You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

HRR216K8VYA - Can't Pull Mower Backwards - FIXED (READ HERE FOR TIPS)

#1

B

Briantii

B

Briantii

EDIT: Anyone reading this please check out my newer thread regarding how to upgrade from this bushing system to bearings. The bushings need to be kept clean at a minimum and ideally switched to bearings. The below thread addresses this as well as has other good preventive ideas:

https://www.lawnmowerforum.com/thre...kwards-hrr216vla-to-bearing-conversion.57255/

This is my first post on this forum, but I've read some of Robert @ Honda's posts and I must say THANK YOU. I recently went through troubleshooting my HRR216K8VYA mower which had been having problems with the rear wheels locking up and not spinning backwards. Lots of searching tended to yield lots of conflicting messages as to how the system works, and random suggestions regarding what may actually fix the issue. Given that I've solved it on mine, I wanted to share what I did and found in the hopes that maybe it helps someone else with this issue.

The HRR216 K8 VYA model I have is about 3 - 4 years old, it has the grey smart drive paddles, and has the rotostop blade clutch. I believe most of the modern Hondas (without Hydrostatic transmissions) will be very similar in operation to mine, however I can't comment on anything other than the model I have.

Symptom: The mower increasingly got harder and harder to pull backwards, eventually getting so bad that the rear wheels would just lock up and the mower would be dragged across the lawn. ANNOYING AS CAN BE.

What I found:

1) Contrary to a lot of info online, the ratcheting drive wheel sprockets are NOT the problem. If these are locked up you will not hear clicking sounds when you push the mower forward with it turned off. Pulling the mower backwards will ALWAYS turn the driveshaft and the transmission. The wheels will lock when the transmission tilts and is tightened on the belt. Basically pulling the mower backwards with the self propelled disengaged means the belt connecting the crankshaft and transmission will not be under tension and will slip. The ratcheting drive gears are there to allow you to turn the mower while you've got the self propelled engaged. Essentially it allows each wheel to overrun the speed of the solid drive shaft.

2) Since pulling the mower backwards means that the entire driveline minus the belt must be able to spin freely, it's CRITICAL that all items in the driveline are able to move smoothly. Keep in mind the ratcheting gears in the wheels will be locked to drive shaft speed, so these really don't count, but they should still be cleaned.

What I did:

1) I pulled the transmission out, drained the oil from it and inspected it. I found I had a minor chip on one of the gear surfaces and lots of metal in the oil. I cleaned it all out, filled it back up with ATF (probably not recommended, I hear 10w-30 is the stuff, but I don't care - I wanted ATF) and put it back together. Despite the chipped tooth it still operated smoothly so I chose not to replace it at this time, though best practice would be to replace it. This did NOT resolve my issue, though I'm sure it's help keep the transmission from self destructing. Keep in mind my yard is absolutely horrible for hills, rocks, etc and I don't blame the transmission for the failure... My yard is just THAT bad.

2) Replaced the adjusters / the bushings. !!!! - I think this it the biggest key - !!!! Upon close inspection of the bushings that the driveshaft rides in, they were dry and scored. My theory is that as I mowed the driveshaft and bushings would heat up and seize up just enough to create drag on the driveshaft, not enough to stop it form going forward under self propelled drive power, but enough to add drag and keep the assembly from spinning freely when pulled backwards. I greased the new bushings very well when reassembling as I suspect they may not have been "full" when they left the factory. The fully assembled bushings / adjusters cost about $12 per side, you can press in / out new bushings for a lot less... but I just bought the whole assembly because I'm lazy and $12 just isn't that expensive.

3) Replaced the belt. I'm not sure if this really solved much, but my theory is that if the belts contact surface with the pulleys was starting to wear, it could in theory cause the belt to be more "grabby" than it normally is when new. Keep in mind the belt has a fiber / fabric type covering, so this may not be as crazy as it sounds. The belt is $5 so it seemed stupid not to replace it while there.

4) Cleaned the pulleys with brake parts cleaner. Seemed like a good idea to get the belt contact surfaces as clean and nice as possible. Remember the belt MUST SLIP to pull the lawn mower backwards.

Anyway, after doing all of the above my mower is working absolutely like new again. The above steps were attempted after cleaning / lubing the ratcheting gears in the wheels and adjusting the smart drive cable didn't work. Honestly I think mine had been going bad for a while because I can't remember the last time this thing rolled this smoothly - if ever. In short, look for drag in the driveline and REPLACE the driveshaft bushings.

Good luck and hopefully the above helps someone one day.

https://www.lawnmowerforum.com/thre...kwards-hrr216vla-to-bearing-conversion.57255/

This is my first post on this forum, but I've read some of Robert @ Honda's posts and I must say THANK YOU. I recently went through troubleshooting my HRR216K8VYA mower which had been having problems with the rear wheels locking up and not spinning backwards. Lots of searching tended to yield lots of conflicting messages as to how the system works, and random suggestions regarding what may actually fix the issue. Given that I've solved it on mine, I wanted to share what I did and found in the hopes that maybe it helps someone else with this issue.

The HRR216 K8 VYA model I have is about 3 - 4 years old, it has the grey smart drive paddles, and has the rotostop blade clutch. I believe most of the modern Hondas (without Hydrostatic transmissions) will be very similar in operation to mine, however I can't comment on anything other than the model I have.

Symptom: The mower increasingly got harder and harder to pull backwards, eventually getting so bad that the rear wheels would just lock up and the mower would be dragged across the lawn. ANNOYING AS CAN BE.

What I found:

1) Contrary to a lot of info online, the ratcheting drive wheel sprockets are NOT the problem. If these are locked up you will not hear clicking sounds when you push the mower forward with it turned off. Pulling the mower backwards will ALWAYS turn the driveshaft and the transmission. The wheels will lock when the transmission tilts and is tightened on the belt. Basically pulling the mower backwards with the self propelled disengaged means the belt connecting the crankshaft and transmission will not be under tension and will slip. The ratcheting drive gears are there to allow you to turn the mower while you've got the self propelled engaged. Essentially it allows each wheel to overrun the speed of the solid drive shaft.

2) Since pulling the mower backwards means that the entire driveline minus the belt must be able to spin freely, it's CRITICAL that all items in the driveline are able to move smoothly. Keep in mind the ratcheting gears in the wheels will be locked to drive shaft speed, so these really don't count, but they should still be cleaned.

What I did:

1) I pulled the transmission out, drained the oil from it and inspected it. I found I had a minor chip on one of the gear surfaces and lots of metal in the oil. I cleaned it all out, filled it back up with ATF (probably not recommended, I hear 10w-30 is the stuff, but I don't care - I wanted ATF) and put it back together. Despite the chipped tooth it still operated smoothly so I chose not to replace it at this time, though best practice would be to replace it. This did NOT resolve my issue, though I'm sure it's help keep the transmission from self destructing. Keep in mind my yard is absolutely horrible for hills, rocks, etc and I don't blame the transmission for the failure... My yard is just THAT bad.

2) Replaced the adjusters / the bushings. !!!! - I think this it the biggest key - !!!! Upon close inspection of the bushings that the driveshaft rides in, they were dry and scored. My theory is that as I mowed the driveshaft and bushings would heat up and seize up just enough to create drag on the driveshaft, not enough to stop it form going forward under self propelled drive power, but enough to add drag and keep the assembly from spinning freely when pulled backwards. I greased the new bushings very well when reassembling as I suspect they may not have been "full" when they left the factory. The fully assembled bushings / adjusters cost about $12 per side, you can press in / out new bushings for a lot less... but I just bought the whole assembly because I'm lazy and $12 just isn't that expensive.

3) Replaced the belt. I'm not sure if this really solved much, but my theory is that if the belts contact surface with the pulleys was starting to wear, it could in theory cause the belt to be more "grabby" than it normally is when new. Keep in mind the belt has a fiber / fabric type covering, so this may not be as crazy as it sounds. The belt is $5 so it seemed stupid not to replace it while there.

4) Cleaned the pulleys with brake parts cleaner. Seemed like a good idea to get the belt contact surfaces as clean and nice as possible. Remember the belt MUST SLIP to pull the lawn mower backwards.

Anyway, after doing all of the above my mower is working absolutely like new again. The above steps were attempted after cleaning / lubing the ratcheting gears in the wheels and adjusting the smart drive cable didn't work. Honestly I think mine had been going bad for a while because I can't remember the last time this thing rolled this smoothly - if ever. In short, look for drag in the driveline and REPLACE the driveshaft bushings.

Good luck and hopefully the above helps someone one day.

#2

E

ekie

E

ekie

I wish my mower (HRR216K8VKA) would pull back as easily as it pushes forward. I have an environment equal to yours, if not worse, and I ended up replacing the blades and belt, the belt only because I had everything disassembled. I cleaned and lubricating everything as the drive train has never been serviced. My rear wheels had completely seized up. Transmission seemed very clean. Wheels seemed ok. Pinion gears ok with key moving freely. After the cleaning and lube of the drive train I could pull the mower back but it still should not be this hard. I went and looked at a brand new identical mower and surprisingly the new one did not pull back as easily as I thought they should, but mine was still a bit tougher to reverse. I was focusing on the adjuster/bushing when I ran across your post, a confirmation of what I was suspecting. What else can it be? Has to a bushing right? But then why doesn't the bushing cause forward movement to be labored as well? You mentioned the belt and the one thing I haven't tried is slowing the mowing speed down a bit, hoping this will reduce the tension and allow the belt to slip. This thing mows faster than I can run. I will replace the bushing. Thanks for your post.

#3

B

Briantii

Sounds just like what I did. I actually cleaned and lubed everything first, but it didn't really help much. I'm 99% sure it's those bushings that get dry and start to seize up, potentially as you're mowing and it gets hotter. The reason it's always easier to push forward than it is to pull backwards is because the ratcheting gears in the wheels "slip" when you push it forward. When you push forward only the wheels and the small gear on the shaft turn. When you pull backwards the gear engages the shaft and the entire assembly (drive shaft through both bushings, and transmission) all has to spin.

If I were you I'd order the adjuster / bushing assembly for both sides, take those off (need a snap ring pliers), clean the shaft very well, and then pack the bushings with as much grease as you can. There is a lip inside of it between the bushing and the dust seal, I tried to pack mine as full as possible. It worked for me and should only run ~$25 to try. Literally mine went from being completely seized and unable to pull backwards on the yard to rolling exactly as it did when new.

Good luck and let me know if it fixes it - I sure hope it does. The problem is beyond infuriating.

B

Briantii

I wish my mower (HRR216K8VKA) would pull back as easily as it pushes forward. I have an environment equal to yours, if not worse, and I ended up replacing the blades and belt, the belt only because I had everything disassembled. I cleaned and lubricating everything as the drive train has never been serviced. My rear wheels had completely seized up. Transmission seemed very clean. Wheels seemed ok. Pinion gears ok with key moving freely. After the cleaning and lube of the drive train I could pull the mower back but it still should not be this hard. I went and looked at a brand new identical mower and surprisingly the new one did not pull back as easily as I thought they should, but mine was still a bit tougher to reverse. I was focusing on the adjuster/bushing when I ran across your post, a confirmation of what I was suspecting. What else can it be? Has to a bushing right? But then why doesn't the bushing cause forward movement to be labored as well? You mentioned the belt and the one thing I haven't tried is slowing the mowing speed down a bit, hoping this will reduce the tension and allow the belt to slip. This thing mows faster than I can run. I will replace the bushing. Thanks for your post.

Sounds just like what I did. I actually cleaned and lubed everything first, but it didn't really help much. I'm 99% sure it's those bushings that get dry and start to seize up, potentially as you're mowing and it gets hotter. The reason it's always easier to push forward than it is to pull backwards is because the ratcheting gears in the wheels "slip" when you push it forward. When you push forward only the wheels and the small gear on the shaft turn. When you pull backwards the gear engages the shaft and the entire assembly (drive shaft through both bushings, and transmission) all has to spin.

If I were you I'd order the adjuster / bushing assembly for both sides, take those off (need a snap ring pliers), clean the shaft very well, and then pack the bushings with as much grease as you can. There is a lip inside of it between the bushing and the dust seal, I tried to pack mine as full as possible. It worked for me and should only run ~$25 to try. Literally mine went from being completely seized and unable to pull backwards on the yard to rolling exactly as it did when new.

Good luck and let me know if it fixes it - I sure hope it does. The problem is beyond infuriating.

#4

D

Dockem

D

Dockem

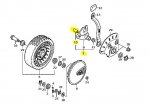

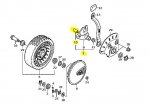

Is there a diagram that shows the parts/assemblies?

I have a hrx217vya that has a similar problem. Tried adjusting the drive cable to no avail.

I have a hrx217vya that has a similar problem. Tried adjusting the drive cable to no avail.

#5

B

Briantii

I bought and replaced the whole assembly (#7), but the portion that's bad I believe is #15. Keep in mind you'll have to press (I've heard hammer works too?) the new one in / out if you don't purchase the assembly and you'll also likely need to replace the dust seals too.

B

Briantii

Is there a diagram that shows the parts/assemblies?

I have a hrx217vya that has a similar problem. Tried adjusting the drive cable to no avail.

I bought and replaced the whole assembly (#7), but the portion that's bad I believe is #15. Keep in mind you'll have to press (I've heard hammer works too?) the new one in / out if you don't purchase the assembly and you'll also likely need to replace the dust seals too.

#7

D

Dadillac

D

Dadillac

My mower had the same issue almost from day 1. I finally got around to doing something about it about a month ago. Took it apart and cleaned the shaft under the bushings. Put it back together and still no go. Started adjusting the drive cable and it got better. Adjusted it more and it got better. Adjusted it out a heck of a long way and voila. I have a mower that will back up. My cable is adjusted out very far. Way more than what would seem normal. If you have this backing up issue please try adjusting the cable first before tearing apart the drive axle

Don

Don

#8

S

slomo

S

slomo

Another "can't pull my mower backwards" post? Never heard of a quality mower doing this.

slomo

slomo

#9

C

civic

Wheels getting locked

Have you ever looked at the back wheels of your Honda self propelled lawnmower while making a turn? Although we expect the left wheel to rotate while turning right, none of the wheels rotates. This is because of a key that transmits power from the shaft to the driven gear. You can see this gear once if you open the wheel.

You can solve this problem by just placing the key upside down. This simple step solves this issue. Even though it doesn’t feel like a big problem, fixing it will help you find the difference before and after; you will surely experience better handling later than the former.

C

civic

I went to this link and saw something that was interesting and wonder if anyone here has done this:Faced the same issue. Try steps in this, worked for me!

Wheels getting locked

Have you ever looked at the back wheels of your Honda self propelled lawnmower while making a turn? Although we expect the left wheel to rotate while turning right, none of the wheels rotates. This is because of a key that transmits power from the shaft to the driven gear. You can see this gear once if you open the wheel.

You can solve this problem by just placing the key upside down. This simple step solves this issue. Even though it doesn’t feel like a big problem, fixing it will help you find the difference before and after; you will surely experience better handling later than the former.

#10

B

Briantii

I kinda thought the whole thing was scammy click bait. I can’t see how flipping the key upside down would do anything except increase wear. The act of greasing the gear on the shaft however could solve the problem (which is a completely different issue than the pulling backwards one). Basically it may “fix it” but only as a side effect because you had to take it apart and clean it to get there.

B

Briantii

I went to this link and saw something that was interesting and wonder if anyone here has done this:

Wheels getting locked

Have you ever looked at the back wheels of your Honda self propelled lawnmower while making a turn? Although we expect the left wheel to rotate while turning right, none of the wheels rotates. This is because of a key that transmits power from the shaft to the driven gear. You can see this gear once if you open the wheel.

You can solve this problem by just placing the key upside down. This simple step solves this issue. Even though it doesn’t feel like a big problem, fixing it will help you find the difference before and after; you will surely experience better handling later than the former.

I kinda thought the whole thing was scammy click bait. I can’t see how flipping the key upside down would do anything except increase wear. The act of greasing the gear on the shaft however could solve the problem (which is a completely different issue than the pulling backwards one). Basically it may “fix it” but only as a side effect because you had to take it apart and clean it to get there.

#11

C

civic

C

civic

The issue I see is the key will not go down in the cavity which might make it worse. When I that this thing apart I will check it out.

#12

G

gardenlover

Yes. It works. But I think posting solutions here, from the website isn't a good thing.

G

gardenlover

I went to this link and saw something that was interesting and wonder if anyone here has done this:

Wheels getting locked

Have you ever looked at the back wheels of your Honda self propelled lawnmower while making a turn? Although we expect the left wheel to rotate while turning right, none of the wheels rotates. This is because of a key that transmits power from the shaft to the driven gear. You can see this gear once if you open the wheel.

You can solve this problem by just placing the key upside down. This simple step solves this issue. Even though it doesn’t feel like a big problem, fixing it will help you find the difference before and after; you will surely experience better handling later than the former.

Yes. It works. But I think posting solutions here, from the website isn't a good thing.

#13

B

Briantii

B

Briantii

Its not a solution, unless you like potentially destroying your self propelled. Honestly if you don’t want self propelled just take the sprocket off. It’ll always pull backwards perfectly then. The website looks like clickbait.Yes. It works. But I think posting solutions here, from the website isn't a good thing.

#14

C

civic

C

civic

OK, I tried this and what happens is the pinion gear does not ratchet back so I didn't follow through. To me this will lock up the trans and you will not be able to roll backwards at all. I don't advice doing this.