You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Cub Cadet SC900 Self Propelled no start

#1

J

jb2873

J

jb2873

Hey everyone, I have a new to me SC900 rear wheel self propelled mower. Had been running great, only used a dozen times or so until a month ago....

Was taking a long time to get it to fire up.. over time, it went from 1 single pull, increasing over time to 6 or 7 pulls, then up to a couple dozen pulls or so to get it to cough and start.

Now it won't start at all.

What I have done:

*Pulled & inspected plug (plug looksd but is getting wet after multiple pulls ((obviously it's getting fuel)).

*Grounded out spark plug to verify spark ( no visible spark)

*Pulled fuel tank off to inspect "kill switch"

This is what has me puzzled. I have never seen a kill switch designed this way. I'm confused on how this can work if when squeezing closed the safety start lever and pull starting the mower, the metal kill tab makes contact with the metal pivoting arm....but when you let off the safety lever, that same metal grounding tab makes contact again, just on the opposite side of this same metal pivoting arm.

Can someone explain how this works and whether it should be doing this. I would think it should ground out only when releasing the safety lever.

I'm assuming my issue is either the kills switch (which may need some adjusting or a faulty coil module).

And yes, mower has fuel

Thanks

Was taking a long time to get it to fire up.. over time, it went from 1 single pull, increasing over time to 6 or 7 pulls, then up to a couple dozen pulls or so to get it to cough and start.

Now it won't start at all.

What I have done:

*Pulled & inspected plug (plug looksd but is getting wet after multiple pulls ((obviously it's getting fuel)).

*Grounded out spark plug to verify spark ( no visible spark)

*Pulled fuel tank off to inspect "kill switch"

This is what has me puzzled. I have never seen a kill switch designed this way. I'm confused on how this can work if when squeezing closed the safety start lever and pull starting the mower, the metal kill tab makes contact with the metal pivoting arm....but when you let off the safety lever, that same metal grounding tab makes contact again, just on the opposite side of this same metal pivoting arm.

Can someone explain how this works and whether it should be doing this. I would think it should ground out only when releasing the safety lever.

I'm assuming my issue is either the kills switch (which may need some adjusting or a faulty coil module).

And yes, mower has fuel

Thanks

#2

ILENGINE

ILENGINE

The actual model and serial from the mower as well as the model information from the engine if possible.. I tried looking up the SC900 and it came back with a briggs engine, but that doesn't look like briggs

#3

J

jb2873

I'm almost certain it's a cubcadet motor and not a briggs.

J

jb2873

Hi, the model is SC900 rear wheel drive & motor ser# 5X70AU/1811131A0082 the best I can tell on the faded decal on the motor.The actual model and serial from the mower as well as the model information from the engine if possible.. I tried looking up the SC900 and it came back with a briggs engine, but that doesn't look like briggs

I'm almost certain it's a cubcadet motor and not a briggs.

#4

M

MowerNick

M

MowerNick

The spot thats touching on the flywheel is the engine brake. The pad on it is not metal so it will not ground out there.

#6

O

Oddjob

O

Oddjob

The fact that it got harder and harder to start and now there is no visible spark, would point in the direction of a failing coil. Sometimes it is hard to see a spark when you ground a plug. I prefer to use a spark tester. Less than $10 at Harbor Freight. It is also possible that the grounding switch got bent and it is grounding even with the safety bale pulled up. That would give you a “no spark” condition despite a good coil. If that is a possibility, I stick a piece of thin plastic, like a credit card, between the poles of the grounding switch to temporarily disable it, then test for spark.

A Cub Cadet coil will cost around $80. Amazon has a number of Chinese clones from $15-$30. I’m guessing that this is a made-in-China engine and that the made-in-China coils are what Cub Cadet in China used. So, if it were me, I’d buy the Amazon replacement rather than “OEM”.

A Cub Cadet coil will cost around $80. Amazon has a number of Chinese clones from $15-$30. I’m guessing that this is a made-in-China engine and that the made-in-China coils are what Cub Cadet in China used. So, if it were me, I’d buy the Amazon replacement rather than “OEM”.

#7

J

jb2873

J

jb2873

The spot thats touching on the flywheel is the engine brake. The pad on it is not metal so it will not ground out there.Yes, I see the brake pad that touches the "flywheel". When motor is not running, the kill switch arm touches the metal.pivot arm that this brake pad is attached to. But when the motor is running and the pad is not in contact with the flywheel, the kills switch is still contacting this same metal pivot arm that the brake is attached to, only that it's touching the opposite side of this pivot....hard to explain. I will try to take more pics for clarification.

#8

J

jb2873

J

jb2873

See pic showing with the safety lever closed ready to start vs safety lever open to stop motor.

The kill switch arm still makes contact (grounding out), whether safety lever is squeezed closed to run or released to stop motor from running. The grounding happens at two different locations on the metal pivot arm that the brake is attached to, whether its in run or kill mode.

Am I not seeing this correctly?

The kill switch arm still makes contact (grounding out), whether safety lever is squeezed closed to run or released to stop motor from running. The grounding happens at two different locations on the metal pivot arm that the brake is attached to, whether its in run or kill mode.

Am I not seeing this correctly?

Attachments

#9

J

jb2873

J

jb2873

My thoughts as well...my confusion is more about the kill switch operation

I'm completely confused on this kill switch design, and how this actually works based on what I'm seeing during the safety lever activated and the safety lever released (plz see my attached pics)

The fact that it got harder and harder to start and now there is no visible spark, would point in the direction of a failing coil. Sometimes it is hard to see a spark when you ground a plug. I prefer to use a spark tester. Less than $10 at Harbor Freight. It is also possible that the grounding switch got bent and it is grounding even with the safety bale pulled up. That would give you a “no spark” condition despite a good coil. If that is a possibility, I stick a piece of thin plastic, like a credit card, between the poles of the grounding switch to temporarily disable it, then test for spark.

A Cub Cadet coil will cost around $80. Amazon has a number of Chinese clones from $15-$30. I’m guessing that this is a made-in-China engine and that the made-in-China coils are what Cub Cadet in China used. So, if it were me, I’d buy the Amazon

I agree....i just want to rule out the kill switch.The fact that it got harder and harder to start and now there is no visible spark, would point in the direction of a failing coil. Sometimes it is hard to see a spark when you ground a plug. I prefer to use a spark tester. Less than $10 at Harbor Freight. It is also possible that the grounding switch got bent and it is grounding even with the safety bale pulled up. That would give you a “no spark” condition despite a good coil. If that is a possibility, I stick a piece of thin plastic, like a credit card, between the poles of the grounding switch to temporarily disable it, then test for spark.

A Cub Cadet coil will cost around $80. Amazon has a number of Chinese clones from $15-$30. I’m guessing that this is a made-in-China engine and that the made-in-China coils are what Cub Cadet in China used. So, if it were me, I’d buy the Amazon replacement rather than “OEM”.

I'm completely confused on this kill switch design, and how this actually works based on what I'm seeing during the safety lever activated and the safety lever released (plz see my attached pics)

#11

R

Rivets

R

Rivets

Is it possible you can take a picture of the backside of that kill switch, plastic area where the bolt/nut are and electrical connection?

#12

O

Oddjob

O

Oddjob

Hard to tell from the pics, but I think you are saying that the long lever hits the short stub to ground the coil when the blade brake engages the flywheel, and also hits the metal backing of the brake when the blade brake is disengaged. I noticed a screw on the fitting for the long lever. Can you loosen that screw and move the lever arm a little counterclockwise so it misses the brake backing?My thoughts as well...my confusion is more about the kill switch operation

I agree....i just want to rule out the kill switch.

I'm completely confused on this kill switch design, and how this actually works based on what I'm seeing during the safety lever activated and the safety lever released (plz see my attached pics)

#13

R

Rivets

R

Rivets

The reason I’d like to see the backside, I’m wonder if the lever should be opening the circuit in one direction and closing it in the other direction.

#14

J

jb2873

J

jb2873

I'll take additional pictures tomorrow morning. I greatly appreciate everyone's help & input thus far.

#15

M

MowerNick

M

MowerNick

It may be a microswitch. If so the tab would be pushed down when starting. I would check that your auto choke system is working correctly

#16

J

jb2873

J

jb2873

This is definitely not a microswitch....there is no switch persa, just a metal tab screwed to the block where the coil wire attaches. It's basically a grounding circuit I assume, that kills the coil when activated.It may be a microswitch. If so the tab would be pushed down when starting. I would check that your auto choke system is working correctly

#18

J

jb2873

J

jb2873

Some more pictures. See how it touches when safety is engaged & when not engaged. Not a microswitch as you can see in pic ( I initially thought it was a microswitch but there's no switch to this, just a screwed in metal tab).

I wrapped some tape around the end of the metal tab to insulate it from touching when I engaged safety and still won't start.

I'm assuming the coil setup is faulty....BUT.... I still can't figure out this kill switch setup... I ordered another coil module and I will see what happens...

I wrapped some tape around the end of the metal tab to insulate it from touching when I engaged safety and still won't start.

I'm assuming the coil setup is faulty....BUT.... I still can't figure out this kill switch setup... I ordered another coil module and I will see what happens...

#19

R

Rivets

R

Rivets

That’s why I want to see the other side of the switch. Looks to me like the plastic block needs to be rotated counterclockwise when the lever is in the run position. This will not allow contact with the back of the brake pad.

#20

M

MowerNick

M

MowerNick

Yes the top view was a better pic. I just assumed because it looked similar to the old toro microswitches. I will try looking it back up and see whats going on

#21

M

MowerNick

M

MowerNick

Could you possibly bend the tab away from the brake pad side to give enough clearance or maybe mount the tab to the backside instead? Just a thought.

#22

J

jb2873

J

jb2873

I bent the tab away from the brake pad so that it wouldn't touch in the run position. Still wouldn't start, so I bent it back into its original position. I should have a new coil setup tomorrow. I'll install that and then report back.That’s why I want to see the other side of the switch. Looks to me like the plastic block needs to be rotated counterclockwise when the lever is in the run position. This will not allow contact with the back of the brake pad.

#23

J

jb2873

J

jb2873

Good suggestion & I tried that, didn't make a difference as far as starting up. I should have my new coil tomorrow and then I'll see what happens after installing it.Could you possibly bend the tab away from the brake pad side to give enough clearance or maybe mount the tab to the backside instead? Just a thought.

#24

J

jb2873

J

jb2873

I bent the tab away so it would contact during the starting process but nothing. I have new coil coming in tomorrow. I will try it and see what happens & report back to the forum.Yes the top view was a better pic. I just assumed because it looked similar to the old toro microswitches. I will try looking it back up and see whats going on

#25

R

Rivets

R

Rivets

Disconnect the kill wire from that terminal and see if it will start. That will tell us a lot. Also I hate bending tabs, will lead to more problems. That’s why I recommended rotating the block.

#26

J

jb2873

J

jb2873

I installed a brand new coil. Still will not start. I put a tester between the spark plug and boot and I'm seeing no spark. I also attempted to disconnect the kill switch wire as suggested and still nothing. I see that there is an adjustment for the coil to be spaced off the flywheel. Not sure what this tolerance should be. Carburetor is definitely pumping fuel because after many many attempts the plug is damp.Disconnect the kill wire from that terminal and see if it will start. That will tell us a lot. Also I hate bending tabs, will lead to more problems. That’s why I recommended rotating the block.

#27

J

jb2873

J

jb2873

This is the new coil installed. I'm not sure what the Gap should be between flywheel and pick ups on coil. I have it fairly close as it is. I'm getting no spark coming out of this brand new coil. Now I'm assuming that the original coil was probably okay but there's something else going on. I've tried to bypass the kill switch by removing the wire off the coil and still nothing. I literally put my hand in line with the spark tester and there's absolutely nothing coming through.

The carburetor is pumping fuel. I cleaned the fuel bowl ( not that that is a spark issue but did it anyways). The spark plug is getting damp after many many attempts to pull start it. The oil level is optimum. I'm just not sure what is going on here LOL

I just saw on the top of the coil it said cylinder side so could this possibly be mounted upside down? LOL I'm going to flip it over and see if that makes a difference and I'll report back.

The carburetor is pumping fuel. I cleaned the fuel bowl ( not that that is a spark issue but did it anyways). The spark plug is getting damp after many many attempts to pull start it. The oil level is optimum. I'm just not sure what is going on here LOL

I just saw on the top of the coil it said cylinder side so could this possibly be mounted upside down? LOL I'm going to flip it over and see if that makes a difference and I'll report back.

Attachments

#28

M

MowerNick

M

MowerNick

Yes, it is definitely upside down. You can use a standard business card for the air gap it is not that crucial

#30

J

jb2873

J

jb2873

Yes, it is definitely upside down. You can use a standard business card for the air gap it is not that crucial

Attachments

#31

J

jb2873

J

jb2873

Okay I flipped the coil over and set a basic Gap. I had to make a longer wire for the kill switch. Still no spark. I disconnected the kill switch and attempted to start and still nothing. The coil is directly from my local Cub Cadet dealer.

Attachments

#33

F

Freddie21

F

Freddie21

Bend the kill switch arm away from the metal bracket when in the run position. It should then contact the other bracket point in the off position.

#34

Reverett

Reverett

When you adjusted the coil gap did you rotate the engine to the contact point? That gap does not look right for the area shown in picture

#35

O

Oddjob

O

Oddjob

With the kill wire disconnected you can’t be shorting out the spark, so the most likely culprit for no spark is a defective coil. Could be a bad magnet/flywheel, but that’s got to be pretty rare. I’d bring the coil back to dealer and let him test it. Maybe put it on another machine in stock and see if it produces a spark.Okay I flipped the coil over and set a basic Gap. I had to make a longer wire for the kill switch. Still no spark. I disconnected the kill switch and attempted to start and still nothing. The coil is directly from my local Cub Cadet dealer.

#36

J

jb2873

J

jb2873

I rotated the flywheel to the magnet points then used a feeler gauge to set gap. I think that's how it should be......?When you adjusted the coil gap did you rotate the engine to the contact point? That gap does not look right for the area shown in picture

#37

J

jb2873

J

jb2873

I tried that early on...still, no spark / no run.Bend the kill switch arm away from the metal bracket when in the run position. It should then contact the other bracket point in the off position.

#38

M

MyBillyC

M

MyBillyC

Try disconnecting the ground wire from the deadman apparatus. If it starts, your problem is with the control cable, the ground wire or the assembly itself. I lean towards a failing coil, though. Good luck.

#39

J

jb2873

I'll see if they can check the coil for me (doubt they will put it on another mower....those customer service days are far & few anymore but I'll try. The mower has only had about a dozen mowings on it. I purchased from a friend who used it twice before he realized he needed something much bigger for his property.

J

jb2873

I think I've tried just about everything to get this to start. It ran like a champ originally, then after a few mowings, it would get harder to start, until eventually it just wouldn't, no matter how many attempts. Weird how each time leading up to this no start situation, it would take maybe 3-4 pulls, then next time it would be 7-8 pulls, then 12-15 then finally nothing...With the kill wire disconnected you can’t be shorting out the spark, so the most likely culprit for no spark is a defective coil. Could be a bad magnet/flywheel, but that’s got to be pretty rare. I’d bring the coil back to dealer and let him test it. Maybe put it on another machine in stock and see if it produces a spark.

I'll see if they can check the coil for me (doubt they will put it on another mower....those customer service days are far & few anymore but I'll try. The mower has only had about a dozen mowings on it. I purchased from a friend who used it twice before he realized he needed something much bigger for his property.

#40

J

jb2873

J

jb2873

I tried that...still nothing. Put a new coil on and still nothing. Wondering if new coil is faulty.Try disconnecting the ground wire from the deadman apparatus. If it starts, your problem is with the control cable, the ground wire or the assembly itself. I lean towards a failing coil, though. Good luck.

#41

J

jb2873

J

jb2873

I lined up the flywheel magnet with the new coil and set airgap at .008

The coil I received from Cubcadet looks slightly different and it's a briggs part. Can a briggs coil cross over to a Cubcadet sc900 motor? Maybe that's the problem? If it won't cross over, then someone at the parts counter needs a lesson in manufacture parts compatibility. I took pics of mower, as well as pic of serial number so i could show parts counter. She was quick to hand me the briggs coil....

The coil I received from Cubcadet looks slightly different and it's a briggs part. Can a briggs coil cross over to a Cubcadet sc900 motor? Maybe that's the problem? If it won't cross over, then someone at the parts counter needs a lesson in manufacture parts compatibility. I took pics of mower, as well as pic of serial number so i could show parts counter. She was quick to hand me the briggs coil....

#42

R

Rivets

R

Rivets

Have you tried starting the unit with the kill wire at the coil disconnected at the coil? If you get spark the kill wire is shorted somewhere.

#43

J

jb2873

I'm wondering if cubcadet gave me the wrong coil, a briggs coil for cubcadet motor? They had the motor serial # as well as pics I took of mower.

J

jb2873

I have...I even had to build my own kill wire when installing the new coil (the new coil was a briggs part from cubcadet and it didn't come with a preattached kill wire). I checked continuity of my new homemade wire and the end connectors, and all is good.Have you tried starting the unit with the kill wire at the coil disconnected at the coil? If you get spark the kill wire is shorted somewhere.

I'm wondering if cubcadet gave me the wrong coil, a briggs coil for cubcadet motor? They had the motor serial # as well as pics I took of mower.

#44

StarTech

StarTech

What numbskull dealer are you buying parts from? Of course a Briggs coil will not work on a MTD engine correctly..

The 2019 SC900 had a MTD 5X70AU engine; not a Briggs engine.

The 2019 SC900 had a MTD 5X70AU engine; not a Briggs engine.

#45

Reverett

Reverett

Correct. Should be set to .02-.04mmI rotated the flywheel to the magnet points then used a feeler gauge to set gap. I think that's how it should be......?

#46

R

Rivets

R

Rivets

This thread is so confusing I don’t know if I could fix your unit if I followed all the DIY posts given. I just reread this entire thread, particularly those posts by the OP, and 2+2=? To the OP, your troubleshooting procedure and throwing parts at this unit don’t make a lot of sense. On top of that many have chimed in with suggestions which only hurt your chances of solving the problem. If I were you and you really want to solve this problem, I suggest you start over. First, get a great understanding of how the ignition systems works and how the kill system works. Until you know this, you are just hurting your chances of being successful. Second, take all your engine and unit numbers to a different dealer and have them look up the coil part number. Better yet, take the entire unit to the dealer so there is no questions that you gave them the wrong numbers. As Star said, that is not a Briggs engine, so a Briggs coil will not work. That dealer is just a DIY idiot. Third, after you have the correct coil, install it will a .010” air gap and no kill wire attached. If at this point you have no spark, it is time to have a good technician fix the problem. I’m will to bet that if I or Star were to have this unit in front of us, we would be able to fix the problem in less than 30 minutes. Ball is in your court as how you want to proceed.

#47

J

jb2873

Come Monday morning, I'll be having a conversation with the young lady who sold this part.

J

jb2873

LOL well I assumed since I gave them the serial number, as well as an overall pic of the sc900 mower, the Cubcadet dealer would know exactly what the h*ll part to give me. You know what they say when you assume............I thought maybe the coil was a crossover part.What numbskull dealer are you buying parts from? Of course a Briggs coil will not work on a MTD engine correctly..

The 2019 SC900 had a MTD 5X70AU engine; not a Briggs engine.

Come Monday morning, I'll be having a conversation with the young lady who sold this part.

#48

StarTech

StarTech

Nevermind just a Space Cadet salesperson. I got a couple of those I deal with at the distributors here too.

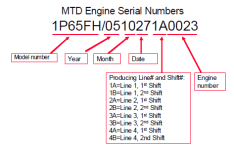

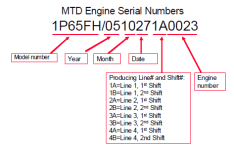

What I am going by is the model serial number you posted of the engine. The engine was produced Nov 13, 2018 but is considered a 2019 engine and was 82nd engine built on the 1st shift.

5X70AU/1811131A0082

Decoder

BTW the ignition coil is PN 925-07165 with a suggest retail of $76.98 per my distributor. O f course an after market is cheaper but it is also a crap shot.

What I am going by is the model serial number you posted of the engine. The engine was produced Nov 13, 2018 but is considered a 2019 engine and was 82nd engine built on the 1st shift.

5X70AU/1811131A0082

Decoder

BTW the ignition coil is PN 925-07165 with a suggest retail of $76.98 per my distributor. O f course an after market is cheaper but it is also a crap shot.

#49

J

jb2873

Yes, space cadet is a nice way to describe her.... I'll be visiting them bright & early Tuesday morning to get this all straightened out. I'll report back once I have the correct part in hand.

Thanks !

J

jb2873

Wow thanks for all that info!Nevermind just a Space Cadet salesperson. I got a couple of those I deal with at the distributors here too.

What I am going by is the model serial number you posted of the engine. The engine was produced Nov 13, 2018 but is considered a 2019 engine and was 82nd engine built on the 1st shift.

5X70AU/1811131A0082

Decoder

View attachment 67622

BTW the ignition coil is PN 925-07165 with a suggest retail of $76.98 per my distributor. O f course an after market is cheaper but it is also a crap shot.

Yes, space cadet is a nice way to describe her.... I'll be visiting them bright & early Tuesday morning to get this all straightened out. I'll report back once I have the correct part in hand.

Thanks !

#50

S

smallenginerepairs

S

smallenginerepairs

Most ladies behind the counter have never worked on a small engine, which is a bad start right off the bat! They are trained by the owner who doesn't want to pay a decent wage for an experienced technician. He just reaches her what websites to look up parts on and puts her behind the counter.

Here's where your compassion comes in ! She is trying to do her best to not only help you ,but also help her husband put food on the table for her kids. Your response could greatly help this lady from making the same mistake for someone else. I know getting the wrong part further complicates your effort,but try to overcome your frustration and help her learn more about coils than she obviously knows. Remember she was trying to help you, but she made a mistake as we all do on occasions.

I think getting the right coil will solve your dilemma. Good luck on fixing your mower,Pete's small engine repair

Here's where your compassion comes in ! She is trying to do her best to not only help you ,but also help her husband put food on the table for her kids. Your response could greatly help this lady from making the same mistake for someone else. I know getting the wrong part further complicates your effort,but try to overcome your frustration and help her learn more about coils than she obviously knows. Remember she was trying to help you, but she made a mistake as we all do on occasions.

I think getting the right coil will solve your dilemma. Good luck on fixing your mower,Pete's small engine repair

#51

StarTech

StarTech

Lacking of proper training does cause a lot grief. This is why I am so picky about having all the equipment info even here. It makes looking the correct parts a lot easier.

My Gardner rep still don't get it that you must have and use this info looking up parts. Matter of fact she still haven't return a solution to my last problems and that have been over a month now. I reckon Gardner don't need the business as until my problem is resolved I am not ordering from them.

My Gardner rep still don't get it that you must have and use this info looking up parts. Matter of fact she still haven't return a solution to my last problems and that have been over a month now. I reckon Gardner don't need the business as until my problem is resolved I am not ordering from them.