mowfixer

Forum Newbie

- Joined

- Oct 25, 2020

- Threads

- 2

- Messages

- 6

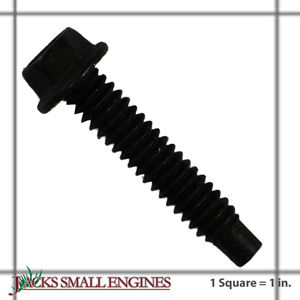

I have a generator with a Tecumseh HM100 159409P motor. The generator was running and suddenly a loud noise and engine quit. When I removed blower housing I found the ignition coil flopping around loose. The coil is mounted to two posts that are a part of the block with two 3/4 in extensions to move coil out over the magnets. Those extensions use a 10-24 bolt and both were broken off in the block. Looking at the coil I saw damage where it had made solid contact with the flywheel causing the mounting bolts to shear.

Seems like a poor design as the weight of the coil is being held by 10-24 1/2 in long threads. I have worked on small engines for 20 years and I have never seen a failure like this.

From what I can see, one side of the coil mounting extension broke allowing one side of the coil to drop down and hit the flywheel. I checked the flywheel to see if it is properly attached to the crankshaft and checked it for runout but all looks fine. I have removed the broken bolts and ordered replacement extensions and replacement coil.

Any ideas what might have caused this? Has anyone else seen this before?

Gary (Mowfixer)

Seems like a poor design as the weight of the coil is being held by 10-24 1/2 in long threads. I have worked on small engines for 20 years and I have never seen a failure like this.

From what I can see, one side of the coil mounting extension broke allowing one side of the coil to drop down and hit the flywheel. I checked the flywheel to see if it is properly attached to the crankshaft and checked it for runout but all looks fine. I have removed the broken bolts and ordered replacement extensions and replacement coil.

Any ideas what might have caused this? Has anyone else seen this before?

Gary (Mowfixer)

Attachments

Last edited: