You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Bottom right valve cover bolt

#1

PTmowerMech

PTmowerMech

Kohler V twin. Gonna adjust the valves on it because it's not turning over very well. Kind of starts and stops turning over mid stream. The battery is charged fully.

I've had one or two of these break off. It's always the same one. Bottom right. So these two bolts (both cylinders) are tight as all get out. I haven't put anything more than a cheap 1/4 walmart brand impact on them (yet).

So before I go gorilla on it and snap it off, I'm thinking I'd better check with the experts first. I'm thinking maybe run it til it get hot, then cools down?

Anyone know any trick to this? My luck the bolt will break off below the surface.

P.S. I tried tightening and loosening. But that didn't help.

I've had one or two of these break off. It's always the same one. Bottom right. So these two bolts (both cylinders) are tight as all get out. I haven't put anything more than a cheap 1/4 walmart brand impact on them (yet).

So before I go gorilla on it and snap it off, I'm thinking I'd better check with the experts first. I'm thinking maybe run it til it get hot, then cools down?

Anyone know any trick to this? My luck the bolt will break off below the surface.

P.S. I tried tightening and loosening. But that didn't help.

#2

StarTech

StarTech

Sometimes you just have to break them off as they are galdded badly from the area heat up so much that it melts the aluminum. Drill out those 6mm screws and tap to M7-1.00 and you be fine. Just a pain to have to it. Just got to the drill bit centered.

#3

PTmowerMech

The two i've done before, I was lucky enough to have a ridge right in the middle of the broken screw. It's a real pain in the rear trying to angle that drill bit back to center.

PTmowerMech

Sometimes you just have to break them off as they are galdded badly from the area heat up so much that it melts the aluminum. Drill out those 6mm screws and tap to M7-1.00 and you be fine. Just a pain to have to it. Just got to the drill bit centered.

The two i've done before, I was lucky enough to have a ridge right in the middle of the broken screw. It's a real pain in the rear trying to angle that drill bit back to center.

#4

StarTech

StarTech

Try doing it on an engine that turned sideway of normal position even harder. Sometimes you have to pull the engine.

As I said it is a pain to do.

As I said it is a pain to do.

#7

V

VegetiveSteam

If this engine is 4 to 6 years old check for a bent starter shaft. That was very common and could cause the condition you are describing.

V

VegetiveSteam

Don't snap it off yet. Valve clearance is NOT your issue. I'm going to guess you're working on a Courage twin or 7000 series? Improper valve clearance will not cause hard cranking on a Kohler twin. There is no compression release so the engine is always cranking under full compression. Nothing can go wrong with the clearance that would raise compresson. If anything, improper valve clearance could cause lower than normal compression. Check your cable connections for both being loose or dirty. Also those solenoids used by the mower mfg. are not the greatest. A couple of proper voltage tests in the right spots can narrow down any voltage issues.Kohler V twin. Gonna adjust the valves on it because it's not turning over very well. Kind of starts and stops turning over mid stream. The battery is charged fully.

I've had one or two of these break off. It's always the same one. Bottom right. So these two bolts (both cylinders) are tight as all get out. I haven't put anything more than a cheap 1/4 walmart brand impact on them (yet).

So before I go gorilla on it and snap it off, I'm thinking I'd better check with the experts first. I'm thinking maybe run it til it get hot, then cools down?

Anyone know any trick to this? My luck the bolt will break off below the surface.

P.S. I tried tightening and loosening. But that didn't help.

If this engine is 4 to 6 years old check for a bent starter shaft. That was very common and could cause the condition you are describing.

#9

PTmowerMech

Thanks for that. I should've looked that up. But adjusting the values is pretty easy. Well, that is if you can get to them.

PTmowerMech

Don't snap it off yet. Valve clearance is NOT your issue. I'm going to guess you're working on a Courage twin or 7000 series? Improper valve clearance will not cause hard cranking on a Kohler twin. There is no compression release so the engine is always cranking under full compression. Nothing can go wrong with the clearance that would raise compresson. If anything, improper valve clearance could cause lower than normal compression. Check your cable connections for both being loose or dirty. Also those solenoids used by the mower mfg. are not the greatest. A couple of proper voltage tests in the right spots can narrow down any voltage issues.

If this engine is 4 to 6 years old check for a bent starter shaft. That was very common and could cause the condition you are describing.

Thanks for that. I should've looked that up. But adjusting the values is pretty easy. Well, that is if you can get to them.

#10

V

VegetiveSteam

V

VegetiveSteam

Yep it is but like you say, if you can get the rocker cover off. And you probably already know but if you do adjust them make sure to loosen the center set screw first while holding the adjusting nut before trying to turn the adjusting nut. If not the nut will likely break in half. Seen it dozens of times. But a 2010 built 840 might have still been using a jam nut and not the center set screw. I just can't remember when Kohler made the change.

If you can, check the voltage at the battery and see what it drops to while cranking when it acts up. Then if your tester leads are long enough, leave the black lead on the negative terminal of the battery and touch the red lead to the starter terminal where the cable connects. Crank the engine and see what the voltage is again when it acts up. If the voltage drop between what you had at the battery and what you had at the starter is less than about 2 or 3 volts check the ground side. Again leaving the black lead on the negative terminal of the battery, touch the red lead to the outside case of the starter. Crank the engine and see if you read any voltage. You should not. You should never read voltage on the ground side. If you do, you have a ground issue. Either a connection issue or bad cable.

If the battery voltage drop in that first test is more than about 2 or 3 volts follow that starter cable back to what I call the starter side of the solenoid and do another voltage test to see what the voltage is while cranking with the issue. If it's the same as what you had at the starter do another test but this time on the battery side of the solenoid. While cranking with or without the issue, the voltages should be pretty much the same from the battery, to and through the solenoid and down at the starter terminal. You're going to loose a few 10ths through the solenoid but if you're dropping volts, like 4 or 5 from one side of the solenoid to the other then you're probably in need of a new solenoid.

You can probably do these voltage tests in about 5 minutes but may need a helper to crank the engine while you're holding test leads.

You may already know all of this but some people are really intimidated by anything electrical. I figure it's never hurts to give more info than less in case someone doesn't know.

If you can, check the voltage at the battery and see what it drops to while cranking when it acts up. Then if your tester leads are long enough, leave the black lead on the negative terminal of the battery and touch the red lead to the starter terminal where the cable connects. Crank the engine and see what the voltage is again when it acts up. If the voltage drop between what you had at the battery and what you had at the starter is less than about 2 or 3 volts check the ground side. Again leaving the black lead on the negative terminal of the battery, touch the red lead to the outside case of the starter. Crank the engine and see if you read any voltage. You should not. You should never read voltage on the ground side. If you do, you have a ground issue. Either a connection issue or bad cable.

If the battery voltage drop in that first test is more than about 2 or 3 volts follow that starter cable back to what I call the starter side of the solenoid and do another voltage test to see what the voltage is while cranking with the issue. If it's the same as what you had at the starter do another test but this time on the battery side of the solenoid. While cranking with or without the issue, the voltages should be pretty much the same from the battery, to and through the solenoid and down at the starter terminal. You're going to loose a few 10ths through the solenoid but if you're dropping volts, like 4 or 5 from one side of the solenoid to the other then you're probably in need of a new solenoid.

You can probably do these voltage tests in about 5 minutes but may need a helper to crank the engine while you're holding test leads.

You may already know all of this but some people are really intimidated by anything electrical. I figure it's never hurts to give more info than less in case someone doesn't know.

#11

PTmowerMech

Actually, I didn't know it in those terms. As in loss of voltage from the solenoid. But I'm pretty sure it's not going to be an electrical issue, because this starter is making some kind of racket when it's engaged. I'm going to check to see if the shaft is bent, as you mentioned.

PTmowerMech

Yep it is but like you say, if you can get the rocker cover off. And you probably already know but if you do adjust them make sure to loosen the center set screw first while holding the adjusting nut before trying to turn the adjusting nut. If not the nut will likely break in half. Seen it dozens of times. But a 2010 built 840 might have still been using a jam nut and not the center set screw. I just can't remember when Kohler made the change.

If you can, check the voltage at the battery and see what it drops to while cranking when it acts up. Then if your tester leads are long enough, leave the black lead on the negative terminal of the battery and touch the red lead to the starter terminal where the cable connects. Crank the engine and see what the voltage is again when it acts up. If the voltage drop between what you had at the battery and what you had at the starter is less than about 2 or 3 volts check the ground side. Again leaving the black lead on the negative terminal of the battery, touch the red lead to the outside case of the starter. Crank the engine and see if you read any voltage. You should not. You should never read voltage on the ground side. If you do, you have a ground issue. Either a connection issue or bad cable.

If the battery voltage drop in that first test is more than about 2 or 3 volts follow that starter cable back to what I call the starter side of the solenoid and do another voltage test to see what the voltage is while cranking with the issue. If it's the same as what you had at the starter do another test but this time on the battery side of the solenoid. While cranking with or without the issue, the voltages should be pretty much the same from the battery, to and through the solenoid and down at the starter terminal. You're going to loose a few 10ths through the solenoid but if you're dropping volts, like 4 or 5 from one side of the solenoid to the other then you're probably in need of a new solenoid.

You can probably do these voltage tests in about 5 minutes but may need a helper to crank the engine while you're holding test leads.

You may already know all of this but some people are really intimidated by anything electrical. I figure it's never hurts to give more info than less in case someone doesn't know.

Actually, I didn't know it in those terms. As in loss of voltage from the solenoid. But I'm pretty sure it's not going to be an electrical issue, because this starter is making some kind of racket when it's engaged. I'm going to check to see if the shaft is bent, as you mentioned.

#12

StarTech

StarTech

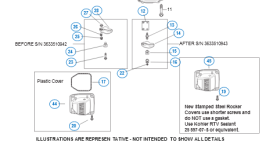

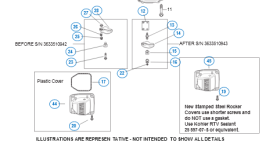

Well it using a torch could be a problem as back during this time frame they had either the stamp steel or plastic covers. And I personally had more problems with the screws seizing on the plastic covers over the exhaust port. Plus according to the IPL it will have set screws.

And for the starter IPL show an Inertia Drive Starter which tends to wear out the top bushing causing the starter to drag. I have heard of the bent shafts but personally never seen one in my shop.

Glad I only see heavy frost this morning and not four feet of snow. Boy went from Summer to Winter over night. I got to get the office/storage building built so I can use my shop for what it is intented for with heat.

And for the starter IPL show an Inertia Drive Starter which tends to wear out the top bushing causing the starter to drag. I have heard of the bent shafts but personally never seen one in my shop.

Glad I only see heavy frost this morning and not four feet of snow. Boy went from Summer to Winter over night. I got to get the office/storage building built so I can use my shop for what it is intented for with heat.

#13

ILENGINE

ILENGINE

I have not seen bent shafts either, but have had a few come in with shaft broken even with the top of the starter bushing. So it is possible they bent before breaking off.Well it using a torch could be a problem as back during this time frame they had either the stamp steel or plastic covers. And I personally had more problems with the screws seizing on the plastic covers over the exhaust port. Plus according to the IPL it will have set screws.

View attachment 62823

And for the starter IPL show an Inertia Drive Starter which tends to wear out the top bushing causing the starter to drag. I have heard of the bent shafts but personally never seen one in my shop.

Glad I only see heavy frost this morning and not four feet of snow. Boy went from Summer to Winter over night. I got to get the office/storage building built so I can use my shop for what it is intented for with heat.

#14

StarTech

StarTech

I agree. Anything possible. I never say something is impossible because as soon I say it happens. Heck if a new calculator can add wrong then other things can happen. Please don't tell that is impossible as I change 100 CPU chips years ago because of it.

Heck if a new calculator can add wrong then other things can happen. Please don't tell that is impossible as I change 100 CPU chips years ago because of it.

I did have one Briggs last year where the pinion gear was jammed under the ring gear and that one could have bent the shaft but I was lucky as it didn't. The first time the it jammed I had free it up while under the mower. The next time it happen I pulled the shroud before doing anything else. Chipped teeth was the root cause. I finally use that pinion gear that I had for 5 yrs.

Oh well got to get started here. I got a rework from another shop. The carburetor is flooding the engine and the tech done supposedly cleaned the carburetor 3 times. Must be a rookie at that woman owned shop. That shop has been screwing up every since she took over. The report I got back on the last repair that I reworked was that head gasket could have not been the problem. But that is what fixed the engine as the customer said it been working fine ever since I replaced it. Boy some tech are so hard headed that they can't accept that they don't know everything. Even the most experience tech don't. I learn new things all the time.

I did have one Briggs last year where the pinion gear was jammed under the ring gear and that one could have bent the shaft but I was lucky as it didn't. The first time the it jammed I had free it up while under the mower. The next time it happen I pulled the shroud before doing anything else. Chipped teeth was the root cause. I finally use that pinion gear that I had for 5 yrs.

Oh well got to get started here. I got a rework from another shop. The carburetor is flooding the engine and the tech done supposedly cleaned the carburetor 3 times. Must be a rookie at that woman owned shop. That shop has been screwing up every since she took over. The report I got back on the last repair that I reworked was that head gasket could have not been the problem. But that is what fixed the engine as the customer said it been working fine ever since I replaced it. Boy some tech are so hard headed that they can't accept that they don't know everything. Even the most experience tech don't. I learn new things all the time.

#15

Hammermechanicman

Hammermechanicman

I don't like to bad mouth others work but when something comes in the shop that has crap done to it like things bent to change a belt or hacked up wiring i always bring it to the owners attention so they know i didn't do it. A lot of it comes from the same one man shop in the next town. From the gaskets that look like a 5 yr old made them to the wire nuts and black tape to the big glob of RTV he is the guy that gives small shops a bad name. But he is cheaper than me so i guess that is a plus for him.Oh well got to get started here. I got a rework from another shop. The carburetor is flooding the engine and the tech done supposedly cleaned the carburetor 3 times. Must be a rookie at that woman owned shop. That shop has been screwing up every since she took over. The report I got back on the last repair that I reworked was that head gasket could have not been the problem. But that is what fixed the engine as the customer said it been working fine ever since I replaced it. Boy some tech are so hard headed that they can't accept that they don't know everything. Even the most experience tech don't. I learn new things all the time.

#16

StarTech

StarTech

Well I do as they makes it looks bad on the good techs out there. Once someone get burned by one these idiots they everyone is the same.

Well at least he not using scotch tape, yet... When I first relocated my shop I even a push mower come in with the blade duct taped on.

Yes people will go to whoever the cheapest until get burned enough. I got several DIYers here I wish weren't around. It takes me at least twice as long to do a repair. Now I gotten to where I charge extra just for undoing the crappy workmanship. I got a Kawasaki 3010 that has been el patcho. This week came back in because the electric fuel pump was giving problems. Well the fuel filter was filled with black RTV coming of the fuel tank. No what the DIYers thought he doing using that in a fuel tank. When the filter got packed it caused the fuel pump to run dry which in turn damage the brand new fuel I installed a few weeks ago. Customer got off easy as I only charge for a new pump, filter, and no labor. I just wish he just sell the 3010 and get it out of my shop range. The engine was nearly because of RTV patching. And the current owner don't want to spend any more on it.

Well at least he not using scotch tape, yet... When I first relocated my shop I even a push mower come in with the blade duct taped on.

Yes people will go to whoever the cheapest until get burned enough. I got several DIYers here I wish weren't around. It takes me at least twice as long to do a repair. Now I gotten to where I charge extra just for undoing the crappy workmanship. I got a Kawasaki 3010 that has been el patcho. This week came back in because the electric fuel pump was giving problems. Well the fuel filter was filled with black RTV coming of the fuel tank. No what the DIYers thought he doing using that in a fuel tank. When the filter got packed it caused the fuel pump to run dry which in turn damage the brand new fuel I installed a few weeks ago. Customer got off easy as I only charge for a new pump, filter, and no labor. I just wish he just sell the 3010 and get it out of my shop range. The engine was nearly because of RTV patching. And the current owner don't want to spend any more on it.

#17

V

VegetiveSteam

V

VegetiveSteam

You may have to look close. Sometimes it's very subtle and other times it's quite noticeable if you're looking for it. It doesn't take much of a bend to cause the starter gear to bind somewhat against the flywheel ring gear and slow things down.Actually, I didn't know it in those terms. As in loss of voltage from the solenoid. But I'm pretty sure it's not going to be an electrical issue, because this starter is making some kind of racket when it's engaged. I'm going to check to see if the shaft is bent, as you mentioned.

#18

PTmowerMech

I can probably just wiggle the top of the starter to see if the bushing is worn enough to cause it to bind?

You're in TN, right?

I'm in Arkansas, and there's nothing summer or even early spring here. Got down to 29 last night.

PTmowerMech

Well it using a torch could be a problem as back during this time frame they had either the stamp steel or plastic covers. And I personally had more problems with the screws seizing on the plastic covers over the exhaust port. Plus according to the IPL it will have set screws.

View attachment 62823

And for the starter IPL show an Inertia Drive Starter which tends to wear out the top bushing causing the starter to drag. I have heard of the bent shafts but personally never seen one in my shop.

Glad I only see heavy frost this morning and not four feet of snow. Boy went from Summer to Winter over night. I got to get the office/storage building built so I can use my shop for what it is intented for with heat.

I can probably just wiggle the top of the starter to see if the bushing is worn enough to cause it to bind?

You're in TN, right?

I'm in Arkansas, and there's nothing summer or even early spring here. Got down to 29 last night.

#19

StarTech

As for the starter it depends how it worn most I can barely wiggle them them, just noisier than normal. Kinda a feeling I get from experience.

StarTech

Is that all. I woke to 23F this morning and 20F yesterday morning. Boy that a big drop from 80F Tuesday for daytime temps. Go thing I keeping the house at 55F when the temp drops. Help getting used the freezing temps for outside work. Have to hunt the housecoat in the mornings until the hot coffee kicks in. Losing 20+ doesn't help either. A lot my insulation is gone.I can probably just wiggle the top of the starter to see if the bushing is worn enough to cause it to bind?

You're in TN, right?

I'm in Arkansas, and there's nothing summer or even early spring here. Got down to 29 last night.

As for the starter it depends how it worn most I can barely wiggle them them, just noisier than normal. Kinda a feeling I get from experience.