You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Honda GXV140 - something loose in piston assembly

#1

C

CM-NC

C

CM-NC

Hey!

I am in the process of disassembling the GXV140 engine on my mower to get at the piston, and I have discovered that I can't get the lower cover off - the mounting plate for the blades and spool for the belt (which are welded together) are in the way.

Backstory: The mower has given over a decade of useful service, and just recently I was told that the mower is 'not in a runnable state' and the engine was 'beating itself up'. Being the handyman, I pull the mower and discovered there is a slop somewhere in the linkage between the piston and crankshaft by as much as 15 degrees at TDC and BDC, and as few as 3 at any halfway points between this. Since the piston is still captured by the crankshaft (I.e. it doesn't just push the piston up, it pulls it back down as well), I am assuming that the connecting rod hasn't been broken, and that either the end caps are loose, or there is serious damage where the connecting rod mates the piston.

Problem is, I can't get inside the block - the cover is located 3mm right behind the spool/blade mounting assembly (which itself will not budge).

Can anyone help? Does anyone even understand what I am rambling on about?

Thanks a million!

-CM

I am in the process of disassembling the GXV140 engine on my mower to get at the piston, and I have discovered that I can't get the lower cover off - the mounting plate for the blades and spool for the belt (which are welded together) are in the way.

Backstory: The mower has given over a decade of useful service, and just recently I was told that the mower is 'not in a runnable state' and the engine was 'beating itself up'. Being the handyman, I pull the mower and discovered there is a slop somewhere in the linkage between the piston and crankshaft by as much as 15 degrees at TDC and BDC, and as few as 3 at any halfway points between this. Since the piston is still captured by the crankshaft (I.e. it doesn't just push the piston up, it pulls it back down as well), I am assuming that the connecting rod hasn't been broken, and that either the end caps are loose, or there is serious damage where the connecting rod mates the piston.

Problem is, I can't get inside the block - the cover is located 3mm right behind the spool/blade mounting assembly (which itself will not budge).

Can anyone help? Does anyone even understand what I am rambling on about?

Thanks a million!

-CM

#2

robert@honda

Is this just a Honda engine, or a Honda engine on a Honda mower?

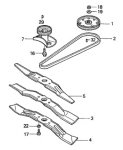

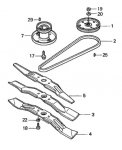

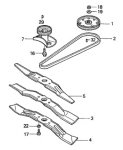

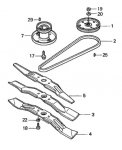

The Honda GXV140 engine was only used on belt-drive Honda HRM/HRB models mowers with a Xenoy "plastic" mower deck. To remove the engine, you must first remove the blades, blade holder, and blade control mechanism (where applicable); here's a couple of pages from the shop manual:

robert@honda

Hey!

I am in the process of disassembling the GXV140 engine on my mower to get at the piston, and I have discovered that I can't get the lower cover off - the mounting plate for the blades and spool for the belt (which are welded together) are in the way.

Is this just a Honda engine, or a Honda engine on a Honda mower?

The Honda GXV140 engine was only used on belt-drive Honda HRM/HRB models mowers with a Xenoy "plastic" mower deck. To remove the engine, you must first remove the blades, blade holder, and blade control mechanism (where applicable); here's a couple of pages from the shop manual:

#3

C

CM-NC

C

CM-NC

Wow, what a fast response!

It is a Honda engine on a Honda mower, the HRB. (You are correct regarding the belt drive and plastic deck) There wasn't any blade control mechanism, though I will give the second page you uploaded a go tomorrow when I retry it! I do want to say that, at a first look at the second uploaded page, the blade holder and pulley are shown separately, and are welded together on my setup (which makes me only slightly nervous about actually succeeding).

Wow, and from a guy who actually works for Honda? What luck! :smile:

-CM

It is a Honda engine on a Honda mower, the HRB. (You are correct regarding the belt drive and plastic deck) There wasn't any blade control mechanism, though I will give the second page you uploaded a go tomorrow when I retry it! I do want to say that, at a first look at the second uploaded page, the blade holder and pulley are shown separately, and are welded together on my setup (which makes me only slightly nervous about actually succeeding).

Wow, and from a guy who actually works for Honda? What luck! :smile:

-CM

#4

bwdbrn1

bwdbrn1

What does the blade holder look like? I had one with a round blade holder that didn't want to budge once too.

Like item #7 in this diagram.

All Years HRM215K4 HXA LAWN MOWER, USA Honda Lawnmower ROTARY BLADE Diagram and Parts

That same engine had connecting rod bolts that had loosened and backed out 1/4 to 1/2", and it acted very much like what you are describing.

Like item #7 in this diagram.

All Years HRM215K4 HXA LAWN MOWER, USA Honda Lawnmower ROTARY BLADE Diagram and Parts

That same engine had connecting rod bolts that had loosened and backed out 1/4 to 1/2", and it acted very much like what you are describing.

#5

robert@honda

There is a version of the HRB without the blade control parts called the SDA; the blades are mounted to a holder/pulley which is held onto the crankshaft with a single bolt & Woodruff key.

The parts used on the SDA changed a bit; here's a drawing of the early and late versions. Both come apart the same way:

Early version Later version

robert@honda

There wasn't any blade control mechanism, though I will give the second page you uploaded a go tomorrow when I retry it! I do want to say that, at a first look at the second uploaded page, the blade holder and pulley are shown separately, and are welded together on my setup

There is a version of the HRB without the blade control parts called the SDA; the blades are mounted to a holder/pulley which is held onto the crankshaft with a single bolt & Woodruff key.

The parts used on the SDA changed a bit; here's a drawing of the early and late versions. Both come apart the same way:

Early version Later version

#6

robert@honda

I see you are from North Carolina; guess where your Honda mower (including the engine) was built?

Click here and scroll down 1/2 Page

robert@honda

Wow, and from a guy who actually works for Honda? What luck! :smile:

I see you are from North Carolina; guess where your Honda mower (including the engine) was built?

Click here and scroll down 1/2 Page

#7

C

CM-NC

Also, that is quite cool that they are manufactured here, though I can't say I am surprised. There are tons of engine and gearheads around these parts. The quality sure is impeccable, this is the first problem this mower has ever had, and I used to mow nearly 1.5 ACRES OF YARD with this baby every other week. Haha I can't say that any car I have ever had has been anywhere near this reliable, that's for sure.

I am about to head out and give it a go, wish me luck! Thanks much you guys.

-CM

C

CM-NC

What does the blade holder look like? I had one with a round blade holder that didn't want to budge once too.

Like item #7 in this diagram.

That same engine had connecting rod bolts that had loosened and backed out 1/4 to 1/2", and it acted very much like what you are describing.

Bwdbrn1, you have my situation exactly - it looks exactly like the number 7 part! This is also the same part in the later version of the image you posted, Robert. Forgive me for not disclosing the model #earlier, but it is the hrb2154sda.There is a version of the HRB without the blade control parts called the SDA; the blades are mounted to a holder/pulley which is held onto the crankshaft with a single bolt & Woodruff key.

The parts used on the SDA changed a bit; here's a drawing of the early and late versions. Both come apart the same way

Also, that is quite cool that they are manufactured here, though I can't say I am surprised. There are tons of engine and gearheads around these parts. The quality sure is impeccable, this is the first problem this mower has ever had, and I used to mow nearly 1.5 ACRES OF YARD with this baby every other week. Haha I can't say that any car I have ever had has been anywhere near this reliable, that's for sure.

I am about to head out and give it a go, wish me luck! Thanks much you guys.

-CM

#8

bwdbrn1

bwdbrn1

Robert can no doubt give you better guidance on the best method to remove that blade holder than I can. But, I'd recommend spraying Liquid Wrench or Kroil around where that shaft meets the blade holder, and let it sit, repeat, and sit, for a day or two, then use a harmonic gear puller to free it up. A bit of heat on the outside of the puller could help too.

Good luck, I wound up having to find another crank shaft for mine, but I'm sure yours will go better for you.

Good luck, I wound up having to find another crank shaft for mine, but I'm sure yours will go better for you.

#9

C

CM-NC

A new crankshaft??! Geez, I hope mine goes better too.

-CM

C

CM-NC

Its funny you mention the liquid wrench bit, I was just about to ask how in the world you get enough leverage on this thing to get it off. Worse, if the only thing retaining the crankshaft is the flywheel, then there is the possibility that the least-secured part will free first, which in this case would almost definitely be the flywheel rather than the blade holder.Robert can no doubt give you better guidance on the best method to remove that blade holder than I can. But, I'd recommend spraying Liquid Wrench or Kroil around where that shaft meets the blade holder, and let it sit, repeat, and sit, for a day or two, then use a harmonic gear puller to free it up. A bit of heat on the outside of the puller could help too.

Good luck, I wound up having to find another crank shaft for mine, but I'm sure yours will go better for you.

A new crankshaft??! Geez, I hope mine goes better too.

-CM

#10

robert@honda

Unless rusted/seized onto the crankshaft, a bit of penetrating oil, overnight soaking and maybe a little heat ought to loosen it enough to pull off without excessive force. The blade holder can be bent/damaged if you get too aggressive with it. If it does get beat up too much, a new one would likely be necessary, 'cause a damaged holder will not spin smoothly, nor will the blades bolted to it.

robert@honda

Its funny you mention the liquid wrench bit, I was just about to ask how in the world you get enough leverage on this thing to get it off.

Unless rusted/seized onto the crankshaft, a bit of penetrating oil, overnight soaking and maybe a little heat ought to loosen it enough to pull off without excessive force. The blade holder can be bent/damaged if you get too aggressive with it. If it does get beat up too much, a new one would likely be necessary, 'cause a damaged holder will not spin smoothly, nor will the blades bolted to it.

#11

bwdbrn1

bwdbrn1

You wont' need to worry about pulling the flywheel off from the PTO end. If that happens, Honda does sell a very complete line of replacement engines.:biggrin: When the blade holder let's loose, it will happen in one of two ways. It will either come off slowly, or suddenly pop off. Just to let you know in case it's the second.

We haven't discussed this yet, and in case you haven't done so, do drain all gasoline and oil out of the engine before you start moving it around at the angles you'll need to to get the blade holder off. I'd also recommend you put the bolt back into the PTO shaft, loosened a bit, for the gear puller to push against, and not just the open end of the PTO.

Robert, would you recommend putting a gear puller on the blade holder, applying some pressure on it, then striking the end of the gear puller shaft with a hammer to get the holder off? Not like you're going to ring the bell at one of those carnival he man sledge hammer things, but similar to the method recommended for getting an aluminum flywheel off of the GCV160.

We haven't discussed this yet, and in case you haven't done so, do drain all gasoline and oil out of the engine before you start moving it around at the angles you'll need to to get the blade holder off. I'd also recommend you put the bolt back into the PTO shaft, loosened a bit, for the gear puller to push against, and not just the open end of the PTO.

Robert, would you recommend putting a gear puller on the blade holder, applying some pressure on it, then striking the end of the gear puller shaft with a hammer to get the holder off? Not like you're going to ring the bell at one of those carnival he man sledge hammer things, but similar to the method recommended for getting an aluminum flywheel off of the GCV160.

#12

robert@honda

I can tell you Honda shop manual procedures specifically say NOT to whack stuff like flywheel nuts, crankshaft bolts, etc. to loosen 'em, even if it is common practice with most service shops. That's all I can say about that. :wink:

robert@honda

... putting a gear puller on the blade holder, applying some pressure on it, then striking the end of the gear puller shaft with a hammer to get the holder off?

I can tell you Honda shop manual procedures specifically say NOT to whack stuff like flywheel nuts, crankshaft bolts, etc. to loosen 'em, even if it is common practice with most service shops. That's all I can say about that. :wink:

#14

robert@honda

Okay, as long as you use a Metric hammer :laughing:

robert@honda

Sorry, striking was too harsh a word.:tongue: The word used was "tap".:thumbsup:

Okay, as long as you use a Metric hammer :laughing:

#15

C

chance123

C

chance123

Anytime I have to use a hammer on the end of a crankshaft, I will always use a sacrificial nut or bolt. I actually rarely use a puller. One good wack with a hammer usually breaks the FW from the taper. Briggs and Tec actually have a tool to put over the crankshaft end that you hit with a hammer. Briggs tool slips over the starter clutch shank and the Tec, screws on the crank threads. On other pulling projects, I will use an air hammer, again,, on a sacrificial nut or bolt.

I actually think that a puller puts more strain on the parts because it is a gradual process. Using a hammer "shocks" the FW off with little effort

I actually think that a puller puts more strain on the parts because it is a gradual process. Using a hammer "shocks" the FW off with little effort

#16

bwdbrn1

We'll save the whacking for the HRX decks.:wink:

bwdbrn1

Okay, as long as you use a Metric hammer :laughing:

We'll save the whacking for the HRX decks.:wink:

#17

C

CM-NC

Forgive this possible silly question: The bolt on the end of the blade holder, what is its purpose? I would imagine that, when I look into the hole, I am looking at the crankshaft and the bolt retains the blade holder.

The reason I ask is because, if this is the case, there is nothing on the blade holder that I could attach a sacrificial nut and bolt to. For the record, the retaining bolt is off, but the holder is seized/rusted on to the shaft.

Another: What is a PTO?

You guys are fantastic,

-CM

C

CM-NC

I have a feeling this is rusted on the crankshaft, and after last night's soaking, no success today. Fortunately, I can't get too aggressive on it, the angle and proximity to the engine precludes getting anything behind the blade holder that can actually produce force.Unless rusted/seized onto the crankshaft, a bit of penetrating oil, overnight soaking and maybe a little heat ought to loosen it enough to pull off without excessive force. The blade holder can be bent/damaged if you get too aggressive with it.

Forgive this possible silly question: The bolt on the end of the blade holder, what is its purpose? I would imagine that, when I look into the hole, I am looking at the crankshaft and the bolt retains the blade holder.

The reason I ask is because, if this is the case, there is nothing on the blade holder that I could attach a sacrificial nut and bolt to. For the record, the retaining bolt is off, but the holder is seized/rusted on to the shaft.

Another: What is a PTO?

You guys are fantastic,

-CM

#18

robert@honda

Sure sounds like it; keep soaking, and maybe some heat? Be sure the mower is FULLY drained of all fuel and oil!

Correct. I've never personally had one of these apart, but looking at the shop manual and parts catalog, I think you are spot-on with the function of the bolt.

robert@honda

I have a feeling this is rusted on the crankshaft

Sure sounds like it; keep soaking, and maybe some heat? Be sure the mower is FULLY drained of all fuel and oil!

Forgive this possible silly question: The bolt on the end of the blade holder, what is its purpose? I would imagine that, when I look into the hole, I am looking at the crankshaft and the bolt retains the blade holder.

Correct. I've never personally had one of these apart, but looking at the shop manual and parts catalog, I think you are spot-on with the function of the bolt.

Power Take-Off; an industry term to describe the tip of the engine's crankshaft where power is "taken off" and used to turn some device (mower blades, tiller transmission, generator head, etc.)Another: What is a PTO?

#19

C

chance123

You screw a sacrificial bolt through the blade retainer and into the crankshaft itself. (You use a "sacrificial" bolt so you don't ruin the original heat treated bolt.) You also use this bolt when using a puller. You might not have an air compressor and air hammer, but if you do, just pulling by hand the hub, and at the same time using the air hammer on the sacrificial bolt, they usually come off quite easy. When re assembling, always use anti seize compound to avoid this problem in the future.

In effect, what you are doing is "pushing" the crank shaft out of the hub (with the hammer or puller screw) while you are pulling (by hand or the jaws of the puller) the hub off of the crank shaft

edit:

I just thought of something. Does your machine have a BBC? (blade brake clutch)

C

chance123

and the blade tooForgive this possible silly question: The bolt on the end of the blade holder, what is its purpose? I would imagine that, when I look into the hole, I am looking at the crankshaft and the bolt retains the blade holder. -CM

The reason I ask is because, if this is the case, there is nothing on the blade holder that I could attach a sacrificial nut and bolt to.-CM

You screw a sacrificial bolt through the blade retainer and into the crankshaft itself. (You use a "sacrificial" bolt so you don't ruin the original heat treated bolt.) You also use this bolt when using a puller. You might not have an air compressor and air hammer, but if you do, just pulling by hand the hub, and at the same time using the air hammer on the sacrificial bolt, they usually come off quite easy. When re assembling, always use anti seize compound to avoid this problem in the future.

In effect, what you are doing is "pushing" the crank shaft out of the hub (with the hammer or puller screw) while you are pulling (by hand or the jaws of the puller) the hub off of the crank shaft

edit:

I just thought of something. Does your machine have a BBC? (blade brake clutch)

#20

bwdbrn1

bwdbrn1

CM-NC, here's what the Power Take Off end of the GXV140 looks like, without the blade holder, of course, and the bolt you have should look something like this one. It screws into the end of the PTO. (Pictured below)

If the blade holder you have does look like part #7 in that parts diagram, if I remember right, it is a blade holder/belt pulley all in one package. I think the single bolt you are talking about is the one that holds it to the PTO. The cutting blade(s) were held to that blade holder by two bolts. If you have access to a harmonic gear puller, you might be able to use the two holes for the blade bolts to hold the "wings" of the puller, and use another bolt for the center of the puller to push against to protect the end of the PTO and threads inside it.

Sorry I don't have that blade holder that was on mine any more to show you how to set it up. Just keep putting the penetrating oil on it and letting it soak. It may take a few days, actually.

If the blade holder you have does look like part #7 in that parts diagram, if I remember right, it is a blade holder/belt pulley all in one package. I think the single bolt you are talking about is the one that holds it to the PTO. The cutting blade(s) were held to that blade holder by two bolts. If you have access to a harmonic gear puller, you might be able to use the two holes for the blade bolts to hold the "wings" of the puller, and use another bolt for the center of the puller to push against to protect the end of the PTO and threads inside it.

Sorry I don't have that blade holder that was on mine any more to show you how to set it up. Just keep putting the penetrating oil on it and letting it soak. It may take a few days, actually.

#21

C

CM-NC

The problem I am having is that the blade holder started to slightly deform and it *still* won't budge (even after 'tapping' with a hammer). When I first noticed this, I backed it off and the blade holder returned to it's initial state, so I rotated the gear puller (so I didn't pull on the exact same spot as last time), reapplied with more force, applied more PB-blaster, 'tapped' it, and it still won't budge.

Bwdbrn1, thanks for the photo. It has been soaking for 4 days now, with oil applied from both ends of the blade holder. I am not sure about the difference between a harmonic gear puller and the one I am using right now, this one seems to be just a generic one rented from Advance Auto?

C

CM-NC

The engine is fully drained, and I captured everything (not to be reused, but around these parts you cant just dump it out back, especially since we are all on wells around here!). I am trying to get a small propane torch, since I have a feeling the rather massive propane weed burner will be too imprecise and just make a mess/bake everything onto the chassis.Sure sounds like it; keep soaking, and maybe some heat? Be sure the mower is FULLY drained of all fuel and oil!

The problem I am having is that the blade holder started to slightly deform and it *still* won't budge (even after 'tapping' with a hammer). When I first noticed this, I backed it off and the blade holder returned to it's initial state, so I rotated the gear puller (so I didn't pull on the exact same spot as last time), reapplied with more force, applied more PB-blaster, 'tapped' it, and it still won't budge.

The mower does not have a BBC. Question: I have no other bolts sitting about that will fit into the PTO end, what is the worst that could happen with using the original bolt? (I had already started before I read this, and have already put a minor dent into the top of the original bolt.)I just thought of something. Does your machine have a BBC? (blade brake clutch)

Bwdbrn1, thanks for the photo. It has been soaking for 4 days now, with oil applied from both ends of the blade holder. I am not sure about the difference between a harmonic gear puller and the one I am using right now, this one seems to be just a generic one rented from Advance Auto?

#24

C

CM-NC

C

CM-NC

Guys! Great news, I got it off, and confirmed that the connecting rod bolts had backed off maybe 3/8ths of an inch, as happened to someone else on this forum.

I have some pictures to post here for the record, so that if anyone else comes across this thread in the future via search or whatever, they can see what may be involved to fix it.

For starters, the blade holder was SERIOUSLY rusted on. After many failed attempts at making it budge (in a manner that didn't break anything), and after sitting in PB blaster for 1.5 weeks, I finally decided to get violent with it. The general procedure was to get the largest ratchet I had, tighten the forcing screw with as much force as can be managed, then pull the hammer and start striking upwards from the bottom of the holder. Of course, this much force caused the heavy steel blade holder to start to warp, but I knew I would be replacing it going in. Care just needs to be taken so that this is the only part needing replacing. Also, at the earliest stages, when the most force needs being applied, the retaining bolt for the holder should probably be nearly all the way in, to give it maximum thread to push against when you start applying these huge forces.

Effectiveness was gauged by how much 'progress' I could make in turning the forcing screw. 'Tapping' the forcing screw was nearly useless. I would make 'forceful strikes' against the bottom of the holder, maybe 10 to 12, distributed around the rim of the holder, before I would stop making progress and had to take up the slack in the forcing screw.

After 8 or so iterations of this, and realizing I was finally starting to make progress (about 2mm worth of progress, but I had been making none before), my resolve was strengthened. This wasn't just some guy removing a stuck blade holder from his mower engine, this was a MAN laying waste to an enemy that had defeated him repeatedly over the past week or so.

Eventually, after moving it about 4mm, I found that I could 'almost' move it entirely without the hammer (at this point I had an enormous breaker bar on the forcing screw and a 2 foot lever that rested against my knee so that it wouldn't move on me as a heaved against the breaker bar). All of the sudden - BOOOM!!!! My ears were ringing and as I realized what happened, I was looking around for what had broken (and hoping it wasn't attached to the rented gear puller). Imagine my surprise when I noticed the blade holder had moved a 1/4 inch! :wink: After picking up the breaker bar (which flew into my knee) and the lever I was using to brace it (which flew across the shop), I got back to work!

Four 'Boom!'s later (all of which were considerably quieter), I had the thing off!!! :smile:

Pics below, and even one of the culprit head bolts. I imagine they underestimated the torque specs on these babies - I have never heard of any kind of connecting rod bolt backing off. Guessing that these are probably torque-to-yield, so I will probably just check the crank for damage, then retighten them to spec (since it took years to back off on us, not much to gain by overtightening).

Thanks guys!

~CM-NC

I have some pictures to post here for the record, so that if anyone else comes across this thread in the future via search or whatever, they can see what may be involved to fix it.

For starters, the blade holder was SERIOUSLY rusted on. After many failed attempts at making it budge (in a manner that didn't break anything), and after sitting in PB blaster for 1.5 weeks, I finally decided to get violent with it. The general procedure was to get the largest ratchet I had, tighten the forcing screw with as much force as can be managed, then pull the hammer and start striking upwards from the bottom of the holder. Of course, this much force caused the heavy steel blade holder to start to warp, but I knew I would be replacing it going in. Care just needs to be taken so that this is the only part needing replacing. Also, at the earliest stages, when the most force needs being applied, the retaining bolt for the holder should probably be nearly all the way in, to give it maximum thread to push against when you start applying these huge forces.

Effectiveness was gauged by how much 'progress' I could make in turning the forcing screw. 'Tapping' the forcing screw was nearly useless. I would make 'forceful strikes' against the bottom of the holder, maybe 10 to 12, distributed around the rim of the holder, before I would stop making progress and had to take up the slack in the forcing screw.

After 8 or so iterations of this, and realizing I was finally starting to make progress (about 2mm worth of progress, but I had been making none before), my resolve was strengthened. This wasn't just some guy removing a stuck blade holder from his mower engine, this was a MAN laying waste to an enemy that had defeated him repeatedly over the past week or so.

Eventually, after moving it about 4mm, I found that I could 'almost' move it entirely without the hammer (at this point I had an enormous breaker bar on the forcing screw and a 2 foot lever that rested against my knee so that it wouldn't move on me as a heaved against the breaker bar). All of the sudden - BOOOM!!!! My ears were ringing and as I realized what happened, I was looking around for what had broken (and hoping it wasn't attached to the rented gear puller). Imagine my surprise when I noticed the blade holder had moved a 1/4 inch! :wink: After picking up the breaker bar (which flew into my knee) and the lever I was using to brace it (which flew across the shop), I got back to work!

Four 'Boom!'s later (all of which were considerably quieter), I had the thing off!!! :smile:

Pics below, and even one of the culprit head bolts. I imagine they underestimated the torque specs on these babies - I have never heard of any kind of connecting rod bolt backing off. Guessing that these are probably torque-to-yield, so I will probably just check the crank for damage, then retighten them to spec (since it took years to back off on us, not much to gain by overtightening).

Thanks guys!

~CM-NC

#25

bwdbrn1

bwdbrn1

Congratulations! That's gotta' make you feel pretty darn good getting that thing off!

Yep, the one I had looked pretty much like that when I opened it up. Bolts were backed out about 1/4" or so. Check the bearing surface on the connecting rod, and the crank to see what they look like. Connecting rod bolts get torqued to 9 ft lbs.

New pan gasket and lower oil seal, and you should be good if everything else inside is O.K. I found it easier to put one of those oil seals in after the engine is back together than to put the seal in the pan and slip it on over the crankshaft. The inner lips of the seal tend to want to fold out too easily otherwise.

Yep, the one I had looked pretty much like that when I opened it up. Bolts were backed out about 1/4" or so. Check the bearing surface on the connecting rod, and the crank to see what they look like. Connecting rod bolts get torqued to 9 ft lbs.

New pan gasket and lower oil seal, and you should be good if everything else inside is O.K. I found it easier to put one of those oil seals in after the engine is back together than to put the seal in the pan and slip it on over the crankshaft. The inner lips of the seal tend to want to fold out too easily otherwise.

#26

C

chance123

C

chance123

You might want to check if any of the aluminum from the rod has transfered to the crank. If so, DON'T use sandpaper/emery cloth. Soak it in Muratic acid (same as swimming pool acid.) This will eat the aluminum off of the steel crank. I would recommend replacing the con rod because the rod cap threads "might" be stretched and the bolts might back out again. The cost of a new rod assembly pales in contrast to the work to do it all over again.

#27

C

CM-NC

Also, I didn't manage to take a photo of the camshaft alignment, and I removed it to get at the rod bolts :ashamed: Would you happen to know how to align the camshaft?

Chance123, The crankshaft is actually entirely smooth. I didn't take a picture of it, but, although the cap/rod have small grooves in them, the crank is entirely smooth to the touch. As far as the threads stretching, I may be wrong, but wouldn't stretching be something you might expect on a steel conn rod? I had always thought that aluminum was stiffer than steel.

So here is the parts list on order:

Oil Pan Gasket

Head Cover Gasket (removed it to make sure the valves and such were not worn)

Oil Seal (didn't look damaged, but the mower was starting to slowly leak oil recently...)

Blade Holder (I kinda trashed this)

The bolts look fine, and at 9 ft-lbs, I don't imagine the bolts would be stretched, but a picture is attached just in case.

~CM-NC

C

CM-NC

Oh man, you have no idea! Success is sweeter than wine.Congratulations! That's gotta' make you feel pretty darn good getting that thing off!

I was REALLY happy to hear I wasn't the only person that this happened to (the whole strength-in-numbers thing), so this is why I am trying to take so many pictures - just in case there are any others! Everything looks okay as far as I can tell, and there was no metal particulate in the oil. I have hi-res pictures attached, I am curious if these are good to go. The bearing surface has no discernible impact marks, but does have grooves from normal wear. I lighted the bearings with relief to make all grooves/aberrations/marks on the bearing surfaces stand out in the pictures. I estimate them to be about 20 thousandths deep at the maximums.Yep, the one I had looked pretty much like that when I opened it up. Bolts were backed out about 1/4" or so. Check the bearing surface on the connecting rod, and the crank to see what they look like. Connecting rod bolts get torqued to 9 ft lbs.

New pan gasket and lower oil seal, and you should be good if everything else inside is O.K. I found it easier to put one of those oil seals in after the engine is back together than to put the seal in the pan and slip it on over the crankshaft. The inner lips of the seal tend to want to fold out too easily otherwise.

Also, I didn't manage to take a photo of the camshaft alignment, and I removed it to get at the rod bolts :ashamed: Would you happen to know how to align the camshaft?

Chance123, The crankshaft is actually entirely smooth. I didn't take a picture of it, but, although the cap/rod have small grooves in them, the crank is entirely smooth to the touch. As far as the threads stretching, I may be wrong, but wouldn't stretching be something you might expect on a steel conn rod? I had always thought that aluminum was stiffer than steel.

So here is the parts list on order:

Oil Pan Gasket

Head Cover Gasket (removed it to make sure the valves and such were not worn)

Oil Seal (didn't look damaged, but the mower was starting to slowly leak oil recently...)

Blade Holder (I kinda trashed this)

The bolts look fine, and at 9 ft-lbs, I don't imagine the bolts would be stretched, but a picture is attached just in case.

~CM-NC

#28

bwdbrn1

bwdbrn1

With regard to what Chance said, there should be obvious signs of aluminum material adhering to it. Mine didn't have any on it when I got it apart, and it's a little hard to tell, but the scoring on the connecting rod ends looked to be about the same as mine did too. To be on the safe side, you might call a Honda, or small engine mechanic and ask if they'd mind looking at it to give their opinion.

So far as returning the cam to it's rightful spot, and getting the timing correct, here's what you do. Take a look back at the pictures in your previous post showing the cam shaft in place. There should be a very thin thrust washer on the crankshaft. Take that off, and look very very closely at the flat surface that was under that thrust washer. You may even have to shine a flashlight across it to help see it, but you will find a very faint "0" scribed on the flat. That lines up with that indentation that looks like a punch mark on the cam shaft. Don't forget to put the thrust washer back on.

So far as returning the cam to it's rightful spot, and getting the timing correct, here's what you do. Take a look back at the pictures in your previous post showing the cam shaft in place. There should be a very thin thrust washer on the crankshaft. Take that off, and look very very closely at the flat surface that was under that thrust washer. You may even have to shine a flashlight across it to help see it, but you will find a very faint "0" scribed on the flat. That lines up with that indentation that looks like a punch mark on the cam shaft. Don't forget to put the thrust washer back on.

#29

C

CM-NC

C

CM-NC

Okay, the rebuild went well! I just wanted to thank all who had chimed in, you guys were immensely helpful. She starts, she runs, and she doesn't make weird noises.

One final question however, what is the gap for the ignition coil? When I reinstalled the coil, I set it all the way back for safety, but I don't want the spark to be any weaker than it needs to.

I am about to go put the mower to work ^^

Thanks again,

-Cm-NC

One final question however, what is the gap for the ignition coil? When I reinstalled the coil, I set it all the way back for safety, but I don't want the spark to be any weaker than it needs to.

I am about to go put the mower to work ^^

Thanks again,

-Cm-NC

#30

robert@honda

For the GXV140 engine: ignition coil air gap is 0.2~0.5 mm (0.008~0.002 inch)

robert@honda

One final question however, what is the gap for the ignition coil?

For the GXV140 engine: ignition coil air gap is 0.2~0.5 mm (0.008~0.002 inch)

#31

bwdbrn1

Congratulations! Nothing more satisfying than getting them back together...and they run:thumbsup:

I just put one of my mowers back together, and well, I had to use one of those cursed blade adaptors like yours. I made sure I put plenty of anti-seize on it first. Hope it doesn't grab onto the shaft like ours did.:thumbdown:

bwdbrn1

Congratulations! Nothing more satisfying than getting them back together...and they run:thumbsup:

I just put one of my mowers back together, and well, I had to use one of those cursed blade adaptors like yours. I made sure I put plenty of anti-seize on it first. Hope it doesn't grab onto the shaft like ours did.:thumbdown: