You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Kohler ECV870 misfiring

#1

H

heavy_kevie

H

heavy_kevie

Have a 2016 Dixie Chopper Classic with a Kohler ECV870-3013 and it has an odd issue. It starts fine and runs good for about 2-3 minutes then gets weak RPM drops from 3300 to 26-2800 and exhaust smells rich. Shut it off, restart it and runs good for 2-3 minutes rinse repeat. Check the primary side of the coils from the ecu connector and measures 1.2 ohms starter side and 1.3 ohms oil filter side. Checked the secondary side and measures 77 kohm on starter side coil and 22 kohm on oil filter side. Replaced the coil on the starter side and still have the same indications. Kinda at a loss from here.

#2

Tiger Small Engine

Never heard of that Kohler model number (double check if correct). What made you use a multimeter to check ignition coils? Did you take them off of mower to check? Did you pull kill wires or spark plug boots to coils and plugs to see if any change in power? Sounds more like choke on carburetor is not functioning correctly? Do you have black smoke from muffler? Have you pulled the spark plugs to check condition of plugs?

Tiger Small Engine

Have a 2016 Dixie Chopper Classic with a Kohler ECV870-3013 and it has an odd issue. It starts fine and runs good for about 2-3 minutes then gets weak RPM drops from 3300 to 26-2800 and exhaust smells rich. Shut it off, restart it and runs good for 2-3 minutes rinse repeat. Check the primary side of the coils from the ecu connector and measures 1.2 ohms starter side and 1.3 ohms oil filter side. Checked the secondary side and measures 77 kohm on starter side coil and 22 kohm on oil filter side. Replaced the coil on the starter side and still have the same indications. Kinda at a loss from here.

Never heard of that Kohler model number (double check if correct). What made you use a multimeter to check ignition coils? Did you take them off of mower to check? Did you pull kill wires or spark plug boots to coils and plugs to see if any change in power? Sounds more like choke on carburetor is not functioning correctly? Do you have black smoke from muffler? Have you pulled the spark plugs to check condition of plugs?

#3

I

ILENGINE

I

ILENGINE

Do you have a MIL light on when this happens. That would give some direction to the problem. But sounds like the issue starts when it goes into closed loop. Disconnect the O2 sensor and then start it and see what happens.

#4

H

heavy_kevie

H

heavy_kevie

Unfortunately no MIL light, the engine model number is for the Kohler 31hp fuel injected engine used on Dixie Chopper lawn mowers so there is no choke or carburetor. The primary side was checked from the ECU connector terminals through the coil with a DVM. The coil supports a dual spark plug design and were checked on the secondary side from one boot terminal to the other boot terminal with a DVM. Did not pull kill wire nor pull spark plugs as I believe I am not getting spark steady for some reason and the exhaust smells rich. Spark plugs are platinum and were installed two years ago. I may be able to use my DVM to simulate the MIL light if I can find the 6 wire connector that Kohler uses to power the MIL.

#6

V

VegetiveSteam

V

VegetiveSteam

Do you see any black smoke when you feel it's running rich? Lean exhaust also stinks and burns eyes but there wouldn't be any black smoke.

And like ILENGINE mentioned. Try running it with the O2 sensor disconnected. If it runs better don't automatically think you need a new O2 sensor. You might need one, but there are other things that influence the O2 sensor so some other testing will be needed.

Are there any lights that come on when you turn the key to the start position? Key on, engine off.

My main question would be, do you see any black smoke?

And like ILENGINE mentioned. Try running it with the O2 sensor disconnected. If it runs better don't automatically think you need a new O2 sensor. You might need one, but there are other things that influence the O2 sensor so some other testing will be needed.

Are there any lights that come on when you turn the key to the start position? Key on, engine off.

My main question would be, do you see any black smoke?

#7

H

heavy_kevie

H

heavy_kevie

Tried to hook up my DVM to the MIL output terminal (pins 3 and 4 on 6 wire connector) but it doesn't respond quick enough to capture the voltage change. Ran engine at 2600rpm for 4 minutes, started missing but no black smoke. Disconnected o2 sensor and ran at 2600 for 4 minutes, no miss detected, ran at 3600 for 2 minutes, still no miss detected. Does that mean it is running okay in open loop but the miss appears when it is running in closed loop?

#8

V

VegetiveSteam

V

VegetiveSteam

Have you tried actually using the equipment with the O2 sensor disconnected? My guess is it will lack power as I believe it might actually be running lean.

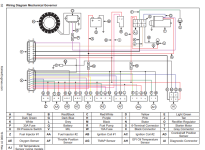

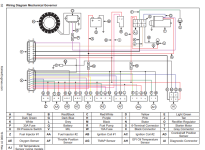

To make a MIL, you'll need a test light with an incandescent bulb, not an LED. Clip it to the positive terminal of the battery and probe the backside of the tan wire 3 in the engine to equipment connector S. You just made a MIL light. The link below should take you to the Kohler Service Manual which might be nice to have.

If you could test the fuel pressure that could answer a lot.

To make a MIL, you'll need a test light with an incandescent bulb, not an LED. Clip it to the positive terminal of the battery and probe the backside of the tan wire 3 in the engine to equipment connector S. You just made a MIL light. The link below should take you to the Kohler Service Manual which might be nice to have.

If you could test the fuel pressure that could answer a lot.

#9

H

heavy_kevie

H

heavy_kevie

Yes, I ran it with the O2 sensor disconnected, that was in my previous post. It seemed to run fine with the o2 sensor disconnected. And thank-you for the download link, I'll get that right now. I'll see about getting a small incandescent light tomorrow. I have an old pressure gage but it only goes up to 20lbs.

#10

V

VegetiveSteam

V

VegetiveSteam

It was in your previous post that you ran the engine. I was trying to ask if you actually tried using the equipment? Make it do work so the engine has to carry a load.Yes, I ran it with the O2 sensor disconnected, that was in my previous post. It seemed to run fine with the o2 sensor disconnected. And thank-you for the download link, I'll get that right now. I'll see about getting a small incandescent light tomorrow. I have an old pressure gage but it only goes up to 20lbs.

#11

H

heavy_kevie

H

heavy_kevie

I ran it for about 2.5 hours today with the O2 sensor disconnected. It seemed to run about normal, 3400 rpm with desk engaged, no load; 3320-3180 while cutting grass. Actual no rpm is around 4300, I've always thought that was too high, maybe I've been running lean all this time. I bought the mower used in November of 2020. Didn't appear to have the best of maintenance performed on it as I found the area around the heads packed with grass.

#12

V

VegetiveSteam

V

VegetiveSteam

Sounds like ignition and fuel pressure are fine. It could simply be a bad O2 sensor. If you could get codes from the ECU that could help.

And apologies if I missed it, but when the issue first started and you felt it was running rich, did you ever notice any black smoke. If so, how do the exhaust manifold gaskets seem? Also, are there any holes in the muffler that shouldn't be there? Even something as small as a missing heat shield screw.

Most heat shield screws don't normally go into the muffler flow area, but I did run into one that did and the little bit of oxygen that hole let in, fooled the O2 sensor into thinking the mixture was lean and that sent a signal to the ECU to richen up the mixture causing the engine to run rich. Once we found the hole and replaced the screw, the engine once again ran as designed. Having never run into that before it was not an easy thing to find. After running into it, if I have an EFI running rich, I check for anything that might let oxygen get to where it isn't supposed to be.

And apologies if I missed it, but when the issue first started and you felt it was running rich, did you ever notice any black smoke. If so, how do the exhaust manifold gaskets seem? Also, are there any holes in the muffler that shouldn't be there? Even something as small as a missing heat shield screw.

Most heat shield screws don't normally go into the muffler flow area, but I did run into one that did and the little bit of oxygen that hole let in, fooled the O2 sensor into thinking the mixture was lean and that sent a signal to the ECU to richen up the mixture causing the engine to run rich. Once we found the hole and replaced the screw, the engine once again ran as designed. Having never run into that before it was not an easy thing to find. After running into it, if I have an EFI running rich, I check for anything that might let oxygen get to where it isn't supposed to be.

#13

H

heavy_kevie

H

heavy_kevie

Okay, finally got my test light set up, I have codes 0032 and 0132 set in the ecu. With key on and engine not running, I have 11.7v on pin A of O2 connector (red+black wire), 0v on pin B (green wire), 3.4v on pin C (violet wire), and 0v on pin D (black wire). Resistance between pin D and the negative battery terminal is.01 ohms. With engine running about 5 minutes, voltages on pin A were 13.2, pin B 0v, pin c 0v, and pin D 0v. I didn't check the resistance between the ecu and pins A,B,and C. Is this enough information to say the o2 sensor is bad? I have a little bit of oil leakage around the valve covers, I was thinking about picking up some carb cleaner and spraying around the intake path between the air cleaner outlet and the heads and determine if I have any leaks. I looked around the heat shield and everything appears to be fine.

#14

H

heavy_kevie

H

heavy_kevie

Oh, I forgot to add that the manual says 0032 Oxygen Sensor Heater Circuit High and 0132 Oxygen Sensor 1 Circuit High Voltage.Okay, finally got my test light set up, I have codes 0032 and 0132 set in the ecu. With key on and engine not running, I have 11.7v on pin A of O2 connector (red+black wire), 0v on pin B (green wire), 3.4v on pin C (violet wire), and 0v on pin D (black wire). Resistance between pin D and the negative battery terminal is.01 ohms. With engine running about 5 minutes, voltages on pin A were 13.2, pin B 0v, pin c 0v, and pin D 0v. I didn't check the resistance between the ecu and pins A,B,and C. Is this enough information to say the o2 sensor is bad? I have a little bit of oil leakage around the valve covers, I was thinking about picking up some carb cleaner and spraying around the intake path between the air cleaner outlet and the heads and determine if I have any leaks. I looked around the heat shield and everything appears to be fine.

#15

V

VegetiveSteam

If you have any trouble with the reset, reply back and I'll find and post the simplified version I created for new Kohler techs.

V

VegetiveSteam

Yeah, you likely set those codes when you ran it with the O2 sensor disconnected. Check the manual for the ECU reset procedure to clear those codes. I don't remember that procedure off the top of my head or I'd tell you how to do it. It's pretty simple but needs to be precise. Then run it again with the O2 sensor reconnected and see what codes if any come back. Anytime you disconnect anything connected to the ECU and turn the key on, it will set a code. If you would unplug one of the fuel injectors and turn the key on, it would set a fuel injector code.Oh, I forgot to add that the manual says 0032 Oxygen Sensor Heater Circuit High and 0132 Oxygen Sensor 1 Circuit High Voltage.

If you have any trouble with the reset, reply back and I'll find and post the simplified version I created for new Kohler techs.

#16

V

VegetiveSteam

V

VegetiveSteam

I looked at the ECU reset instruction to refresh my memory and the only thing I did differently was instead of waiting 10 seconds, I would advise techs to wait 15 seconds. The issue I came across one time was, I was on the phone with a tech trying to help him do the reset and when I said to turn the key on/off and wait 10 seconds, he started counting 1...2...3 ect. At the same time, I was watching the second hand on the clock in our office. When he got to 10, our clock had only ticked off 6 seconds. Going more than 10 seconds isn't a problem. Going less than 10 seconds is. I always taught 15 seconds for those who counted to 15 instead of watching a clock.

The reason to wait the 10 seconds is to give the ECU enough time to completely shut down and that takes around 10 seconds. Some ECUs might take 9 seconds, but some might actually take 11 or 12 seconds to completely shut down.

One more thing. A paper clip is just the right size to jump the white and black wires in the 4 pin diagnostic plug connector. Just be sure you don't jump to the red/black wire or dark blue wire.

The reason to wait the 10 seconds is to give the ECU enough time to completely shut down and that takes around 10 seconds. Some ECUs might take 9 seconds, but some might actually take 11 or 12 seconds to completely shut down.

One more thing. A paper clip is just the right size to jump the white and black wires in the 4 pin diagnostic plug connector. Just be sure you don't jump to the red/black wire or dark blue wire.

#17

B

billbud

B

billbud

Have a 2016 Dixie Chopper Classic with a Kohler ECV870-3013 and it has an odd issue. It starts fine and runs good for about 2-3 minutes then gets weak RPM drops from 3300 to 26-2800 and exhaust smells rich. Shut it off, restart it and runs good for 2-3 minutes rinse repeat. Check the primary side of the coils from the ecu connector and measures 1.2 ohms starter side and 1.3 ohms oil filter side. Checked the secondary side and measures 77 kohm on starter side coil and 22 kohm on oil filter side. Replaced the coil on the starter side and still have the same indications. Kinda at a loss from here.

#18

B

billbud

B

billbud

I would check the lifter/ tappet to valve clearanceHave a 2016 Dixie Chopper Classic with a Kohler ECV870-3013 and it has an odd issue. It starts fine and runs good for about 2-3 minutes then gets weak RPM drops from 3300 to 26-2800 and exhaust smells rich. Shut it off, restart it and runs good for 2-3 minutes rinse repeat. Check the primary side of the coils from the ecu connector and measures 1.2 ohms starter side and 1.3 ohms oil filter side. Checked the secondary side and measures 77 kohm on starter side coil and 22 kohm on oil filter side. Replaced the coil on the starter side and still have the same indications. Kinda at a loss from here.

#19

I

ILENGINE

I

ILENGINE

Hydraulic lifters therefore not clearances to checkI would check the lifter/ tappet to valve clearance

#20

V

VegetiveSteam

V

VegetiveSteam

No hydraulic lifters on this one. They are solid. But valve lash isn't the issue.

#21

T

TobyU

T

TobyU

A classic example of making something over complicated that didn't need to be that way.

We turn these mowers into a complicated bi-directional computer system a fuel management etc which makes them far harder to troubleshoot and makes the parts far more expensive and more of them.

I'll pass.

I will admit I really wouldn't want to go back to carburetors on cars because fuel injection is just so convenient and near perfect and consistent... But for lawn mowers, I need nothing more than a carburetor.

I will be driving one of my car toys tomorrow that has a Holley carburetor on it though.

It is almost as perfect and consistent as fuel injection and I used to have a 67 Pontiac with a 750 double pumper that was the best starting, running, carbureted engine I've ever had so in that case who cares about fuel injection!

We turn these mowers into a complicated bi-directional computer system a fuel management etc which makes them far harder to troubleshoot and makes the parts far more expensive and more of them.

I'll pass.

I will admit I really wouldn't want to go back to carburetors on cars because fuel injection is just so convenient and near perfect and consistent... But for lawn mowers, I need nothing more than a carburetor.

I will be driving one of my car toys tomorrow that has a Holley carburetor on it though.

It is almost as perfect and consistent as fuel injection and I used to have a 67 Pontiac with a 750 double pumper that was the best starting, running, carbureted engine I've ever had so in that case who cares about fuel injection!

#22

V

VegetiveSteam

V

VegetiveSteam

For the average do-it-yourselfer, no question, EFI engines are harder to troubleshoot sometimes.

The issues I would often run into trying to help techs troubleshoot EFI engines is, they seem to forget it's an engine. An engine comes in their shop lacking power and they immediately want to blame the EFI system. They spend hours swapping parts with no success only to later discover the engine is low on compression due to leaking valves or just plain worn out. They forget to start with the basics.

Give me a fuel pressure tester and the diagnostic program and I'll take working on an EFI engine over a carbureted engine anytime.

I'll admit I'm not very smart so having the ability to connect an engine to a diagnostic program that when used correctly will pretty much tell me what if anything is wrong with the EFI system is great for me.

The issues I would often run into trying to help techs troubleshoot EFI engines is, they seem to forget it's an engine. An engine comes in their shop lacking power and they immediately want to blame the EFI system. They spend hours swapping parts with no success only to later discover the engine is low on compression due to leaking valves or just plain worn out. They forget to start with the basics.

Give me a fuel pressure tester and the diagnostic program and I'll take working on an EFI engine over a carbureted engine anytime.

I'll admit I'm not very smart so having the ability to connect an engine to a diagnostic program that when used correctly will pretty much tell me what if anything is wrong with the EFI system is great for me.

#23

H

heavy_kevie

H

heavy_kevie

Okay, got the o2 sensor plugged back in and the ecu reset, fired it up ran good for 6-7 minutes then started misfiring. Hooked up my light to check for codes and no codes set, just the end message of 61. Also, didn't get a chance to do the tps learn procedure due to the misfiring.I looked at the ECU reset instruction to refresh my memory and the only thing I did differently was instead of waiting 10 seconds, I would advise techs to wait 15 seconds. The issue I came across one time was, I was on the phone with a tech trying to help him do the reset and when I said to turn the key on/off and wait 10 seconds, he started counting 1...2...3 ect. At the same time, I was watching the second hand on the clock in our office. When he got to 10, our clock had only ticked off 6 seconds. Going more than 10 seconds isn't a problem. Going less than 10 seconds is. I always taught 15 seconds for those who counted to 15 instead of watching a clock.

The reason to wait the 10 seconds is to give the ECU enough time to completely shut down and that takes around 10 seconds. Some ECUs might take 9 seconds, but some might actually take 11 or 12 seconds to completely shut down.

One more thing. A paper clip is just the right size to jump the white and black wires in the 4 pin diagnostic plug connector. Just be sure you don't jump to the red/black wire or dark blue wire.

#24

V

VegetiveSteam

Any chance you could post a short video of it when it's misfiring?

V

VegetiveSteam

It's good to do the TPS learn but not the end of the world if you don't.Okay, got the o2 sensor plugged back in and the ecu reset, fired it up ran good for 6-7 minutes then started misfiring. Hooked up my light to check for codes and no codes set, just the end message of 61. Also, didn't get a chance to do the tps learn procedure due to the misfiring.

Any chance you could post a short video of it when it's misfiring?

#25

H

heavy_kevie

H

heavy_kevie

Okay, I've got the file compressed in the mp4 format to 3.3MB, but it says the file is too large. What do I do now?

#26

H

heavy_kevie

H

heavy_kevie

I think I finally got it. Compressed the file further and converted to zip file. Temp while recording was 68F, 42% humidity, 29.89 barometric pressure. Engine had been running for 5 minutes.

Attachments

#27

V

VegetiveSteam

I also thought of another test involving the O2 sensor but it's been a while since I've run tests without the diagnostic program. It involves a test with a voltmeter and what the service manual shows I believe is incorrect. I want to run it by someone first to make sure I'm correct before I have you waste time with it. He's one of the best with Kohler EFI and he will know immediately if the manual is accurate.

V

VegetiveSteam

Was it acting up? Unfortunately, I didn't catch anything that sounded all that unusual. Does it still smell like it's running rich? And sorry if I missed your answer to this but have you ever seen any black smoke from the exhaust?I think I finally got it. Compressed the file further and converted to zip file. Temp while recording was 68F, 42% humidity, 29.89 barometric pressure. Engine had been running for 5 minutes.

I also thought of another test involving the O2 sensor but it's been a while since I've run tests without the diagnostic program. It involves a test with a voltmeter and what the service manual shows I believe is incorrect. I want to run it by someone first to make sure I'm correct before I have you waste time with it. He's one of the best with Kohler EFI and he will know immediately if the manual is accurate.

#28

H

heavy_kevie

H

heavy_kevie

Yes, it was misfiring as you can see from the rpm display. Typically it would idle 1500-1550 rpm but as the video shows it dropped to the 1300's, and when the deck is engaged with the mower setting still it typically runs between 3300-3400 rpm but with the o2 connected it was dropping down to 2800 rpm. I did not notice any black smoke when it started misfiring and the smell was more acrid rather than rich.Was it acting up? Unfortunately, I didn't catch anything that sounded all that unusual. Does it still smell like it's running rich? And sorry if I missed your answer to this but have you ever seen any black smoke from the exhaust?

I also thought of another test involving the O2 sensor but it's been a while since I've run tests without the diagnostic program. It involves a test with a voltmeter and what the service manual shows I believe is incorrect. I want to run it by someone first to make sure I'm correct before I have you waste time with it. He's one of the best with Kohler EFI and he will know immediately if the manual is accurate.

#29

V

VegetiveSteam

V

VegetiveSteam

I spoke with my EFI person and in describing your issue he's 99% sure you have a bad O2 sensor. There is a test you could do but it involves probing through the insulation on the black and purple O2 sensor wires. It really won't hurt anything if you're replacing the O2 sensor but if not, you'd want to seal up the holes you made with some sealant.

We wouldn't do this type of test very often but when we did, we would either use a straight pin or a small pointed meter probe. You'd be measuring DC voltage with a voltmeter. The O2 sensor puts out between 0 and 1 volt DC. The sensor will put out closer to 1 volt when it senses less oxygen in the exhaust or rich. Maybe something like .8 or .9 volts. You'd want to test the voltage after the engine warms up and goes into closed-loop.

More oxygen or a lean condition will give a lower voltage reading closer to 0 volts. Maybe something like .1 or .2 volts. It appears your issue is a lean condition which should result in a low voltage reading but, if the O2 sensor is faulty you are probably going to read something closer to 1 volt. That would fool the ECU into thinking the mixture was rich and lean it out causing the issue.

If you do decide to pin the wires, make sure you don't pin the red/black wire. That is battery voltage for the O2 heater. The purple wire is the DC voltage created by the O2 sensor and is being sent back to the ECU. The black wire is the ground for that circuit.

I hope this helps.

We wouldn't do this type of test very often but when we did, we would either use a straight pin or a small pointed meter probe. You'd be measuring DC voltage with a voltmeter. The O2 sensor puts out between 0 and 1 volt DC. The sensor will put out closer to 1 volt when it senses less oxygen in the exhaust or rich. Maybe something like .8 or .9 volts. You'd want to test the voltage after the engine warms up and goes into closed-loop.

More oxygen or a lean condition will give a lower voltage reading closer to 0 volts. Maybe something like .1 or .2 volts. It appears your issue is a lean condition which should result in a low voltage reading but, if the O2 sensor is faulty you are probably going to read something closer to 1 volt. That would fool the ECU into thinking the mixture was rich and lean it out causing the issue.

If you do decide to pin the wires, make sure you don't pin the red/black wire. That is battery voltage for the O2 heater. The purple wire is the DC voltage created by the O2 sensor and is being sent back to the ECU. The black wire is the ground for that circuit.

I hope this helps.

#30

C

cliffeby

C

cliffeby

It sounds like a condenser issue on an old points type ignition system. I don’t see it in your diagram but does the ignition system have an ignition capacitor? I replaced mine two times before I got one that didn’t fail after a few minutes.Have a 2016 Dixie Chopper Classic with a Kohler ECV870-3013 and it has an odd issue. It starts fine and runs good for about 2-3 minutes then gets weak RPM drops from 3300 to 26-2800 and exhaust smells rich. Shut it off, restart it and runs good for 2-3 minutes rinse repeat. Check the primary side of the coils from the ecu connector and measures 1.2 ohms starter side and 1.3 ohms oil filter side. Checked the secondary side and measures 77 kohm on starter side coil and 22 kohm on oil filter side. Replaced the coil on the starter side and still have the same indications. Kinda at a loss from here.

#31

I

ILENGINE

I

ILENGINE

Engine is EFI so the fuel pump, ignition modules, fuel injectors , timing is all controlled by an ECM.It sounds like a condenser issue on an old points type ignition system. I don’t see it in your diagram but does the ignition system have an ignition capacitor? I replaced mine two times before I got one that didn’t fail after a few minutes.

#32

T

TobyU

I guess we could get specific on how the definition of misfiring but it normally means when something is running fine on all cylinders some are most of the time but occasionally or every few seconds etc one of those cylinders stops firing either completely or mostly. It usually comes and goes.

While this can affect engine rpms, it's usually not drastic.

It's usually just a slight roughness or a burble.

In fact, a small air-cooled twin engine like on the average riding lawn mower can start and run on one cylinder and still be within a couple of hundred RPMs of its normal operating speed or be right at it's normal RPMs if it's not under a load or once the load becomes consistent.

It's only when you put a load on it like engaging the blades or even if you're sitting there with the blades on as soon as you drive into grass that makes it drop significantly on the RPMs.

A far more common cause of RPMs dropping and engines even stalling out would be fuel starvation which really isn't misfiring at all unless one cylinder gets the fuel taken away a little bit earlier than the other and then it comes back so technically that would be misfying but in normal use, when you start to starve the fuel from an engine, it doesn't really start to misfire other than it just stops firing altogether.

T

TobyU

An RPM reduction doesn't mean it's misfiring 100%.Yes, it was misfiring as you can see from the rpm display. Typically it would idle 1500-1550 rpm but as the video shows it dropped to the 1300's, and when the deck is engaged with the mower setting still it typically runs between 3300-3400 rpm but with the o2 connected it was dropping down to 2800 rpm. I did not notice any black smoke when it started misfiring and the smell was more acrid rather than rich.

I guess we could get specific on how the definition of misfiring but it normally means when something is running fine on all cylinders some are most of the time but occasionally or every few seconds etc one of those cylinders stops firing either completely or mostly. It usually comes and goes.

While this can affect engine rpms, it's usually not drastic.

It's usually just a slight roughness or a burble.

In fact, a small air-cooled twin engine like on the average riding lawn mower can start and run on one cylinder and still be within a couple of hundred RPMs of its normal operating speed or be right at it's normal RPMs if it's not under a load or once the load becomes consistent.

It's only when you put a load on it like engaging the blades or even if you're sitting there with the blades on as soon as you drive into grass that makes it drop significantly on the RPMs.

A far more common cause of RPMs dropping and engines even stalling out would be fuel starvation which really isn't misfiring at all unless one cylinder gets the fuel taken away a little bit earlier than the other and then it comes back so technically that would be misfying but in normal use, when you start to starve the fuel from an engine, it doesn't really start to misfire other than it just stops firing altogether.

#33

H

heavy_kevie

H

heavy_kevie

Sorry it's taken so long to respond. Finally received the O2 sensor and got it installed. It appears that is the solution as there is no loss of power and no misfire when engine warmed up and deck engaged. Thank-you everyone for all the suggestions and patience with me. You folks saved me a lot of money and time!