You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Interlock question

#1

G

GeorgiaDave

G

GeorgiaDave

I have just resurrected a Gravely 150 PRO - this is a recoil, not battery start engine. Can anyone tell me or give me a functional schematic of an interlock module for a non-battery powered engine. I understand that the interlock is powered from the ignition coil primary, but I've looked and looked, and can't find any documentation for any module that runs from the primary side of the coil. The interlock is bad, I hate bypassing it, but I also hate that the cost for the interlock is a bit higher than I want to spend (just shy of $200). I have quite a bit of experience with circuit design, but I don't know much about the voltage(s) on the primary side. I suppose I can dig out my o-scope and see for myself, but if anyone here has knowledge regarding this, or an example circuit, I would sincerely appreciate it !

Worst case, I'll buy the interlock, but I'd have a lot more fun building my own...

Worst case, I'll buy the interlock, but I'd have a lot more fun building my own...

#2

StarTech

StarTech

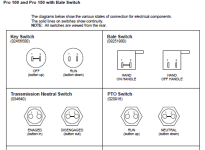

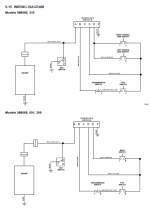

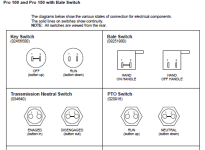

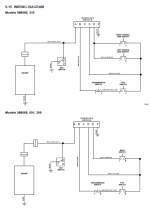

Basically it is a grounding module. Take a little and study the diagram and you should see what I am referring to.

Basically once the tiny circuit board is removed (provided it is one I thinking it is) you will see what a con job it is and how easy you rewire to keep all the safeties fully working as intended.

Basically once the tiny circuit board is removed (provided it is one I thinking it is) you will see what a con job it is and how easy you rewire to keep all the safeties fully working as intended.

#3

G

GeorgiaDave

G

GeorgiaDave

No way that I can envision this working without the module. Sure, I can bypass the safety's, that's simple, but that's not what I'm trying to accomplish. I have a failed interlock - rather than buy one, I'd rather build one.

I humbly invite anyone to show how rewiring this circuit can get the safety's functional. Not being negative, but I don't believe it can be done without a module controlling the primary to ground. No, it's not okay to require the handles to be held to run or start ! It has to run in neutral, no PTO, no hands on handlebars. It had to run in gear, with or without PTO, or in neutral, with PTO, or in gear or PTO with hands on handlebar.

I would be exceptionally happy to be proved wrong!

BTW, my Pro 150 is 988059, but same wiring as 988089.

I humbly invite anyone to show how rewiring this circuit can get the safety's functional. Not being negative, but I don't believe it can be done without a module controlling the primary to ground. No, it's not okay to require the handles to be held to run or start ! It has to run in neutral, no PTO, no hands on handlebars. It had to run in gear, with or without PTO, or in neutral, with PTO, or in gear or PTO with hands on handlebar.

I would be exceptionally happy to be proved wrong!

BTW, my Pro 150 is 988059, but same wiring as 988089.

#4

StarTech

StarTech

Well I would normally sit here and figure this out but right now I dealing a Lower Left Molar tooth giving me a lot of pain and no pain meds to deaden it until at least late Tuesday. I have been in pain since Thursday a week ago. Can't keep my mind on anything long.

I already ran off one nit picking customer Friday that thought lying to me would get me to lower my estimate. Well it did. I just put back in his old transaxle and told him to hit the road Thursday. He came back and got his Friday thinking I installed another transaxle which I didn't. No bill and he is lucky as I could had charged for my time of finding out what was wrong.

I already ran off one nit picking customer Friday that thought lying to me would get me to lower my estimate. Well it did. I just put back in his old transaxle and told him to hit the road Thursday. He came back and got his Friday thinking I installed another transaxle which I didn't. No bill and he is lucky as I could had charged for my time of finding out what was wrong.

#5

A

Auto Doc's

A

Auto Doc's

Prove all the safety switches work before you condemn the interlock. It is a simple device that gives the correct go ahead from the switches for safe operations. Likely bugs and connector corrosion has taken place. A simple meter should find your problem.I have just resurrected a Gravely 150 PRO - this is a recoil, not battery start engine. Can anyone tell me or give me a functional schematic of an interlock module for a non-battery powered engine. I understand that the interlock is powered from the ignition coil primary, but I've looked and looked, and can't find any documentation for any module that runs from the primary side of the coil. The interlock is bad, I hate bypassing it, but I also hate that the cost for the interlock is a bit higher than I want to spend (just shy of $200). I have quite a bit of experience with circuit design, but I don't know much about the voltage(s) on the primary side. I suppose I can dig out my o-scope and see for myself, but if anyone here has knowledge regarding this, or an example circuit, I would sincerely appreciate it !

Worst case, I'll buy the interlock, but I'd have a lot more fun building my own...

#6

G

GeorgiaDave

G

GeorgiaDave

Already verified all wiring and switches. Only thing left is the interlock. The unit starts and runs just fine, but only way to turn it off is via the key switch. The safeties are all non-functional.

Likely this forum is the wrong place for electrical questions. Logic tells me that the module is required, but odd that it failed in the wrong direction, I would have expected it to fail with the primary grounded, not open. At least it's usable now, just not very safe...

Thanks!

Likely this forum is the wrong place for electrical questions. Logic tells me that the module is required, but odd that it failed in the wrong direction, I would have expected it to fail with the primary grounded, not open. At least it's usable now, just not very safe...

Thanks!

#7

StarTech

StarTech

What you are describing is an open circuit.

Even though the wiring is verified have you verified the wire terminals?

Image of NOS interlock

Newer version

This show that the mating connector housing would likely have F56/Packard/Dephi female terminals. These do have a habit of breaking at the hinge point thus creating loose connections that may make contact or not.

Even though the wiring is verified have you verified the wire terminals?

Image of NOS interlock

Newer version

This show that the mating connector housing would likely have F56/Packard/Dephi female terminals. These do have a habit of breaking at the hinge point thus creating loose connections that may make contact or not.

#8

G

GeorgiaDave

G

GeorgiaDave

Yes, verified all connections, including the terminal blocks. In addition, I also use wire piercing clamps to check all connections (and a touch of liquid sealant on the tiny hole left). The newer version is what I have on my mower. As stated earlier, I would much rather build a replacement than buy and learn something in the process. This is not a customer unit, it's for my brother-in-law who lost everything in Helene; just doing my part to help.

Honestly, I'm just trying to understand the best method to produce steady DC from the primary on the ignition coil. I haven't measured it yet, but I'd expect fairly high and variable voltage on the primary, but obviously it's been done. If I had a spare interlock, I'd remove the potting compound and look at the circuit.

Other than accomplishing DC, it's a simple circuit to reproduce the switch logic. I was hoping maybe someone here had toyed with this. My concern would be loading the primary with the DC conversion and wreaking havoc on the ignition.

Honestly, I'm just trying to understand the best method to produce steady DC from the primary on the ignition coil. I haven't measured it yet, but I'd expect fairly high and variable voltage on the primary, but obviously it's been done. If I had a spare interlock, I'd remove the potting compound and look at the circuit.

Other than accomplishing DC, it's a simple circuit to reproduce the switch logic. I was hoping maybe someone here had toyed with this. My concern would be loading the primary with the DC conversion and wreaking havoc on the ignition.

#9

A

Auto Doc's

A

Auto Doc's

I am not aware of any ignition coil producing DC power. The way I read the diagram that is an interlock ignition coil shutdown wire.

Does this engine have only a charging stator under the flywheel to operate lights, or no running power supply system at all?

Does this engine have only a charging stator under the flywheel to operate lights, or no running power supply system at all?

#10

G

GeorgiaDave

G

GeorgiaDave

It's not DC as we think of it, nor AC. Everytime the magnet passes in front, it causes a magnetic field to form in the ignition coil primary. When the magnet passes, the field collapses causing current to flow in the primary. The primary current causes current to flow in the secondary (not sure of the voltage multiplication, probably at least 100:1) which causes a spark to flow across the spark plug terminals. While this occurs, the primary voltage goes from zero, to perhaps a few hundred volts, then back to zero as the field collapses. The voltage measured would be more AC like than DC, but without any negative component. On an oscope, this will likely show as a very noisy square wave (I'm guessing, haven't hooked mine up yet). The frequency would vary with the motor RPM, which is why I say it's almost AC. The trick would be to convert that noisy square wave to DC to run a safety switching circuit. What I'd like to know is the method the interlock uses to convert that square wave to DC. I'm supposing a cap diode and resistor would do trick, but I was hoping someone here has already figured that part out...

If you turn your flywheel to TDC during the ignition cycle, you'll see the magnet has already moved past the center of the ignition coil - this is how simple engines are timed.

If you turn your flywheel to TDC during the ignition cycle, you'll see the magnet has already moved past the center of the ignition coil - this is how simple engines are timed.

#11

A

Auto Doc's

I have only seen inline diodes for each coil used on the primary kill wire of most V-twin engines. It prevents primary "kill wire" discharge into each of the opposing coils.

I'm not sure about the idea of feeding coil "flyback" voltage back into an interlock device. As you say it would be a noisy square wave, or just a bunch of hash spikes.

I am not certain this or any interlock device is meant to be powered, it is simply a ground signal junction for all of the safety switches to meet at.

I have such an interlock (small version) on an old 1980's Snapper (no-electric start and no battery or lights) and all it does is ground the coil if the deck engage switch is in the on position or the key is switched to off. With both switches in their proper (start) position, it will allow the coil to work, and the engine can be started with the pull rope. Otherwise, a person could pull on the rope until they are blue in the face.

Lawnmower (magnetic induction) coils do not work quite the same as conventional old school 2-wire 12V automotive coils.

According to the diagram the key switch has its "master" ground, and the interlock has its own ground for the series of safety switches. The way I read it, each switch has to be in the correct open or closed position for the interlock to do its job.

In this case an Ohm meter would be used to verify the switches agree with the diagram legend at the top.

A

Auto Doc's

Hi Georgia Dave,It's not DC as we think of it, nor AC. Everytime the magnet passes in front, it causes a magnetic field to form in the ignition coil primary. When the magnet passes, the field collapses causing current to flow in the primary. The primary current causes current to flow in the secondary (not sure of the voltage multiplication, probably at least 100:1) which causes a spark to flow across the spark plug terminals. While this occurs, the primary voltage goes from zero, to perhaps a few hundred volts, then back to zero as the field collapses. The voltage measured would be more AC like than DC, but without any negative component. On an oscope, this will likely show as a very noisy square wave (I'm guessing, haven't hooked mine up yet). The frequency would vary with the motor RPM, which is why I say it's almost AC. The trick would be to convert that noisy square wave to DC to run a safety switching circuit. What I'd like to know is the method the interlock uses to convert that square wave to DC. I'm supposing a cap diode and resistor would do trick, but I was hoping someone here has already figured that part out...

If you turn your flywheel to TDC during the ignition cycle, you'll see the magnet has already moved past the center of the ignition coil - this is how simple engines are timed.

I have only seen inline diodes for each coil used on the primary kill wire of most V-twin engines. It prevents primary "kill wire" discharge into each of the opposing coils.

I'm not sure about the idea of feeding coil "flyback" voltage back into an interlock device. As you say it would be a noisy square wave, or just a bunch of hash spikes.

I am not certain this or any interlock device is meant to be powered, it is simply a ground signal junction for all of the safety switches to meet at.

I have such an interlock (small version) on an old 1980's Snapper (no-electric start and no battery or lights) and all it does is ground the coil if the deck engage switch is in the on position or the key is switched to off. With both switches in their proper (start) position, it will allow the coil to work, and the engine can be started with the pull rope. Otherwise, a person could pull on the rope until they are blue in the face.

Lawnmower (magnetic induction) coils do not work quite the same as conventional old school 2-wire 12V automotive coils.

According to the diagram the key switch has its "master" ground, and the interlock has its own ground for the series of safety switches. The way I read it, each switch has to be in the correct open or closed position for the interlock to do its job.

In this case an Ohm meter would be used to verify the switches agree with the diagram legend at the top.

#12

G

GeorgiaDave

G

GeorgiaDave

Looking at the wiring diagram, I don't see how it's possible that the module is not powered. Otherwise, why a 'module' in the first place, it has to be active (ie, powered), not passive, or it would have no value at all. For example, no non-mechanical switch can be thrown without power, thus it has to be powered by the primary feeding back to the module.

Take a look at the wiring diagram for either 988088 or 988089. These show the switch positions in the safety position. Look at the transmission switch (NC) and PTO switch (NO). Someone please explain to me how the engine can be started, and immediately stall when the transmission switch is in the open position and the bale or handle switch is left in the start/default position, without some form of 'electronic' switching in the module. Simply opening the transmission switch alone can't possibly signal to the module that the switch is open because the PTO is open.

Feel like I'm beating a dead horse, but appreciate the thoughts. Show me a diagram of how you think a passive (non-powered) module can control the primary grounding based on these schematics. If it's passive, it can only consist of wires, so please show me the wiring diagram internal to the module, it's not possible in any way I can imagine.

Many thanks!

Take a look at the wiring diagram for either 988088 or 988089. These show the switch positions in the safety position. Look at the transmission switch (NC) and PTO switch (NO). Someone please explain to me how the engine can be started, and immediately stall when the transmission switch is in the open position and the bale or handle switch is left in the start/default position, without some form of 'electronic' switching in the module. Simply opening the transmission switch alone can't possibly signal to the module that the switch is open because the PTO is open.

Feel like I'm beating a dead horse, but appreciate the thoughts. Show me a diagram of how you think a passive (non-powered) module can control the primary grounding based on these schematics. If it's passive, it can only consist of wires, so please show me the wiring diagram internal to the module, it's not possible in any way I can imagine.

Many thanks!

#13

A

Auto Doc's

It is a ground side only system, no "positive" power needed. Technically if any of the switches are not in the correct position, the coil is being grounded and prevent running.

To narrow down the running issue disconnect the coil "kill" wire and see if the engine will run normal. If not, the problem is on the engine side. If it runs well, then there is one of the "ground safety" switches at fault.

That is not to say the interlock cannot still have an issue, but it is a matter of narrowing down where the fault exactly is.

Don't forget a worn ignition key ground switch can also be at fault in the circuit.

A

Auto Doc's

The key word I think is interlock. The word "module" is just a technical descriptor for circuit meeting place. It is where all of the safety switches meet.Looking at the wiring diagram, I don't see how it's possible that the module is not powered. Otherwise, why a 'module' in the first place, it has to be active (ie, powered), not passive, or it would have no value at all. For example, no non-mechanical switch can be thrown without power, thus it has to be powered by the primary feeding back to the module.

Take a look at the wiring diagram for either 988088 or 988089. These show the switch positions in the safety position. Look at the transmission switch (NC) and PTO switch (NO). Someone please explain to me how the engine can be started, and immediately stall when the transmission switch is in the open position and the bale or handle switch is left in the start/default position, without some form of 'electronic' switching in the module. Simply opening the transmission switch alone can't possibly signal to the module that the switch is open because the PTO is open.

Feel like I'm beating a dead horse, but appreciate the thoughts. Show me a diagram of how you think a passive (non-powered) module can control the primary grounding based on these schematics. If it's passive, it can only consist of wires, so please show me the wiring diagram internal to the module, it's not possible in any way I can imagine.

Many thanks!

It is a ground side only system, no "positive" power needed. Technically if any of the switches are not in the correct position, the coil is being grounded and prevent running.

To narrow down the running issue disconnect the coil "kill" wire and see if the engine will run normal. If not, the problem is on the engine side. If it runs well, then there is one of the "ground safety" switches at fault.

That is not to say the interlock cannot still have an issue, but it is a matter of narrowing down where the fault exactly is.

Don't forget a worn ignition key ground switch can also be at fault in the circuit.

#14

G

GeorgiaDave

G

GeorgiaDave

So, if all the switches meet up in the module, then it's simply a wire, or other passive components, such as resistors, caps, etc.

Please, someone show me a diagram of those wires and passive components - I would love to be schooled on how that can work.

I'm not trying to be an @ss here - I truly want to know how any group of wires or passive components, no matter how connected, and make that circuit work. Saying it's so is not the same as showing a diagram of how it works.

My mower works fine, but no safeties. Every switch and wire has been verified, therefore it must be the module. If the module is simply a passive component, then there must be a way to add a wire here and there to bypass it. Show me a schematic, and it will all become clear.

Thanks again!

Please, someone show me a diagram of those wires and passive components - I would love to be schooled on how that can work.

I'm not trying to be an @ss here - I truly want to know how any group of wires or passive components, no matter how connected, and make that circuit work. Saying it's so is not the same as showing a diagram of how it works.

My mower works fine, but no safeties. Every switch and wire has been verified, therefore it must be the module. If the module is simply a passive component, then there must be a way to add a wire here and there to bypass it. Show me a schematic, and it will all become clear.

Thanks again!

#15

A

Auto Doc's

A

Auto Doc's

Without knowing the internals of the interlock module, that is a wild guess on anyone's part. I cannot advise bypassing any safety device.So, if all the switches meet up in the module, then it's simply a wire, or other passive components, such as resistors, caps, etc.

Please, someone show me a diagram of those wires and passive components - I would love to be schooled on how that can work.

I'm not trying to be an @ss here - I truly want to know how any group of wires or passive components, no matter how connected, and make that circuit work. Saying it's so is not the same as showing a diagram of how it works.

My mower works fine, but no safeties. Every switch and wire has been verified, therefore it must be the module. If the module is simply a passive component, then there must be a way to add a wire here and there to bypass it. Show me a schematic, and it will all become clear.

Thanks again!

#16

G

GeorgiaDave

I'm not asking for advice in how to bypass it, remove it, or do without it. My hope was someone on this forum had intimate electrical knowledge of the interlock unit itself.

Enough for now, appreciate the time!

G

GeorgiaDave

As noted in my OP, I'm not interested in bypassing, I'm interested in knowing the internal circuitry of the bypass. I will purchase an interlock, but my curiosity leads me to want to understand how it works. As noted, it appears to me that the device cannot operate passively, so again, being curious, I want to know how it's being powered from the primary.Without knowing the internals of the interlock module, that is a wild guess on anyone's part. I cannot advise bypassing any safety device.

I'm not asking for advice in how to bypass it, remove it, or do without it. My hope was someone on this forum had intimate electrical knowledge of the interlock unit itself.

Enough for now, appreciate the time!

#17

StarTech

StarTech

Very few of us have ever seen one of these units in the first place (doubt even a Gravely has seen very often either) and then it would take someone with initiative to simple pull the circuit board out the interlock module housing. If it is like another OEM one I did pull out several years ago it is so simple it wasn't funny. I wish had took the time to record the info about it but I didn't even think of doing at the time as I wasn't running my own forum at the time and had serious family health problem that require a lot more of my attention at the time. If I remember correctly it is just a printed circuit with a couple jumpers and one lead that is a false lead, no magic components.

But since you willing to replace it there is little harm in taking the module apart for a look see. I would do it here if I had one in hand but I don't and have no reason to buy one currently. Besides I would most like start hard re-wiring once I knew how it was setup to keep costs down like I do with the JD ECUs on the Z800 and Z900 series ZTRs.

But since you willing to replace it there is little harm in taking the module apart for a look see. I would do it here if I had one in hand but I don't and have no reason to buy one currently. Besides I would most like start hard re-wiring once I knew how it was setup to keep costs down like I do with the JD ECUs on the Z800 and Z900 series ZTRs.

#18

A

Auto Doc's

A

Auto Doc's

The interlock is not powered in any way. It is simply and interrupt deviceAs noted in my OP, I'm not interested in bypassing, I'm interested in knowing the internal circuitry of the bypass. I will purchase an interlock, but my curiosity leads me to want to understand how it works. As noted, it appears to me that the device cannot operate passively, so again, being curious, I want to know how it's being powered from the primary.

I'm not asking for advice in how to bypass it, remove it, or do without it. My hope was someone on this forum had intimate electrical knowledge of the interlock unit itself.

Enough for now, appreciate the time!

#19

S

Steven65

www.manualslib.com

www.manualslib.com

S

Steven65

Here is the whole manual..I have just resurrected a Gravely 150 PRO - this is a recoil, not battery start engine. Can anyone tell me or give me a functional schematic of an interlock module for a non-battery powered engine. I understand that the interlock is powered from the ignition coil primary, but I've looked and looked, and can't find any documentation for any module that runs from the primary side of the coil. The interlock is bad, I hate bypassing it, but I also hate that the cost for the interlock is a bit higher than I want to spend (just shy of $200). I have quite a bit of experience with circuit design, but I don't know much about the voltage(s) on the primary side. I suppose I can dig out my o-scope and see for myself, but if anyone here has knowledge regarding this, or an example circuit, I would sincerely appreciate it !

Worst case, I'll buy the interlock, but I'd have a lot more fun building my own...

GRAVELY PRO 150 OWNER'S/OPERATOR'S MANUAL Pdf Download

View and Download Gravely Pro 150 owner's/operator's manual online. Walk-Behind Mower Power Unit. Pro 150 lawn mower pdf manual download. Also for: 988088, 988091, 988092, 988309.

#20

grumpyunk

grumpyunk

The late 1980's Snapper has/had a module that required the shift/gear lever be in neutral in order to enable the ignition. There is no seat occupancy switch, and, it's been over 20 years, it may have had a blade release cutout switch also.

It was not powered by the battery. In Neutral and with the blade dis-engaged, it would allow spark generation. I figured it must use part of the generator circuit to make a transistor conduct(?) before it would generate spark. I got tired of it being finicky, working fine and then not working at all, with me grinding down the battery, or in worse case, wearing myself out pulling the starter rope. A CV14 is hard enough to pull over that I decided it being disconnected was not a safety problem as I would be the only operator. A replacement was available, but 1)it added complexity and un-reliability, and 2)it was not reasonably priced.

The original replacement(exact) has been superseded to another box, containing who knows what, and it has not become more affordable. It is staying on the vendor shelf as far as I am concerned.

I did not take it apart, but figure it has to be a very simple circuit that grounds the ignition when the switch(es) are not in proper position. It really is kind of worthless, IMO.

It is inside a black plastic box, and might be destroyed if an attempt was made to examine the actual circuit.

I really just got tired of it killing the engine now and again while in use, and being very difficult to get started.

tom

It was not powered by the battery. In Neutral and with the blade dis-engaged, it would allow spark generation. I figured it must use part of the generator circuit to make a transistor conduct(?) before it would generate spark. I got tired of it being finicky, working fine and then not working at all, with me grinding down the battery, or in worse case, wearing myself out pulling the starter rope. A CV14 is hard enough to pull over that I decided it being disconnected was not a safety problem as I would be the only operator. A replacement was available, but 1)it added complexity and un-reliability, and 2)it was not reasonably priced.

The original replacement(exact) has been superseded to another box, containing who knows what, and it has not become more affordable. It is staying on the vendor shelf as far as I am concerned.

I did not take it apart, but figure it has to be a very simple circuit that grounds the ignition when the switch(es) are not in proper position. It really is kind of worthless, IMO.

It is inside a black plastic box, and might be destroyed if an attempt was made to examine the actual circuit.

I really just got tired of it killing the engine now and again while in use, and being very difficult to get started.

tom

#21

R

Red Good

R

Red Good

No battery and no regulator then it is not DC , dc is solely for battery storage so the e start will have energy to draw from . no e start then it is ac from the stator and magnet .

#22

B

bentrim

B

bentrim

See if this helps

Here is a links for a manual for a Pro 150. Note the first few pages give a way to eliminate the module.

Note to ALL: Please when you ask for help with a Gravely (maybe others) include the model #. Should be a tag on the engine deck and is six digits as 988100, 988101 etc. Gravely used trade model and a spec number. To say Pro 150 is like saying I have a Silverado pickup.

Here is a links for a manual for a Pro 150. Note the first few pages give a way to eliminate the module.

Note to ALL: Please when you ask for help with a Gravely (maybe others) include the model #. Should be a tag on the engine deck and is six digits as 988100, 988101 etc. Gravely used trade model and a spec number. To say Pro 150 is like saying I have a Silverado pickup.

#23

StarTech

StarTech

Hmmm that circuit diagram is what I came up on this end from studying the original wiring schematic with the module but part safety operation didn't jive with it. Maybe I mis read his post.

#24

S

SamB

Crippling any safety feature is like disabling one's vehicle brakes. All is fine until the need arises!

S

SamB

On one of my older ZTR mowers, I did away with the 'module' and wired all safety switches in series so if any one of them were in incorrect position, open or closed, the engine quit, the blade brake clamped down and the seat occupied switch killed everything also.. A separate grounding circuit isn't difficult to build. Reinventing a 'modern' safety system can be frustrating.(and expensive. Or NLA parts)Very few of us have ever seen one of these units in the first place (doubt even a Gravely has seen very often either) and then it would take someone with initiative to simple pull the circuit board out the interlock module housing. If it is like another OEM one I did pull out several years ago it is so simple it wasn't funny. I wish had took the time to record the info about it but I didn't even think of doing at the time as I wasn't running my own forum at the time and had serious family health problem that require a lot more of my attention at the time. If I remember correctly it is just a printed circuit with a couple jumpers and one lead that is a false lead, no magic components.

But since you willing to replace it there is little harm in taking the module apart for a look see. I would do it here if I had one in hand but I don't and have no reason to buy one currently. Besides I would most like start hard re-wiring once I knew how it was setup to keep costs down like I do with the JD ECUs on the Z800 and Z900 series ZTRs.

Crippling any safety feature is like disabling one's vehicle brakes. All is fine until the need arises!

#25

B

bentrim

B

bentrim

If you review my previos post on page 1 & 2 esentialy does that and elinimates the module.

The issue is the switches used with the module are normally open and when activated are closed. The switched in the "kit" are normally closed and open when activated. This means if a switch is deactivated the ignition is shorted to ground and kills the engine, and also deactivates the clutch.

The issue is the switches used with the module are normally open and when activated are closed. The switched in the "kit" are normally closed and open when activated. This means if a switch is deactivated the ignition is shorted to ground and kills the engine, and also deactivates the clutch.

#26

B

bentrim

B

bentrim

If you review my previos post on page 1 & 2 esentialy does that and elinimates the module.

The issue is the switches used with the module are normally open and when activated are closed. The switched in the "kit" are normally closed and open when activated. This means if a switch is deactivated the ignition is shorted to ground and kills the engine, and also deactivates the clutch. The only question left is are the parts cheaper than a module?

The issue is the switches used with the module are normally open and when activated are closed. The switched in the "kit" are normally closed and open when activated. This means if a switch is deactivated the ignition is shorted to ground and kills the engine, and also deactivates the clutch. The only question left is are the parts cheaper than a module?

#27

S

SamB

S

SamB

My apologies. I didn't click on your link and study it. Changing out an NO switch to a NC switch is sometimes needed if the part uses NO switches. User protection needs to be taken seriously. One never knows who is going to use that OPE down the road. Defeating safety features puts the one who did that at risk, also.If you review my previos post on page 1 & 2 esentialy does that and elinimates the module.

The issue is the switches used with the module are normally open and when activated are closed. The switched in the "kit" are normally closed and open when activated. This means if a switch is deactivated the ignition is shorted to ground and kills the engine, and also deactivates the clutch. The only question left is are the parts cheaper than a module?