Over reving is only because the governor is not working , their is an air leak or the cam is excessivly worn

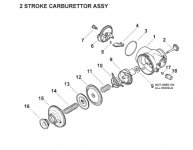

Verify the governor by putting some longer tube on the governor spiggot on the diaphragm cap # 15 and sucking on it hard.

By far the most common cause is the diaphragm # 12 getting dislodged when the diaphragm cap # 15 is replaced

The cap # 15 should always be replaced with out the long governor spring # 14 in place to prevent this happening then replace the spring & finally the plug #16 .

I like to put a little rubber grease around the diaphragm to help it stay in place.

Also note the poppet valve # 2 has a cut away and must be replaced with the letter C by the emulsion tube cut out .

You can put up to 5 spacer washers # 9 ( printing error , should have been 8 ) but I have never needed more than 3 and that was on a commercial with around 5000 hours on it .

I have had the odd decompressor fail but you usually can see & hear them when they go west .

Also the diaphragm cap can shrink a little and be very hard to snap fully closed.

Also make sure you have the legs of the Lifter # 10 running in their little slots

The burning question is why did you pull it down.

These carbs will happily run 20 years with no problems whatsoever

To make sure we are all talking about the same bits the numbers above refer to this diagram

And of course how is the head gasket .

Again you can usually hear feel & see a blown one.

Occasionally they make the engine run a bit faster

And by "over reving " what exactly do you mean ?

A bit too fast or like it is about to blow up ?