You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Belt keeps popping off.

#1

R

Rich A

R

Rich A

Craftsman 2011 - 247.28881 7 speed Shift-on-the-Go lawn tractor.

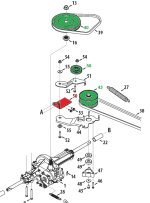

What would cause the smaller vari-speed belt to instantly pop off when engaging clutch? Could this be caused by a miss-adjusted part of the linkage? The user manual does not have any instructions for brake or clutch adjustments and says to "contact the nearest service center" for those repairs. I thought the problem was the smaller idler pulley bracket which was slightly out of line and tilted downward a few degrees. I've since replaced ALL the brackets and belts with new OEM parts and the slight tilt of that idler pulley is exactly the same with the new part purchaced. I've tried various manufacturers belts as well as supposed OEM MTD parts from Sears, MTD etc. And also found some NOS parts that had the original brackets. Nothing works. Help !!

What would cause the smaller vari-speed belt to instantly pop off when engaging clutch? Could this be caused by a miss-adjusted part of the linkage? The user manual does not have any instructions for brake or clutch adjustments and says to "contact the nearest service center" for those repairs. I thought the problem was the smaller idler pulley bracket which was slightly out of line and tilted downward a few degrees. I've since replaced ALL the brackets and belts with new OEM parts and the slight tilt of that idler pulley is exactly the same with the new part purchaced. I've tried various manufacturers belts as well as supposed OEM MTD parts from Sears, MTD etc. And also found some NOS parts that had the original brackets. Nothing works. Help !!

Attachments

#2

B

Barrett50

B

Barrett50

I'm new here, my first post. You have replaced the belt. Is the belt the exact same width as the old belt? Just from the photo, it appears the new belt is too wide for the idler pulley. Or - is the idler pulley tilting on the driven axis when engaged? If you still have it, use the old belt and see if the issue remains.

#4

A

Auto Doc's

A

Auto Doc's

I agree the small idler pulley is too narrow for the belt being used. A belt should never ride far to the outside of the "V" of the pulley.

#5

Scrubcadet10

Scrubcadet10

That belt isn't tensioned in the picture, so it may sit fine in the pulley when applied

#6

StarTech

StarTech

247.288810 appears the OP dropped the ending zero.

Which belt are you using? OEM belt PN 954-0241A [954-05040] which is 5/8 x 35-1/4 or the one Sears is claiming is the replacement belt [490-501-Y087 5/8 x 35-11/16]. If using the longer belt that may be the problem as nearly a half inch is quite a bit on the smaller size since adding 1/2 to circumference increases the diameter by nearly a 1/4 inch and these CVT systems are very sensitive to belt width and lengths.

Which belt are you using? OEM belt PN 954-0241A [954-05040] which is 5/8 x 35-1/4 or the one Sears is claiming is the replacement belt [490-501-Y087 5/8 x 35-11/16]. If using the longer belt that may be the problem as nearly a half inch is quite a bit on the smaller size since adding 1/2 to circumference increases the diameter by nearly a 1/4 inch and these CVT systems are very sensitive to belt width and lengths.

#7

R

Rich A

R

Rich A

Thanks everyone. I think "StarTech" has the best grasp of this problem. Yeah, the "model number" is strange when trying to get info. The printed manual that came with the thing is a 28881. The actual model of the tractor from the chassis label is 247.288810, Serial 1C301B80276, and was manufactured 03/2011.

The proper number for the upper drive belt should be 954-0241A. I have THREE new belts here From Sears Part's Direct, Stens, MTD and all were ordered as replacements for the 954-0241A orignal part. Should be a 5/8 inch x 35.25 in belt. One belt was 35.5, another was 36 and a third was 35.0. They all don't work. I can't seem to find one that is exactly 35.25. The widths are all close to 5/8 inch. but the "V" dimensions look slightly different.

Gonna try yet another supplier and told them to MEASURE the physical product and send me a photo of the measurement before shipping <sigh>

The upper drive belt part number appears on the hood label as well as printed parts manual.

954-0241A

I was asking about how to "adjust" the linkage BECAUSE I thought I could make a mechanical adjustment that might get one of the slightly too big or too short belts to work. Am now waiting for the 4th new belt .. It's strange that the belt length is so "critical". But StarTech got me thinking ...

The proper number for the upper drive belt should be 954-0241A. I have THREE new belts here From Sears Part's Direct, Stens, MTD and all were ordered as replacements for the 954-0241A orignal part. Should be a 5/8 inch x 35.25 in belt. One belt was 35.5, another was 36 and a third was 35.0. They all don't work. I can't seem to find one that is exactly 35.25. The widths are all close to 5/8 inch. but the "V" dimensions look slightly different.

Gonna try yet another supplier and told them to MEASURE the physical product and send me a photo of the measurement before shipping <sigh>

The upper drive belt part number appears on the hood label as well as printed parts manual.

954-0241A

I was asking about how to "adjust" the linkage BECAUSE I thought I could make a mechanical adjustment that might get one of the slightly too big or too short belts to work. Am now waiting for the 4th new belt .. It's strange that the belt length is so "critical". But StarTech got me thinking ...

Attachments

#8

StarTech

StarTech

Being a '11 model has you checked the CVT pulley bearings [6203-2RS]?

And there is no adjustment related to the CVT pulley to transaxle belt.

But here is a question where exactly is the belt coming off? Could be transaxle rotating causing to come off its pulley. The anti screws do break off at times or simply fall out.

And there is no adjustment related to the CVT pulley to transaxle belt.

But here is a question where exactly is the belt coming off? Could be transaxle rotating causing to come off its pulley. The anti screws do break off at times or simply fall out.

#9

Tiger Small Engine

Tiger Small Engine

No belt length is that critical to a 1/4” inch. There is something else most likely going on that is wrong causing problems with 3 belts so far.Thanks everyone. I think "StarTech" has the best grasp of this problem. Yeah, the "model number" is strange when trying to get info. The printed manual that came with the thing is a 28881. The actual model of the tractor from the chassis label is 247.288810, Serial 1C301B80276, and was manufactured 03/2011.

The proper number for the upper drive belt should be 954-0241A. I have THREE new belts here From Sears Part's Direct, Stens, MTD and all were ordered as replacements for the 954-0241A orignal part. Should be a 5/8 inch x 35.25 in belt. One belt was 35.5, another was 36 and a third was 35.0. They all don't work. I can't seem to find one that is exactly 35.25. The widths are all close to 5/8 inch. but the "V" dimensions look slightly different.

Gonna try yet another supplier and told them to MEASURE the physical product and send me a photo of the measurement before shipping <sigh>

The upper drive belt part number appears on the hood label as well as printed parts manual.

954-0241A

I was asking about how to "adjust" the linkage BECAUSE I thought I could make a mechanical adjustment that might get one of the slightly too big or too short belts to work. Am now waiting for the 4th new belt .. It's strange that the belt length is so "critical". But StarTech got me thinking ...

#10

ILENGINE

ILENGINE

I suspect the anti rotate bracket has come off or not connected allowing the tranny to tilt. Picture of frame to axle mounting bolts kind of show hints of something not correct, like possible cracking around mounting bolts.Being a '11 model has you checked the CVT pulley bearings [6203-2RS]?

And there is no adjustment related to the CVT pulley to transaxle belt.

But here is a question where exactly is the belt coming off? Could be transaxle rotating causing to come off its pulley. The anti screws do break off at times or simply fall out.

#11

StarTech

StarTech

Bull I personally know it matters as I maintained Husqvarna HWT625s for a local nursery where belt being off a by 1/4 caused problems and these MTD CVTs are just as touchy where it actual can cause speed changes.No belt length is that critical to a 1/4” inch. There is something else most likely going on that is wrong causing problems with 3 belts so far.

#12

R

Rich A

R

Rich A

Thanks very much for all the detailed replies. I'm going to take the tractor apart while waiting for the new belt to arrive and will post some pictures with hopefully better views of the system.

But some comments here first:

To quote ILENGINE: "I suspect the anti rotate bracket has come off or not connected allowing the tranny to tilt. Picture of frame to axle mounting bolts kind of show hints of something not correct, like possible cracking around mounting bolts"

What and where is that "anti rotate bracket" you are referencing? I ask because when the belt does pop off, it can be found intact and laying free. I can reach under the tractor and just pull it out. As you probably know the main tranny large pulley belt can not be squeezed into place because the space between the pulley and chassis is too small to get a new belt installed. AND when that belt pops off it does so with such force that the belt is forced past that very very tight space. There is no burning or fraying etc. But it looks like the force of engaging the drive system is "warping" the geometry of things that causes a mis-alignment of the belt where it CAN get past that opening and maybe because the tranny is "moving"?

So what exactly IS that anti-rotate bracket? There is a possibilty this could be the result of some damage done when I was backing up in the woods and ran over a hidden snow covered stump. That is when this whole belt problem started last winter. I will take some better pictures and hope you can point out this area of concern. I can not thank you guys enough .. Pictures to follow later.

But some comments here first:

To quote ILENGINE: "I suspect the anti rotate bracket has come off or not connected allowing the tranny to tilt. Picture of frame to axle mounting bolts kind of show hints of something not correct, like possible cracking around mounting bolts"

What and where is that "anti rotate bracket" you are referencing? I ask because when the belt does pop off, it can be found intact and laying free. I can reach under the tractor and just pull it out. As you probably know the main tranny large pulley belt can not be squeezed into place because the space between the pulley and chassis is too small to get a new belt installed. AND when that belt pops off it does so with such force that the belt is forced past that very very tight space. There is no burning or fraying etc. But it looks like the force of engaging the drive system is "warping" the geometry of things that causes a mis-alignment of the belt where it CAN get past that opening and maybe because the tranny is "moving"?

So what exactly IS that anti-rotate bracket? There is a possibilty this could be the result of some damage done when I was backing up in the woods and ran over a hidden snow covered stump. That is when this whole belt problem started last winter. I will take some better pictures and hope you can point out this area of concern. I can not thank you guys enough .. Pictures to follow later.

#14

ILENGINE

Item 50 part number 683-04176A sub to 783-04567B

ILENGINE

Item 50 part number 683-04176A sub to 783-04567B

But some comments here first:

To quote ILENGINE: "I suspect the anti rotate bracket has come off or not connected allowing the tranny to tilt. Picture of frame to axle mounting bolts kind of show hints of something not correct, like possible cracking around mounting bolts"

What and where is that "anti rotate bracket" you are referencing? I ask because when the belt does pop off, it can be found intact and laying free. I can reach under the tractor and just pull it out. As you probably know the main tranny large pulley belt can not be squeezed into place because the space between the pulley and chassis is too small to get a new belt installed. AND when that belt pops off it does so with such force that the belt is forced past that very very tight space. There is no burning or fraying etc. But it looks like the force of engaging the drive system is "warping" the geometry of things that causes a mis-alignment of the belt where it CAN get past that opening and maybe because the tranny is "moving"?

So what exactly IS that anti-rotate bracket? There is a possibilty this could be the result of some damage done when I was backing up in the woods and ran over a hidden snow covered stump. That is when this whole belt problem started last winter. I will take some better pictures and hope you can point out this area of concern. I can not thank you guys enough .. Pictures to follow later.

#15

H

hlw49

H

hlw49

There is not tension on the short belt it has a spring on the arm that put tension on the belt. IPL does not show it were you can tell where it goes. I think it item no 25 on the IPL. It hooks on the idler arm and pulls the idler toward the frame on the right side there is a large hole with a smaller hole in front of the large hole the hook on the spring goes through the large hole and hooks in the small hole.

#16

R

Rich A

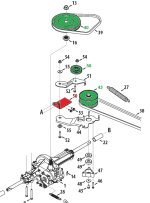

Look at my image above .. to Ilengine thanks. I now know what #50 is called. <grin> I've got the tractor up on jacks and removed the large lug wheels and body and the problem is now visible. Looks like I have a damaged tranny case (top right of tranny axle housing is cracked open) and the frame where the tranny mounting bolts are located 2 long bolts at bottom left of picture) is slightly bent. Sorry the bolt item #'s got cropped out of pic.

So looking at it carefully, I think I can repair the frame. The tranny does work but has signs of worn gears and as I noted the right side top is cracked open. I'll probably get a new transmission for it. I DO see something more clearly now. It looke like that main large trans pully #40 is tilted down a few degrees from being horizontal with the chassis. The other pulleys are equally aligned and horizontally level with the chassis. Like the chassis rail is 180 degree flat level and those two pulleys 56 and 43 are also at 180 degree level.

Like they are "--- ---- " BUT the large one is like " \ " High to the rear and a 1/2 inch low to the front. Part # 50 doesn't look like it's bent and I'm wondering if those two screws #'s 53 can be loosened to tilt the tranny a little for alignment? Sorry I haven't touched that #50 bracket yet, and just wondering that IS adjustable. I definitely have some signs of damage to that left side (not shown) frame area. Looks like I might be able to reapair that.

Guess best thing at this point is hunt for a new tranny cus of that nasty broken right axle housing?

The brackets 44 and 51 are brand new. #51 came with a new pulley as a kit. Tomorrow I'll see what's up with #50 and if it's bent or can be adjusted etc. The issue is definately damage to the frame on one side where the tranny is mounted to the frame. Arrgghhh. I hope I can salvage this before the snow starts this winter.

R

Rich A

Yeah I know .. The spring in the picture was disconnected. It's not an issue. I've changed belts and had this thing apart several times over the years. This current problem is something different and new from anything I've experienced in the last 8 or so years I've been using it. For everyone reading .. thanks to all the info and suggestions here, I think I have it figured out.There is not tension on the short belt it has a spring on the arm that put tension on the belt. IPL does not show it were you can tell where it goes. I think it item no 25 on the IPL. It hooks on the idler arm and pulls the idler toward the frame on the right side there is a large hole with a smaller hole in front of the large hole the hook on the spring goes through the large hole and hooks in the small hole.

Look at my image above .. to Ilengine thanks. I now know what #50 is called. <grin> I've got the tractor up on jacks and removed the large lug wheels and body and the problem is now visible. Looks like I have a damaged tranny case (top right of tranny axle housing is cracked open) and the frame where the tranny mounting bolts are located 2 long bolts at bottom left of picture) is slightly bent. Sorry the bolt item #'s got cropped out of pic.

So looking at it carefully, I think I can repair the frame. The tranny does work but has signs of worn gears and as I noted the right side top is cracked open. I'll probably get a new transmission for it. I DO see something more clearly now. It looke like that main large trans pully #40 is tilted down a few degrees from being horizontal with the chassis. The other pulleys are equally aligned and horizontally level with the chassis. Like the chassis rail is 180 degree flat level and those two pulleys 56 and 43 are also at 180 degree level.

Like they are "--- ---- " BUT the large one is like " \ " High to the rear and a 1/2 inch low to the front. Part # 50 doesn't look like it's bent and I'm wondering if those two screws #'s 53 can be loosened to tilt the tranny a little for alignment? Sorry I haven't touched that #50 bracket yet, and just wondering that IS adjustable. I definitely have some signs of damage to that left side (not shown) frame area. Looks like I might be able to reapair that.

Guess best thing at this point is hunt for a new tranny cus of that nasty broken right axle housing?

The brackets 44 and 51 are brand new. #51 came with a new pulley as a kit. Tomorrow I'll see what's up with #50 and if it's bent or can be adjusted etc. The issue is definately damage to the frame on one side where the tranny is mounted to the frame. Arrgghhh. I hope I can salvage this before the snow starts this winter.

#18

G

Gord Baker

G

Gord Baker

It sounds to me like you have a seized up part somewhere that is not rotating when it needs to.Craftsman 2011 - 247.28881 7 speed Shift-on-the-Go lawn tractor.

What would cause the smaller vari-speed belt to instantly pop off when engaging clutch? Could this be caused by a miss-adjusted part of the linkage? The user manual does not have any instructions for brake or clutch adjustments and says to "contact the nearest service center" for those repairs. I thought the problem was the smaller idler pulley bracket which was slightly out of line and tilted downward a few degrees. I've since replaced ALL the brackets and belts with new OEM parts and the slight tilt of that idler pulley is exactly the same with the new part purchaced. I've tried various manufacturers belts as well as supposed OEM MTD parts from Sears, MTD etc. And also found some NOS parts that had the original brackets. Nothing works. Help !!View attachment 72066

#19

D

Davenj4f

D

Davenj4f

Look for debris stuck in the pulley.Craftsman 2011 - 247.28881 7 speed Shift-on-the-Go lawn tractor.

What would cause the smaller vari-speed belt to instantly pop off when engaging clutch? Could this be caused by a miss-adjusted part of the linkage? The user manual does not have any instructions for brake or clutch adjustments and says to "contact the nearest service center" for those repairs. I thought the problem was the smaller idler pulley bracket which was slightly out of line and tilted downward a few degrees. I've since replaced ALL the brackets and belts with new OEM parts and the slight tilt of that idler pulley is exactly the same with the new part purchaced. I've tried various manufacturers belts as well as supposed OEM MTD parts from Sears, MTD etc. And also found some NOS parts that had the original brackets. Nothing works. Help !!View attachment 72066

#20

S

sparg45

S

sparg45

Wrong. It would add .14-.15" to the dia., depending on the true circumfernce difference or your 1/2" example. Not .25"247.288810 appears the OP dropped the ending zero.

Which belt are you using? OEM belt PN 954-0241A [954-05040] which is 5/8 x 35-1/4 or the one Sears is claiming is the replacement belt [490-501-Y087 5/8 x 35-11/16]. If using the longer belt that may be the problem as nearly a half inch is quite a bit on the smaller size since adding 1/2 to circumference increases the diameter by nearly a 1/4 inch and these CVT systems are very sensitive to belt width and lengths.

#21

O

outdoorpowermike

O

outdoorpowermike

The pic shows the tensioner spring is not hooked up to the frame at the correct spot and you are missing the belt guide at the smaller v pulley that keeps the belt on pulley.

#22

R

Rich A

R

Rich A

Finally got around to where I could see the problem. Part #50 (anti-rotate bracket) was cracked and only being held together by a thread. It wasn't bent but actually cracked at the bend and became more of a hinge than a bracket. So it didn't fully break appart but flexed enough to allow the tranny to flex. After I removed the two large lug type wheels I could also see where the right side trans / axle mount part of the frame was also badly broken. I was moving fast in reverse backing into the woods so I could move a large snow bank and hit a tree stump hidden in several inches of snow. Had to completely dissasemble the whole back end AND also found the transmission case cracked as well. I can't believe the whole thing was being held together at all.

Sorry to not get back to the replies quicker. Spent a few days repairing and modifying the frame and am waiting for the new bracket and transmission to arrive.

Sorry to not get back to the replies quicker. Spent a few days repairing and modifying the frame and am waiting for the new bracket and transmission to arrive.

#23

O

outdoorpowermike

O

outdoorpowermike

Belt guide missing for the small pulley and the tensioner spring needs to be put in correct place at frame.

#24

K

k_damore

K

k_damore

that small pulley MUST be aligned exactly with the other 2, as a matter fact you need to get down and look across all of them together and assure alignment. I bought an RZT for $800 once because the owner said it kept eating drive belts. I go it home and the engine pulley was off about 1/4 inch so I replaced it with NOS, it aligned perfectly and I sold it for $1800 a week later

#25

Tiger Small Engine

Tiger Small Engine

Where the belt rides on the deck pulleys is really important. I have had to modify the pulley height on newer mowers (less than 5 years old) to have the deck belt ride correctly and last.that small pulley MUST be aligned exactly with the other 2, as a matter fact you need to get down and look across all of them together and assure alignment. I bought an RZT for $800 once because the owner said it kept eating drive belts. I go it home and the engine pulley was off about 1/4 inch so I replaced it with NOS, it aligned perfectly and I sold it for $1800 a week later

#26

R

Rich A

And when all is assembled the idler pulley is tilted downward a couple degrees. Are you SURE that's not right? To me it look like it's designed to be this way.

R

Rich A

I've replaced the damaged anti-rotate bracket and new transmission and all the brackets holding the three pulleys. The two main pulleys were always in perfect alignment. But the smaller idiler pulley was always (before the damage occured) slightly tilted a couple degrees. I assembled with all new factory parts and that idler is still exactly tilted the same. I put all the old orignal brackets side by side and they are all absolutely exactly identical in every way. The old original larger two pulleys and their mounting hardware are all identical to my original. And the new idler and pulley are ALSO exactly identical to my originals.that small pulley MUST be aligned exactly with the other 2, as a matter fact you need to get down and look across all of them together and assure alignment. I bought an RZT for $800 once because the owner said it kept eating drive belts. I go it home and the engine pulley was off about 1/4 inch so I replaced it with NOS, it aligned perfectly and I sold it for $1800 a week later

And when all is assembled the idler pulley is tilted downward a couple degrees. Are you SURE that's not right? To me it look like it's designed to be this way.

#27

K

k_damore

K

k_damore

back to basics, as someone said before, there may be belt guides missing as the belt certainly looks too loose. And just because the new and old bracket for idler look the same if it doesn't line up even with the others then whatever it mounts to is damaged. The only place an idler is tilted a few degrees is on the deck to compensate for it being raised and loweredI've replaced the damaged anti-rotate bracket and new transmission and all the brackets holding the three pulleys. The two main pulleys were always in perfect alignment. But the smaller idiler pulley was always (before the damage occured) slightly tilted a couple degrees. I assembled with all new factory parts and that idler is still exactly tilted the same. I put all the old orignal brackets side by side and they are all absolutely exactly identical in every way. The old original larger two pulleys and their mounting hardware are all identical to my original. And the new idler and pulley are ALSO exactly identical to my originals.

And when all is assembled the idler pulley is tilted downward a couple degrees. Are you SURE that's not right? To me it look like it's designed to be this way.

#28

R

Rich A

R

Rich A

I'll send a better picture .. the picture I originally posted, was taken when the thing was partially disassembled. Belt LOOKS loose cus spring(s) etc. were detached. When assembled everything is exactly as it was out of the box 12 years ago.

About 6 years ago I turned this thing into a snow plow only tractor. No mowing deck , no deck pulleys, belt or ANY mowing deck mechanics are on the frame. I've BEEN using it for 6 years for snow plowing and hauling a small trailer around 13 acres to haul cut up logs etc. It has run flawlessly and perfectly for that time UNTIL I backed over a stump. Only then did I have a problem with the belt popping off and it was only until a week ago when I finally completely tore everything apart did I see the damage which was hidden from view and was EXTENSIVE.

I can assure you that the idler pulley and it's bracket, ALWAYS had a slight downward tllt from the day I got it over 10 years ago. The damage caused recently was to the frame, transmission case and that part #50 what everyone calls the "anti-torgue bracket" which is called in the factory manual "Transmission Bracket Assembly". That bracket was almost completely broken in half and only being held together by a thread. AND because of that, it flexed when the tractor was put in gear, allowing the whole transmission to twist downward damaging the frame where the tranny axles mounts are, and mis-aligning the belt causing it to pop off.

Note, I could run the tractor at any speed in neutral and the belts pulleys etc. worked fine, properly aligned and no burning slippage or popping off. BUT as soon as I let the clutch out in either forward or reverse the whole transmission would flex because the transmssion bracket assembly was broken and the main drive belt would fly off. THIS is the cause of the belt flying off:

That part along with ALL the other "brackets" have been replaced and so far every NEW OEM replacement part is identical (to a few thousanths of an inch) in every way, bends, angles, thickness. AND yet that one idler pulley is still (just like it was out of the box when new) tilted downward a couple degrees.

Thanks for all the comments but I think the tolerance of the allignment of pulleys and belts on this tractor as shipped from the factory, while somewhat critical is not out of spec in my case. Maybe a 3 or more degree tilt will affect things but a 2 or less degree tilt is not a problem? So today I will fully re-assemble the whole thing with all the "new" OEM brackets, etc. and still see a 2 degree off-set of that idler and it will either work or not work. If not ... I'll be open to any other ideas. I really appreciate the suggestions and help. But this problem is obviously kinda un-common?

More pics to follow. I hope all this detail and info helps someone else in the future.

About 6 years ago I turned this thing into a snow plow only tractor. No mowing deck , no deck pulleys, belt or ANY mowing deck mechanics are on the frame. I've BEEN using it for 6 years for snow plowing and hauling a small trailer around 13 acres to haul cut up logs etc. It has run flawlessly and perfectly for that time UNTIL I backed over a stump. Only then did I have a problem with the belt popping off and it was only until a week ago when I finally completely tore everything apart did I see the damage which was hidden from view and was EXTENSIVE.

I can assure you that the idler pulley and it's bracket, ALWAYS had a slight downward tllt from the day I got it over 10 years ago. The damage caused recently was to the frame, transmission case and that part #50 what everyone calls the "anti-torgue bracket" which is called in the factory manual "Transmission Bracket Assembly". That bracket was almost completely broken in half and only being held together by a thread. AND because of that, it flexed when the tractor was put in gear, allowing the whole transmission to twist downward damaging the frame where the tranny axles mounts are, and mis-aligning the belt causing it to pop off.

Note, I could run the tractor at any speed in neutral and the belts pulleys etc. worked fine, properly aligned and no burning slippage or popping off. BUT as soon as I let the clutch out in either forward or reverse the whole transmission would flex because the transmssion bracket assembly was broken and the main drive belt would fly off. THIS is the cause of the belt flying off:

That part along with ALL the other "brackets" have been replaced and so far every NEW OEM replacement part is identical (to a few thousanths of an inch) in every way, bends, angles, thickness. AND yet that one idler pulley is still (just like it was out of the box when new) tilted downward a couple degrees.

Thanks for all the comments but I think the tolerance of the allignment of pulleys and belts on this tractor as shipped from the factory, while somewhat critical is not out of spec in my case. Maybe a 3 or more degree tilt will affect things but a 2 or less degree tilt is not a problem? So today I will fully re-assemble the whole thing with all the "new" OEM brackets, etc. and still see a 2 degree off-set of that idler and it will either work or not work. If not ... I'll be open to any other ideas. I really appreciate the suggestions and help. But this problem is obviously kinda un-common?

More pics to follow. I hope all this detail and info helps someone else in the future.

#29

K

k_damore

K

k_damore

make sure you check withI'll send a better picture .. the picture I originally posted, was taken when the thing was partially disassembled. Belt LOOKS loose cus spring(s) etc. were detached. When assembled everything is exactly as it was out of the box 12 years ago.

About 6 years ago I turned this thing into a snow plow only tractor. No mowing deck , no deck pulleys, belt or ANY mowing deck mechanics are on the frame. I've BEEN using it for 6 years for snow plowing and hauling a small trailer around 13 acres to haul cut up logs etc. It has run flawlessly and perfectly for that time UNTIL I backed over a stump. Only then did I have a problem with the belt popping off and it was only until a week ago when I finally completely tore everything apart did I see the damage which was hidden from view and was EXTENSIVE.

I can assure you that the idler pulley and it's bracket, ALWAYS had a slight downward tllt from the day I got it over 10 years ago. The damage caused recently was to the frame, transmission case and that part #50 what everyone calls the "anti-torgue bracket" which is called in the factory manual "Transmission Bracket Assembly". That bracket was almost completely broken in half and only being held together by a thread. AND because of that, it flexed when the tractor was put in gear, allowing the whole transmission to twist downward damaging the frame where the tranny axles mounts are, and mis-aligning the belt causing it to pop off.

Note, I could run the tractor at any speed in neutral and the belts pulleys etc. worked fine, properly aligned and no burning slippage or popping off. BUT as soon as I let the clutch out in either forward or reverse the whole transmission would flex because the transmssion bracket assembly was broken and the main drive belt would fly off. THIS is the cause of the belt flying off:

View attachment 72169

That part along with ALL the other "brackets" have been replaced and so far every NEW OEM replacement part is identical (to a few thousanths of an inch) in every way, bends, angles, thickness. AND yet that one idler pulley is still (just like it was out of the box when new) tilted downward a couple degrees.

Thanks for all the comments but I think the tolerance of the allignment of pulleys and belts on this tractor as shipped from the factory, while somewhat critical is not out of spec in my case. Maybe a 3 or more degree tilt will affect things but a 2 or less degree tilt is not a problem? So today I will fully re-assemble the whole thing with all the "new" OEM brackets, etc. and still see a 2 degree off-set of that idler and it will either work or not work. If not ... I'll be open to any other ideas. I really appreciate the suggestions and help. But this problem is obviously kinda un-common?

More pics to follow. I hope all this detail and info helps someone else in the future.

make sure you spend some time on the Craftsman or Jacks or whatever other sight has the detail diagrams to ensure you have all the parts shown/listed and something didn't fall off and go missingI'll send a better picture .. the picture I originally posted, was taken when the thing was partially disassembled. Belt LOOKS loose cus spring(s) etc. were detached. When assembled everything is exactly as it was out of the box 12 years ago.

About 6 years ago I turned this thing into a snow plow only tractor. No mowing deck , no deck pulleys, belt or ANY mowing deck mechanics are on the frame. I've BEEN using it for 6 years for snow plowing and hauling a small trailer around 13 acres to haul cut up logs etc. It has run flawlessly and perfectly for that time UNTIL I backed over a stump. Only then did I have a problem with the belt popping off and it was only until a week ago when I finally completely tore everything apart did I see the damage which was hidden from view and was EXTENSIVE.

I can assure you that the idler pulley and it's bracket, ALWAYS had a slight downward tllt from the day I got it over 10 years ago. The damage caused recently was to the frame, transmission case and that part #50 what everyone calls the "anti-torgue bracket" which is called in the factory manual "Transmission Bracket Assembly". That bracket was almost completely broken in half and only being held together by a thread. AND because of that, it flexed when the tractor was put in gear, allowing the whole transmission to twist downward damaging the frame where the tranny axles mounts are, and mis-aligning the belt causing it to pop off.

Note, I could run the tractor at any speed in neutral and the belts pulleys etc. worked fine, properly aligned and no burning slippage or popping off. BUT as soon as I let the clutch out in either forward or reverse the whole transmission would flex because the transmssion bracket assembly was broken and the main drive belt would fly off. THIS is the cause of the belt flying off:

View attachment 72169

That part along with ALL the other "brackets" have been replaced and so far every NEW OEM replacement part is identical (to a few thousanths of an inch) in every way, bends, angles, thickness. AND yet that one idler pulley is still (just like it was out of the box when new) tilted downward a couple degrees.

Thanks for all the comments but I think the tolerance of the allignment of pulleys and belts on this tractor as shipped from the factory, while somewhat critical is not out of spec in my case. Maybe a 3 or more degree tilt will affect things but a 2 or less degree tilt is not a problem? So today I will fully re-assemble the whole thing with all the "new" OEM brackets, etc. and still see a 2 degree off-set of that idler and it will either work or not work. If not ... I'll be open to any other ideas. I really appreciate the suggestions and help. But this problem is obviously kinda un-common?

More pics to follow. I hope all this detail and info helps someone else in the future.