are cool.

#16

A

Auto Doc's

A

Auto Doc's

Hello Snapper 87,

I have had the best luck with Acetone and ATF mixed 50/50. The Acetone leads the ATF deep down into the rust.

It's the same mix I have used since I was a restoration body man back in the 80's. Conventional spray can stuff is just a wallet flush in most cases. WD-40 works very well, but it takes days for it to sit and creep in.

No, they don't build anything anymore that can hold a candle to one of these old Snapper series 6 mowers.

They are great for small yards. I also have a couple of Cub Cadet zero turn mowers that I acquired and rebuilt over the years. I use them to cut much larger areas.

I have had the best luck with Acetone and ATF mixed 50/50. The Acetone leads the ATF deep down into the rust.

It's the same mix I have used since I was a restoration body man back in the 80's. Conventional spray can stuff is just a wallet flush in most cases. WD-40 works very well, but it takes days for it to sit and creep in.

No, they don't build anything anymore that can hold a candle to one of these old Snapper series 6 mowers.

They are great for small yards. I also have a couple of Cub Cadet zero turn mowers that I acquired and rebuilt over the years. I use them to cut much larger areas.

#17

R

RevB

R

RevB

Most don't know about this mix.....they usually thing it's just some backwoods ****** that invented it. They always mention that they don't "mix" (immiscible is the proper term)....so just shake it up so that both materials are present on application. The one caution is acetone will burn at much lower ignition temperatures (869f) so be careful when applying to very hot surfaces.Hello Snapper 87,

I have had the best luck with Acetone and ATF mixed 50/50. The Acetone leads the ATF deep down into the rust.

It's the same mix I have used since I was a restoration body man back in the 80's. Conventional spray can stuff is just a wallet flush in most cases. WD-40 works very well, but it takes days for it to sit and creep in.

No, they don't build anything anymore that can hold a candle to one of these old Snapper series 6 mowers.

They are great for small yards. I also have a couple of Cub Cadet zero turn mowers that I acquired and rebuilt over the years. I use them to cut much larger areas.

OT - Penetrating Oil

In a thread in the antique machinery forum, there was a discussion what to use to free up a part. Southbendmodel34 had mentioned a study in Machinist Workshop stating that Automatic transmission fluid and Acetone mixed was the best. I just received a newsletter today from Tim Carter mentioning...

www.practicalmachinist.com

#18

S

SamB

S

SamB

I have a couple of these RER Snappers and have owned several more. I have fixed just about anything that can or could go wrong with these great rider mowers. The OP had me a bit confused about a 'drive pulley' as there isn't a drive pulley on a RER Snapper. Drive plate maybe. Or bladedrive pulley, maybe? However, I'm glad to see the issue is fixed for OP. The drive plate does screw onto the belt pulley mount, which really needs to slide up and down when the set screws are loosened a bit to properly set clearance to the driven 'tire' on the axle. Anti-seize on a clean shaft is critical here, as the drive plate may need to be moved up to install a new blade belt and then back down to properly clearance it to the drive disc. Too wide a clearance there will cause premature on that driven disc and maybe a lack of hill climbing ability, due to slippage.Hello Snapper 87,

I have had the best luck with Acetone and ATF mixed 50/50. The Acetone leads the ATF deep down into the rust.

It's the same mix I have used since I was a restoration body man back in the 80's. Conventional spray can stuff is just a wallet flush in most cases. WD-40 works very well, but it takes days for it to sit and creep in.

No, they don't build anything anymore that can hold a candle to one of these old Snapper series 6 mowers.

They are great for small yards. I also have a couple of Cub Cadet zero turn mowers that I acquired and rebuilt over the years. I use them to cut much larger areas.

#19

A

Auto Doc's

A

Auto Doc's

I recall when I was a kid, one of my uncles had a Snapper walk behind mower with a similar friction disc drive. He was amazed when I tightened the drive tension spring on it.... I did it out of necessity because it was too heavy to push if the drive was constantly slipping. He never did understand anything mechanical. LOL

My series 6 Snapper has not been run so far this year, but I need to. Machines that set too much can be as bad or worse than machines that are abused. I got this thing from an elderly friend who has now passed away, but he loved talking about it. I think the only reason it got parked was due to a stripped blade bar. I have since reconditioned most of the machine and worked a lot of the kinks out of it.

I might get energetic and even paint it someday soon. These machines were built simple and built to last.

My series 6 Snapper has not been run so far this year, but I need to. Machines that set too much can be as bad or worse than machines that are abused. I got this thing from an elderly friend who has now passed away, but he loved talking about it. I think the only reason it got parked was due to a stripped blade bar. I have since reconditioned most of the machine and worked a lot of the kinks out of it.

I might get energetic and even paint it someday soon. These machines were built simple and built to last.

#20

G

Gord Baker

G

Gord Baker

MAP gas is still obtainable and is much hotter than Propane.Guessing she is rusted onto the crankshaft. Two set screws are all I know about securing it on the crank. I couldn't get mine off either.

There is an adjustment needs to be made. The depth of the steel drive disk TO the rubber ring, driven disk. If yours doesn't pull a hill then you need more contact here.

Several ways to remove it. Candle wax and a propane torch. MAP gas is no longer made. It was only 50 degrees F hotter anyway. Everyone swore by MAP gas LOL. Basically the same burn temp as propane. Air hammer if you can get on it. Soak it in PB Blaster for a couple weeks no joke. Spray it down daily.

#21

S

SamB

S

SamB

Rustoleum Professional Safety Red is what I use on my Snappers with good results. I prefer the quart cans of it, using it with a Harbor Freight cheap HVLP gun.Their cheapest guns spray as good as their more expensive ones. I don't like the spray head on the spray cans, but it is a handier way to paint something. The Rustoleum spray cans tend to have the siphon tube inside the can fall off and you have to hold the can upside-down to get it to spray. I know this because I have cut several of the cans open and have found this to be the case multiple times.I recall when I was a kid, one of my uncles had a Snapper walk behind mower with a similar friction disc drive. He was amazed when I tightened the drive tension spring on it.... I did it out of necessity because it was too heavy to push if the drive was constantly slipping. He never did understand anything mechanical. LOL

My series 6 Snapper has not been run so far this year, but I need to. Machines that set too much can be as bad or worse than machines that are abused. I got this thing from an elderly friend who has now passed away, but he loved talking about it. I think the only reason it got parked was due to a stripped blade bar. I have since reconditioned most of the machine and worked a lot of the kinks out of it.

I might get energetic and even paint it someday soon. These machines were built simple and built to last.

#22

S

slomo

S

slomo

#23

S

slomo

S

slomo

Gord Baker said:

MAP gas is still obtainable and is much hotter than Propane.

Here are the burn temps from Google, propane vs mapp. You will never know the difference with a hundred degree spread.

MAP gas is still obtainable and is much hotter than Propane.

Here are the burn temps from Google, propane vs mapp. You will never know the difference with a hundred degree spread.