bertsmobile1

Lawn Royalty

- Joined

- Nov 29, 2014

- Threads

- 64

- Messages

- 24,705

OK fellas, I am stuck with this one

Got a 345 in the shop

originally it had a broken piston which killed the bore as well

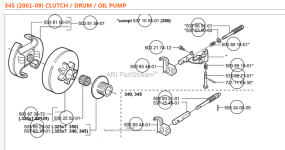

Replaced the barrel , piston bearings & seals

Saw runs perfectly

But not a drop of oil to the bar

1) pressurised the oil tank & oil ouzed out around the rubber seal, so replaced the seal-no change

2) replaced the spindle - no change

3) removed the filter , it was clean

4) replaced the entire pump, worm gear & another rubber seal, still no oil

The only non standard thing is the drum which is now a rim sprocket in place of the spur sprocket , but I have checked the drum is triving the oil pump worm gear

This has the cheaper pump with no flow adjuster .

As this is mainly a mower forum I have also posted to OPE

I would rip my hair out but it is all gone already .

Any one got some ideas ?

Got a 345 in the shop

originally it had a broken piston which killed the bore as well

Replaced the barrel , piston bearings & seals

Saw runs perfectly

But not a drop of oil to the bar

1) pressurised the oil tank & oil ouzed out around the rubber seal, so replaced the seal-no change

2) replaced the spindle - no change

3) removed the filter , it was clean

4) replaced the entire pump, worm gear & another rubber seal, still no oil

The only non standard thing is the drum which is now a rim sprocket in place of the spur sprocket , but I have checked the drum is triving the oil pump worm gear

This has the cheaper pump with no flow adjuster .

As this is mainly a mower forum I have also posted to OPE

I would rip my hair out but it is all gone already .

Any one got some ideas ?