Hello!

Can anyone help with a diagnostic procedure to reliably rule out a broken compression release mechanism/pin versus a valve clearance that needs to be tweaked, or other possible causes for a B&S not turning over easily? I have a B&S 28W707 16.5HP which is showing symptoms resembling compression release issues when starting cold. When attempting key start, it turns a little then locks. The battery does not seem to be the issue, as jumping it does not change anything and also it does not get weaker with the number or length of turn attempts. When I turn the engine by hand, it reaches a compression point past which it is very hard to turn and I can only do so using both hands. It does start eventually but the only way I am able to do it is by turning it by hand a couple of turns then by key for about 6-7 seconds which, needless to say, floods the engine to the point where I have gas sprayed out the exhaust... Once started/hot, I can easily turn it off and on again without issues, which I find confusing. It started doing this after I recently adjusted the valve clearances, which I did find to be out of spec. The reason I did the clearance check in the first place was because it would after-fire in the exhaust when I shut the engine off. (The fuel valve does seem to work, as I can hear/feel it click with the switch.) After clearance adjustment, I am no longer getting the after-fire, except rarely, but now I am getting the hard starts. I can of course open the valve cover and check the clearances again, but I doubt I got them wrong the 1st time, hence this question. Is there any way I can rule out a broken compression release mechanism without opening up the engine? I am also confused as to why it starts easily after it has run for a few minutes: would this be an indicatation that tweaking the valve tolerances could solve the problem, since the running temperature seems to be a factor? Or am I missing something else?

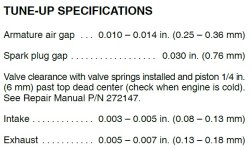

For specs: engine manual lists the following clearances: 0.08-0.13 mm intake and 0.13-0.18 mm exhaust. I set them at 0.10 and 0.15, respectively.

Thank you in advance for any help; I am comfortable getting my nose into things but I am not always good at diagnosing them

Can anyone help with a diagnostic procedure to reliably rule out a broken compression release mechanism/pin versus a valve clearance that needs to be tweaked, or other possible causes for a B&S not turning over easily? I have a B&S 28W707 16.5HP which is showing symptoms resembling compression release issues when starting cold. When attempting key start, it turns a little then locks. The battery does not seem to be the issue, as jumping it does not change anything and also it does not get weaker with the number or length of turn attempts. When I turn the engine by hand, it reaches a compression point past which it is very hard to turn and I can only do so using both hands. It does start eventually but the only way I am able to do it is by turning it by hand a couple of turns then by key for about 6-7 seconds which, needless to say, floods the engine to the point where I have gas sprayed out the exhaust... Once started/hot, I can easily turn it off and on again without issues, which I find confusing. It started doing this after I recently adjusted the valve clearances, which I did find to be out of spec. The reason I did the clearance check in the first place was because it would after-fire in the exhaust when I shut the engine off. (The fuel valve does seem to work, as I can hear/feel it click with the switch.) After clearance adjustment, I am no longer getting the after-fire, except rarely, but now I am getting the hard starts. I can of course open the valve cover and check the clearances again, but I doubt I got them wrong the 1st time, hence this question. Is there any way I can rule out a broken compression release mechanism without opening up the engine? I am also confused as to why it starts easily after it has run for a few minutes: would this be an indicatation that tweaking the valve tolerances could solve the problem, since the running temperature seems to be a factor? Or am I missing something else?

For specs: engine manual lists the following clearances: 0.08-0.13 mm intake and 0.13-0.18 mm exhaust. I set them at 0.10 and 0.15, respectively.

Thank you in advance for any help; I am comfortable getting my nose into things but I am not always good at diagnosing them

Attachments

Last edited: