You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Pulley Problem

#1

M

moangrass

M

moangrass

I rebuilt the mower deck on my Craftsman GT3000 tractor last spring. After grinding off the rust, epoxying the underside and painting it, I replaced several pulleys, belts, and one of the bearing/blade holder assemblies. Yesterday while mowing, I heard a loud squeal followed by smoke and burning rubber. Pulled it into the garage, and this AM I pulled the deck. The drive belt for the deck was twisted and frayed.

The cause was separation of the top and bottom halves of one of the new replacement pulleys. (See Picture). I bought all of my parts from eBay, since Sears is pretty much gone and has only a few parts available for shipping sometime in this century. Despite paying a bit more for "OEM" parts I have to wonder if the parts I bought really are OEM. After all, the original pulleys and belts on this tractor only lasted 20 odd years. (When I rebuilt the deck, one of the pulleys (not this one) had similarly failed, but it did not eat the belt.)

Is this a common problem? Can I expect a new pulley to also bite the dust in a matter of months? I mow about 3/4 acre every other week during the growing season. The tractor usually logs fewer than 50 hours a year - probably a lot closer to 20 or 30. Note that in the picture I've not started loosening the retaining nut. What you see is what I saw when I yanked the deck.

The cause was separation of the top and bottom halves of one of the new replacement pulleys. (See Picture). I bought all of my parts from eBay, since Sears is pretty much gone and has only a few parts available for shipping sometime in this century. Despite paying a bit more for "OEM" parts I have to wonder if the parts I bought really are OEM. After all, the original pulleys and belts on this tractor only lasted 20 odd years. (When I rebuilt the deck, one of the pulleys (not this one) had similarly failed, but it did not eat the belt.)

Is this a common problem? Can I expect a new pulley to also bite the dust in a matter of months? I mow about 3/4 acre every other week during the growing season. The tractor usually logs fewer than 50 hours a year - probably a lot closer to 20 or 30. Note that in the picture I've not started loosening the retaining nut. What you see is what I saw when I yanked the deck.

Attachments

#2

StarTech

StarTech

No it is not a common problem even with after market parts. It appears the pulley was defective to start with.

A second just because Sears is not carrying many of the parts doesn't mean Husqvarna doesn't have the parts for the mower. Craftsman didn't make the mower but has it made by Husqvarna. Third eBay is called RipBay for a reason. The 146763 (4.25 V-idler) superseded to 532146763 > 593787801 is still available. But if you wish a good aftermarket pulley either Stens 280-714 or Rotary 12620 would be a good choice but the costs are about the same as OEM pulley.

A second just because Sears is not carrying many of the parts doesn't mean Husqvarna doesn't have the parts for the mower. Craftsman didn't make the mower but has it made by Husqvarna. Third eBay is called RipBay for a reason. The 146763 (4.25 V-idler) superseded to 532146763 > 593787801 is still available. But if you wish a good aftermarket pulley either Stens 280-714 or Rotary 12620 would be a good choice but the costs are about the same as OEM pulley.

#4

M

moangrass

Edit: I just did a search (memo to me, search first, ask questions later) and found Stens pulleys on ebay. Looks exactly the same down to the rivets. The pic on Stens website did not show the rivets.

M

moangrass

The Stens website says you must be a dealer and logged in to buy from them. Who else (retailer/distributor) carries Stens parts?But if you wish a good aftermarket pulley either Stens 280-714 or Rotary 12620

Edit: I just did a search (memo to me, search first, ask questions later) and found Stens pulleys on ebay. Looks exactly the same down to the rivets. The pic on Stens website did not show the rivets.

#5

Tiger Small Engine

Tiger Small Engine

Sounds like a defective part. I have bought lots of aftermarket parts from Amazon and EBay and overall, have had great service, quality, and price. Even if you are a dealer with Stens, to get free shipping, they have a $170 minimum order. Based on tiered volume pricing, the Stens representative told me they are about 14% lower than Amazon (not that much). When you only need one pulley, that is why I often end up ordering it on Amazon.The Stens website says you must be a dealer and logged in to buy from them. Who else (retailer/distributor) carries Stens parts?

Edit: I just did a search (memo to me, search first, ask questions later) and found Stens pulleys on ebay. Looks exactly the same down to the rivets. The pic on Stens website did not show the rivets.

#7

StarTech

For some reason Stens is not giving me any discount on this pulley.

StarTech

Must be looking at a different website. Here is what I getting.The Stens website says you must be a dealer and logged in to buy from them. Who else (retailer/distributor) carries Stens parts?

Edit: I just did a search (memo to me, search first, ask questions later) and found Stens pulleys on ebay. Looks exactly the same down to the rivets. The pic on Stens website did not show the rivets.

For some reason Stens is not giving me any discount on this pulley.

#8

M

moangrass

M

moangrass

The Stens website says you must be a dealer and logged in to buy from them.But if you wish a good aftermarket pulley either Stens 280-714 or Rotary 12620

#9

M

moangrass

M

moangrass

In the upper right corner of your picture, it says Welcome and below that My Account. I tried again and a different page offered me an account and said "Become a Dealer". So I was mistaken. Run of the mill public can create an account and buy from them. Dealers probably get a bigger discount.Must be looking at a different website. Here is what I getting.

View attachment 67179

For some reason Stens is not giving me any discount on this pulley.

#10

Tiger Small Engine

Tiger Small Engine

After expressing interest in doing business with Stens early this Spring via the Internet, a representative called me. Said he would be in my area and come by my shop. No call and no show and never heard back from them. Also, they were not at the Equipment Expo this year. Business must be good for Stens…In the upper right corner of your picture, it says Welcome and below that My Account. I tried again and a different page offered me an account and said "Become a Dealer". So I was mistaken. Run of the mill public can create an account and buy from them. Dealers probably get a bigger discount.

#11

StarTech

One of the problems is turnover of sales staff. In the last ten years of being with Stens I have been thru six salespersons and only one ever visited the shop.

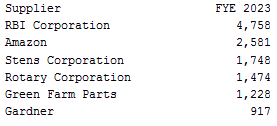

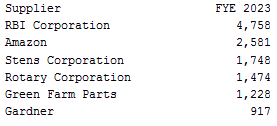

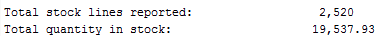

I only so far this year purchased about $23,000 in parts but none the vendors have over $4758 in sales. You probably not surprise how small purchases from different vendors quickly add up. Plus every year is different. So purchases from Gardner are way down but RBI is way up. Stens is down and Rotary is up.

Here is some of the top vendors here. And this don't include shipping charges.

StarTech

Sometimes it takes you doing follow-ups. It took me several years just to get into Gardner but with RBI it took a very short time. What is a major problem was that had a very lazy local salesman. He only lived 20 miles from me and never came out. It took firing him and hiring a new salesman before I got signed up. They are very slow to correct problems too. A couple years ago Gardner started charging 2.5% for CC use but had ACH transfers supposedly available. It took 7 months to get switch over to where I send a check after every purchase. They never setup Codis to do ACH transfers. What worst is now I have a Space Cadet for a salesperson. She calls and have no idea of what she is calling about. But RBI has Codis setup and payments get done in three days.After expressing interest in doing business with Stens early this Spring via the Internet, a representative called me. Said he would be in my area and come by my shop. No call and no show and never heard back from them. Also, they were not at the Equipment Expo this year. Business must be good for Stens…

One of the problems is turnover of sales staff. In the last ten years of being with Stens I have been thru six salespersons and only one ever visited the shop.

I only so far this year purchased about $23,000 in parts but none the vendors have over $4758 in sales. You probably not surprise how small purchases from different vendors quickly add up. Plus every year is different. So purchases from Gardner are way down but RBI is way up. Stens is down and Rotary is up.

Here is some of the top vendors here. And this don't include shipping charges.

#12

Tiger Small Engine

Thanks for your reply. I only do about $2500 to $3500 per year in parts buying. If I were in a position right now where I was getting crappy service, late deliveries, mis-picked orders, billing issues, prices too high, then I would be chomping at the bit for help with a new parts vendor. As it stands, none of the issues are happening.

I used to be in outside sales in the 90’s and covered 3/4 of Missouri, and 1/2 of Arkansas. I was a hustler and dealers appreciated seeing me 4 to 6 weeks. Nothing upsets me more than complaining, complacent, lazy workers. It seems that a potential customer shouldn’t have to beg to do business with a company. The company should hustle for the customer’s business. Anyway, it will all shake out in the future. I am going to do some more planning over the winter, getting more organized, shop clean up, vendors, etc.

Tiger Small Engine

Star Tech-Sometimes it takes you doing follow-ups. It took me several years just to get into Gardner but with RBI it took a very short time. What is a major problem was that had a very lazy local salesman. He only lived 20 miles from me and never came out. It took firing him and hiring a new salesman before I got signed up. They are very slow to correct problems too. A couple years ago Gardner started charging 2.5% for CC use but had ACH transfers supposedly available. It took 7 months to get switch over to where I send a check after every purchase. They never setup Codis to do ACH transfers. What worst is now I have a Space Cadet for a salesperson. She calls and have no idea of what she is calling about. But RBI has Codis setup and payments get done in three days.

One of the problems is turnover of sales staff. In the last ten years of being with Stens I have been thru six salespersons and only one ever visited the shop.

I only so far this year purchased about $23,000 in parts but none the vendors have over $4758 in sales. You probably not surprise how small purchases from different vendors quickly add up. Plus every year is different. So purchases from Gardner are way down but RBI is way up. Stens is down and Rotary is up.

Here is some of the top vendors here. And this don't include shipping charges.

View attachment 67190

Thanks for your reply. I only do about $2500 to $3500 per year in parts buying. If I were in a position right now where I was getting crappy service, late deliveries, mis-picked orders, billing issues, prices too high, then I would be chomping at the bit for help with a new parts vendor. As it stands, none of the issues are happening.

I used to be in outside sales in the 90’s and covered 3/4 of Missouri, and 1/2 of Arkansas. I was a hustler and dealers appreciated seeing me 4 to 6 weeks. Nothing upsets me more than complaining, complacent, lazy workers. It seems that a potential customer shouldn’t have to beg to do business with a company. The company should hustle for the customer’s business. Anyway, it will all shake out in the future. I am going to do some more planning over the winter, getting more organized, shop clean up, vendors, etc.

#13

StarTech

StarTech

You are lucky then as I have been dealing just that all year long here.

Back in the early 2010's companies were willing to have small companies like mine buying from them. Now the same companies are raising the minimum annual purchases to where I have to switch vendors. A&I that I was with for nearly 13 yrs to start demanding a 2K annual minimum purchase that just came off a restriction I placed them on because of unresolved problems. I was having to bring back in stock their products after I had already replaced them from Stens products. I was already had brought $200 in Briggs parts after having them on a six month suspension when they sent me three threatening emails. With Briggs dying off here I figured I could just buy the parts elsewhere. That was last year. Normally I was buying nearly 3K from them when they were Sunbelt Outdoors. Same problem with Power Distributors they dump me because A&I was giving me a better discount. So I now not selling new engines beside $200 to ship an small engine is too much.

Every year my needs change around based on what is coming into the shop. The last couple years it has heavy with large ZTRs with Kawasaki engines. Who knows what the coming year will bring in. At least next June I be going on SS for a stable income so I will start selling down my inventory to get ready to close the business. Just plain tire of all the hassles dealing with parts procurement.

And yes I got start the annual shop cleaning and inventory soon too. Dreading the inventory part especially while keeping the shop open. Just over 19.5K in parts to count.

Back in the early 2010's companies were willing to have small companies like mine buying from them. Now the same companies are raising the minimum annual purchases to where I have to switch vendors. A&I that I was with for nearly 13 yrs to start demanding a 2K annual minimum purchase that just came off a restriction I placed them on because of unresolved problems. I was having to bring back in stock their products after I had already replaced them from Stens products. I was already had brought $200 in Briggs parts after having them on a six month suspension when they sent me three threatening emails. With Briggs dying off here I figured I could just buy the parts elsewhere. That was last year. Normally I was buying nearly 3K from them when they were Sunbelt Outdoors. Same problem with Power Distributors they dump me because A&I was giving me a better discount. So I now not selling new engines beside $200 to ship an small engine is too much.

Every year my needs change around based on what is coming into the shop. The last couple years it has heavy with large ZTRs with Kawasaki engines. Who knows what the coming year will bring in. At least next June I be going on SS for a stable income so I will start selling down my inventory to get ready to close the business. Just plain tire of all the hassles dealing with parts procurement.

And yes I got start the annual shop cleaning and inventory soon too. Dreading the inventory part especially while keeping the shop open. Just over 19.5K in parts to count.

#14

T

Tornadoman

T

Tornadoman

LOOK CLOSELY>> The rivets did not come loose. The bottom pulley half cracked apart. I have seen this. It does happen, but usually when very old. Could the belt tension have been too tight? Pulleys out of alignment? Or just a defective part?

#15

M

Mattmotors

M

Mattmotors

It happens. I also had a pulley separate on my gt3000 a few years ago. it was the original pulley.

#16

StarTech

StarTech

Never seen to fail this way; unless, defective metal was used. With after market being sold by fly by night operators anything is possible. I have in the past seen one double stack pulley to come apart because the stop welds failed. That is the only one I seen in 14+ yrs of working on mowers.

But anything is possible especially when they tell you it is impossible. When I repairing electronic calculator I came across a batch where they were adding wrong. I call tecj support and they it was impossible but I proved them wrong by simply giving them the set of test numbers. Kinda wished I didn't as I to change over 100 cpu chips.

But anything is possible especially when they tell you it is impossible. When I repairing electronic calculator I came across a batch where they were adding wrong. I call tecj support and they it was impossible but I proved them wrong by simply giving them the set of test numbers. Kinda wished I didn't as I to change over 100 cpu chips.

#17

L

LMPPLUS

L

LMPPLUS

I rebuilt the mower deck on my Craftsman GT3000 tractor last spring. After grinding off the rust, epoxying the underside and painting it, I replaced several pulleys, belts, and one of the bearing/blade holder assemblies. Yesterday while mowing, I heard a loud squeal followed by smoke and burning rubber. Pulled it into the garage, and this AM I pulled the deck. The drive belt for the deck was twisted and frayed.

The cause was separation of the top and bottom halves of one of the new replacement pulleys. (See Picture). I bought all of my parts from eBay, since Sears is pretty much gone and has only a few parts available for shipping sometime in this century. Despite paying a bit more for "OEM" parts I have to wonder if the parts I bought really are OEM. After all, the original pulleys and belts on this tractor only lasted 20 odd years. (When I rebuilt the deck, one of the pulleys (not this one) had similarly failed, but it did not eat the belt.)

Is this a common problem? Can I expect a new pulley to also bite the dust in a matter of months? I mow about 3/4 acre every other week during the growing season. The tractor usually logs fewer than 50 hours a year - probably a lot closer to 20 or 30. Note that in the picture I've not started loosening the retaining nut. What you see is what I saw when I yanked the deck.

#18

L

LMPPLUS

L

LMPPLUS

Many of the steel pulleys are American made sold by both OEM and aftermarket suppliers, not all but many, but generally a bearing will fail long before the pulley will split.

#19

R

RevB

. Betcha you can find someone to spot weld it back. Failing a spot weld, there is always the rosette method. Just drill holes through one of the halves and then holes through the other half but offset from the first set. Then any competent welder ( sometimes even incompetent ones) can just weld in rosettes through each hole to bond the assembly. MIG, rod (GMAW or MAW), TIG or gas can all be used. Cheaper and better than new.

. Betcha you can find someone to spot weld it back. Failing a spot weld, there is always the rosette method. Just drill holes through one of the halves and then holes through the other half but offset from the first set. Then any competent welder ( sometimes even incompetent ones) can just weld in rosettes through each hole to bond the assembly. MIG, rod (GMAW or MAW), TIG or gas can all be used. Cheaper and better than new.

Had an issue with clip nuts used to secure items to a seam. Called the company and asked if they made their own. They did and told them to crank up the amperage on the "spot" welder because half of them had the "welded" nut fall off the clip. They called back a couple hours later and said, yup...someone had dialed back the amperage on one of the machines so they sent a bag of new stock gratis.....

R

RevB

Nothing wrong with the old pulleyI rebuilt the mower deck on my Craftsman GT3000 tractor last spring. After grinding off the rust, epoxying the underside and painting it, I replaced several pulleys, belts, and one of the bearing/blade holder assemblies. Yesterday while mowing, I heard a loud squeal followed by smoke and burning rubber. Pulled it into the garage, and this AM I pulled the deck. The drive belt for the deck was twisted and frayed.

The cause was separation of the top and bottom halves of one of the new replacement pulleys. (See Picture). I bought all of my parts from eBay, since Sears is pretty much gone and has only a few parts available for shipping sometime in this century. Despite paying a bit more for "OEM" parts I have to wonder if the parts I bought really are OEM. After all, the original pulleys and belts on this tractor only lasted 20 odd years. (When I rebuilt the deck, one of the pulleys (not this one) had similarly failed, but it did not eat the belt.)

Is this a common problem? Can I expect a new pulley to also bite the dust in a matter of months? I mow about 3/4 acre every other week during the growing season. The tractor usually logs fewer than 50 hours a year - probably a lot closer to 20 or 30. Note that in the picture I've not started loosening the retaining nut. What you see is what I saw when I yanked the deck.

Had an issue with clip nuts used to secure items to a seam. Called the company and asked if they made their own. They did and told them to crank up the amperage on the "spot" welder because half of them had the "welded" nut fall off the clip. They called back a couple hours later and said, yup...someone had dialed back the amperage on one of the machines so they sent a bag of new stock gratis.....

#21

F

farmerdave1954

F

farmerdave1954

I could have put a new pulley on and mowed half my yard in the time it's taken to read through this thread. Why did you replace the original pulley to begin with?

#22

L

Lostviking

L

Lostviking

just a typical cheap made pulley..even the OEM pulley's are as cheaply made.. no quality control any more..I rebuilt the mower deck on my Craftsman GT3000 tractor last spring. After grinding off the rust, epoxying the underside and painting it, I replaced several pulleys, belts, and one of the bearing/blade holder assemblies. Yesterday while mowing, I heard a loud squeal followed by smoke and burning rubber. Pulled it into the garage, and this AM I pulled the deck. The drive belt for the deck was twisted and frayed.

The cause was separation of the top and bottom halves of one of the new replacement pulleys. (See Picture). I bought all of my parts from eBay, since Sears is pretty much gone and has only a few parts available for shipping sometime in this century. Despite paying a bit more for "OEM" parts I have to wonder if the parts I bought really are OEM. After all, the original pulleys and belts on this tractor only lasted 20 odd years. (When I rebuilt the deck, one of the pulleys (not this one) had similarly failed, but it did not eat the belt.)

Is this a common problem? Can I expect a new pulley to also bite the dust in a matter of months? I mow about 3/4 acre every other week during the growing season. The tractor usually logs fewer than 50 hours a year - probably a lot closer to 20 or 30. Note that in the picture I've not started loosening the retaining nut. What you see is what I saw when I yanked the deck.

#23

R

RevB

R

RevB

But....but....there are those here who want you to buy another ****ty pulley.....just a typical cheap made pulley..even the OEM pulley's are as cheaply made.. no quality control any more..

#24

ILENGINE

ILENGINE

I have had idler pulleys in the past that there was wobble in the bearing and ordered a new OEM pulley and the new pulley had more bearing slop than the one that was already on it. About to the point that they get replaced if they break or there is actual bearing noise.

#25

M

moangrass

M

moangrass

Your diagnosis is all wrong. The pulley ripped apart and is beyond saving. Were I on a desert island w/ no access to parts, and had a shop with grinders and welding equipment, then sure, it could be restored if there were no other options. But for twenty odd bucks it is simply not worth it. I have a MIG and could weld it if I thought it were worth while.Nothing wrong with the old pulley. Betcha you can find someone to spot weld it back. Failing a spot weld, there is always the rosette method. Just drill holes through one of the halves and then holes through the other half but offset from the first set. Then any competent welder ( sometimes even incompetent ones) can just weld in rosettes through each hole to bond the assembly. MIG, rod (GMAW or MAW), TIG or gas can all be used. Cheaper and better than new.

Had an issue with clip nuts used to secure items to a seam. Called the company and asked if they made their own. They did and told them to crank up the amperage on the "spot" welder because half of them had the "welded" nut fall off the clip. They called back a couple hours later and said, yup...someone had dialed back the amperage on one of the machines so they sent a bag of new stock gratis.....

#26

M

moangrass

M

moangrass

After 20 years some of the pulleys' bearings felt dry. I think I replaced 4 of the 6 on the deck. The ones that remained felt fine.I could have put a new pulley on and mowed half my yard in the time it's taken to read through this thread. Why did you replace the original pulley to begin with?

#27

StarTech

StarTech

As with everything, nothing is perfect. Sometimes things just get miss during assembly. Even with us humans things goes wrong from the beginning at times.

It when I see multiple failures during inspection that I start questioning if the product I am getting is defective. But say if a new pulley fails from one vendor it is likely they gotten in a bad batch of them so I order from one of my other trusted vendors. Even then they might also part of the same batch.

That a group of spindles I ordered for a Cub Cadet here a few years ago. A&I sold Rotary ones so I ordered a set but they had excessive end play. Then I order supposedly OEM spindles from Amazon I got the same spindles. That is when I just rebuilt the ones I had on hand; although, it took going to three different auto part stores to get all six bearings. I have since gotten the bearings from my regular bearing supplier.

It when I see multiple failures during inspection that I start questioning if the product I am getting is defective. But say if a new pulley fails from one vendor it is likely they gotten in a bad batch of them so I order from one of my other trusted vendors. Even then they might also part of the same batch.

That a group of spindles I ordered for a Cub Cadet here a few years ago. A&I sold Rotary ones so I ordered a set but they had excessive end play. Then I order supposedly OEM spindles from Amazon I got the same spindles. That is when I just rebuilt the ones I had on hand; although, it took going to three different auto part stores to get all six bearings. I have since gotten the bearings from my regular bearing supplier.

#28

R

RevB

R

RevB

Bull****.Your diagnosis is all wrong. The pulley ripped apart and is beyond saving. Were I on a desert island w/ no access to parts, and had a shop with grinders and welding equipment, then sure, it could be restored if there were no other options. But for twenty odd bucks it is simply not worth it. I have a MIG and could weld it if I thought it were worth while.

#29

StarTech

StarTech

I believe the Moangrass is in a better place to do the diagnosis then some remote person. Even I could see it ripped apart in the image he posted and not a rivet failure or spot weld failure. I only had one double stack the did the same thing and it was definitely none repairable.

RevB just accept it that not everything can be repair like new. THe only time I would even attempt something like welding it is if the pulley was a NLA one but even then an alternate can easily be retro fitted.

RevB just accept it that not everything can be repair like new. THe only time I would even attempt something like welding it is if the pulley was a NLA one but even then an alternate can easily be retro fitted.

#30

M

moangrass

I could make a cross section of a V-belt, (well, a few of them), grind the torn steel off the top pulley half, position the cross sections properly, clamp it all together, set up my MIG, don the appropriate respirator (the pulley is plated), and weld the two halves together. BUT, I value my time a bit more than the $20 for a new one, and the welding might damage the bearing (it would likely melt the grease). Much much better for me to go out and buy a Precision Matthews Lathe, grab a hunk of solid steel, machine a new pulley, press in bearings, and get on with mowing. The latter course would be fun, but again, by the time I'm finished winter will be here and I will not be able to mow the leaves. (Which I will do today, since I installed the new pulley and belt yesterday).

@RevB, you can spend your life repairing things, I have better things to do with my time when I find an easier alternative.

Couple of pictures:

M

moangrass

Ok, I admit EVERY inanimate object in life can be repaired. "That's the best durn axe I've ever had. Replaced the handle three times and the head twice".Bull****.

I could make a cross section of a V-belt, (well, a few of them), grind the torn steel off the top pulley half, position the cross sections properly, clamp it all together, set up my MIG, don the appropriate respirator (the pulley is plated), and weld the two halves together. BUT, I value my time a bit more than the $20 for a new one, and the welding might damage the bearing (it would likely melt the grease). Much much better for me to go out and buy a Precision Matthews Lathe, grab a hunk of solid steel, machine a new pulley, press in bearings, and get on with mowing. The latter course would be fun, but again, by the time I'm finished winter will be here and I will not be able to mow the leaves. (Which I will do today, since I installed the new pulley and belt yesterday).

@RevB, you can spend your life repairing things, I have better things to do with my time when I find an easier alternative.

Couple of pictures:

#31

F

farmerdave1954

F

farmerdave1954

Yep! That pulley is most definitely NON-repairable. I just hope the new one doesn't do the same thing to you. There was no quality in that one to control in the first place. Kind of an odd failure mode.