You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Old Flywheel - new short block - spark timing way out ?

#1

S

Scottishlad

S

Scottishlad

Calling for help all the way from the Scottish Highlands!

I recently bought a "spares of repair" ride on from a friend with a 15.5 HP BS intek engine which had thrown a con rod, through lack of lubrication. After assessment I reckoned that a new short block was the most economic fix.

This arrived Friday and i built it up over the weekend with all the old parts transferring without (apparent issue) ... however she wont fire up ....

I checked for spark and fuel and all looks good / valve clearances set (4 thou for inlet and 6 exhaust). 12 thou air gap at flywheel /coil interface

Checking valves clearances again this morning I set TDC with a screwdriver in the bore and just before checking valves I noticed that my flywheel magnets are almost 90 degree behind where I'd expect them to be ( I assume that the magnet and the coil should be more or less in alignment?

(also realised that the exhaust / muffler was noticeably warm despite the lack of running - id put this down to just the compression of the gas but suspect now that I had combustion but just not at the right time.....

Checked the flywheel key way and key and all in alignment with the crank (no sign of damage etc)

Looks awfully like my original flywheel and the new crank are not a match?

My original engine is Model 31 A6 07 Type 01 26 B1 080818ZD

New short Block is Serial 2109028139679 Model 592059A

I'm hoping that if I'm right then Briggs will take the block back or send my a new compatible flywheel ....

Questions -

Where should the flywheel magnet be with respect to the two legs of the coil at TDC ?

Can anyone help to confirm my diagnosis (or provide other hints)

Thanks in anticipation

I recently bought a "spares of repair" ride on from a friend with a 15.5 HP BS intek engine which had thrown a con rod, through lack of lubrication. After assessment I reckoned that a new short block was the most economic fix.

This arrived Friday and i built it up over the weekend with all the old parts transferring without (apparent issue) ... however she wont fire up ....

I checked for spark and fuel and all looks good / valve clearances set (4 thou for inlet and 6 exhaust). 12 thou air gap at flywheel /coil interface

Checking valves clearances again this morning I set TDC with a screwdriver in the bore and just before checking valves I noticed that my flywheel magnets are almost 90 degree behind where I'd expect them to be ( I assume that the magnet and the coil should be more or less in alignment?

(also realised that the exhaust / muffler was noticeably warm despite the lack of running - id put this down to just the compression of the gas but suspect now that I had combustion but just not at the right time.....

Checked the flywheel key way and key and all in alignment with the crank (no sign of damage etc)

Looks awfully like my original flywheel and the new crank are not a match?

My original engine is Model 31 A6 07 Type 01 26 B1 080818ZD

New short Block is Serial 2109028139679 Model 592059A

I'm hoping that if I'm right then Briggs will take the block back or send my a new compatible flywheel ....

Questions -

Where should the flywheel magnet be with respect to the two legs of the coil at TDC ?

Can anyone help to confirm my diagnosis (or provide other hints)

Thanks in anticipation

#2

Scrubcadet10

Scrubcadet10

do you still have access to your old (original flywheel)? i would take both flywheels, and line the key ways in them up, and see if the magnet is in a different position

#3

StarTech

StarTech

Back in 2013 Briggs changed the flywheel and crankshaft key ways. In order to repair a 2008 model with 2021 short block there two ways either you clean up a usable crankshaft and install it or you install the new flywheel. But Briggs will not send you a free newer flywheel or a free older crankshaft. Of course using the old crankshaft if good is the cheapest route as you only need a new sump and rocker gasket (RTV on some engines).

Now a new flywheel will sit you back $185 retail.

Now a new flywheel will sit you back $185 retail.

#4

S

Scottishlad

S

Scottishlad

Thanks for that … as Briggs were given the engine code details when I ordered the short block should they not point out the incompatibility between old and new ? By the time I buy another flywheel I’d have been as well to buy a complete motor and save the time rebuilding …. The old crank was wrecked by the failed Con-rodBack in 2013 Briggs changed the flywheel and crankshaft key ways. In order to repair a 2008 model with 2021 short block there two ways either you clean up a usable crankshaft and install it or you install the new flywheel. But Briggs will not send you a free newer flywheel or a free older crankshaft. Of course using the old crankshaft if good is the cheapest route as you only need a new sump and rocker gasket (RTV on some engines).

Now a new flywheel will sit you back $185 retail.

#5

S

Scottishlad

S

Scottishlad

Also wonder if I could get a machine shop to cut a new jetway in the fy wheel if I knew the position ? Presumably it wouldn’t weaken it any more than the existing one ?Thanks for that … as Briggs were given the engine code details when I ordered the short block should they not point out the incompatibility between old and new ? By the time I buy another flywheel I’d have been as well to buy a complete motor and save the time rebuilding …. The old crank was wrecked by the failed Con-rod

#6

S

Scottishlad

S

Scottishlad

Hi and thanks for your reply … I’ve no new flywheel as the short block is just the crankcase and internal parts. It seems from another reply that the flywheels are indeed different … only wish Briggs had told me before I ordered it!do you still have access to your old (original flywheel)? i would take both flywheels, and line the key ways in them up, and see if the magnet is in a different position

#7

ILENGINE

ILENGINE

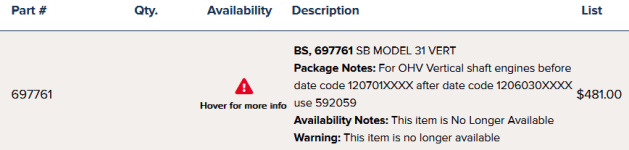

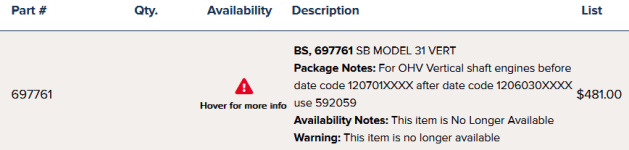

Briggs has a special note for shortblock replacement

Shortblock Notes

- Engines Built Prior to 07/12/2012 should use short block 697761. Engines built on or after 07/12/2012 should use short block 592059.

#8

StarTech

StarTech

Correct according to Power Distributors it is NLA back at the first July it was but that has changed now and only the 592059 is available.Briggs has a special note for shortblock replacement

Shortblock Notes

And it appears that the 697761 short block is no longer available.

- Engines Built Prior to 07/12/2012 should use short block 697761. Engines built on or after 07/12/2012 should use short block 592059.

#9

E

Elkins45

E

Elkins45

That would be the route I would try. You could probably do it yourself with a file if you knew the correct position.Also wonder if I could get a machine shop to cut a new jetway in the fy wheel if I knew the position ? Presumably it wouldn’t weaken it any more than the existing one ?

#10

S

Scottishlad

S

Scottishlad

Many, many thanks for this ! That's an excellent bit of information .... it may be that I can use this to return the incorrectly supplied shortblock or get them to give me a new flywheel compatible with the newer engine keyway ... the risk with that is that i'll then discover that the diameter of the new flywheel is different so i'll need a new coil too or that the starter ring gear is a different profile and I'll need a new startermotor.....Aargh!Correct according to Power Distributors it is NLA back at the first July it was but that has changed now and only the 592059 is available.

View attachment 62692

#11

S

Scottishlad

S

Scottishlad

Hi, and thanks - from other posts it looks like they've actually supplied the wrong block as the one for my engine is no longer available. I'll see how i get on trying to argue this with Briggs and take it from there.....That would be the route I would try. You could probably do it yourself with a file if you knew the correct position.

#12

S

Scottishlad

S

Scottishlad

THANK YOU ... with all your help this is beginning to look like I have the start of a solution ....Briggs has a special note for shortblock replacement

Shortblock Notes

And it appears that the 697761 short block is no longer available.

- Engines Built Prior to 07/12/2012 should use short block 697761. Engines built on or after 07/12/2012 should use short block 592059.

#13

S

Scottishlad

S

Scottishlad

Update

As you've suggested Briggs have confirmed that I need a new flywheel AND cooling fan to make this engine work .. some £200 of additional cost and getting very close to the price I could have bought a complete new motor for!

They have acknowledged that my short block engine is no longer available so i'm currently in "discussion" as to why they supplied the incorrect engine which requires additional parts which were not highlighted at the point of ordering. To my mind this was therefore an incorrectly supplied part and it should be their reponsibility to rectify and not mine by paying more money .... lets see what happens.....!

As you've suggested Briggs have confirmed that I need a new flywheel AND cooling fan to make this engine work .. some £200 of additional cost and getting very close to the price I could have bought a complete new motor for!

They have acknowledged that my short block engine is no longer available so i'm currently in "discussion" as to why they supplied the incorrect engine which requires additional parts which were not highlighted at the point of ordering. To my mind this was therefore an incorrectly supplied part and it should be their reponsibility to rectify and not mine by paying more money .... lets see what happens.....!

#14

StarTech

StarTech

Now you know why so many small and large shops no longer do engine rebuilds. A surplus new replacement engine is more economical to install. Now in your case if the old crankshaft was savable then things would have been fine as you could have swap it out.

Even though I have the tools to resize a bore I still do not do rebuilds any longer. Customer don't seem to understand the costs and time involved as they got use to cheap things. Back years ago it was feasible to do rebuilds as costs were more inline and new were more costly when compared to rebuilds. On top even to do a resize now we are very on the replacement pistons and rings. We use to have .010 to .030 oversizes available but now we are lucky if there is a .020 oversize.

It like the Hydro Gear EZT transaxle that needs repaired or replaced here. It costs the customer around $850 to rebuild with a 30 day warranty and a new one is about the same cost (around $1000) with 5-6 month warranty. Prices include labor. It makes better sense to replace with new. I can do this as a HG dealer where Bad Boy will only give the customer a 30 day warranty on a new transaxle.

It getting to a point now that we have to make decisions of installing new engines and transaxles over rebuilding them here in my neck of the woods. Just not cost effective. Manufactures only care about keep the factories operating at peak output now instead customers loyalties or the environment. It is all about the money most times. Plus there is just not enough space to keep older tooling hardware around as space is limited.

Even though I have the tools to resize a bore I still do not do rebuilds any longer. Customer don't seem to understand the costs and time involved as they got use to cheap things. Back years ago it was feasible to do rebuilds as costs were more inline and new were more costly when compared to rebuilds. On top even to do a resize now we are very on the replacement pistons and rings. We use to have .010 to .030 oversizes available but now we are lucky if there is a .020 oversize.

It like the Hydro Gear EZT transaxle that needs repaired or replaced here. It costs the customer around $850 to rebuild with a 30 day warranty and a new one is about the same cost (around $1000) with 5-6 month warranty. Prices include labor. It makes better sense to replace with new. I can do this as a HG dealer where Bad Boy will only give the customer a 30 day warranty on a new transaxle.

It getting to a point now that we have to make decisions of installing new engines and transaxles over rebuilding them here in my neck of the woods. Just not cost effective. Manufactures only care about keep the factories operating at peak output now instead customers loyalties or the environment. It is all about the money most times. Plus there is just not enough space to keep older tooling hardware around as space is limited.

#15

Hammermechanicman

Hammermechanicman

On very rare occasion will i rebuild an engine or a hydro. I understand why dealers don't do it and i don't for the same reason. The time it takes and parts to do it right puts you near the cost of a new engine. Folks sometimes don't understand how long it takes to disassemble, clean off old gaskets, clean block and parts, inspect all the parts for wear or damage and at a minimum use a ball hone to break the glaze and reclean the block and then reassemble the engine. Plus time to look up parts. And then warranty the work. Opening a box and bolting on an engine warranted by someone else is more cost effective.

#16

S

Scottishlad

S

Scottishlad

Star Tech and Hammermechanicman

Thanks for your reply

Looks like i'm learning this the hard way ... its my own mower and bought as a project so labour cost is not such an issue. From a saving the planet (!) perspective I was trying to do the right thing and minimise throwing stuff away ... sadly, the crank and con rod had all but welded themselves together so it seemed to make sense to go for the short motor at just over half price of a whole new motor - all the other components are sound.

Not sure where to go from here .. I bought the short motor from a BS agent with all the original engine codings so i'm not happy that they supplied a later series engine without any suggestion that id have to buy more bits to make it work.....

As the correct motor is listed as NLA I think its a clear cut case of so incorrect supply on their behalf. I've said i'll return the new engine for a full refund or they can send me an foc flywheel and fan .....

Finally, has anyone got any thoughts on the viability of cutting a new key-way in the existing flywheel? In theory at least a cheaper fix if it didn't threaten the integrity of the flywheel and assuming I can accurately establish the new location ....

Thanks for your reply

Looks like i'm learning this the hard way ... its my own mower and bought as a project so labour cost is not such an issue. From a saving the planet (!) perspective I was trying to do the right thing and minimise throwing stuff away ... sadly, the crank and con rod had all but welded themselves together so it seemed to make sense to go for the short motor at just over half price of a whole new motor - all the other components are sound.

Not sure where to go from here .. I bought the short motor from a BS agent with all the original engine codings so i'm not happy that they supplied a later series engine without any suggestion that id have to buy more bits to make it work.....

As the correct motor is listed as NLA I think its a clear cut case of so incorrect supply on their behalf. I've said i'll return the new engine for a full refund or they can send me an foc flywheel and fan .....

Finally, has anyone got any thoughts on the viability of cutting a new key-way in the existing flywheel? In theory at least a cheaper fix if it didn't threaten the integrity of the flywheel and assuming I can accurately establish the new location ....

#17

Hammermechanicman

Hammermechanicman

Where you are it may be difficult but check around any small engine shops that may have a bad engine with the flywheel you need for a few coins.

#18

StarTech

StarTech

I agree with Drama Llama as it a good chance you can find the new style flywheel as these engines are contastly self destructing due head gasket issues. Just took a load of scrap engines to the recycler Friday.

#19

S

Scottishlad

I'll ask around though ... do you know if the required flywheel is fitted to other engines or it specific to the 15.5 intek engines?

Thank for taking the time to reply and the help you are offering

S

Scottishlad

A good idea - though as you say small engine shops are few and far between ...coming to think of it almost everything around here is few and far between !!Where you are it may be difficult but check around any small engine shops that may have a bad engine with the flywheel you need for a few coins.

I'll ask around though ... do you know if the required flywheel is fitted to other engines or it specific to the 15.5 intek engines?

Thank for taking the time to reply and the help you are offering

#20

S

Scottishlad

S

Scottishlad

Another update ... as supected Briggs acknowledged they supplied the wrong block BUT will not provide the required flywheel and fan at anything another other than full cost! They have agreed however agreed to take the shortblock back (a bit mad for them because they probably wont be able to sell it given I've already fitted it and filled it with oil etc)

So depending on whether I find a used flywheel or a replacement engine first - i may just strip it out and send ... what a fiasco!

I've found a complete used motor 31A607 / 0470 - B1 / 090925ZA which I suspect is the same as my old motor so would be straight swap - he's asking £200 - a bargain if its not worn out but a further waste of time and money it is a bad 'un

The motors not fitted so cant be run so other than checking for lash at the crank and hand turned compression are there any other good checks I can do without dismantling to assess condition...?

Thanks again

So depending on whether I find a used flywheel or a replacement engine first - i may just strip it out and send ... what a fiasco!

I've found a complete used motor 31A607 / 0470 - B1 / 090925ZA which I suspect is the same as my old motor so would be straight swap - he's asking £200 - a bargain if its not worn out but a further waste of time and money it is a bad 'un

The motors not fitted so cant be run so other than checking for lash at the crank and hand turned compression are there any other good checks I can do without dismantling to assess condition...?

Thanks again