Hi everyone,

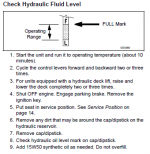

I just changed out a Hydraulic hose line that leaked out to the point of losing power, and now I am about to add some Mobile One 15W50 Synthetic motor oil as recommended in my manual. Since I am not doing a complete oil filter change, because it was changed last year, that knowing how much oil the manual says it takes will not help me in my case. I know how to purge the unit by way of the two bolts on the the two pumps, but I have a question about how to determine what is to little oil or to much oil by way of the dipstick reading, that these old Zero Turns lawnmowers used back then.

My question is this:

Should I measure the oil in the Hydraulic tank by screwing the dipstick all the way in, or by unscrewing the dipstick and measure it by dipping it in unscrewed?

As seen in the photo below circled in "Blue" you can see that there is a good 1 inch difference in the reading screwed in or not screwed in.

I just changed out a Hydraulic hose line that leaked out to the point of losing power, and now I am about to add some Mobile One 15W50 Synthetic motor oil as recommended in my manual. Since I am not doing a complete oil filter change, because it was changed last year, that knowing how much oil the manual says it takes will not help me in my case. I know how to purge the unit by way of the two bolts on the the two pumps, but I have a question about how to determine what is to little oil or to much oil by way of the dipstick reading, that these old Zero Turns lawnmowers used back then.

My question is this:

Should I measure the oil in the Hydraulic tank by screwing the dipstick all the way in, or by unscrewing the dipstick and measure it by dipping it in unscrewed?

As seen in the photo below circled in "Blue" you can see that there is a good 1 inch difference in the reading screwed in or not screwed in.

Attachments

Last edited: