I have a 100 series J D lawn tractor one of the blades just fell off the other day so I put it back on and cut for about 15 minutes and it fell off again, it didnt sound right when it was engaged before it fell off, whats the problem

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Blade on John Deere tractor keeps falling off

- Thread starter Monk Monk

- Start date

More options

Export threadProblem with the blade bolt/washers/not property torqued. Could also be an issue with the blade adapter preventing the blade from fitting correctly. You will need to remove the blade and take a look under the deck and see what things look like.

Make sure they are OEM or equivalent blades for YOUR machine. Oregon blades BTW are the best that I have found.

Push mowers have a bolt torque of 30-35 ft lbs. Yours should be similar. Check your mower manual for proper torque value.

slomo

Push mowers have a bolt torque of 30-35 ft lbs. Yours should be similar. Check your mower manual for proper torque value.

slomo

- Joined

- Feb 19, 2020

- Threads

- 91

- Messages

- 11,492

I wonder which 100 series. 100, l100, lt100, etc. with the correct series then someone can lookup the spec in the owners manual.

The plain 100 series the blades were torqued at 46 ft-lbs. And if a Bellevue washer was used that it is installed the right way so it clamps properly. And guessing at the torque don't cut it.

And Slomo many of the walk behind blades here are torque to 55 ft-lbs per the OMs. This is so the keep from shearing the blade adapters.

The plain 100 series the blades were torqued at 46 ft-lbs. And if a Bellevue washer was used that it is installed the right way so it clamps properly. And guessing at the torque don't cut it.

And Slomo many of the walk behind blades here are torque to 55 ft-lbs per the OMs. This is so the keep from shearing the blade adapters.

I use anti-seize on blade bolts and muffler bolts. Have to cut the torque back a smidge.And Slomo many of the walk behind blades here are torque to 55 ft-lbs per the OMs. This is so the keep from shearing the blade adapters.

Depending on bolt size say 7/16" coarse, 55ft lbs is over slammed with lube on a grade 5. Dry is max bolt slam for that bolt. Guess most pusher blades are 1/2" bolts??. I need to measure one of mine.

A lubed coarse 1/2" grade 5 is basically at max slam at 55ft lbs.

If OEM's say 55ft lbs then use it. Sounds good to me.

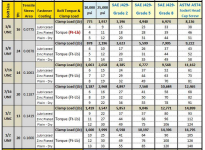

Depending on which model of 100 series could have one of three different blade mounting methods/adapters. Do need to know which one the OP has.I wonder which 100 series. 100, l100, lt100, etc. with the correct series then someone can lookup the spec in the owners manual.

The plain 100 series the blades were torqued at 46 ft-lbs. And if a Bellevue washer was used that it is installed the right way so it clamps properly. And guessing at the torque don't cut it.

And Slomo many of the walk behind blades here are torque to 55 ft-lbs per the OMs. This is so the keep from shearing the blade adapters.