OCMA-Mower

Forum Newbie

- Joined

- Aug 10, 2022

- Threads

- 1

- Messages

- 3

Hello all,

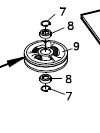

Our Model Airplane club has a Ransomes 951D mower. We are a non-profit and maintain our airfield ourselves, all volunteer. We have an issue with an Idler Pulley in one of the wing decks. The bearings no longer fit tight and the pulley wobbles. I have been looking all over for a source for parts and not found one yet. I am hoping someone has or can point me in the direction where I can find one. According to the manual, part number is: 146169. As a last resort we may be able to have a machine shop repair it, but we'd really like to replace it with a good one.

Please contact me via email: Tim.Cardin@Cardinwest.Com

Thanks!

Our Model Airplane club has a Ransomes 951D mower. We are a non-profit and maintain our airfield ourselves, all volunteer. We have an issue with an Idler Pulley in one of the wing decks. The bearings no longer fit tight and the pulley wobbles. I have been looking all over for a source for parts and not found one yet. I am hoping someone has or can point me in the direction where I can find one. According to the manual, part number is: 146169. As a last resort we may be able to have a machine shop repair it, but we'd really like to replace it with a good one.

Please contact me via email: Tim.Cardin@Cardinwest.Com

Thanks!