You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Fast Attach Blade System Problem

#1

J

jmacgreg

J

jmacgreg

I purchased a Cub Cadet XT2 GX50 earlier this summer. I have a little more than 4 acres to manage. This includes about 3.5 acres of pasture and the rest is lawn surrounding my house. I bought this tractor because I could dual purpose it and change blades quickly. Standard blades for the pasture and mulching system for my yard. The fast attach system seemed ideal as I could jack the mower up and change blades quickly. I think there might be a design problem with the locking collars because they have become impossible to remove by hand. I have to wedge the collars up and pound the blades off with a rubber mallet. I think that debris collects inside the collar making it extremely hard to push it up to clear the dowel pins that secure the blades. I will be calling the Cub Cadet help line, but was wondering if any of the other users on the forum have experienced similar problems and what, if any, solutions there are. Overall, I'm pleased with the mower except for this. Thanks.

#2

R

rpking

R

rpking

I bought a XT2 with the fast attach blade system too.

I haven't mowed with it yet.

I didn't really want a fast attach deck when I bought my mower, but the features I wanted on the tractor only came with that deck.

Kind of sucks a person can't pick the tractor and the deck separately, I think that option is available on the XT3 series, but those are out of my price range.

Do you use the deck wash system after you mow? I have not owned a mower with the deck wash feature.

I was just wondering if it worked or not. If you use it evidently it doesn't work very well.

Good luck.

I haven't mowed with it yet.

I didn't really want a fast attach deck when I bought my mower, but the features I wanted on the tractor only came with that deck.

Kind of sucks a person can't pick the tractor and the deck separately, I think that option is available on the XT3 series, but those are out of my price range.

Do you use the deck wash system after you mow? I have not owned a mower with the deck wash feature.

I was just wondering if it worked or not. If you use it evidently it doesn't work very well.

Good luck.

#3

J

jmacgreg

J

jmacgreg

Yes, I use the deck wash system. It does not remove ALL of the buildup around the deck's perimeter. I have to use a big screwdriver for that. I called the Cub Cadet customer service people and they weren't much help. The guy said he hadn't received any other calls on this issue. I think he will. He said I should take the machine to the dealer where I purchased it. The openings on the collar that retains the blades faces downward which I think might be a design problem. I'll try blowing some high pressure air into the collar to see if that helps. I can't imagine anything other than debris limiting the upward travel of the retaining collar. If this problem continues, I'll see if I can retrofit bolt-on blade spindles to the deck. With an air impact wrench Itwould have taken me maybe 10 minutes to change blades instead of the 2 hours of banging with a rubber mallet and cussing.

#4

R

Rivets

R

Rivets

If you are using the deck wash systems, two things to remember. First, do it as soon as possible, so debris does not have time to stick tight. Second, run the deck for 15 minutes after you disconnect the water. This is to insure that you dry everything off. There are those here who will tell you not to use it due to premature deck and bearing failure, but we have been doing this a shop and never had a problem.

#5

R

rpking

R

rpking

Good idea on the retrofit idea of regular spindles.

Keep us posted, if you do that I would be interested in knowing what spindles you use.

Keep us posted, if you do that I would be interested in knowing what spindles you use.

#6

Jeffalex2

Jeffalex2

I was struggling with it too... I figured out the following:

https://youtu.be/nGbWTgfgAVg

That said, I will probably replace with regular spindles when these wear out.

- Raise the tractor and work from underneath... tap the collars with a mallet and the dirt drop out

- Clean the top of the collar so that it can retract all of the way allowing the blade to move

https://youtu.be/nGbWTgfgAVg

That said, I will probably replace with regular spindles when these wear out.

#7

J

jmacgreg

J

jmacgreg

Thanks for the replies. I will try cleaning the top of the retainers. I'll also use high pressure air on them as well. I think the concept is a good one, but I suspect Cub did not do a whole lot of field testing before releasing this "feature." I also can't believe that the service rep had not received any complaints about this problem. Since the tractor is new, I'm not ready to pay more money to fix this issue yet. I will endeavor to live with it until the spindles give out and need replacing. Thanks again!

#8

H

Husky16913

H

Husky16913

I have had similar problems with my XT2 with 54" fab deck and Fast-Attach system. I found cleaning the area with a screwdriver, scraping out the debris( I much a lot so I get quite an accumulation) and then hitting the area with a wire brush removes enough of the material to allow the mechanism to be lifted upward. I anticipate it getting more problematic as the mower deck gets older, though.

I have also contacted CC to ask about some kind of fixture to allow blade balancing after sharpening. Right now the "s" shaped opening in the

blade does not allow conventional blade balancers to be used. Apparently after having this system out for almost 2 years, they( CC) have not addressed this problem.

My dealer has been as helpful as one can expect. Checking on the parts and prices to change spindles and blades the parts alone would be $395! Ouch! It would be much, much faster to change blades( and balance) with an impact rather than the Fast-Attach system. From an engineering standpoint, the FA system looks nice, but I suspect it will disappear due to its inherent issues.

I have also contacted CC to ask about some kind of fixture to allow blade balancing after sharpening. Right now the "s" shaped opening in the

blade does not allow conventional blade balancers to be used. Apparently after having this system out for almost 2 years, they( CC) have not addressed this problem.

My dealer has been as helpful as one can expect. Checking on the parts and prices to change spindles and blades the parts alone would be $395! Ouch! It would be much, much faster to change blades( and balance) with an impact rather than the Fast-Attach system. From an engineering standpoint, the FA system looks nice, but I suspect it will disappear due to its inherent issues.

#11

N

NEWUNHAPPYCUBOWNER

N

NEWUNHAPPYCUBOWNER

I have a Cub Cadet XT2 GX54D with the Fast Attach Blade system with 1 half season and right at 25 hours on it and this System is Horrible!!!

Have any of you found a replacement spindle with the star blades that works to replace these with!!!

Have any of you found a replacement spindle with the star blades that works to replace these with!!!

#12

StarTech

StarTech

I have not personally seen the system but I thinking that standard MTD spindle will replace it. Most of my customers are smart enough to avoid gimmicks.

#13

H

Homeuser66

H

Homeuser66

This is the one feature that I'm not looking forward to. I haven't purchased this tractor yet, but it says my first choice for what I need it for. I called the dealer near me and he hsiang laughed at me. He said this isn't an issue. There's no way debris gets in there. I told him, that's not true, from what I've read. He also told me there was no replacement spindles for it, only the quick connect ones. Unfortunately, if I do get this, he's the only dealer near me.

#14

StarTech

StarTech

One of my fellow mechanic said they are a problem to get release as he has clean off all the muck and then use hammer to get to release.This is the one feature that I'm not looking forward to. I haven't purchased this tractor yet, but it says my first choice for what I need it for. I called the dealer near me and he hsiang laughed at me. He said this isn't an issue. There's no way debris gets in there. I told him, that's not true, from what I've read. He also told me there was no replacement spindles for it, only the quick connect ones. Unfortunately, if I do get this, he's the only dealer near me.

#15

H

Homeuser66

H

Homeuser66

Thanks.One of my fellow mechanic said they are a problem to get release as he has clean off all the muck and then use hammer to get to release.

#16

L

lava

L

lava

Love my cub cadet xt2 but HATE the fast attach!

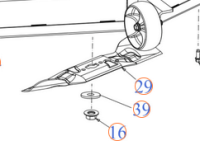

I did find a guy who commented on a YouTube video about changing the spindles. He suggest the spindle kit for the xt1 gt will swap out as long as you flip the two spacers on the tensioner pully along with removing the spacer from the solid mount idler pully. I have ordered this kit off of Amazon for 126 dollars. New spindles and blades.

I did find a guy who commented on a YouTube video about changing the spindles. He suggest the spindle kit for the xt1 gt will swap out as long as you flip the two spacers on the tensioner pully along with removing the spacer from the solid mount idler pully. I have ordered this kit off of Amazon for 126 dollars. New spindles and blades.

#17

L

lava

L

lava

I would also note I have contacted cub about this and I was also told they were surprised because they don't have any complaints about this system. Bull!Love my cub cadet xt2 but HATE the fast attach!

I did find a guy who commented on a YouTube video about changing the spindles. He suggest the spindle kit for the xt1 gt will swap out as long as you flip the two spacers on the tensioner pully along with removing the spacer from the solid mount idler pully. I have ordered this kit off of Amazon for 126 dollars. New spindles and blades.

#18

S

scruffythejanitor

S

scruffythejanitor

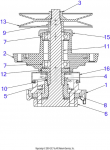

Another voice here happy with the tractor (Enduro XT2 GX54) but can't stand the "FastAttach" blades. They're terrible. Recently tried to sharpen the blades and one of the spindles was broken -- the spindle collar pins had snapped off (probably because we hit something) and we couldn't remove the thing. Had to completely disassemble the spindle. We bought a replacement spindle collar (OEM) but I'd like to find a standard spindle with the star pattern and nut. Does anyone have a part number that they know will fit the 54" fabricated deck? I'm going to give Cub Cadet a call and ask if there's a standard spindle that I can replace the FastAttach spindles with but if anyone knows the part number I'd appreciate it.

#19

S

scruffythejanitor

S

scruffythejanitor

Hey, so it's been a while, but I was being lazy.  However, I found the replacement parts I needed, so I wanted to post here to hopefully help someone else in the future who may search for things like "replace fast attach spindles with star" or "swap fast attach spindles for something that actually works well". Hehe.

However, I found the replacement parts I needed, so I wanted to post here to hopefully help someone else in the future who may search for things like "replace fast attach spindles with star" or "swap fast attach spindles for something that actually works well". Hehe.

Anyway, MTD part number 918-06991 or 618-06991 is a 6-point star spindle assembly that fits the 54" fabricated deck (and probably others) on the XT2. The bolt pattern for mounting is a standard 5" x 5" pattern. The pulley sits above the deck the same amount as the stock fast attach spindles, and the blade is held the same distance below the deck. The spindle is between 6.5" and 6 7/8" depending on the listing you find. They run as cheap as $20-ish for the aftermarket stuff to $50-ish for Stens or $100-ish for Cub Cadet. I'm trying the 8TEN brand, which are around $25 each.

Some of the replacement spindles come with the nuts for the blades, and some don't. I tried a cheap aftermarket 3-pack of nuts for $5 (they are 5/8" x 18 TPI) but the threads were not cut properly. The MTD nuts are $10 for a 3-pack so I ordered those, and they fit fine.

The pulley on the 918-06991 is not quite the same. The outer diameter thickness is 3/4" where the originals are 1". The inside thickness at the edge is 1/2" where the originals are 5/8". The groove depth on the 06991 is 5/8" where the originals are 7/8". This all means that the belt doesn't quite sit fully in the pulley. I don't know if that's an issue, but you can move the pulleys from your original fast attach spindles to the new ones (just be careful -- the fast attach are spring-loaded and will blow apart when you take the nut off). The splines on the pulleys are the same. Or, you can order new 756-05038 pulleys (Cub Cadet or aftermarket) for around $15-$25 each. I found a 3-pack of OEM for $56.

I hope that's helpful to someone. I'm looking forward to not dealing with that fast attach madness anymore.

Anyway, MTD part number 918-06991 or 618-06991 is a 6-point star spindle assembly that fits the 54" fabricated deck (and probably others) on the XT2. The bolt pattern for mounting is a standard 5" x 5" pattern. The pulley sits above the deck the same amount as the stock fast attach spindles, and the blade is held the same distance below the deck. The spindle is between 6.5" and 6 7/8" depending on the listing you find. They run as cheap as $20-ish for the aftermarket stuff to $50-ish for Stens or $100-ish for Cub Cadet. I'm trying the 8TEN brand, which are around $25 each.

Some of the replacement spindles come with the nuts for the blades, and some don't. I tried a cheap aftermarket 3-pack of nuts for $5 (they are 5/8" x 18 TPI) but the threads were not cut properly. The MTD nuts are $10 for a 3-pack so I ordered those, and they fit fine.

The pulley on the 918-06991 is not quite the same. The outer diameter thickness is 3/4" where the originals are 1". The inside thickness at the edge is 1/2" where the originals are 5/8". The groove depth on the 06991 is 5/8" where the originals are 7/8". This all means that the belt doesn't quite sit fully in the pulley. I don't know if that's an issue, but you can move the pulleys from your original fast attach spindles to the new ones (just be careful -- the fast attach are spring-loaded and will blow apart when you take the nut off). The splines on the pulleys are the same. Or, you can order new 756-05038 pulleys (Cub Cadet or aftermarket) for around $15-$25 each. I found a 3-pack of OEM for $56.

I hope that's helpful to someone. I'm looking forward to not dealing with that fast attach madness anymore.

#20

StarTech

StarTech

If you want to stay with "S" blades then the 618P09256 with (5.37 DIA) DIA pulleys; although, you might need to change spindle pulleys to the 5.2 dia ones.

I'll have to check my balancer with the blades before I say if it will work or not.

Edit> I have tried my Oregon balancer with the tapered cone and the blades balances fine. Most of the new blades are not perfectly balanced but no new blade usually is according to my balancer. Especially since the weight of a small paper clip cause a blade to be out balance on it.

I'll have to check my balancer with the blades before I say if it will work or not.

Edit> I have tried my Oregon balancer with the tapered cone and the blades balances fine. Most of the new blades are not perfectly balanced but no new blade usually is according to my balancer. Especially since the weight of a small paper clip cause a blade to be out balance on it.

#21

S

scruffythejanitor

S

scruffythejanitor

I don't have experience with the S blades, but from what I've heard they're more expensive. Anything's got to be better than the Fast Attach though. I'm going to try these spindles and star blades this season and see how it goes. I have automotive tools including an impact wrench so pulling off the 5/8" nuts isn't a big deal. I can see why someone who doesn't have the tooling might have trouble taking the blades off for sharpening, but for me these will be significantly easier than the Fast Attach.

#23

S

scruffythejanitor

S

scruffythejanitor

Heh -- the wonderful thing about standards is that there are so many to choose from.

Thanks for the additional info. It's nice to have it all in one place for anyone searching for it.

Thanks for the additional info. It's nice to have it all in one place for anyone searching for it.

#24

StarTech

StarTech

But I do admit the older style spindles will be a cheaper conversion as they do have after markets available for them where the new "S" style yet to have any after markets available.

And it the same with the Husqvarna tool-less blade system. Just cheaper to convert than the parts that are required the repair that system.

And it the same with the Husqvarna tool-less blade system. Just cheaper to convert than the parts that are required the repair that system.

#25

D

Dogjaw

D

Dogjaw

While I'm waiting on a new transmission for my XT2 SLX50 Fab, I just replaced the fast attach spindles and blades with a kit that has a 6 point center hole from 8tenparts.com I was tired of pulling the deck off, flipping it upside down, and beating the collars with a mallet to get the blades off. While I can't mow yet, here's my take so far. My Cub spindle sheaves are 5" dia., and the 8ten are the same diameter. The height is exactly the same. The bolt hole pattern is exact. You'll need a 10mm to remove the Cub spindles, and a 1/2" to install the 8ten. I matched up the new blades with my high lift blades, and are the same length. A big difference is the 8ten blades are thicker and have a 1" longer cutting edge at each end than the OME Cub blades. The only downside is that they don't supply the 5/8"-18 nuts for the blades. I emailed them (got a response within 2 hours on Sunday) asking if the spindles were pre-greased (they are) and suggested they add a few bucks to the price and supply the nuts. Customer service was passing the suggestion on to their product folks, so that may no be an issue sometime in the future. The website was easy to use. Pick equipment type, make, and model. The price isn't much more than a set of the S pattern blades.

Here's what I ordered for MY 50" deck. https://8tenparts.com/products/8ten-mk1002313

Here's what I ordered for MY 50" deck. https://8tenparts.com/products/8ten-mk1002313