You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

dieseling engine when shut down

#1

D

dd20399

D

dd20399

Hello, i have a 16LTH Simplicity with a Briggs Vanguard engine...303777 0122-01 5526 90041811. The fuel shut off was bad so i replaced with an electric inline one. When engine is hot it don t want to stop, found on internet what i had But 170.00 in cost and that`s to much. the inline one takes awhile to shut off.....a lot of fuel inline valve to carb...the only thing i can do if put a switch on dash to shut valve off and wait for engine to die..............is there a better way thanks for reading

#2

R

Rivets

R

Rivets

I’m confused, would you please provide us with pictures of the old fuel shutoff and the electric inline shutoff you installed. The only fuel shutoff on that Briggs engine is the electric solenoid mounted on the bottom of the carb, which is electric.

#3

ILENGINE

ILENGINE

My first thought is the ignition modules are not being shutdown when the key is switched off. So they are continuing to produce spark and engine runs until the carb runs out of fuel.

#5

FixItFrank

FixItFrank

I think you have two options. Try letting the engine idle for a minute to cool down before you turn it off. That worked for me on a similar tractor.

Or look for an 'aftermarket' replacement for that solenoid. You can usually find them for $30 or $40 instead of $170.

Or look for an 'aftermarket' replacement for that solenoid. You can usually find them for $30 or $40 instead of $170.

#6

StarTech

The original fuel solenoid was to block the main jet and quickly stave the engine of raw fuel entering the exhaust and exploding. Now with you current solenoid you are having to run the engine until all the fuel in the carburetor is used up.

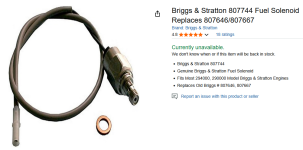

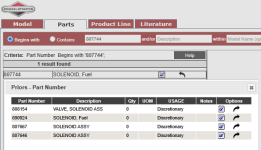

The fuel solenoid pn for date code of 1990 is 807744 which is a design that simply cost due to the tariffs and Briggs greed.

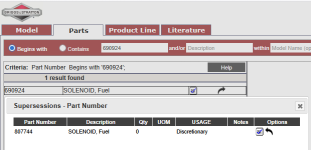

Now if you are quick you can get one for $85 using the 690924 PN which was supersedes to 807744. Now this is based on Briggs Power Portal info on the supersedes. The solenoid maybe of a different design. Now take with a grain of salt as I am using their info so I the OEM has the correct info. There is another version of this solenoid but would require new wiring.

Briggs 690924

StarTech

I'm think IL has the right idea on this but also it necessary to have the correct solenoid. The problem is both coils seldom fail so it is more likely a wiring or switch problem.My first thought is the ignition modules are not being shutdown when the key is switched off. So they are continuing to produce spark and engine runs until the carb runs out of fuel.

The original fuel solenoid was to block the main jet and quickly stave the engine of raw fuel entering the exhaust and exploding. Now with you current solenoid you are having to run the engine until all the fuel in the carburetor is used up.

The fuel solenoid pn for date code of 1990 is 807744 which is a design that simply cost due to the tariffs and Briggs greed.

Now if you are quick you can get one for $85 using the 690924 PN which was supersedes to 807744. Now this is based on Briggs Power Portal info on the supersedes. The solenoid maybe of a different design. Now take with a grain of salt as I am using their info so I the OEM has the correct info. There is another version of this solenoid but would require new wiring.

Briggs 690924

#7

ILENGINE

ILENGINE

But also need to keep in mind that there are a handful of mowers out there that were designed without a kill wire connected to the ignition modules. They use the fuel solenoid depowering to kill the engine by shutting off the fuel. So incorrect fuel solenoid on the carb, or one that has been modified will not kill the engine.

#8

StarTech

StarTech

And I have ran into those myself and I usually leave them as is; unless, I having a problem with shutdown then it is a little rewiring. But is better to shutdown the coils whenever possible. I had a mower in last year in the seat switch connector had gotten to where the shorting strip was causing it not to start. Some DIYer just clipped the kill wire at the engine under the shroud. This was a safety issue the customer was complaining about as the mower would not shut down if he got the seat.

Now JD is one that uses the fuel solenoid the shut some the ZTR series mowers but that is done through relays or the ECUs. They also have the oil pressure switch into the circuit so cranking time is longer as oil pressure must be present to activate the system.

Now JD is one that uses the fuel solenoid the shut some the ZTR series mowers but that is done through relays or the ECUs. They also have the oil pressure switch into the circuit so cranking time is longer as oil pressure must be present to activate the system.

#9

A

Auto Doc's

This mower model shows to be made from 1990-1993. We would need the product label information to confirm.

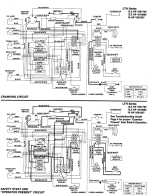

These B&S engines require a combination of functions to shut the motor down as quickly as possible. The ignition switch has to short/ground out both coils and also cut power to the carburetor bowl solenoid at the same time for the quickest possible shutdown.

You will likely not improve the situation by trying to modify or re-engineer the original system design.

Keep it simple. There is no true "instant off" with just the push of a button. I recommend installing a manual fuel shutoff near the fuel pulse pump inlet. Turn the valve off and set the engine at low idle. It will gradually run out of fuel in the carburetor bowl and quit running.

It is also likely that the ignition coil "kill" function is not working for some reason.

I suspect if you remove the upper fan cover/shroud, you will find one or both coils disconnected. That is likely because the kill wire harness segment needs to be replaced due to a bad inline diode. I've seen a lot of V-twin mowers parted out or sent to salvage for this simple yet ingenious little harness that B&S uses.

Ignition switches can also create some strange problems when the internal contacts have worn down. Be aware that not all switches are designed the same. They can have the same appearance on the outside but be totally different on the inside. The pin locations and letter assignments have to be an exact match.

If the switch has been replaced in the past, it could easily be the wrong ignition switch was installed.

A

Auto Doc's

Hello D.,Hello, i have a 16LTH Simplicity with a Briggs Vanguard engine...303777 0122-01 5526 90041811. The fuel shut off was bad so i replaced with an electric inline one. When engine is hot it don t want to stop, found on internet what i had But 170.00 in cost and that`s to much. the inline one takes awhile to shut off.....a lot of fuel inline valve to carb...the only thing i can do if put a switch on dash to shut valve off and wait for engine to die..............is there a better way thanks for reading

This mower model shows to be made from 1990-1993. We would need the product label information to confirm.

These B&S engines require a combination of functions to shut the motor down as quickly as possible. The ignition switch has to short/ground out both coils and also cut power to the carburetor bowl solenoid at the same time for the quickest possible shutdown.

You will likely not improve the situation by trying to modify or re-engineer the original system design.

Keep it simple. There is no true "instant off" with just the push of a button. I recommend installing a manual fuel shutoff near the fuel pulse pump inlet. Turn the valve off and set the engine at low idle. It will gradually run out of fuel in the carburetor bowl and quit running.

It is also likely that the ignition coil "kill" function is not working for some reason.

I suspect if you remove the upper fan cover/shroud, you will find one or both coils disconnected. That is likely because the kill wire harness segment needs to be replaced due to a bad inline diode. I've seen a lot of V-twin mowers parted out or sent to salvage for this simple yet ingenious little harness that B&S uses.

Ignition switches can also create some strange problems when the internal contacts have worn down. Be aware that not all switches are designed the same. They can have the same appearance on the outside but be totally different on the inside. The pin locations and letter assignments have to be an exact match.

If the switch has been replaced in the past, it could easily be the wrong ignition switch was installed.

#12

D

dd20399

D

dd20399

Guys, thanks for your reply`s and your time to read them.......if you would look at a picture of an 807744 part, this fuel valve is differant than most...very long with 2 sets of threads...no aftermarket on this one... would very much like to stay with the oem ...been looking for over a year for a used one....the inline electric valves are nice for alot of applications.....i have one on a 57 Ferguson tractor , never cut the fuel off, never floods..but i knew this would have too much fuel in line to cut off quick for this mower.......this oem valve was this high dollar in cost before the tariffs hit........wonderful mower and a shame it will cause a terminal problem one day with the dieseling...found too you can turn the key back alittle and it will stop power to solenoid and stay running till the trapped fuel is gone and turn key to fully off and pull the key out.................guys if you know where an oem used i could buy i would like to know....its old so chances are not many around. can`t find new for less that 170, most that list one if you try to order will say no more ..........will try letting it idle longer and someone said high test fuel would solve it...thanks for your researching and part #s....

#15

D

dd20399

D

dd20399

And if you don't believe my records maybe you will believe Briggs and Stratton.

View attachment 72394

View attachment 72395

I did find one New Old Stock 690924 available. Link in post #6.

#16

D

dd20399

D

dd20399

StarTech, i am not the smartest but i followed your link and bought the 690924...cost 82.00 with the tax.....i have spent more money than i will ever get out of it ..new rear tires ,battery, fuel pump etc , but was father in laws and selling his stuff and i`m bad about spending more that it will bring .....but if it won`t shut off it would be a hard sell...i don`t understand why it will need to be wired differant............i will see when i get it................StarTech thanks for having to tell me twice.........I am excited to get it..hopefully they still have it.... it went through

#17

StarTech

StarTech

Most professional eBay sellers usually keep the system up to date.

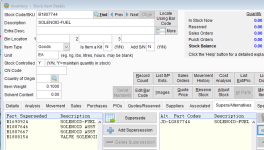

Having the superseded part numbers was one thing I fought with my Accounting System programmer to include in the inventory software as I have older superseded parts in stock. When PNs got superseded that I had in stock the bin locations had to follow the superseding too so I could find them easily.

As in this case sometimes eBay sellers are just clearing out their inventory and only have the PN on packages to goes by.

By this it makes me good at procuring parts that many shop simply give up on finding. Yes it takes time to do this but with the system I have in place if I have crossed a part usually it help me to lower the cost to me and my customers.

Too bad my main distributor source of this info has make their price files into junk price files. If I have hunt down the older PNs then I can usually find a better price elsewhere so they are losing sales.

Having the superseded part numbers was one thing I fought with my Accounting System programmer to include in the inventory software as I have older superseded parts in stock. When PNs got superseded that I had in stock the bin locations had to follow the superseding too so I could find them easily.

As in this case sometimes eBay sellers are just clearing out their inventory and only have the PN on packages to goes by.

By this it makes me good at procuring parts that many shop simply give up on finding. Yes it takes time to do this but with the system I have in place if I have crossed a part usually it help me to lower the cost to me and my customers.

Too bad my main distributor source of this info has make their price files into junk price files. If I have hunt down the older PNs then I can usually find a better price elsewhere so they are losing sales.

#18

D

dd20399

D

dd20399

You saved me some hair on this part....i will let you know how this comes out when i have it installed..... have a wonderful ThanksgivingMost professional eBay sellers usually keep the system up to date.

Having the superseded part numbers was one thing I fought with my Accounting System programmer to include in the inventory software as I have older superseded parts in stock. When PNs got superseded that I had in stock the bin locations had to follow the superseding too so I could find them easily.

As in this case sometimes eBay sellers are just clearing out their inventory and only have the PN on packages to goes by.

By this it makes me good at procuring parts that many shop simply give up on finding. Yes it takes time to do this but with the system I have in place if I have crossed a part usually it help me to lower the cost to me and my customers.

Too bad my main distributor source of this info has make their price files into junk price files. If I have hunt down the older PNs then I can usually find a better price elsewhere so they are losing sales.

#19

S

Skippydiesel

S

Skippydiesel

The term "DIESELING" is usually used to describe an engine that continues to run after ignition turned of due to SPONTANEOUS COMBUSTION.

Spontaneous combustion is usually due to carbon build up in the cylinder, that is glowing red hot at the time the ignition turned off. The red hot carbon ignites the fuel and the cycle continues as long as there is fuel.

Unusually sounding engine noise (knocking), very rough running (ignition running out of synch with valves opening closing etc) and backfiring can be expected from a petrol engine that is actually DIESELING.

Back in the day when engines were regularly "de- coked" dieseling was not uncommon, especially if the ignition was turned off when the engine especially hot.

What is being discussed here is not "DIESELING"

Spontaneous combustion is usually due to carbon build up in the cylinder, that is glowing red hot at the time the ignition turned off. The red hot carbon ignites the fuel and the cycle continues as long as there is fuel.

Unusually sounding engine noise (knocking), very rough running (ignition running out of synch with valves opening closing etc) and backfiring can be expected from a petrol engine that is actually DIESELING.

Back in the day when engines were regularly "de- coked" dieseling was not uncommon, especially if the ignition was turned off when the engine especially hot.

What is being discussed here is not "DIESELING"

#20

StarTech

StarTech

Skippy I got for you.

A 2 cycle that runs away [ well above the design 10K rpm] at full throttle and idles normally. Even the local dealer tech couldn't figure that one that was under warranty. I did find the problem using a tach and it has been back with its owner for a year now.

Really would been nice save all the extra power and fuel but it would had probably self destructed from excessive rpms.

A 2 cycle that runs away [ well above the design 10K rpm] at full throttle and idles normally. Even the local dealer tech couldn't figure that one that was under warranty. I did find the problem using a tach and it has been back with its owner for a year now.

Really would been nice save all the extra power and fuel but it would had probably self destructed from excessive rpms.

#21

J

Johner

Let it run to cool down, I have the same problem when the weather is hot. Just let it idle and cool down.

J

Johner

Hello, i have a 16LTH Simplicity with a Briggs Vanguard engine...303777 0122-01 5526 90041811. The fuel shut off was bad so i replaced with an electric inline one. When engine is hot it don t want to stop, found on internet what i had But 170.00 in cost and that`s to much. the inline one takes awhile to shut off.....a lot of fuel inline valve to carb...the only thing i can do if put a switch on dash to shut valve off and wait for engine to die..............is there a better way thanks for reading

Let it run to cool down, I have the same problem when the weather is hot. Just let it idle and cool down.

#22

R

RevB

R

RevB

I'm at a loss about your "fuel shut off" . Is this the carburetor solenoid or a manual valve? The solenoid is only $16 or less from plenty of sources and there isn't any $170 fuel parts anywhere on this engine.Hello, i have a 16LTH Simplicity with a Briggs Vanguard engine...303777 0122-01 5526 90041811. The fuel shut off was bad so i replaced with an electric inline one. When engine is hot it don t want to stop, found on internet what i had But 170.00 in cost and that`s to much. the inline one takes awhile to shut off.....a lot of fuel inline valve to carb...the only thing i can do if put a switch on dash to shut valve off and wait for engine to die..............is there a better way thanks for reading

#23

ILENGINE

ILENGINE

Fuel solenoid on this carb is https://www.partstree.com/parts/briggs-stratton-806472/. And I suspect the shutoff the OP was referring to is a electric inline fuel shutoff similar to this https://www.amazon.com/s?k=electric...5&ref=nb_sb_ss_p13n-expert-pd-ops-ranker_1_17I'm at a loss about your "fuel shut off" . Is this the carburetor solenoid or a manual valve? The solenoid is only $16 or less from plenty of sources and there isn't any $170 fuel parts anywhere on this engine.

#24

B

bentrim

B

bentrim

I admit I did NOT read all the posts but hope I can add to the discussion.

The antifire solenoid mounted in the carburetor stops fuel flow thru the main jet, it does not stop flow to the carburetor the needle and seat do that.

If an inline fuel shut off is used whether manual or electric, the engne will not stop until the carburetor is empty, this may also result in engine run on, unless the ignition is killed 1st.

With the carburetor mounted antifire solenoid. the manufactures recommend to shut the engine down at 3/4 to full throttle. Why? as the engine winds down mainly air is pumped thru the engine and into the muffler. This is supposed to pump the fuel out of the muffler so you dong get that BANG. Even if the ignition kills the spark, which should be killed when the switch is shut off.

From the Kohler command opperators manual:

Stopping

1. Remove the load by disengaging all PTO driven

attachments.

2. For Carbureted Engines Without A Shutdown

Solenoid: Move the throttle to the slow or low

idle position. Allow the engine to run at idle for

30-60 seconds; then stop the engine.

For Carbureted Engines Equipped With A

Shutdown Solenoid: Position the throttle control

somewhere between half and full throttle; then

stop the engine.

For EFI Engines: Move the throttle to the slow or

idle position; turn key off to stop engine.

The antifire solenoid mounted in the carburetor stops fuel flow thru the main jet, it does not stop flow to the carburetor the needle and seat do that.

If an inline fuel shut off is used whether manual or electric, the engne will not stop until the carburetor is empty, this may also result in engine run on, unless the ignition is killed 1st.

With the carburetor mounted antifire solenoid. the manufactures recommend to shut the engine down at 3/4 to full throttle. Why? as the engine winds down mainly air is pumped thru the engine and into the muffler. This is supposed to pump the fuel out of the muffler so you dong get that BANG. Even if the ignition kills the spark, which should be killed when the switch is shut off.

From the Kohler command opperators manual:

Stopping

1. Remove the load by disengaging all PTO driven

attachments.

2. For Carbureted Engines Without A Shutdown

Solenoid: Move the throttle to the slow or low

idle position. Allow the engine to run at idle for

30-60 seconds; then stop the engine.

For Carbureted Engines Equipped With A

Shutdown Solenoid: Position the throttle control

somewhere between half and full throttle; then

stop the engine.

For EFI Engines: Move the throttle to the slow or

idle position; turn key off to stop engine.

#25

J

jviews12

J

jviews12

I agree, fuel valve as close to carb as reasonable. let it run dry. have a cvlean and empty carb which does not plug up.

#26

S

Skippydiesel

S

Skippydiesel

FACT:

An engine will not continue to run if:

An engine will not continue to run if:

- The fuel supply is cut off

- The ignition (in a spark ignition engines) is grounded

- Its not receiving sufficient O2 (air) to support combustion (not usually used to stop an engine)

- Dieseling/spontaneous combustion, due to the continued supply of fuel. Investigate overheating/carbon build up.

- Ignition not actually off/grounded. Investigate switch action/terminal condition, ignition kill wires for continuity (broken) or not making contact.

- Fuel not off & spark ignition not off. Investigate fuel shut of system (if fitted) AND ignition kill system (above).

#27

StarTech

Come on the mower was setup shut the carb fuel solenoid blocking the main jet, starving the engine of the fuel. I worked mowers with such a setup. They do need a backup system and get one installed at my place.

StarTech

Hmmm that's a new one. An engine that runs on natural air only that doesn't have a fuel system.

- Fuel not off & spark ignition not off. Investigate fuel shut of system (if fitted) AND ignition kill system (above).

Come on the mower was setup shut the carb fuel solenoid blocking the main jet, starving the engine of the fuel. I worked mowers with such a setup. They do need a backup system and get one installed at my place.

#28

S

Skippydiesel

The ignition wont turn off (kill circuit inoperative)

AND

The fuel wont turn off

Engine keeps running despite operator thinking kill circuit (switch/button/lever position) activated.

S

Skippydiesel

I think you misread/understood what I wrote.Hmmm that's a new one. An engine that runs on natural air only that doesn't have a fuel system.

Come on the mower was setup shut the carb fuel solenoid blocking the main jet, starving the engine of the fuel. I worked mowers with such a setup. They do need a backup system and get one installed at my place.

- Fuel not off & spark ignition not off.

The ignition wont turn off (kill circuit inoperative)

AND

The fuel wont turn off

Engine keeps running despite operator thinking kill circuit (switch/button/lever position) activated.

- Investigate fuel shut of system (if fitted) AND ignition kill system (above).

#29

StarTech

StarTech

I understand what you getting at but these engine still has to have a fuel system of some kind fitted to even give problems and you said Investigate fuel shut of system (if fitted). Key words if fitted. but of we got read of as off. Correct wording is necessary; hence, the edit radio button.

That is what I was poling fun at.

The op has disabled the fuel solenoid by removing it or clipping it. And the ignition kill is not either working or not even present. What the op was calling dieseling was that now it has run until the carburetor fuel bowl is empty.

We basically told to either repair or install the ignition circuit or replace the carburetor fuel solenoid that he removed.

Geesh, I am not a hand holding person even in person.

That is what I was poling fun at.

The op has disabled the fuel solenoid by removing it or clipping it. And the ignition kill is not either working or not even present. What the op was calling dieseling was that now it has run until the carburetor fuel bowl is empty.

We basically told to either repair or install the ignition circuit or replace the carburetor fuel solenoid that he removed.

Geesh, I am not a hand holding person even in person.

#30

S

slomo

Also not recommended by any engine manufacturer to do this. All state to run at max revs all the time for max cooling, lubrication and longevity.

S

slomo

Idling down produces LESS air flow to cool the engine.Try letting the engine idle for a minute to cool down before you turn it off.

Also not recommended by any engine manufacturer to do this. All state to run at max revs all the time for max cooling, lubrication and longevity.

#31

S

slomo

S

slomo

Here's another one. Maybe yours is water cooled with a full pressure lube oil pump??Let it run to cool down, I have the same problem when the weather is hot. Just let it idle and cool down.

#32

StarTech

StarTech

Remember guys, we had a problem with fuel causing vapor conditions. It turned out to be that the fuel suppliers didn't change from winter to summer soon enough. The fuel actually was boiling in the carbs and fuel line due to normal engine heat. This of course is not related to the current problem.

#33

A

Auto Doc's

High airflow is especially important running under loaded conditions.

However, I have to disagree. An engine should not be shut down at full throttle. Rpm should be reduced to reduce the excess heat that has built up while under load. The engine still has more than sufficient air flow at lower RPM with no load.

This cool down idle period does not take very long, but it does reduce after-fire/backfire and run on dieseling problems. This especially important in gas engines that may have excessive carbon deposits on the head or top of the piston because they act like burning embers at higher RPM's.

A

Auto Doc's

Hi slomo,Idling down produces LESS air flow to cool the engine.

Also not recommended by any engine manufacturer to do this. All state to run at max revs all the time for max cooling, lubrication and longevity.

High airflow is especially important running under loaded conditions.

However, I have to disagree. An engine should not be shut down at full throttle. Rpm should be reduced to reduce the excess heat that has built up while under load. The engine still has more than sufficient air flow at lower RPM with no load.

This cool down idle period does not take very long, but it does reduce after-fire/backfire and run on dieseling problems. This especially important in gas engines that may have excessive carbon deposits on the head or top of the piston because they act like burning embers at higher RPM's.

#34

ILENGINE

ILENGINE

True except Kohler/Rehlko. Kohler specs their carbs to were the idle circuit isn't controlled by the anti-afterfire solenoid, therefore Kohler recommends shutting their engines off at full throttle. Since the idle circuit isn't controlled by the fuel solenoid idling down before shutoff can actually cause the backfire to be more likely.However, I have to disagree. An engine should not be shut down at full throttle. Rpm should be reduced to reduce the excess heat that has built up while under load. The engine still has more than sufficient air flow at lower RPM with no load.

This cool down idle period does not take very long, but it does reduce after-fire/backfire and run on dieseling problems. This especially important in gas engines that may have excessive carbon deposits on the head or top of the piston because they act like burning embers at higher RPM's.

#35

S

slomo

S

slomo

All I know, which is NOT MUCH, all the engine manufactures state to run at max revs all the time. Provides max lubrication, cooling and engine longevity. These are not car engines. Especially splash lube engines. Idle down and kill all the lube and cooling.Hi slomo,

High airflow is especially important running under loaded conditions.

However, I have to disagree. An engine should not be shut down at full throttle. Rpm should be reduced to reduce the excess heat that has built up while under load. The engine still has more than sufficient air flow at lower RPM with no load.

This cool down idle period does not take very long, but it does reduce after-fire/backfire and run on dieseling problems. This especially important in gas engines that may have excessive carbon deposits on the head or top of the piston because they act like burning embers at higher RPM's.

#36

M

MParr

M

MParr

Correct! 1/2 to full throttle.True except Kohler/Rehlko. Kohler specs their carbs to were the idle circuit isn't controlled by the anti-afterfire solenoid, therefore Kohler recommends shutting their engines off at full throttle. Since the idle circuit isn't controlled by the fuel solenoid idling down before shutoff can actually cause the backfire to be more likely.

#37

J

Johner

J

Johner

It was like this from day one, very hot day is only time I have a problem. Thanks.Here's another one. Maybe yours is water cooled with a full pressure lube oil pump??

#38

D

dd20399

D

dd20399

Got the part last Saturday.........installed it ...works fine..too cold to be playing with it much..thanks againAnd if you don't believe my records maybe you will believe Briggs and Stratton.

View attachment 72394

View attachment 72395

I did find one New Old Stock 690924 available. Link in post #6.

#39

J

Johner

J

Johner

Will have to look into this.Got the part last Saturday.........installed it ...works fine..too cold to be playing with it much..thanks again