You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Generator w/ 8HP B&S - voltage too high + other questions

#1

H-Towner

H-Towner

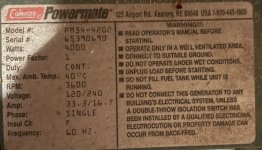

Hi, new to the forum and a novice at small engines. I have a Coleman Powermate 4000 (PM54-4202) powered by an 8hp horizontal Briggs & Stratton engine (194412-1112-01). This was gifted to me by a friend, and when I tried to use it several years ago, the engine surged a lot and threatened to stall unless I partially closed the choke. I put it aside then, and it has since sat in my garage unloved, but I’m motivated now by Hurricane Beryl to get it going if I can. There’s a lot of good and bad information online, and I’ve learned a fair bit, but I could use the benefit of other people’s experience. I’m going to dump a lot of questions here, and I hope that’s alright.

As I understand it the issue before was probably the engine running lean, thus by adjusting the choke I restricted the intake air and helped balance the mixture. So I extracted the needle valve and main jet, cleaned them, and reinstalled, first seating the needle valve, then backing it out 540° (1-1/2 turns). I put some new gas in it and ran it a bit with the air filter off, periodically spraying carb cleaner into the intake. After all that (some of it possibly unnecessary) it seems to run smoothly under no load.

I wanted to test the voltage before powering anything with it, and I got a reading of 130v from the 120v outlet. My first thought was maybe the voltage is too high because the engine rpms are too high, but my second thought was monkeying with rpms will probably affect the a/c frequency.

So my first question is what is likely causing voltage to run hot, and what’s the proper way to correct it?

Following that, how do I check engine speed to verify it’s running at the 1750 rpms called for in the manual? I see lawn mower repair videos where they’re holding some kind of touch free tachometer near the spark plug wire. I have to figure it’s counting spark plug firings by reading the em field like a clamp ammeter. Is that how one would measure engine speed on this unit?

Other questions regarding carburetor adjustment:

I’m guessing that having no load, the engine is running at idle, yet the idle set screw is not resting on the throttle stop. Should it be?

The “Final Adjustment” section of the B&S manual says to put the throttle control in fast position while adjusting the main jet’s needle valve. The generator doesn’t have a user operated throttle control. Should you perform this step after putting a load on the generator, like a space heater? Or do you just hold the throttle open with one hand while turning the needle valve with the other?

Thanks in advance to anyone who read this far, and especially if you were able to answer a question.

As I understand it the issue before was probably the engine running lean, thus by adjusting the choke I restricted the intake air and helped balance the mixture. So I extracted the needle valve and main jet, cleaned them, and reinstalled, first seating the needle valve, then backing it out 540° (1-1/2 turns). I put some new gas in it and ran it a bit with the air filter off, periodically spraying carb cleaner into the intake. After all that (some of it possibly unnecessary) it seems to run smoothly under no load.

I wanted to test the voltage before powering anything with it, and I got a reading of 130v from the 120v outlet. My first thought was maybe the voltage is too high because the engine rpms are too high, but my second thought was monkeying with rpms will probably affect the a/c frequency.

So my first question is what is likely causing voltage to run hot, and what’s the proper way to correct it?

Following that, how do I check engine speed to verify it’s running at the 1750 rpms called for in the manual? I see lawn mower repair videos where they’re holding some kind of touch free tachometer near the spark plug wire. I have to figure it’s counting spark plug firings by reading the em field like a clamp ammeter. Is that how one would measure engine speed on this unit?

Other questions regarding carburetor adjustment:

I’m guessing that having no load, the engine is running at idle, yet the idle set screw is not resting on the throttle stop. Should it be?

The “Final Adjustment” section of the B&S manual says to put the throttle control in fast position while adjusting the main jet’s needle valve. The generator doesn’t have a user operated throttle control. Should you perform this step after putting a load on the generator, like a space heater? Or do you just hold the throttle open with one hand while turning the needle valve with the other?

Thanks in advance to anyone who read this far, and especially if you were able to answer a question.

Attachments

#2

F

Forest#2

F

Forest#2

You have lots of questions:

first 130 volts is not TOO HIGH for your gen. (can be 135v if necessary.

The small emergency gens go for an average of 115-120 volts. with a 80% load or approx 2400-3200 watts resistive load (non-motor), load -no-load.

Freq is read with a Hertz meter sometimes called frequency meter (can be a digital or vibrating reed type, go to ebay and look) as an average of around 60 hz. might be 56-60 loaded and 63-65 unloaded. (not safe for use with electronics) You do not manually hold the throttle in position when checking frequency which is also termed Hertz. Their is usually a adjustment of some sort on the end of the GOVERNOR SPRING when the spring is stretched tighter the Hz increases.

Yours is mainly for lights and temporary operating a freezer or fridge, not electronics such as TV's.The small gens for smooth clean voltage and Hz and maybe safe for use of electronics is termed inverter gens.

Do not use a tach for setting the Hz because emergency gens are set for Hertz and the RPMS at 3750 is just for ball park adjustments.. The gen will be close to 3750 for 60hz. (use a Hertz meter that reads approx 50-70 Hz accurately.

The 1750 you quoted is the no load idle rpms. (and is not critical, it's just to save on gas consumption, and noise when no load is applied. Good rule of thumb is to remove all loads BEFORE killing the engine.

If still available a Kill O watt meter was around $30 and read voltage, Hz.

If using such put it on the end of a cord instead of letting it ride on the gen due to vibration of the electronics inside.

I use electric heaters for loads.

You can use around 1500 electric heater at first maybe. You might burn out quartz lights when trying to use them for a load if the voltage surges too high.

You can find a service manual for yours maybe Briggs or Clymer using your model number. Power mate was also called Coleman.

I have found free pdf's of some Colemate/Powermates on-line every once in awhile. Not sure if they are even still in business. (they had a website/support sometime back) You can use the Model type and code of the Briggs to find service data. The Generator service manual is mainly for electrical testing and troubleshooting.

I suspect yours is probably Ok voltage and Hertz wise if you get the Carb correct and don't start monkeying around with other things until you get the proper test tools.

first 130 volts is not TOO HIGH for your gen. (can be 135v if necessary.

The small emergency gens go for an average of 115-120 volts. with a 80% load or approx 2400-3200 watts resistive load (non-motor), load -no-load.

Freq is read with a Hertz meter sometimes called frequency meter (can be a digital or vibrating reed type, go to ebay and look) as an average of around 60 hz. might be 56-60 loaded and 63-65 unloaded. (not safe for use with electronics) You do not manually hold the throttle in position when checking frequency which is also termed Hertz. Their is usually a adjustment of some sort on the end of the GOVERNOR SPRING when the spring is stretched tighter the Hz increases.

Yours is mainly for lights and temporary operating a freezer or fridge, not electronics such as TV's.The small gens for smooth clean voltage and Hz and maybe safe for use of electronics is termed inverter gens.

Do not use a tach for setting the Hz because emergency gens are set for Hertz and the RPMS at 3750 is just for ball park adjustments.. The gen will be close to 3750 for 60hz. (use a Hertz meter that reads approx 50-70 Hz accurately.

The 1750 you quoted is the no load idle rpms. (and is not critical, it's just to save on gas consumption, and noise when no load is applied. Good rule of thumb is to remove all loads BEFORE killing the engine.

If still available a Kill O watt meter was around $30 and read voltage, Hz.

If using such put it on the end of a cord instead of letting it ride on the gen due to vibration of the electronics inside.

I use electric heaters for loads.

You can use around 1500 electric heater at first maybe. You might burn out quartz lights when trying to use them for a load if the voltage surges too high.

You can find a service manual for yours maybe Briggs or Clymer using your model number. Power mate was also called Coleman.

I have found free pdf's of some Colemate/Powermates on-line every once in awhile. Not sure if they are even still in business. (they had a website/support sometime back) You can use the Model type and code of the Briggs to find service data. The Generator service manual is mainly for electrical testing and troubleshooting.

I suspect yours is probably Ok voltage and Hertz wise if you get the Carb correct and don't start monkeying around with other things until you get the proper test tools.

#3

ILENGINE

ILENGINE

Several multimeters have a Hz setting. A genetic at 3750 will be about 62-63 Hz. But will drop closer to 60 under load. Can't use for sensitive electronics. Too much distortion. Coleman/powermate now owned by Generac

#4

grumpyunk

grumpyunk

There is an app on google play for apple & android named "engine rpm" that may give usable readings. The web site

indicated is:

www.tunelab-world.com/rpm

The author is very responsive to queries(at least was), and likes feedback.

Real Time Specialties in Hopkins, MN is the maker.

Manual at tunelab-world.com/rpm

email info@tunelab-world.com

I own no stock, but like the product.

tom

indicated is:

www.tunelab-world.com/rpm

The author is very responsive to queries(at least was), and likes feedback.

Real Time Specialties in Hopkins, MN is the maker.

Manual at tunelab-world.com/rpm

email info@tunelab-world.com

I own no stock, but like the product.

tom

#5

J

jviews12

J

jviews12

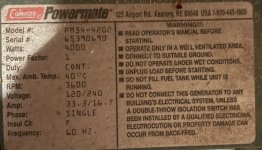

I use this and love it. cheap and useful around home. hope picture comes thru. gived volts hertz amps consumed by device. just push button, no scrolling functions

Attachments

#6

H-Towner

H-Towner

First off, thanks so much for the replies, all.

I didn’t realize how variable the voltage and frequency are under normal conditions. During our recent outage we borrowed a 4000w Predator (not an inverter) to run the refrigerators. At night, we switched to the bedroom circuit for lights and ceiling fan, but when we noticed the modem, router and tv were also energized, we streamed tv with no issue. Perhaps we were playing with fire, or perhaps the newer generator made cleaner power? Fortunately, the electronics have been working fine since then.

Today the Powermate I’m working on didn’t want to run smoothly after starting cold, but was good after warming up. Output voltage read 132v under no load, and fell to 125v with a 1500W heater plugged in. Runs smoothly under that load, too.

So far I’ve changed the oil, cleaned the jet, run carb cleaner through it, spiked the gas with sea foam, and fiddled with the adjustment screws. Far as I can tell the engine’s in good shape until the power output tells me otherwise. I’m planning to replace the fuel line and inline filter soon.

I did find the Kill a Watt on Amazon and saw it reads frequency in addition to power draw. It’s in my cart now. I did not find an iPhone version of the Tune Labs app, but there is a similar app in the Apple App Store. It costs $7.99. I can’t figure out what it is the YouTubers are using to measure rpms in the lawn mower videos, whether it’s acoustic based or reading em fields. But for now I’ll ignore engine rpms if the a/c frequency turns out good.

At this stage, if the engine’s running well, are there any metrics besides voltage and frequency, under load and no-load, that you would measure to check the health of the generator?

Also, is it normal that the engine will backfire almost every time it shuts off, or is that an indication something could be better optimized?

I didn’t realize how variable the voltage and frequency are under normal conditions. During our recent outage we borrowed a 4000w Predator (not an inverter) to run the refrigerators. At night, we switched to the bedroom circuit for lights and ceiling fan, but when we noticed the modem, router and tv were also energized, we streamed tv with no issue. Perhaps we were playing with fire, or perhaps the newer generator made cleaner power? Fortunately, the electronics have been working fine since then.

Today the Powermate I’m working on didn’t want to run smoothly after starting cold, but was good after warming up. Output voltage read 132v under no load, and fell to 125v with a 1500W heater plugged in. Runs smoothly under that load, too.

So far I’ve changed the oil, cleaned the jet, run carb cleaner through it, spiked the gas with sea foam, and fiddled with the adjustment screws. Far as I can tell the engine’s in good shape until the power output tells me otherwise. I’m planning to replace the fuel line and inline filter soon.

I did find the Kill a Watt on Amazon and saw it reads frequency in addition to power draw. It’s in my cart now. I did not find an iPhone version of the Tune Labs app, but there is a similar app in the Apple App Store. It costs $7.99. I can’t figure out what it is the YouTubers are using to measure rpms in the lawn mower videos, whether it’s acoustic based or reading em fields. But for now I’ll ignore engine rpms if the a/c frequency turns out good.

At this stage, if the engine’s running well, are there any metrics besides voltage and frequency, under load and no-load, that you would measure to check the health of the generator?

Also, is it normal that the engine will backfire almost every time it shuts off, or is that an indication something could be better optimized?

#7

J

jviews12

J

jviews12

I am NOT an expert, but concerned running modern refrigerators, washers and such and such with expensive circuit boards with generators. One option which is not cheap is to use a device which cleans up the power to 120vac 60Hz. I use such a device on my expensive tv connected to city power. I have had it for 10+ years (yes poor video) and no issues because the power if constant and clean. cheap insurance. - 2cents

#8

H-Towner

H-Towner

That’s neat. I wonder if a whole home UPS would do the same thing, again very expensive. I can’t complain so far about bad electric service (other than infrequent outages) I’ve got a plasma tv and a network-attached hard drive, both of which have been running directly off grid power since 2011. Fridges are definitely old and not smart. I try to keep my appliances as dumb as possible.I am NOT an expert, but concerned running modern refrigerators, washers and such and such with expensive circuit boards with generators. One option which is not cheap is to use a device which cleans up the power to 120vac 60Hz. I use such a device on my expensive tv connected to city power. I have had it for 10+ years (yes poor video) and no issues because the power if constant and clean. cheap insurance. - 2cents

#9

F

Forest#2

F

Forest#2

You are rolling the dice when operating expensive electronics (or any electronics) and smart appliances from a small emergency gen. If you need tv think about getting a small less expensive tv for such. (or invest in a inverter gen)

Some owners manuals of electronics mention such. (in the warranty section also)

A UPS is not the answer to clean up dirty power from a dirty power emergency gen. (you can consider installing a large ampere hour battery on a UPS and then operate electronics from the UPS similar to the larger RV's) One reason is the UPS also monitors frequency and if it detects dirty power due to erratic frequency ( the waveform of the frequency is also monitored, not just the Hertz) it will switch to backup battery and will usually be switching back and forth from gen to backup battery as the voltage and frequency varies from a small emergency gen to cause such.

If you are going to try (experiment)with a UPS best to not spend several dollars for such obly to find it's only good for on grid power monitoring backup.

The backfire when the engine dies is not anything normally to be concerned about. It's probably due to NOT letting the engine idle for awhile before killing the engine, the governor gives the engine full throttle while the engine is dying and no spark and it dumps raw gas into the hot cylinder and muffler and explodes. Some later model carbs have a ABV (AntiBackfireValve) to cut off gas to the carb jet when the kill switch is operated to reduce chance of a backfire.

Not running smooth on a cold start can sometimes be reduced by slightly tweaking the High speed jet if the carb has one. Sometimes only a 1/8 turn is needed. Adjust it slightly as the engine is warming and then check it when the engine is hot and split the difference if needed.

The newer model engines used a very lean Al Gore going green carb and even cold air would cause hunting and surging of the gen and the gen in very cold weather had to be placed in a box or small shelter so as some heat was captured for the carb intake or some had a metal shield that directed heat from the muffler toward the carb intake. (like some snow blowers use) Hunting and surging on a small emergency gen is not a good thing because the voltage and frequency is also going up and down.

Also best to remove the loads BEFORE killing a small emergency gen.

Also keep in mind that the 120 outlets on the gen may be split wired, for example on a 4kw 220 volt gen each 120v receptacle is about 15 a max intermittent load. (some small emergency gens also do not have any breakers to keep from overloading the outlets and if the full 4kw load is applied to one split wired 120 volt outlet it will let out the smoke and sadness.

Some owners manuals will casually mention such.

Some owners manuals of electronics mention such. (in the warranty section also)

A UPS is not the answer to clean up dirty power from a dirty power emergency gen. (you can consider installing a large ampere hour battery on a UPS and then operate electronics from the UPS similar to the larger RV's) One reason is the UPS also monitors frequency and if it detects dirty power due to erratic frequency ( the waveform of the frequency is also monitored, not just the Hertz) it will switch to backup battery and will usually be switching back and forth from gen to backup battery as the voltage and frequency varies from a small emergency gen to cause such.

If you are going to try (experiment)with a UPS best to not spend several dollars for such obly to find it's only good for on grid power monitoring backup.

The backfire when the engine dies is not anything normally to be concerned about. It's probably due to NOT letting the engine idle for awhile before killing the engine, the governor gives the engine full throttle while the engine is dying and no spark and it dumps raw gas into the hot cylinder and muffler and explodes. Some later model carbs have a ABV (AntiBackfireValve) to cut off gas to the carb jet when the kill switch is operated to reduce chance of a backfire.

Not running smooth on a cold start can sometimes be reduced by slightly tweaking the High speed jet if the carb has one. Sometimes only a 1/8 turn is needed. Adjust it slightly as the engine is warming and then check it when the engine is hot and split the difference if needed.

The newer model engines used a very lean Al Gore going green carb and even cold air would cause hunting and surging of the gen and the gen in very cold weather had to be placed in a box or small shelter so as some heat was captured for the carb intake or some had a metal shield that directed heat from the muffler toward the carb intake. (like some snow blowers use) Hunting and surging on a small emergency gen is not a good thing because the voltage and frequency is also going up and down.

Also best to remove the loads BEFORE killing a small emergency gen.

Also keep in mind that the 120 outlets on the gen may be split wired, for example on a 4kw 220 volt gen each 120v receptacle is about 15 a max intermittent load. (some small emergency gens also do not have any breakers to keep from overloading the outlets and if the full 4kw load is applied to one split wired 120 volt outlet it will let out the smoke and sadness.

Some owners manuals will casually mention such.

#10

H-Towner

H-Towner

Let it not be thought that I’m considering spending thousands on a UPS for my hundreds of dollars worth of tvs. I was only guessing at what kind of equipment would be required to reform sketchy grid ac. Further reading has shown there are all kinds of AVRs and power conditioners available, but that the power supplies on most modern electronics aren’t sensitive to ugly sine waves, frequency fluctuations, or moderate voltage fluctuations. Large voltage spikes and brownouts seem to be another story though. And that’s me wandering off topic from my reason for posting, which was figuring out how to make sure my generator is running properly.

For my purposes, I’m happy that the refrigerator compressors can hum alongside some lights and phone chargers… and must remember to disconnect power before starting and stopping the engine.

Again, really appreciate the insight into reviving and running this generator. I’ll be trying the cold vs hot adjustment.

For my purposes, I’m happy that the refrigerator compressors can hum alongside some lights and phone chargers… and must remember to disconnect power before starting and stopping the engine.

Again, really appreciate the insight into reviving and running this generator. I’ll be trying the cold vs hot adjustment.

#11

H-Towner

H-Towner

Following up, I changed the oil, bought a new fuel line and filter, and bought a Kill-a-Watt. But I took a bit of a break while getting over pneumonia. Yeesh!

Today I got back on it, and I think I’ve got the needle valve dialed in to help with cold starts. We’ll see next time I start it cold.

Now with the Kill-a-Watt, it reads just under 61 Hz with no load and just over 59 Hz with the heater drawing 1000W. A little over 130V at no load and about 121V at 1000W.

I take all this to mean it should be good to go if we lose lights again this season. Thanks a ton for all the advice.

Today I got back on it, and I think I’ve got the needle valve dialed in to help with cold starts. We’ll see next time I start it cold.

Now with the Kill-a-Watt, it reads just under 61 Hz with no load and just over 59 Hz with the heater drawing 1000W. A little over 130V at no load and about 121V at 1000W.

I take all this to mean it should be good to go if we lose lights again this season. Thanks a ton for all the advice.

#12

J

jviews12

J

jviews12

for the record, I use this item. I am NOT an expert but think this helps. This model is retired, but they still make similar devices.

Attachments

#13

F

Forest#2

F

Forest#2

What usually causes most emergency generators problems is long term storage without any exercise which includes long term storage of gasoline in the fuel tank and carb.

#14

A

Auto Doc's

A

Auto Doc's

I looked at your generator pictures and I have one just like that in my collection.

A couple of things to mention is wrap your fuel lines or put a section of hose over them to prevent excessive heat from the muffler causing problems.

The next item is to add an inline shutoff valve where the line comes out of the tank. This way you can use it to shut the unit down without backfire and run the fuel out of the carburetor at the same time. Fuel left sitting in carburetors is a huge issue I deal with. Use non ethanol fuel if you can get it.

A couple of things to mention is wrap your fuel lines or put a section of hose over them to prevent excessive heat from the muffler causing problems.

The next item is to add an inline shutoff valve where the line comes out of the tank. This way you can use it to shut the unit down without backfire and run the fuel out of the carburetor at the same time. Fuel left sitting in carburetors is a huge issue I deal with. Use non ethanol fuel if you can get it.

#15

A

Auto Doc's

A

Auto Doc's

I looked at your generator pictures and I have one just like that in my collection.

A couple of things to mention is wrap your fuel lines or put a section of hose over them to prevent excessive heat from the muffler causing problems.

The next item is to add an inline shutoff valve where the line comes out of the tank. This way you can use it to shut the unit down without backfire and run the fuel out of the carburetor at the same time. Fuel left sitting in carburetors is a huge issue I deal with. Use non ethanol fuel if you can get it.

A couple of things to mention is wrap your fuel lines or put a section of hose over them to prevent excessive heat from the muffler causing problems.

The next item is to add an inline shutoff valve where the line comes out of the tank. This way you can use it to shut the unit down without backfire and run the fuel out of the carburetor at the same time. Fuel left sitting in carburetors is a huge issue I deal with. Use non ethanol fuel if you can get it.