You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

K66 fluid change cost

#1

O

Oldaarpy

O

Oldaarpy

In 2015 I bought a new Husqvarna GTXLSi with the K66 locker on it and the owners manual claimed no service required. I've had great luck with this machine, mowing and plowing snow, except for the so called smart switch! But it has started slowing down going up steep hills. I'd like to get the oil and filter changed in it (at 675 hrs I'm sure it's WAY overdo from what I've read) but I'm not real mechanically inclined. At 75 yrs old I'm on a fixed budget so I'm concerned about service costs. At $100 an hours, and no other problems, can someone give me a 'ball park' figure on what the bill would be. Should I attempt to do this myself?

#2

Tiger Small Engine

Sometimes on transaxles you can only siphon out some of the oil and not change/clean the filter. Sometimes to do the job right, you have to remove transaxle from mower and turn upside down to get all oil out, still not cleaning filter.

You will find most shops will not work on transaxles. Only remove and replace as needed. Won’t comment on your fixed budget at 75 years old, because I will get in trouble.

Tiger Small Engine

The Tuff Torq K66 is a much better transaxle than say the K46. A hundred dollars an hour for shop labor is average in many cases. You are paying experience, overhead, tools, etc. That is book time not actual work time.In 2015 I bought a new Husqvarna GTXLSi with the K66 locker on it and the owners manual claimed no service required. I've had great luck with this machine, mowing and plowing snow, except for the so called smart switch! But it has started slowing down going up steep hills. I'd like to get the oil and filter changed in it (at 675 hrs I'm sure it's WAY overdo from what I've read) but I'm not real mechanically inclined. At 75 yrs old I'm on a fixed budget so I'm concerned about service costs. At $100 an hours, and no other problems, can someone give me a 'ball park' figure on what the bill would be. Should I attempt to do this myself?

Sometimes on transaxles you can only siphon out some of the oil and not change/clean the filter. Sometimes to do the job right, you have to remove transaxle from mower and turn upside down to get all oil out, still not cleaning filter.

You will find most shops will not work on transaxles. Only remove and replace as needed. Won’t comment on your fixed budget at 75 years old, because I will get in trouble.

#3

StarTech

StarTech

Tiger you should look up the K66 as you would see a drain plug that is about 1-1/2" to 2" in diameter. Apparently you are just guessing at what needs to done and being too lazy to even look up the transaxle IPL on the Tuff Torq website.

Just can't change the filter without pulling the transaxle on early versions but later versions it is just a easily changed cartridge. With the number of hours if the drive belt and v-idlers haven't been changed recently it could just be a slipping drive belt.

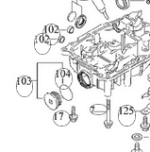

Actually model and serial numbers are needed for proper IPL look up as to which filter would be used. Hopefully it is the cartridge type as in the left image.

or

or

It will require SAE 5w15 synthetic oil. And that plug should have a 3/8 square hole for a ratchet to fit. Careful remove that plug as that hole can be stripped out. Also all the dirt must be from the plug and surrounding area.

And if a shop not willing to do this oil change they are just plain damn lazy. It should be an hour labor plus the oil and filter if it is the cartridge type; longer if the other deep inside the transaxle type filter. But as said the filter don't have to change all the time just depends how bad the oil looks like. IF the shop are the least bit reasonable they will have a senior citizen discount like mine. I give the 65+ group a ten percent discount on repairs. Which here is basically more than just knocking off the sales tax.

Just can't change the filter without pulling the transaxle on early versions but later versions it is just a easily changed cartridge. With the number of hours if the drive belt and v-idlers haven't been changed recently it could just be a slipping drive belt.

Actually model and serial numbers are needed for proper IPL look up as to which filter would be used. Hopefully it is the cartridge type as in the left image.

or

or

It will require SAE 5w15 synthetic oil. And that plug should have a 3/8 square hole for a ratchet to fit. Careful remove that plug as that hole can be stripped out. Also all the dirt must be from the plug and surrounding area.

And if a shop not willing to do this oil change they are just plain damn lazy. It should be an hour labor plus the oil and filter if it is the cartridge type; longer if the other deep inside the transaxle type filter. But as said the filter don't have to change all the time just depends how bad the oil looks like. IF the shop are the least bit reasonable they will have a senior citizen discount like mine. I give the 65+ group a ten percent discount on repairs. Which here is basically more than just knocking off the sales tax.

#4

O

Oldaarpy

O

Oldaarpy

Thanks for the replies. I changed the drive belt this year but the V-idlers have never been changed. Suppose to rain all day so might be a good time to check for those plugs.

#5

O

Oldaarpy

O

Oldaarpy

Some of these tractors have three idlers and some have two. Mine has three and I'm assuming only one is a V-idler? Clutching idler? They all look good but I'll change whatever I should. The gas tank sits over the tranny so I'd bet it's a bear to even add oil.

#6

Tiger Small Engine

In the words of Clint Eastwood, “A good man knows his limitations.”

The skills of customer service and how to treat and talk with people are often just as valuable as being able to repair something.

Tiger Small Engine

Thanks for being upbeat and positive as always. I did not look up the K66 on the drain plug, however was aware some units have plugs. Not wanting to work on hydro transaxles does not make a shop owner/operator lazy, it shows how years of working alone makes a smart person more selective on repairs.Tiger you should look up the K66 as you would see a drain plug that is about 1-1/2" to 2" in diameter. Apparently you are just guessing at what needs to done and being too lazy to even look up the transaxle IPL on the Tuff Torq website.

Just can't change the filter without pulling the transaxle on early versions but later versions it is just a easily changed cartridge. With the number of hours if the drive belt and v-idlers haven't been changed recently it could just be a slipping drive belt.

Actually model and serial numbers are needed for proper IPL look up as to which filter would be used. Hopefully it is the cartridge type as in the left image.

View attachment 69382 orView attachment 69383

It will require SAE 5w15 synthetic oil. And that plug should have a 3/8 square hole for a ratchet to fit. Careful remove that plug as that hole can be stripped out. Also all the dirt must be from the plug and surrounding area.

And if a shop not willing to do this oil change they are just plain damn lazy. It should be an hour labor plus the oil and filter if it is the cartridge type; longer if the other deep inside the transaxle type filter. But as said the filter don't have to change all the time just depends how bad the oil looks like. IF the shop are the least bit reasonable they will have a senior citizen discount like mine. I give the 65+ group a ten percent discount on repairs. Which here is basically more than just knocking off the sales tax.

In the words of Clint Eastwood, “A good man knows his limitations.”

The skills of customer service and how to treat and talk with people are often just as valuable as being able to repair something.

#7

StarTech

StarTech

But around here I see so many local shops just taking advantage of the customers it isn't funny. Sorta like one a couple years ago. They told the customer he need a $4000 engine replacement. Good thing the customer decided to get a second opinion instead going with dealer suggestion. It turn to be a simple head gasket replacement. All of $300 in my shop do some other work that was needed at the same time.

Now I do have a K46 with very weak reverse and it quickly goes downhill when the engine is not running. Needing new center section replacement. Since I am in the Tuff Torq main distributor it cost only a 1/8 more to install a new unit. Considering how rough the customer is on the mower (cutting 10 acres per week) a new unit is his best option in this case. I can just rebuild the old unit for someone that is not as a rough user.

The 7A646084101 including oil lists for $790 plus an hour labor and the repair kit lists for $463.35, $47 for oil, plus my labor. The amount time depend how much cleaning got to be done. So it is just up to customer which way to go. Other words how quickly he needs the mower back. New unit is an one day turn around, rebuilt a few extra days. Actually more profit in the rebuilding but less time to install new unit. Both ways he get a 90 day warranty.

The right now is how much is the shipping. Salesman only gave me a guess price on shipping and his company does this shipping every day. I told to get back to me with a firm price. I don't want to get burned like last year when he told me $40-$50 to ship a short block, I quoted the customer his cost, and then I got slapped with a $200 freight bill after I done billed the customer. Always nice end up losing money on a sale because of a stupid salesman.

By the way I have work alone since 1979 on equipment, no one else was there to depend on for help. 16 yrs for the other man and still had do it all myself from actual repair to ordering and stock parts. Couldn't even depend on the boss to do his job. He was more interested the girls and the booze.

Now I do have a K46 with very weak reverse and it quickly goes downhill when the engine is not running. Needing new center section replacement. Since I am in the Tuff Torq main distributor it cost only a 1/8 more to install a new unit. Considering how rough the customer is on the mower (cutting 10 acres per week) a new unit is his best option in this case. I can just rebuild the old unit for someone that is not as a rough user.

The 7A646084101 including oil lists for $790 plus an hour labor and the repair kit lists for $463.35, $47 for oil, plus my labor. The amount time depend how much cleaning got to be done. So it is just up to customer which way to go. Other words how quickly he needs the mower back. New unit is an one day turn around, rebuilt a few extra days. Actually more profit in the rebuilding but less time to install new unit. Both ways he get a 90 day warranty.

The right now is how much is the shipping. Salesman only gave me a guess price on shipping and his company does this shipping every day. I told to get back to me with a firm price. I don't want to get burned like last year when he told me $40-$50 to ship a short block, I quoted the customer his cost, and then I got slapped with a $200 freight bill after I done billed the customer. Always nice end up losing money on a sale because of a stupid salesman.

By the way I have work alone since 1979 on equipment, no one else was there to depend on for help. 16 yrs for the other man and still had do it all myself from actual repair to ordering and stock parts. Couldn't even depend on the boss to do his job. He was more interested the girls and the booze.

#8

B

biggertv

B

biggertv

Clutching Idler? If so it has a Spring and springs wear out. Especially newer ones. Steel ain't what it used to be, It may not be giving the stretched belt the tension it needs, possibly slipping at Transmission under load. For Fluid Change, I'd use a hand pump. You may have to get creative with hoses, tubing and clamps to make a small enough hose to fit the tranny. remove as much as you can, add a quart and remove all that. Then Refill. Good Luck! Need cheap tools? Some Harbor Freight sockets and wrenches are Much Better than they were 20 years ago. I like the colored sockets. Not Snap-On, but plenty good enough for sub-Space Shuttle Level work.

#9

O

Oldaarpy

O

Oldaarpy

Thanks for the replies. New clutching idler came today and when I went to put it on not only was it in the wrong place but the sides were smoother than the new one. I've never messed with the idlers that I can think of so I think it was assembled wrong. It's raining again so my test drive up the hill was short but it seemed stronger. I may yet have to have the oil changed.

At my age I don't need expensive tools nor can I afford them. The only problem I've had with HF is there bolts and screws are chintzy.

I saw the drain plug. Can it be reused or require a new one? Anything else need to be purchased besides oil? Looks like a major operation taking off the gas tank to get to the tranny. (I'm trying to talk myself into changing the oil myself).

I don't think I'd want a spring any stronger.

At my age I don't need expensive tools nor can I afford them. The only problem I've had with HF is there bolts and screws are chintzy.

I saw the drain plug. Can it be reused or require a new one? Anything else need to be purchased besides oil? Looks like a major operation taking off the gas tank to get to the tranny. (I'm trying to talk myself into changing the oil myself).

I don't think I'd want a spring any stronger.

#10

O

Oldaarpy

O

Oldaarpy

Contacted TuffTorq to see what I needed (exactly) to change the oil and filter. They replied the filter is NOT a servicable item and all I needed was drain plug seals and fluid. In the mean time, on a real hot day, the mower refused to go up a hill with the blades engaged and made a grinding noise, but was fine when not under the stain of mowing. I'm hoping changing the oil does the trick but the seals are on back-order.

#11

Tiger Small Engine

Tiger Small Engine

If the mower won’t go up a hill and is making a grinding noise, it is doubtful changing the oil will help with transaxle.Contacted TuffTorq to see what I needed (exactly) to change the oil and filter. They replied the filter is NOT a servicable item and all I needed was drain plug seals and fluid. In the mean time, on a real hot day, the mower refused to go up a hill with the blades engaged and made a grinding noise, but was fine when not under the stain of mowing. I'm hoping changing the oil does the trick but the seals are on back-order.

#12

StarTech

Even removing is easy compared to removing the engine on Toro TX427 Dingo. Now that is something I probably am going to take a pass on here. Looks like a all day job just to get it out but it is the only to replace the cylinder head. NO room the get to shroud off as you got to remove the flywheel side output shaft. On top most of the hydraulics has to be removed before even being able to lift the engine out.

And as said once they start cavitation they are usually at the end of their life without complete rebuild.

StarTech

Just plain BS about the filter as if it was not a replaceable item they would not be selling it through the part channel. It just that they consider most owner too inept at doing mechanical work.Contacted TuffTorq to see what I needed (exactly) to change the oil and filter. They replied the filter is NOT a servicable item and all I needed was drain plug seals and fluid. In the mean time, on a real hot day, the mower refused to go up a hill with the blades engaged and made a grinding noise, but was fine when not under the stain of mowing. I'm hoping changing the oil does the trick but the seals are on back-order.

Even removing is easy compared to removing the engine on Toro TX427 Dingo. Now that is something I probably am going to take a pass on here. Looks like a all day job just to get it out but it is the only to replace the cylinder head. NO room the get to shroud off as you got to remove the flywheel side output shaft. On top most of the hydraulics has to be removed before even being able to lift the engine out.

And as said once they start cavitation they are usually at the end of their life without complete rebuild.

#13

O

Oldaarpy

O

Oldaarpy

"Filter is not servicable because it is strongly recommend by Tuff Torq that you do not crack the case". I didn't realize a K66 was considered disposable.

#14

StarTech

And I wonder why they have these internal parts available. Yes the unit is non serviceable by the avg Joe but but shops like mine do service them. These unit does a very clean area to service them along the unit being very clean externally.

StarTech

There is two versions on this unit one came an internal filter that requires the case to open and one that does not."Filter is not servicable because it is strongly recommend by Tuff Torq that you do not crack the case". I didn't realize a K66 was considered disposable.

And I wonder why they have these internal parts available. Yes the unit is non serviceable by the avg Joe but but shops like mine do service them. These unit does a very clean area to service them along the unit being very clean externally.

#15

O

Oldaarpy

O

Oldaarpy

I gave TuffTorq the unit number and it sounds like it has the internal filter. Took the deck off today hoping to find vegitation causing the trouble buy no luck there. there's no leaks in any part of the tranny that I can see so I guess that's a small plus. Any idea (ball park) of the cost of a total rebuild?

#16

StarTech

StarTech

Not able to quote labor costs on your end but the overhaul kit run about $500 with oil. This does not include any additional parts that might need replacing.

It is basically the center section, the two pump motors, and seal kit with filter along with 3 liters of 5w50 synthetic oil.

Note this is for the unit with the internal filter. The one with the easily replaced filter cost about $30 more.

It is basically the center section, the two pump motors, and seal kit with filter along with 3 liters of 5w50 synthetic oil.

Note this is for the unit with the internal filter. The one with the easily replaced filter cost about $30 more.

#17

O

Oldaarpy

O

Oldaarpy

Thanks for that info. They get $100 per hr around here. If the oil change doesn't work I'll pull the tranny and head for the dealer.

#18

O

Oldaarpy

O

Oldaarpy

I started tearing this monster apart. Deck is off, seat is off, steering wheel off, all bolts are off and all ready to take the 'body' off if I can figure how to work around the lift spring. The body is loose but the lift lever is in the way. What post(s) am I looking for on here, just 'lift spring removal' under Husqvarna? TKS

#19

Tiger Small Engine

Tiger Small Engine

You are removing the mower from the transaxle, rather than removing the transaxle from the mower. Once you get the body off, you still have to remove the transaxle. Maybe you should stop right there, and think this whole thing through again.I started tearing this monster apart. Deck is off, seat is off, steering wheel off, all bolts are off and all ready to take the 'body' off if I can figure how to work around the lift spring. The body is loose but the lift lever is in the way. What post(s) am I looking for on here, just 'lift spring removal' under Husqvarna? TKS

#20

O

Oldaarpy

O

Oldaarpy

My thought was remove the body, remove the gas tank which would expose the top of the tranny where the fill plugs are. I wasn't going to remove the transaxle until I found out wether changing the oil worked or not. The tranny is fine other than going up a steep hill under FULL load running the blades. It goes up fine with NO load and cuts great on level ground. So I was hoping the oil change would work. Being retired on limited income finding the money to have a rebuild would be tough. Thanks for all your help.

#21

kbowley

kbowley

The issue is refilling it while in the machine. I always drop them, remove the top drain plug, tip it into a stout drain pan, refill per instructions (usually leave about an inch from topped off), with 20-50 Mobil one high mileage oil, purge it by hand and recheck level and put it back in. The K66 is heavy, about 50 lbs. though. I would plan on three hours of labor for a shop to do it. It is unusual for a K66 to get soft, fairly stout tranny rated for 300 lb. ft. of wheel torque. Here is a link to the transmission specs. Here is a link to some YouTube videos with instructions on the procedure.Tiger you should look up the K66 as you would see a drain plug that is about 1-1/2" to 2" in diameter. Apparently you are just guessing at what needs to done and being too lazy to even look up the transaxle IPL on the Tuff Torq website.

Just can't change the filter without pulling the transaxle on early versions but later versions it is just a easily changed cartridge. With the number of hours if the drive belt and v-idlers haven't been changed recently it could just be a slipping drive belt.

Actually model and serial numbers are needed for proper IPL look up as to which filter would be used. Hopefully it is the cartridge type as in the left image.

View attachment 69382 orView attachment 69383

It will require SAE 5w15 synthetic oil. And that plug should have a 3/8 square hole for a ratchet to fit. Careful remove that plug as that hole can be stripped out. Also all the dirt must be from the plug and surrounding area.

And if a shop not willing to do this oil change they are just plain damn lazy. It should be an hour labor plus the oil and filter if it is the cartridge type; longer if the other deep inside the transaxle type filter. But as said the filter don't have to change all the time just depends how bad the oil looks like. IF the shop are the least bit reasonable they will have a senior citizen discount like mine. I give the 65+ group a ten percent discount on repairs. Which here is basically more than just knocking off the sales tax.

#24

O

Oldaarpy

O

Oldaarpy

Why I asked was because they were on really tight when I took them off. Thanks.Just snug, don't want to strip the aluminum because that's a bad day.

#26

O

Oldaarpy

O

Oldaarpy

My son-in-law has a Husqvarna with a different brand tranny and one of the drain bolts came loose. Luckily we found the leak after it was parked for awhile. I know the fan torq is 45.