You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1982 10 hp Craftsman 36" lawn tractor drag link failure

- Thread starter Craiger

- Start date

More options

Export thread- Joined

- Feb 19, 2020

- Threads

- 120

- Messages

- 12,871

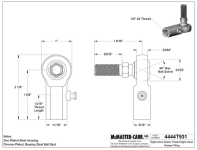

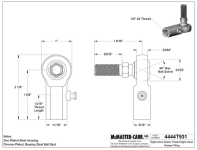

You could always use a version with a grease fitting and weld it on the squarely cut rod. That way you it is lubed. Just got make the you have clearance for the grease fitting.

I have welded these on but usually still had them threaded on too. Now of course I limit the amount of heat from welding as much as I can. Stitch welding. I even weld on some that had the Teflon plastic internally

I have welded these on but usually still had them threaded on too. Now of course I limit the amount of heat from welding as much as I can. Stitch welding. I even weld on some that had the Teflon plastic internally

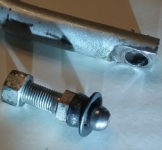

That is a different design from my drag link. Is that a Heim joint? Mine is a simple ball and socket. The socket is in the end of the rod, in the side of the rod end which is ground flat. Why can others attach multiple photos as you have, I just tried once more to attach a single photo and I get the msg "the uploaded file is too large"?Heres how I did this repair on my Craftsman I did get a new shaft but now have this for a spare. I also on the new shaft drilled the ends and put in grease fittings so they can now be greased as needed.View attachment 65688View attachment 65689View attachment 65688View attachment 65689

This was and is a socket in the end and the shaft is flat where the ball goes in, the ball pulled out of the socket as yours did, so I made that collar to go over the shaft to hold the ball into the shaft. The collar has to be tight on the shaft to hold it and the ball in the socket. If you look good at the 65689 picture you can see the flat on the shaft.

To get your pictures to download you may have to resize them to a smaller size for posting on line I use 600x600

To get your pictures to download you may have to resize them to a smaller size for posting on line I use 600x600

You say you have a welder.

What I do when that happens and not have to spend a arm and a leg for new stuff or a new drag link, especially when one end goes bad like yours and the the rod is a solid piece. If possible when I'm looking for parts to weld up I try to look for adjustable type and keep major heat when welding away from the swivel joint.

I go my mower salvage and find one that has a good end/ends or maybe even one that has replaceable ends threaded.

I measure the bad one end to end then cut off the bad end/ends and cut the replacements and weld them onto the old drag link bar. You can overlap the bars for a easy lap/scab weld of the bars.

Easy fix and can save several $$'s and maybe even come up with adjustable toe-in links instead of the fixed type. It's not a machine designed for breaking land speed records or for running at 70 mph. Just go for it.

Heating and hammering around on the existing ball and socket is a waste of time and effort as bertsmobile indicates. Been their, tried that.

What I do when that happens and not have to spend a arm and a leg for new stuff or a new drag link, especially when one end goes bad like yours and the the rod is a solid piece. If possible when I'm looking for parts to weld up I try to look for adjustable type and keep major heat when welding away from the swivel joint.

I go my mower salvage and find one that has a good end/ends or maybe even one that has replaceable ends threaded.

I measure the bad one end to end then cut off the bad end/ends and cut the replacements and weld them onto the old drag link bar. You can overlap the bars for a easy lap/scab weld of the bars.

Easy fix and can save several $$'s and maybe even come up with adjustable toe-in links instead of the fixed type. It's not a machine designed for breaking land speed records or for running at 70 mph. Just go for it.

Heating and hammering around on the existing ball and socket is a waste of time and effort as bertsmobile indicates. Been their, tried that.

Thanks for the tips. I have a commercial Miller MM35 MIG welder and might use that to weld a new ball joint on as posted from McMaster-Carr. They sell one with same size threaded shaft 3/8" x 24 NF for under ten bucks. Looks like one with female threads on the mount would work ok. What I did today for Plan A is looking like it might work. The rod is NOT hardened steel, it files like mild steel. I cleaned the socket and the ball with BrakeKleen solvent and then applied some Moly-Kote GN pasteYou say you have a welder.

What I do when that happens and not have to spend a arm and a leg for new stuff or a new drag link, especially when one end goes bad like yours and the the rod is a solid piece. If possible when I'm looking for parts to weld up I try to look for adjustable type and keep major heat when welding away from the swivel joint.

I go my mower salvage and find one that has a good end/ends or maybe even one that has replaceable ends threaded.

I measure the bad one end to end then cut off the bad end/ends and cut the replacements and weld them onto the old drag link bar. You can overlap the bars for a easy lap/scab weld of the bars.

Easy fix and can save several $$'s and maybe even come up with adjustable toe-in links instead of the fixed type. It's not a machine designed for breaking land speed records or for running at 70 mph. Just go for it.

Heating and hammering around on the existing ball and socket is a waste of time and effort as bertsmobile indicates. Been their, tried that.

(good for about 500,000 psi lubing) and was able to push the ball back into the socket holding it with Vise-Grip pliers just using my hands. Then I supported the rod on an anvil and used a center punch hitting with a one pound hammer briskly going all around the circumference of the socket about 12 spots. Struck right near the edge of the hole. The sharp center punch left a nice deep dimple indicating it moved some metal. It seems to have peened over enough to retain the ball in the socket.

It would not pull out as easily as it went in. Time will tell next week when I mow again.

If it pulls apart again, I'll have to go to Plan B and weld a new ball joint on the end after measuring and cutting end of original rod off. I will post down the road to report how things work out. I don't know how to reduce the size of a jpg file, are there simple instructions to be found on the web? My photo was 1.4 Mb and it was rejected as too large. Picture worth 1000 words.